- Offer Profile

- Our main area of business is

the development, production and sale of electronic subassemblies and

devices. We see ourselves as a comprehensive service-provider in that we

offer our customers – primarily industrial companies – both development and

production services (production planning and product fabrication) for our

custom designed electronic subassemblies.

We are able to offer our customers a complete, project-based service – from the development of a product-concept, the creation of performance specifications and the design of circuits and devices to the fabrication of various models, the planning and engineering of production and the support of the customer in the product approval and certification processes.

As our core area of expertise, we offer engineering services in the field of electronics.

Applications

Examples for use

Transmission monitoring

-

Problem:

By faulty transmission in motors or generators, caused by abrasion or imbalances, grave damages can occur.

Solution:

The use of our USS5 sound sensor for acoustic monitoring of various types of gears in machinery and equipment. Incorrect noises can be detected and processed by the sound sensor (e.g. for error messages or machine shutdowns).

Lighting control in underground car parks

-

Problem:

High electricity costs by a continuous operation of the lighting system, and high costs for the installation of motion detectors.

Solution:

The use of the sound sensor ALC1 guarantees a comprehensive ensurance of the car park lighting, even on locations that are difficult to view within a parking deck. Advantages compared with motion detectors:- reduced installation effort

- cost-effective operation, because larger parking areas can be monitored

- higher energy savings because only emergency lighting is required

Acoustic monitoring of relays and contactors

-

Problem:

In the production of electrical cabinets and their enclosure monitoring faulty relays trigger disturbances.

Solution:

The use of our USS5 sound sensor for acoustic control during tests of relays and contactors. The faulty relay generates noise with a certain frequency if the anchor is not activated by the correct noise. This can be detected by the sound sensor.

Acoustic monitoring of connectors

-

Problem:

During the assembly of electrical cabinets or cable harnesses plug connections don´t snap properly.

Solution:

The use of our USS5 sound sensor for monitoring the production of various connectors. With the sound sensor the noise during the snap mechanism (plug-in contact into the connector) can be checked. In this way the correct operation of the connector can be ensured.

Acoustic leakage testing

-

Problem:

Leakages in pipeline systems or containers.

Solution:

The use of our USS5 sound sensor for leakage testing of pipeline systems. Escaping gases out of containers and pipes cause a usable noise for the sound sensor, which can be used for monitoring and error detection.

Special feature: Due to its high degree of protection (IP67) the sound sensor can also be used under harsh industrial conditions.

Monitoring of filling systems

-

Problem:

The filling and closing of the bottles can cause breakage of glass.

Solution:

The use of our USS5 sound sensor for monitoring of filling systems. (Filling and closing of glasses and bottles) To ensure a continuous filling process the sound sensor is used for glass breakage monitoring. It recognizes, on the basis of an altered noise, the cracking of the facility of the glass container.Quality control of small components

Quality control of small components

-

Problem:

Various factors in the production process, like variations of material properties and process parameters or tool abrasion trigger quality differences in the series production of small parts. So at the end of the production process good and bad parts must be separated.

Solution:

The use of our USS4 sound sensor in the quality inspection of small parts to ensure a faultless quality of parts. The sound sensor is in advance trained on certain resonant frequencies of the good parts and the necessary control parameters for the sound check are set.- After stimulating the parts from the outside, the produced sounds are compared with the trained sound patterns. So the faulty parts can be separated directly from the faultless parts.

- max. 15 different sounds with 30 possible frequencies can be monitored simultaneously

- modulation of the faulty parts can be done via two switching outputs

Monitoring of agricultural machinery

-

Problem:

When obtaining harvest stones, which can then in processing destroy machinery and equipment, are also often transported (e.g. in sugar beet extraction)

Solution:

The use of our USS5 sound sensor for monitoring of harvested crop in sugar beet extraction. By the sound sensor a continuous separation of sugar beets from carried stones is guaranteed for further utilization of the beets in biogas plants.

Application Categories

-

1. Sound and functional tests in machinery and installations

- Noise testing of packaging machines (film tear, grinding noises)

- Acoustic leakage tests in pipelines or vessels

- Monitoring of chemical production processes using noise like screen breakage or foreign elements sounds

- Monitoring of machine tools (detection of tool imbalance or vibration of drilling, punching, stamping, milling, gear cutting tools, etc.)

- Monitoring the supply of material or the lubricating condition by using the tool noise (eg. punching) , monitoring of the driving noise of lifts

2. Sounds, materials and part verification

- Cracking and hardness testing of sintered metals on the example of valve seat inserts

- Material, structure and geometry inspection of drawing, pressing, stamping and roll parts

- Testing of glass and ceramic parts (eg. ceramic insulators, bulb components, pharmaceutical packaging)

3. Noise inspection for production, testing and assembly processes- Verification of locking noises during installation of plug connectors

- Functional testing of relays & contactors

- Noise testing of bonding and connection processes (Snap-In)

- Monitoring tool contact (eg on metal / wafer saws and grinding machines)

- Acoustical monitoring of filling systems, detection of broken glass in the packaging process (eg. baby food, jam filling)

4. General control of machinery, equipment and electrical loads- Acoustical control of sorting lines (eg. sizing with rivets, parts counting)

- Control of sorting operations (eg. separation of stones and sugar beets in the supply process at harvesting machines)

- Acoustic lighting control for carparks and hallways

- Automatic control of the separation process (liquids and solids) in wastewater treatment plants

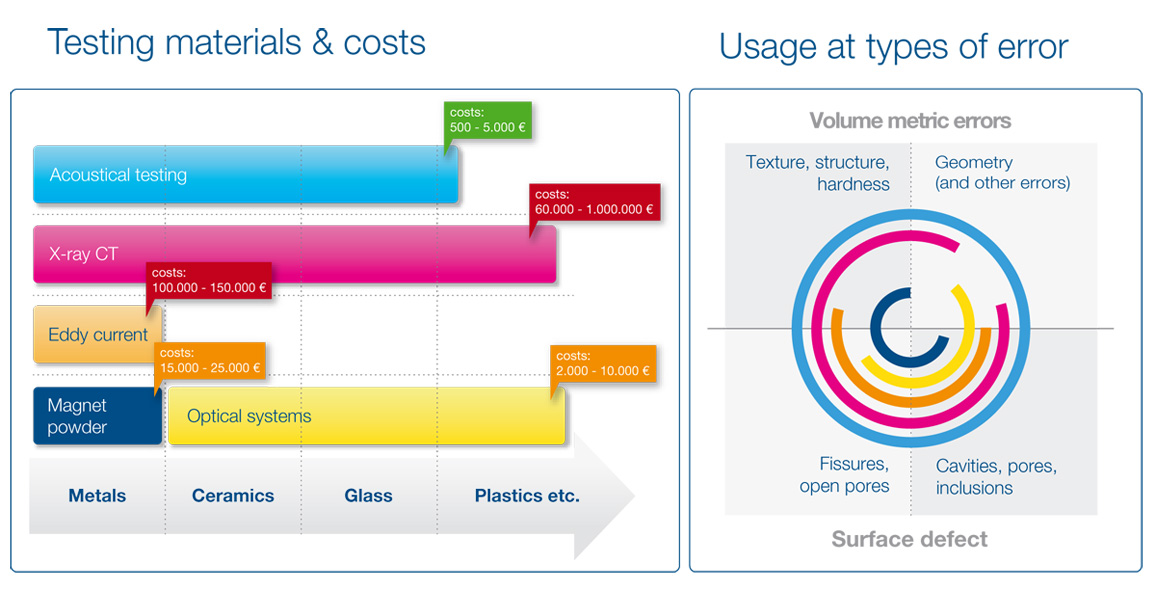

Why acoustic sensors?

-

Certainly, not everyone needs an acoustic sensor.

For everyone else: the sensors of the dsound®series

Equipment for industrial quality testing is often expensive, difficult to install, requires frequent and often difficult maintenance, and is not applicable in many areas. The dsound® USS4 "hears" small changes of sound emitted by small parts or glass containers. Even the tiniest faults, like cracks, inclusions or geometry deviations are reliably detected despite intense ambient noise. Using the means of sound detection, high enclosure class and the compact housing of the sensor; quality testing is now possible in areas where other methods, like for example cameras fail. You will be amazed by the intelligent USS4.

A deviation from the usual sounds of a production process is often the first sign of an operational fault such as ripping material, breaking tools or bursting pressure hoses. With the help of the dsound® USS5, machines and processes can be reliably monitored acoustically. Additionally, assessments of valve- or relay states or snapped-in parts in assembly are viable. If the need arises, the USS5 is able to intervene in the event of unwanted ignitions or emerging leakage. The USS5 provides security to critical processes. comparison of important methods for non-destructive testing of workpieces

Products dsound®

Sound sensors

dsound® USS4 Airborne sensor

-

Universal acoustic sensor for autonomous detection, evaluation, recording and documentation of sounds in industrial environments.

- Integral, high quality electret microphone

- Powerful real-time signal processing in an integrated digital signal processor

- USB 2.0 interface

- Training, parameterization, visualization and storage of sensor data via PC software

- Two switching outputs, one synchronization input and an analog input for direct PLC connection

- Comprises a compact evaluation unit

Application areas:

The sensor is used for automatic recording of acoustic signals in industrial environments, as in general quality assurance

Quality and part inspection:- metal

- ceramic

- glass

- For example: nuts, washers, pins, sleeves, bushings, rings, stamping and deep drawn components, ceramic sintered parts

- bottles

- jars

- lamp bulbs

- vials

dsound® USS4 Structure-borne sound sensor

-

Universal acoustic sensor for autonomous detection, evaluation, recording and documentation of sounds in industrial environments.

Pickup Type N (0,5g - 500g)

or

Pickup Type E (0,05g - 50g)

Connecting cable, 1.5mApplication areas:

Quality and part inspection- Ceramic plates

- Metal plates

- Drives

- Ball bearings

- Drives

- Speed monitoring

- in industrial environments for general quality assurance

- Bottles

- Jars

- Lamp bulbs

- Vials

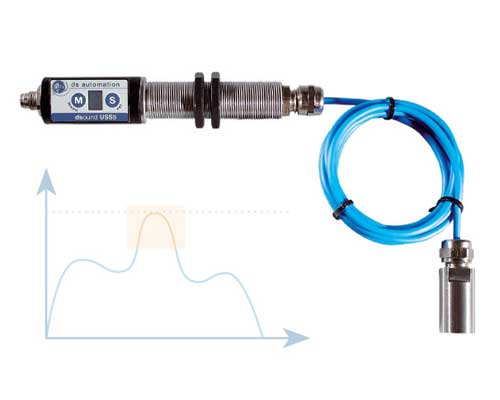

dsound® USS5 Airborne sensor

- Acoustic noise / functional testing and process monitoring

Universal sound sensor for precise frequency-selective monitoring of structure- and air- borne sound in industrial environments:Intelligent microphone with integrated signal processing and a compact evaluation unit

- Integral, high quality electret microphone

- Powerful, parameter stable signal processing by digital signal processor

that is integrated in the sensor - Adjustment of gain, frequency band, smoothing time and desired

switching function via simple menu navigation directly on the sensor - Analog output for direct connection to a monitor or headphones or output

of the measured rms value / peak - Potential free output and synchronization input for direct PLC connection

- RS485-interface

Machine, plant and tool monitoring

(whistling, grinding, buzzing, roaring)- Recognition „tool in the section“

- missing material

- imbalance

- leakages

- solids in fluids

- worn tools

(banging, rushing, hissing)- Detection of lead fracture during arc welding

- waterjet cutting abrasive ratio

- material flow in pipes

- leakage

- parts counting

(interlocking, snapping, bottoming)- Connector assembly

- popping or snapping of retaining rings or locking lugs

- snap-in mounting of housings

- fixed stop monitoring

(Cracking, tearing)- Foil / veneer cracks

- broken glass

- bursting of PET bottles

(clicking, squeaking, grinding)

Monitoring of- keyboard clicks

- acoustic signals

- acoustic emission during switching processes

- motor movements

dsound® USS5 Structure-borne sound sensor

-

Intelligent microphone and integrated signal processing inside a compact evaluation unit

pickup type N (0,5g - 500g)

or

pickup type E (0,05g - 50g)

1.5m connection cableApplication areas:

Machine, plant and tool monitoring, for sounds as whistling, grinding, buzzing, roaring- Missing material

- Imbalance

- Leakages

- Solids in fluids

- Worn tools

- Detection of lead fracture during arc welding

- Waterjet cutting abrasive ration

- Material flow in pipes

- Leakages

- Parts counting

- Connector assembly

- Popping or snapping of retaining rings or locking lugs

- Snap-in mounting of housings

- Fixed stop monitoring

- Foil or veneer cracks

- Broken glass

- Bursting PET bottles

- Keyboard clicks

- acoustic signals

- Acoustic emission during switching processes

- motor movements

Cap Check

- The Cap Check system conducts a contact-free leak-tighntess test via magnetic excitation procedure.

Cap Check

-

Cap Check subjects sausage jars to an acoustic leak tightness test.

A contact-free excitation procedure with high-performance signal processing analyses the jar cap's resonance conditioned by internal pressure. The system detects even slight pressure deviations.- Enclosed construction for simple cleaning

- Wear-free working method

- Cost-efficient compared to alternative measuring methods

Tap Check

- The Tap Check system conducts a damage-free leak-tighntess test of PET and plastic botteles/caps via mechanic excitation procedure.

Tap Check

-

Tap Check subjects PET/plastic bottles and caps to an acoustic leak tightness test.

A damage-free mechanic excitation procedure with high-performance signal processing analyses the resonance of up to 72000 container per hour.- Inspection of plastic caps on PET bottles

- Enclosed construction for simple cleaning

- Cost-efficient compared to alternative measuring methods

- Low maintenance effort

Connection technology

USS4-Con-Box

-

Connection box for sound sensor dsound ® USS4, DIN rail mounting

Application areas:

Connection box for DIN rail mounting

- Connect sensor I / O via screw terminals

- USB service connector for connection of the dsound USS4 sound sensor to the PC

- for connecting the USS4 with USS4-Con box, the sensor cable of type USS4-K-2 / S or USS4-K-4 / S is required

USS5-Con-Box-Can

-

Connection box for sound sensor dsound ® USS5 with CAN USB RS485 router function, DIN rail mounting

Application areas:

- Power supply of the dsound ® USS5 sound sensor

- Connection of the dsound ® USS5 sound sensor with cable USS5 K-2 / S or K-4 USS5 / s

- Configuration of the dsound ® USS5 sound sensor

- CAN/RS485-Interface for connection with PLC

USS4-K-2/S (2m)

-

connection cable for sound sensor dsound® USS4 8-pin, shielded, 2m, socket M9 x 0.5 /

connector M9 x 0.5Application areas:

for connection to sound sensor dsound® USS4 to USS4-Con Box / UCT1

USS5-K-2/S (2m)

-

Connection cable for USS5 8-pin, shielded, 2 m, 0.5 x M9 female / male M9 x 0.5 (for use with USS5-Con box)

Application areas:

used with dsound® USS5, establishes connection between the sensor und USS5-Con-Box

USS5-K-2/A (2m)

-

Connection cable for USS5 8-pin, shielded, 2m, 0.5 x M9 female / single wires with ferrules

Application areas:

used with dsound® USS5, establishes connection between the sensor and control panel / customer connection

Lighting technologz, Panel PC, Software and accessories

dsound® ALC1 Lighting technology

- The first acoustic lighting controller for parking garages, stairways and hallways.

Many people are familiar with the following problem:

Compliance with statutory minimum lighting for public transport routes and corridors causes high power requirements. Because of that energy costs are one of the biggest cost drivers.

An alternative, temporary control lighting system via motion detector due to their short range is very expensiveresepectively complex and is thereby hardly able to generate savings.

With the dsound ® ALC1 there is now the first lighting control, that achieves maximum energy savings and accounts the special needs of parking and garage operators despite the high safety standards.

The advantages are obvious:- up to 80% less energy costs

- range up to 1500 qm (with one sensor!)

- high security due to individual lighting control

- simple configuration via remote control

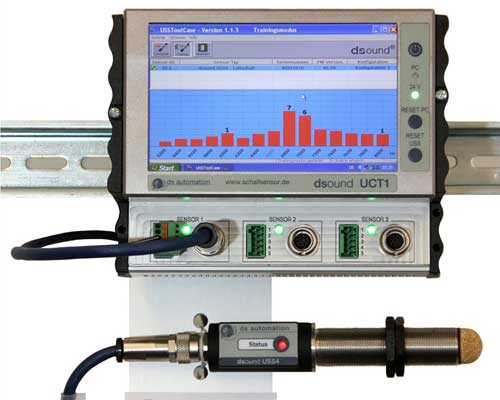

dsound® UCT1 Panel PC

-

Universal Communication Terminal Panel-PC 4,8" dsound® UCT1

New 4.8“ Panel PC Display expansion module for dsound® sound sensors.

A development of our company is the Windows Panel PC with UCT1 4.8“ touch

display. This serves both as a front end for our USS4 and USS5 sound sensors of

the dsound® series and the control of machines and systems in production

processes.

In connection with the dsound®-sound sensors an extensibility of sound detection

systems up to retraining in batch change is possible. Thus, a flexible adjustment of

the sound check to changing parameters is guaranteed.

Because of its Windows operating system, the panel PC UCT1 with its compact

dimensions and its rail mounting is available for a wide range of applications.

Communication with other systems works via USB, LAN, CAN and Digital-I/OPorts.- space-saving and compact design

- wide range of applications for plant and machine control

- Operating system: WinXP, Win7, Win2000, Windows Embedded

- Interfaces: USB, LAN, CAN and Digital I/O-Ports

Software USS5-DLL

- DLL for the development of USS5 communication applications (with free USS5 Control User interface)

Software USS4-CLN-V

- Operating and programming for sound sensor dsound ® USS4, full version

Accessories

-

Mounting systems, holding magnets, earphones, microphones...