EZM Edelstahlzieherei Mark

- Offer Profile

- EZM Edelstahlzieherei Mark is always associated with the production of bright steel, sections (of nearly all steel grades) or titanium alloys. The well-known product lines are successfully established in the market and stand for traditional well-proven know-how: Not only steel machining and treatment belong to usbut also machine and plant construction: In a complex process, textile dyeing machines and spring production machines as well as heat and surface treatment plants are manufactured at the Werdohl location.

Product Portfolio

Products

- Material range

This list is only an excerpt from the range of materials we have produced in recent years.

Certificates

The quality of the applications and of the products manufactured by EZM Edelstahlzieherei Mark is subject to regular tests.

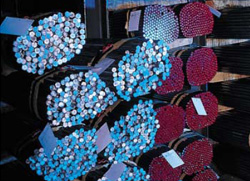

Bright steel

- Bright steel from EZM is characterized by high

dimensional accuracy and high quality bright surfaces. Compared to rolled or

forged products, drawn bright steel offers the advantage of a greater range

of processing options, while the higher degree of prefabrication brings cost

benefits. EZM supplies bright-steel products in the form of steel bars in

drawn, ground or ground and polished versions.

Versions:

Drawn steel bars: 6-28 mm

Drawn/ground/polished steel bars: 10-48 mm

Straightened/ground/polished steel bars: 6-15 mm

Peeled/ground/polished steel bars: 10-48 mm

Sections

- EZM supplies standard and special sections in virtually

every steel material, in cold-drawn and cold-rolled form or in versions

produced using a combination of both cold-forming technologies.

The production plants in Wetter-Wengern and Witten have optimum heat treatment, pickling and coating facilities for each group of materials. Through the combination of these steps with the preceding and subsequent cold-forming processes, EZM ensures that the sections produced precisely meet the customer’s specific requirements.

Symmetrical sections:

- squares

- hexagons

- octagons

Precision bright steel

- Special customer requirements prompted us to manufacture

selected bright-steel specialties in a separate production plant.

Versions:

Drawn steel bars: 2-27 mm

Drawn/ground steel bars: 2-27 mm

Straightened/ground steel bars: 0.5-15 mm

Peeled/ground steel bars: 14-32 mm

Applications

Machinery and plant construction

- Our products for machinery and plant construction focus

on special sections manufactured to customer drawings for linear guide

systems. Linear guide sections from EZM guarantee the greatest possible

closeness to the final dimensions, along with maximum uniformity within a

batch, outstanding straightness, compliance with extremely stringent

dimensional tolerances and high wear resistance.

This high precision, the consistent quality, the wide range and the permanent readiness of the EZM team to tackle new developments in collaboration with customers have made EZM one of the leading suppliers in this market segment. EZM holds a top position in the field of stainless miniature guides and has decades of experience in the processing of anti-friction bearing steels. The EZM products made of these steels are characterized by uniform strength and high purity, and are used in the manufacture of balls, rollers, needles and pins.

Vehicle manufacturing

- With its high-quality bright steels, EZM is a versatile

and dependable partner for vehicle manufacturing and the automotive

industry. Of particular importance in this context is a lead-alloyed carbon

steel for diesel fuel injection pumps.

The unique properties of the EZM products used here offer the perfect solution to such contradictory requirements as extremely high pressure resistance up to approx. 1,800 bar, on the one hand, and optimum machining, on the other.

This specialty has made EZM the world’s leading supplier in this field of application.

Bright steels and sections from EZM are also to be found in virtually every segment of automotive engineering.

Sprags

- Sprag sections from EZM have proven extremely successful in every field of transmission engineering. The high material quality and precision of the cold-drawn sprag sections are a decisive prerequisite for the reliable operation and durability of freewheel devices, clutches, overload protection devices and other driveline elements. Cold drawing guarantees the straightness, accuracy and uniformity of the sprags. The tolerances to be observed for sprag sections are in the micrometer range. In this context, EZM succeeds in maintaining the dimensional accuracy of 3 µm required for the component over a length of 5.6 km.

Tool-making

- Bright steels and special sections from EZM are used in

high-quality hand and machine tools, ratchets, woodworking machines, drills

or chain cutters.

Thanks to their high quality material and precision, they permit the manufacture of tools that are very safe in use, function reliably and have a long service life.

With innovative cold-rolling technology and greatly improved surface roughnesses, EZM caters to the growing demands on the service life of tools.

Medical equipment

- Variety is also a characteristic of the EZM product range

for medical equipment. Round stock in sizes of 0.5 mm to approx. 20.0 mm is

manufactured in drawn and ground versions, as well as flat wire and sections

produced to customer drawings.

In view of their critical use as implants, the materials are made of highly corrosion resistant austenitic steel grades that are additionally remelted to give them a particularly high degree of purity. Demands on the materials are also increasing in line with medical progress. Therefore, EZM engages in constant development work in order to be able to supply its products for medical equipment in titanium as well.

Fluid engineering

- The products for fluid engineering available from EZM

range from ground, round material for solenoid valves and standardized

hexagonal products for fittings and connections, all the way to

high-precision filtering screen sections. Because of the extremely narrow

tolerances to which the dimensions of the filter gaps are subject, these

so-called filtering screen sections place very stringent demands on the

drawing tools. Reproducibility must be absolutely guaranteed.

EZM offers an unusually wide variety of materials, especially for fluid engineering. For example, EZM supplies wear resistant manganese steel grades and offers highly rust-proof austenitic steels to meet the demanding requirements of the foodstuffs industry and the chemical industry. Due to the quality of its materials and the great variety available, EZM is today in great demand as a supplier in this segment.