- Offer Profile

We carry a wide range of our own products. We are also the experts for individual customer solutions.

A good performance, team spirit and an open minded and motivating working atmosphere are our top priority.

Our flexible production possibilities make us strong for high-quality standard products and special services. Our series products are always thoroughly tested before we pass them on to the customer. We ensure this through our DIN-ISO9001 certification as well as our internal quality assurance.

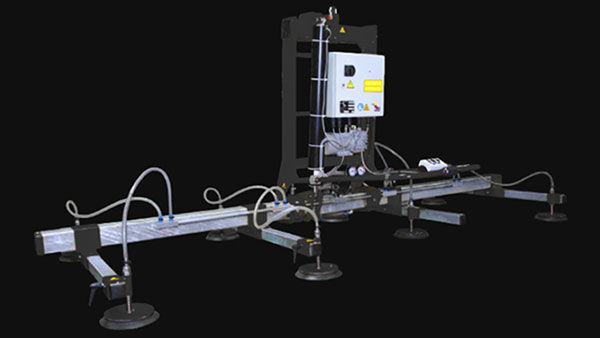

Vacuum Lifting Technology

Vacuum-Lifting Systems

- The tim®LIFT vacuum lifting beams are used in the handling of various materials, such as metal sheets, wooden panels and plastic panels with different dimensions and weights. However, not only flat but also round materials and special shapes can be realised. Various customer-specific solutions can be created. Standard systems from the basicLIFT product line are available for common applications.

Vacuum Hose Lifters

- The vacuum hose lifter tim®LIFT enables you to move various goods such as sacks, cardboard boxes, crates, plates etc. weighing up to 300 kg efficiently and ergonomically. The heart of the vacuum hose lifter is the vacuum pump, which sucks air through the suction hose and the lifting unit. By operating the control unit, the air sucked in is throttled, causing the lifting hose to contract and consequently expand when lifting and lowering the load.

Cranes

- Cranes are used to lift and move loads. Different crane systems can cover all requirements for your operational conditions. The right crane system for your application and spatial conditions is of decisive importance when designing your lifting system. Thanks to our wide range of options, we can adapt your crane system perfectly to your needs. Pillar-mounted slewing cranes and wall-mounted slewing cranes for loads up to 500 kg. Different variants such as fixed, low profile or mobile. As well as our aluminium rail systems due to structural circumstances.

Electric Piston Pumps - KPE Series

-

The electric piston pumps of the tim®ECO series have been especially developed for larger paint supply systems. In addition to a small, compact design, which allows integrating the pumps without significant effort, especially in retrofit projects, the pumps of the series also provide many other benefits.

- Low-shear material flow that increases the service life of the medium.

- Continuous lubricators, which ensure permanent lubrication of the bearings.

- Matched piston drive kinematics ensure a uniform media flow.

- Vertically arranged pistons, which ensure a uniform load on the piston seals and thus better service life.

- Short piping lengths resulting in lower paint filling volumes and thus less wetted surfaces, better rinsing capability and lower fluid consumption (paints, varnishes, solvents, etc.).

These variants are supplied with an intelligent sensor from tim®TRON, which allows real-time testing of the stroke signals via a customer PLC. With connection of our sensor we enable many useful new features that increase profitability, process reliability and facilitate preventive maintenance.

PTI-KPE2020 - 20l/min

Features:

- Pumping that is gentle on the material.

- Process-reliable

- Good chemical resistance

- Low-maintenance

- Permanent lubrication system

- Small, compact design

- Ideally matched piston drive

- Constant delivery volume

- Low filling volume

- Short piping lengths

PTI-KPE1030 - 30l/min

Features:

- Pumping that is gentle on the material.

- Process-reliable

- Good chemical resistance

- Low-maintenance

- Permanent lubrication system

- Small, compact design

- Ideally matched piston drive

- Constant delivery volume

- Low filling volume

- Short piping lengths

PTI-KPE1040 - 40l/min

Features:

- Pumping that is gentle on the material.

- Process-reliable

- Good chemical resistance

- Low-maintenance

- Permanent lubrication system

- Small, compact design

- Ideally matched piston drive

- Constant delivery volume

- Low filling volume

- Short piping lengths

PTI-KPE1060 - 60l/min

Features:

- Pumping that is gentle on the material.

- Process-reliable

- Good chemical resistance

- Low-maintenance

- Permanent lubrication system

- Small, compact design

- Ideally matched piston drive

- Constant delivery volume

- Low filling volume

- Short piping lengths

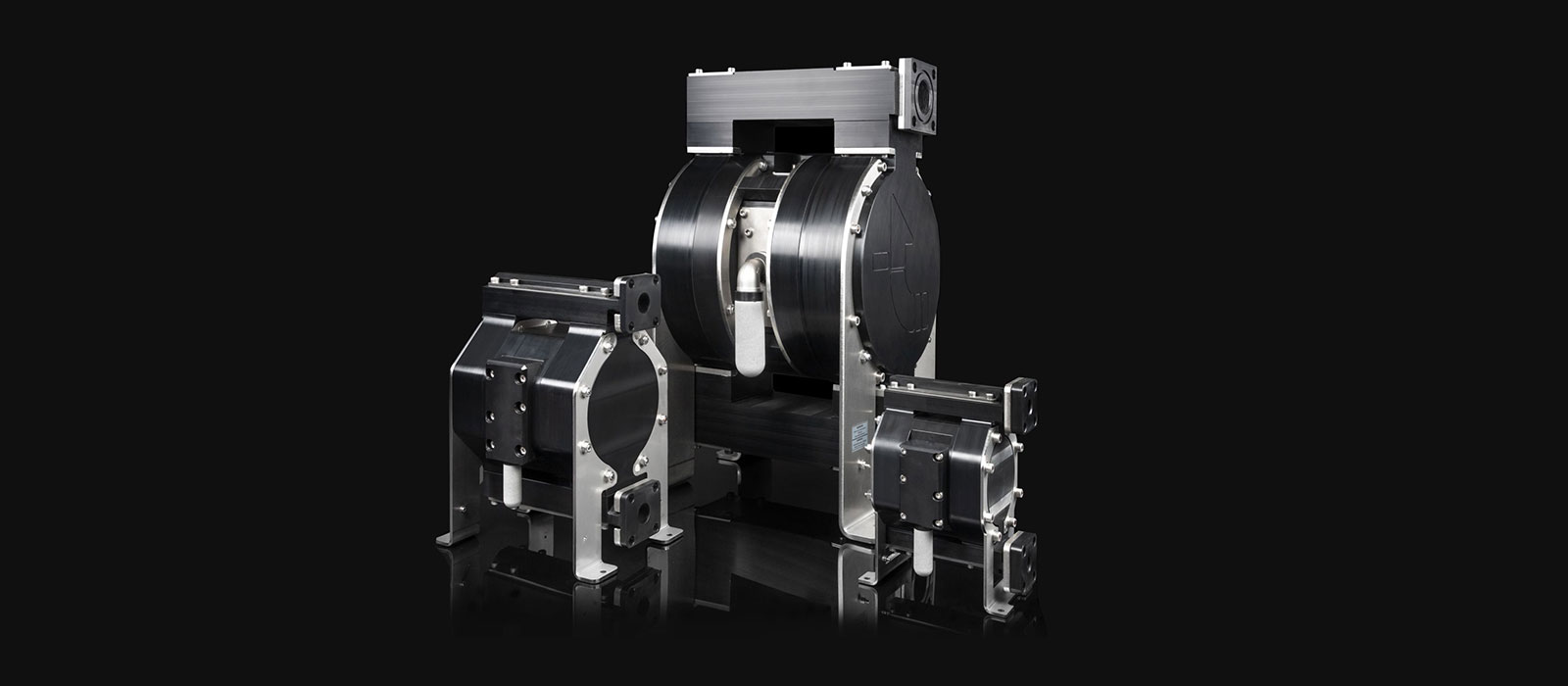

Double Diaphragm Pumps - tim PRO

- Minimum Pulsation: Minimal changeover times in conjunction with the short-stroke principle of the pumps reduce pulsation to a minimum and ensure a more uniform media flow.

- Maximisation of Service Life: The ceramic slide valve that is used works virtually free of wear. The short-stroke principle prevents over-extension of the diaphragm and thus enables a long service life.

- Increased Process Reliability: Safe start-up of the pump is ensured, even in critical operating situations. The bistable, over-centre valve prevents problematic intermediate positions of the control valve.

- Reduced Compressed Air Costs: Optimised geometries with minimal dead spaces, as well as the extremely low start-up pressures, starting at 0.7 bar, reduce energy consumption to a minimum.

- Easy Conversion in Existing Systems: Small, compact design thanks to optimised valve technology.

- Minimal Maintenance Costs: The durable short-stroke diaphragms, the low-wear ceramic slide valve and the maintenance-friendly structure of the pump guarantee extremely low service costs.

PTI-MEM1060-VA (Stainless steel) - 1/2" max. 60 l/min

PTI-MEM1060-AL (Aluminum) - 1/2" max. 60 l/min

PTI-MEM1060V-PP (Polypropylene) - 1/2" max. 60 l/min

PTI-MEM1150-VA (Stainless steel) - 1" max. 150 l/min

PTI-MEM1150-AL (Aluminum) - 1" max. 150 l/min

PTI-MEM5600V (Stainless steel) - 2" max. 600 l/min

PTI-MEM5600V-RE (Stainless steel) - 2" max. 600 l/min

PTI-MEM5600V-AL (Aluminum) - 2" max. 600 l/min

PTI-MEM5600V-AL-RE (Aluminum) - 2" max. 600 l/min

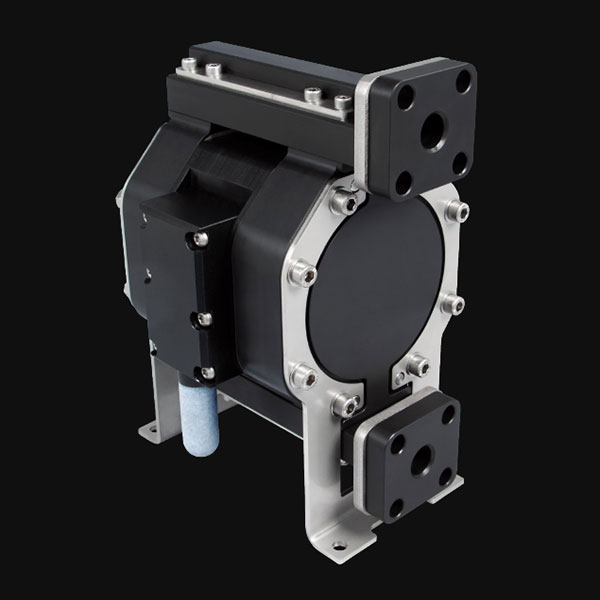

Double Diaphragm Pumps - tim CHEM

Easy Installation: Easy replacement of the valve balls without dismounting the side cover or the unperforated diaphragms.Special tools are not required for mounting / dismounting. Only 4 sealing rings are installed on the media side.

Reduced Compressed Air Costs: Optimised geometries with minimal dead spaces, as well as the extremely low start-up pressures < 0.7 bar, reduce energy consumption to a minimum.

Maximisation of Service Life: The ceramic slide valve that is used works virtually free of wear. The shortstroke principle prevents over-extension of the diaphragm and thus enables a long service life.

Minimum Pulsation: Minimal changeover times in conjunction with the short-stroke principle of the pumps reduce pulsation to a minimum and ensure a more uniform media flow.

Increased Process Reliability: Safe start-up of the pump is ensured, even in critical operating situations. The bistable, over-centre valve prevents problematic intermediate positions of the control valve.

Minimal Maintenance Costs: The durable short-stroke diaphragms, the low-wear ceramic slide valve and the maintenance-friendly structure of the pump guarantee extremely low service costs.

PTI-MEM5060V - 1/2" max. 60 l/min

PTI-MEM5150V - 1" max. 150 l/min

PTI-MEM5600V - 2" max. 600 l/min

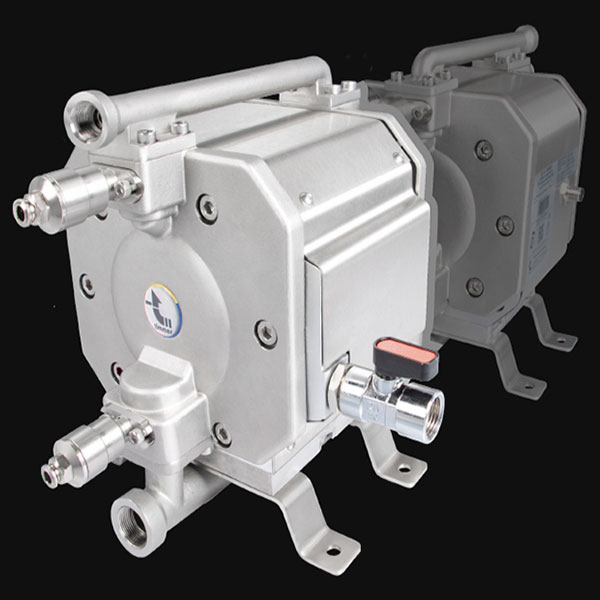

Double Diaphragm Pumps - tim BOOST

Minimum Pulsation: Minimal changeover times in conjunction with the short-stroke principle of the pumps reduce pulsation to a minimum and ensure a more uniform media flow.

Maximisation of Service Life: The ceramic slide valve that is used works virtually free of wear. The shortstroke principle prevents over-extension of the diaphragm and thus enables a long service life.

Increased Process Reliability: Safe start-up of the pump is ensured, even in critical operating situations. The bistable, over-centre valve prevents problematic intermediate positions of the control valve.

Reduced Compressed Air Costs: Optimised geometries with minimal dead spaces, as well as the extremely low start-up pressures, starting at 0.5 bar, reduce energy costs to a minimum.

Easy Conversion in Existing Systems: Small, compact design thanks to optimised valve technology.

Minimal Maintenance Costs: The durable short-stroke diaphragms, the low-wear ceramic slide valve and the maintenance-friendly structure of the pump guarantee extremely low service costs.

PTI-MHD1030-VA (Stainless steel) - 3/8″ max. 30 l/min - Transmission ratio approx. 3,5 to 1

PTI-MHD1050-VA (Stainless steel) - 1/2″ max. 50 l/min - Transmission ratio approx. 3,5 to 1

PTI-MHD1050-VA-RMO (Stainless steel) - 1/2″ max. 28 l/min - Transmission ratio approx. 3,5 to 1

PTI-MHD1050-VA-RMO-RE (Stainless steeel) - 1/2″ max. 28 l/min - Transmission ratio approx. 3,5 to 1

PTI-MHD1065-VA (Stainless steel) - 1/2″ max. 65 l/min - Transmission ratio approx. 3,5 to 1

PTI-MHD1110-VA (Stainless steel) - 1″ max. 110 l/min - Transmission ratio approx. 4 to 1

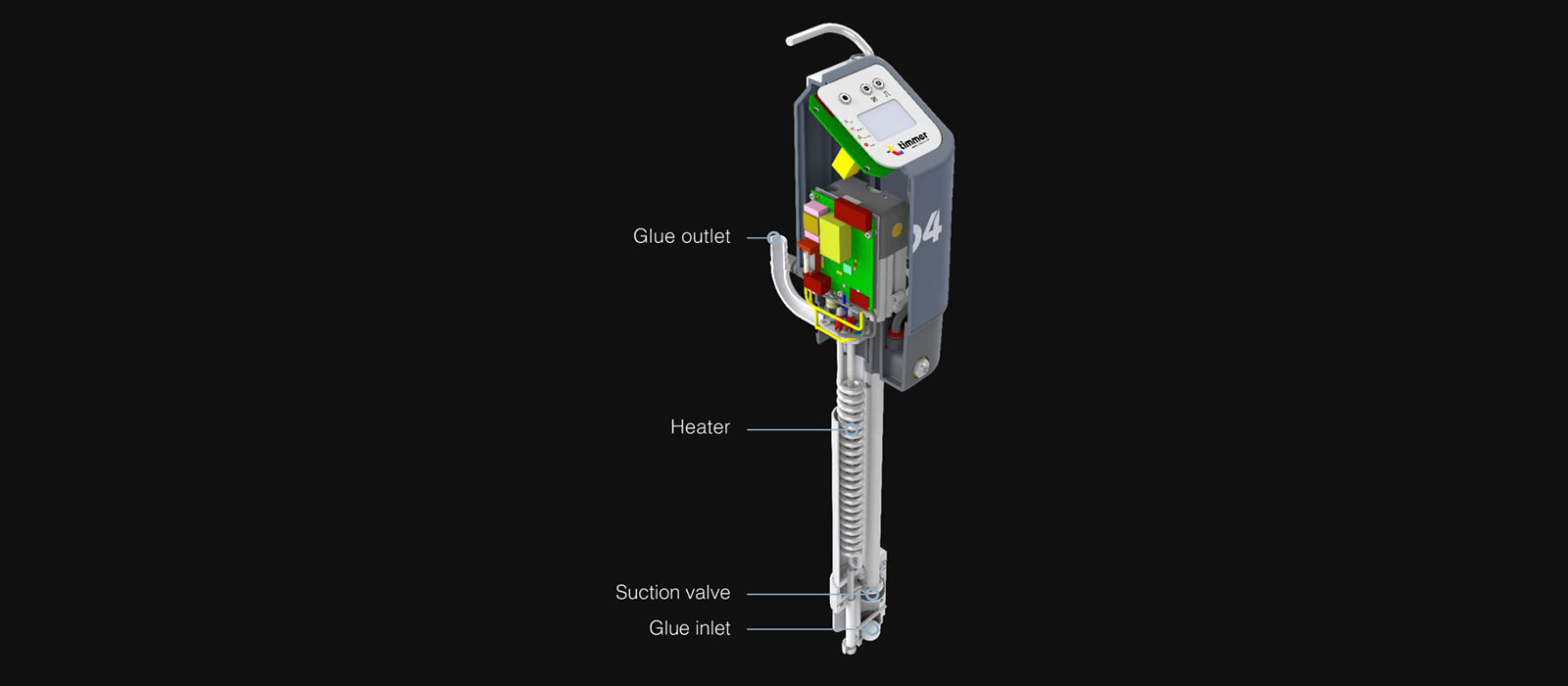

Glue Pumps

PTI-D4-H-400 with Integrated Heater

Distribution Package:

- Heater (stainless steel).

- Nozzle (19 mm, stainless steel).

- Air connection with ball valve 1/4″ and plug nipple DN 7.2.

- Power supply lead with shock-proof plug*, 2m.

- Operation manual.

- Other plugs available.

PTI-D4-O-400 without Heater

Distribution Package:

- Nozzle (19 mm, stainless steel).

- Air connection with ball valve 1/4″

- Operation manual.

PTI-D3-H-Cont 400 with Integrated Heater

Distribution Package:

- Pump with integrated heater and electronic stroke counter.

- Container lid, plastic.

- Clamp ring for mounting.

- Feed hose with filling valve.

- Fastening for feed hose.

- Other plugs available.

- Air connection with ball valve 1/4 “.

- Power supply lead with shock-proof plug, 2m.

- Operation manual.

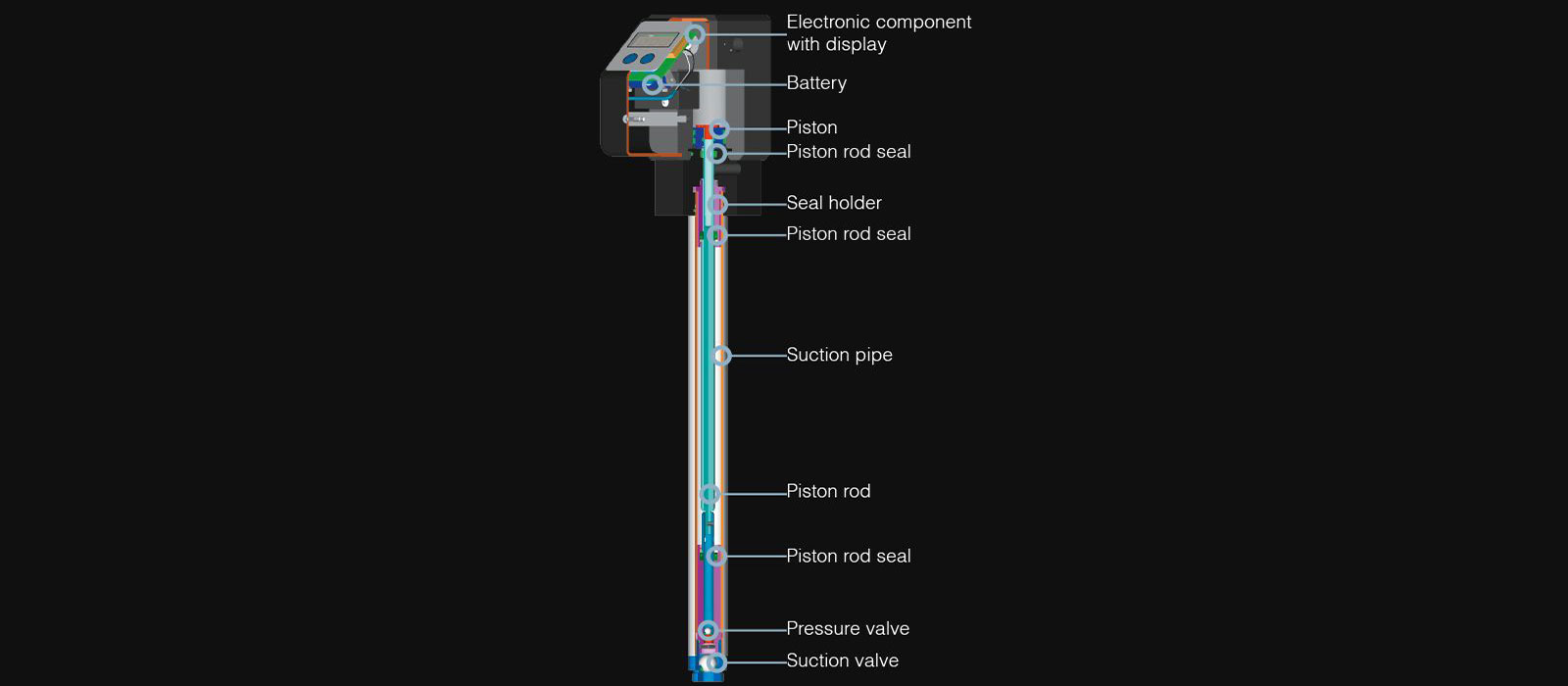

Coagulant Pumps - E2 Series

PTI-E2-KDP-ZST with 630 mm Suctionpipe

Features

- Integrated pneumatic and electronic control unit.

- Separation of air and liquids.

- High vacuum during suction.

- Optimized liquid transport.

- Easy handling.

- Low noise level.

- Cost-effective operation

- Protection Class: IP44.

PTI-E2-KDP-ZST with 400 mm Suctionpipe

Features

- Integrated pneumatic and electronic control unit.

- Separation of air and liquids.

- High vacuum during suction.

- Optimized liquid transport.

- Easy handling.

- Low noise level.

- Cost-effective operation

- Protection Class: IP44.

Pneumatic Accessories

Series A10 - Quick Connectors

- Secure quick connector in a compact design: Thanks to the claw design, our A10 series enables a short tube intake with minimum assembly effort. The claw shape also ensures optimum retention force - even with simple manual assembly. The all-metal fitting made of nickel-plated brass also offers good surface protection against alkalis and acids.

Series B10 - Push-in Fittings

- Our "red series" B10 is an easy way to save costs thanks to quick assembly and disassembly. The O-ring seal on the thread ensures a high level of safety, while the fittings and connectors made of nickel-plated brass have optimum surface protection. The series can be used in a pressure range from -0.99 to 15 bar over a wide temperature range from -18 to +70°C in applications with a wide variety of gases and liquids.

Series B20 - Push-in Fittings

- Low cross-sectional constriction, high pressure range, O-ring sealing and stainless steel collet: our B20 series can do it all. The nickel-plated brass push-in fittings not only offer high-quality surface protection, but are also available in various special designs - whether NSF-compliant, high-pressure or high-temperature up to +130°C and even +185°C for a short time, we make it possible.

Series B30 - Push-in Fittings

- Our "blue series" B30 is available with plastic or brass housing in a variety of designs and can be used with compressed air or vacuum. The operating temperature range extends from 0 to 60°C. Thanks to the lip ring seal on the tube connection and O-ring seal or PTFE coating on the thread, the push-in fittings offer a high level of safety and efficient assembly. Fine-toothed collets offer high holding forces and excellent durability.

Series B40 - Push-in Fittings

- B40 is our stainless steel series that can be used with plastic tubing for compressed air, gases as well as rough vacuum. The push-in fittings can safely withstand even an operating pressure of up to 15 bar over the wide operating temperature range from -20 to +150°C. All designs in the series have a small cross-sectional constriction compared to the internal diameter of the plastic tubing. The quick assembly and disassembly also reduces costs.

Series B50 - Connectors

- Our "black series" B50 is applicable to a wide range of metal or plastic pipes. It is available for a diameter range from 15 to 28 mm and is suitable for compressed air, gases, vacuum as well as liquids. The push-in connections have very good flow properties. Due to the integrated O-ring seal on the thread, no additional sealing material is required. Another advantage of this series: loosening and fastening is possible several times, because by pressing on the loosening ring, the retaining element is pushed back and the connection is easily and quickly released.

Series B70 - Push-in Fittings

- B70 is our H2O series, specially designed for use with water and air. The combination of different designs as well as the large diameter range from 4 to 22 mm results in a wide range of applications. In addition, the entire series is NSF approved and can also be used in the vacuum range up to 99 percent. Upwards, the pressure range extends up to 16 bar, depending on the hose diameter and application temperature.

Series C10 - Cutting Ring Couplings

- Our C10 series cutting ring fittings are used with copper, steel and stainless steel tubes, especially in high pressure ranges. By using an insertion sleeve, they can also be used with plastic tubes. The nickel-plated surface of the brass version provides optimum surface protection. The stainless steel version has high chemical resistance and is also used in the food industry. The large available diameter range rounds off the system.

Series E10 - Hose Connectors

- The grommet hose connectors of the E10 series are mainly used for thick-walled hoses or where there are no push-in fittings for the hoses. The hoses are fastened here by means of hose clamps. Our E10 series is available in four different versions: brass, nickel-plated brass, stainless steel and plastic.

Series F10 - Fittings

- Our F10 series fittings are used as screwable connecting elements for adapting hose and tube connections and are available in four different materials: bright brass, nickel-plated brass, stainless steel and aluminium. Depending on the material, the fittings are suitable for different media: From compressed air, gases and liquids to aggressive media such as acids, alkalis and cleaning agents. A variety of designs and thread sizes close the gaps between different connection sizes and types of diverse components in everyday mechanical engineering.

F20 Series - Rotating Unions

- The rotating unions of the F20 series are used wherever a medium, such as compressed air or vacuum, has to be introduced into a rotating machine element. Up to three independent lines can be fed through a central axis of a rotating machine part. The rotating unions have a wide range of applications: From textile and transfer machines to robots and rotary assembly tables.

Series H10 - Pneumatic Hoses

- The H10 series consists of various hoses and spiral hoses made of polyamide, polyurethane and polyethylene. In addition, you will find various accessories such as hose cutters made of aluminium and plastic as well as replacement blades.

Series H20 - Hoses

- Polyurethane hoses are very flexible and ensure proper function even under installation conditions. Our PU hoses are basically calibrated and therefore suitable for the sealing system of our push-in fitting without any problems.

J10 Series - Installation Materials

- The J10 series includes various installation and connection materials. These include silencers, gaskets, hose clamps, hose ties, blow-out guns as well as tyre inflation gauges, complemented by technical sprays, sealing fluid and sealing tape.

K10 series - Ball Valves

- The manually operated ball valves of the K10 series are used to shut off and divert gaseous or liquid media. In plant construction or in the chemical industry, these ball valves are primarily used for process flows. Our product range includes ball valves in 2/2 and 3/2-way versions made of chrome-plated or nickel-plated brass as well as stainless steel. The standard sizes range from 1/8" to 3". Various actuations such as short, long or lockable levers and other shapes round off the selection options.

K21 Series - Pneuma Ball Valves

- The automatically operated ball valves of the K21 series with pneumatic actuator are used to shut off or divert gaseous and liquid media. Users in plant construction or in the chemical industry primarily use these automatic ball valves for process sequences. They are available in sizes from ¼" to 3" made of nickel-plated brass or stainless steel in 2/2 and 3/2-way design. They have a NAMUR interface for control and are either single or double-acting.

Series K30 - Pneuma Shut-off Valves 2/2-Way

- The Pneuma shut-off valves series K30 are 2/2-way valves and are used as an alternative to the Pneuma ball valves. They are available as single or double-acting versions and in sizes from 3/8'' to 2''. On request, the valves can be equipped with electrical position sensing and are also available with FKM or EPDM seals. The range of application extends from low vacuum up to 10 bar. The valve body is made of nickel-plated brass or stainless steel as required.

Series L10 - Stop and Flow Valves

- Our L10 series consists of various shut-off and flow control valves as well as filters and strainers. In addition to manual slide valves for manually shutting off and venting air supplies, throttle check valves and pilot-operated throttle check valves for controlling travel speeds and check valves for preventing backflow, you will find quick exhaust valves, exhaust air throttles and strainers here.

Series L11 - Check and Flow Control Valves

- In our series L11 you will find check valves in both supply air and exhaust air throttled design as well as and pilot operated check valves in exhaust air throttled design. They differ from the similar components of the L10 series in that they have swivel ring pieces with push-in connections in the same design as our blue B30 series. Unlockable exhaust throttle check valves are commonly used to easily hold cylinders in position in non-critical applications: As long as the release port is not pressurised, the exhaust air is blocked; when pressure is applied, the exhaust air throttle engages.

Series L20 - Safety Valves

- Series L20 adjustable safety valves are used to safeguard a maximum pressure in compressed air systems. If the pressure set on the valve is exceeded, the valve opens and blows off until the set pressure plus a hysteresis is reached again. We offer safety valves for steam or liquids on request. The valves offered here are not approved for the protection of pressure equipment subject to Directive 2014/68/EU.

Series L21 - Safety Valves

- Our TÜV-approved L21 series safety valves are used to safeguard a maximum pressure in compressed air systems and are set and officially sealed according to customer specifications. If the pressure set on the valve is exceeded, the valve opens and blows off until the set pressure plus a hysteresis is reached again. We offer safety valves for steam or liquids on request.

Series L40 - Quick Couplings

- Series L40 quick couplings are used where lines are often disconnected or changed. They can be connected and disconnected with push-in nipples, whereby the flow is automatically blocked in the coupling when disconnected. While the nominal diameter 2.5 is made of nickel-plated brass as standard, the nominal diameters 5 and 7.2 are made of bare brass. The series also includes Kamlock couplings and claw couplings. What all designs have in common is their universal usability through various connection options such as screw-in, screw-on or grommet connections.

Series M10 - Pressure Gauges

- Our M10 series consists of various Bourdon tube and capsule pressure gauges. Bourdon tube pressure gauges in the standard version are used when the display accuracy within a tolerance range of approx. 1.6 percent of the scale value is sufficient. We also offer versions with a three-hole front ring for panel mounting, glycerine-filled Bourdon tube pressure gauges with a damping effect and a chemical version for aggressive media. Our capsule pressure gauges are used for measuring and indicating low pressures in the millibar range and are exclusively suitable for gaseous media.

Series M20 - Pressure Gauge

- The pressure transmitters of the M20 series measure a system pressure and convert it proportionally into an electrical signal. The signal can be output as a voltage (0-10V) or as a current (4-20mA), depending on the device version. Special features of this series are the compact design, the robust ceramic sensor technology and the high temperature resistance.

R10 Series - Air Vane Motors

- Elastic, controllable and safe: the air vane motors of the R10 series are one of the most versatile and robust drives available to modern mechanical engineering. They can be controlled over a wide speed and pressure range and have their greatest torque where it is needed - at start-up. Air vane motors are used in many areas of technology: from mechanical engineering and the chemical industry to robot systems or printing and textile machines.

Series V10 - Solenoid Valves

- Our V10 series solenoid valves are control devices that release or shut off a flowing medium. The actuating element is an electromagnet. Our solenoid valves can be used for water, air, gas and other media according to the materials. For this reason, they can be used in a wide variety of applications: Exhaust gas cleaning, sprinkler technology, dosing technology, conveying technology, air conditioning technology, sanitary engineering and many more.

Series V60 - Pressure switches

- In our V60 series you will find various diaphragm pressure switches (electrical and pneumatic), pressure switches with scale, as well as simple pressure and vacuum switches. Pressure switches are used to convert a specific, adjustable operating pressure into an electrical or pneumatic signal. They are used in line systems with liquid or gaseous media.

V80 Series - Counter and Timer Valves

- The V80 series includes pneumatic and electric timer valves as well as pneumatic preselection and summation counters. The timing valves are available as pneumatic and electric versions and are used for precise control of circuits or systems. Their function is to delay, time limit or interrupt certain processes. While preset counters are used to receive a pneumatic output signal after a preset number of pulses has elapsed, summation counters are used when the number of pneumatic pulses is to be counted.

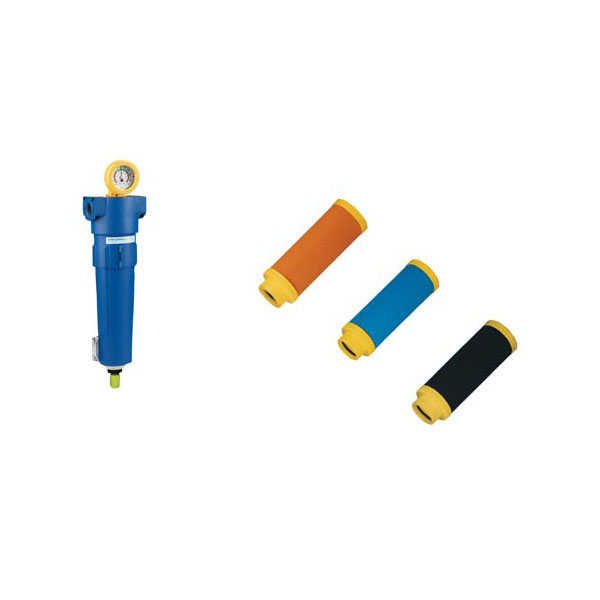

Series W40 - Fine filter

- Whether paint spraying equipment, air-jet weaving machines or refrigeration dryers: Timmer's fine filters are used wherever clean and oil-free compressed air is required. Because contaminated compressed air can quickly lead to problems in pneumatic systems. By using our micro, sub-micro and activated carbon filters of the W40 series, you can safeguard your production processes. In addition, we offer the matching accessories.

W50 Series - Pressure Regulators / Service Units

- Due to the highly developed machines in industry, an ever better compressed air quality is required. With the W50 series, we offer you the necessary pressure regulators that can positively influence the function and service life of many machines. Pressure regulators are used where the incoming medium must be regulated to a desired value that can be set on the regulator. Pressure fluctuations in closed systems and increased secondary pressure can also be regulated with the regulators. In addition, you will find maintenance units, water pressure and material pressure regulators in the W50 series.

Series W60 - Proportional Pressure Regulator

- Proportional pressure regulators are used when different pressure ratios are required. Our W60 series products regulate the output pressure proportionally to an electrical input signal (0 - 10 volts or 4 - 20 mA). The highlight of this series is our piezo-controlled proportional pressure regulator, which regulates a desired pressure very quickly and precisely due to its piezo technology. In addition, our portfolio offers two conventional regulators: in G1/4" size for medium flow rates and in G1/2" for large flow rates.

Series W80 - Maintenance Units

- The W80 series consists of various maintenance units: Combination units, filters, activated carbon and sub-micro filters, pressure regulators, mist lubricators, start-up valves and matching accessories. All products are from the latest generation of units and have a high flow rate. Awarded the iF seal, the units convince with an appealing design. By combining the individual components, complex systems with different air qualities and pressures can be set up.

Series W85 - Maintenance units

- Our W85 series includes various maintenance units in different sizes. These include combination units, 2-part maintenance units, filter water separators, pressure regulators, mist lubricators, shut-off valves, start-up valves, solenoid valves and the matching accessories. The G1/8", G1/4" and G3/8" versions are suitable for small flow rates, G1"/2 for medium flow rates and G1" for large flow rates.

Series Z10 - Clevises and Rod Eyes

- The pneumatic cylinder is subjected to a wide variety of loads when a piston rod is extended. The piston rod performs a variety of movements in one or more axial directions. Clevises are used for low loads and a rotary movement in only one axial direction. Rod eyes are used in the area of force transmission. These positive-locking types of connection compensate for angular deviations and misalignments in all planes. Force transmission under variable tilt angles is easily carried out by these rod eyes.

Series Z90 - Magnet Switch

- Magnet switches are mainly used in pneumatics for sensing the position of the cylinder piston. The magnet switches react to a magnet built into the cylinder piston. When the magnet comes into the switching range of the magnet switch, an electrical signal is switched on or off. Reed contacts work here with a mechanical contact, while the electronic magnet switches work with a semiconductor as the switching element. Our Z90 series includes both electronic and mechanical magnet switches as well as the matching mountings.

Industrial Pneumatics

Cylinder Accessories

- Be it mounting nuts, swivel fork mountings, foot brackets, counter bearing mountings, compensating couplings or magnetic switches - Timmer not only offers a wide range of pneumatic cylinders and valves, but also corresponding accessories. Further components from the world of pneumatics can be found in the pneumatic accessories section. Common to all parts is their high quality.

Series R - Round Cylinder with Swivel Eye

- A round thing: If a larger piston diameter of 32 to 63 mm is required, the round cylinders of the R series from Timmer are used. The high-quality and reliable components have a swivel eye on the base. Non-contact position sensing is standard. Depending on the version, the cylinders may or may not have adjustable end-position cushioning. A wide range of mounting elements opens up a broad field of applications.

RST series - Round Cylinders

- Linear movement in perfection - pneumatic cylinders from Timmer always provide the right drive. The round cylinders according to DIN ISO 6432 score with standardised fitting accuracy. They are available in various versions: all with contactless position sensing, double-acting or single-acting, with or without adjustable end-position cushioning.

Series SZ - Short-stroke Cylinders

- The short-stroke cylinders of our SZ series are manufactured in diameters from 12 to 100 mm. Their standard temperature range is -10 °C to +70 °C. Possible fields of application are all typical pneumatic applications. Depending on the requirements, Timmer offers the cylinders with contactless position sensing, single-acting and double-acting as well as with through piston rod.

Series SZV - Short-stroke Cylinders with Anti-rotation Protection

- Due to their compact dimensions, short-stroke cylinders are particularly suitable for use in tight installation spaces. Timmer's non-rotating, double-acting short-stroke cylinders are available in diameters from 20 to 63 mm. As standard, they have contactless position sensing.

Series FZ - Guide Cylinder

- We are the experts when it comes to pneumatics. That's why we at Timmer know what matters when it comes to pneumatic components. This also applies to our double-acting guide cylinders. They are equipped with contactless position sensing as well as plain bearings or ball bearings. The standard delivery programm includes piston diameters from 16 to 63 mm as well as strokes from 10 to 200 mm. For short strokes, the plain bearing version FZG offers a higher load capacity, whereas for longer strokes, the ball bearing version FZK offers a significantly higher load capacity.

Series NZN - Compact Cylinder

- Compact solutions are required for particularly small installation spaces in pneumatic applications: the NZN series from Timmer, developed in accordance with ISO 21287, meets these requirements. You can choose between different versions, for example single-acting or double-acting as well as PU or FKM rod sealing. Non-contact position sensing is standard. The piston diameters cover the range from 20 to 100 mm.

Series TNC - Standard Cylinder Profile Tube ISO

- This series comprises a selection of double-acting profile tube cylinders and complies with ISO 15552. All cylinders are equipped with adjustable end-position cushioning. Versions for use at high temperatures, with through piston rod or other customised solutions are also available from Timmer.

Series AZV - Standard Cylinder Profile Tube

- This pneumatic cylinder series is non-rotating and double-acting. It is available in piston diameters from 32 to 100 mm. Its features include contactless position sensing, adjustable end-position cushioning. Continuous piston rods, stainless steel piston rods, high-temperature versions and other customised solutions are available on request.

Series TNZ - Standard Cylinder Tie Rod

- Timmer tie rod cylinders are based on ISO 15552 - so standardised fitting accuracy is a given here. The high-quality materials used, such as steel and anodised aluminium, make the components particularly robust and durable. In addition to our standard products, we also offer customised solutions.

Series FSE - Locking Unit - Blocking at Pressure Drop - Piston-Ø 32-125 mm

- This clamping unit is suitable for cylinders with a diameter of 32 to 125 mm. The locking unit is used to hold the cylinders in any position. In the event of a pressure drop at the control input, the component reacts with a blockade.

Series SP - Bellow Cylinders SP - Single Acting

- Air actuators are the ideal solution for tasks requiring a single-acting actuator with short stroke length and high axial force. They are used in pneumatics as a spring element or for vibration damping. Depending on the required stroke, we have single and double air actuators available. Due to their flexibility, they can tolerate up to 30° inclination between the mounting plates.

Series V10 - End Switch Valves

- Limit switch valves are mechanically operated poppet or spool valves that switch an output signal when actuated. You can choose between 3/2 and 5/2-way valves. Depending on the design, they have 4 mm plug-in connections or G1/8" screw connections.

Series V11 - Hand Valves

- The durable Timmer hand valves of the V11 series consist of 2 different designs: Hand lever valves in 3/2-, 5/2- or 5/3-way design in connection sizes 1/8", ¼" and ½" as well as modular combinable valve blocks on which you can mount, for example, push buttons, rotary levers or key switches. So you will find everything you need for manual signal input here.

Series V12 - Foot Valves

- Top performance at an attractive price - we offer our V12 series foot valves as 3/2 or 5/2-way seat valves. You need an additional protective cap? No problem: Timmer also has these in its range.

Series V13 - Pneumatic Valves

- In our range you will find a wide selection of pneumatic valves. They are available as 3/2, 5/2 and 5/3-way piston spool valves with G1/8", G1/4" or G1/2" connection. They are also available in bistable and monostable versions. The bistable valves can also be used for vacuum applications.

Series V14 - Pilot Valves

- Timmer's pilot valves can be used in a wide range of applications, from automotive engineering to the chemical industry. The products of the V14 series are available as single valves, valve manifolds or stackable modular system. As single valve and modular system they have a manual override.

Series V15 - Solenoid Valves

- Solenoid valves are control devices that release, shut off or divert a flowing medium. The actuating element here is an electromagnet. At Timmer the components are available as 3/2-, 5/2- and 5/3-way piston spool valves in G1/8", G1/4" and G1/2". The versions with external control air are suitable for switching vacuum up to -0.9 bar. The valves are available ATEX-compliant on request. What all variants have in common: Robustness, reliability and performance.

Series V16 - NAMUR Valves

- Whether as a pneumatic or solenoid valve: at Timmer you get both. Modern design, durable quality, tested technologies and materials are the features of the V16 series. The valves are used for easy mounting on devices with Namur interface, e.g. coaxial valves and rotary actuators. The products are available as 3/2 and 5/2 spool valves, but can be converted from 5/2 to 3/2 ways by changing the seals under the screw plugs.

Series V17 - Function Valves

- In the series V17 Timmer summarises the logic valves. YES, NOT, AND & OR are the basic logic functions to realise pneumatic controls. With aluminium housing and 1/8" screw or 4 mm plug-in connection, they are versatile.

Series V18 - Special Valves

- You need a pneumatic valve with very specific requirements? No problem! Timmer offers special valves for numerous pneumatic applications. These include dual pressure valves, signal interrupters, vacuum generators, time valves, two-hand safety valves, flip-flop valves and oscillating valves.

Series V19 - Solenoid Valves - Basic-Line

- Basic can be this good: Our Series V19 Basic-Line solenoid valves are characterised by a rational selection of designs. 5/2 and 5/3-way valves make up the majority of valves in pneumatic control systems, so our Basic-Line is limited to these types in a very attractive price structure. For more demanding applications that require a larger selection of designs, our V15 series offers corresponding variety. You will quickly find what you are looking for at Timmer!

Vacuum Technology

TIVAtec - Pneumatic Vacuum Pumps

- Pneumatic vacuum pumps offer many advantages over electromechanical pumps: they are smaller in size and lighter in weight, simpler in design and virtually wear- and maintenance-free. But the pumps offer even more: thanks to their optimal nozzle geometry with additional nozzle stages, our TIVAtec multi-stage ejectors achieve a high degree of efficiency with low energy consumption at the same time.

TIVAtec - Vacuum Pumps Electric

- In the field of electric vacuum pumps, Timmer has 3 types of products available: dry-running or oil-lubricated pumps as well as vacuum blowers. The advantage of oil-free pumps is that there is no contamination of the pumped medium, thus eliminating the need for treatment and disposal of the lubricant. Pumps with oil lubrication are very durable and particularly reliable in continuous operation. The pumps are primarily suitable for evacuating closed containers. Both types are very powerful and achieve a high ultimate vacuum. Vacuum blowers are suitable for the suction and compression of non-explosive gases. Compression is lubricant-free, thus avoiding contamination of the compressed medium by the blower.

TIVAtec - Suction Cups

- At Timmer you will find a wide range of suction cups for vacuum technology. We offer: Flat, bellows, profile, universal suction cups and much more. You can choose between different sizes, shapes and profiles. But we also offer different types of materials and shore hardnesses - according to your needs. All our suction cups are characterised by durable materials and easy installation - just typical Timmer.

TIVAtec - Vacuum Accessories

- At Timmer, you not only get a large selection of vacuum technology, but also the matching accessories. We offer components for various applications. These include various vacuum filters, vacuum gauges, filter inserts and much more - in different sizes and shapes. Just according to your needs. All accessories are characterised by easy installation.

TIVAtec - Pressure and Vacuum Switches

- Vacuum pressure switches are designed to detect pressure changes in a vacuum system. At Timmer you will find products for different applications: These include electrical and pneumatic vacuum switches as well as digital precision pressure switches. They are characterised by high quality, durability and high measuring and switching accuracy. When selecting the appropriate pressure switch, we will advise you comprehensively on the respective advantages of the different solutions.