Hänel

Videos

Loading the player ...

- Offer Profile

- Since the 1950s the name 'Hänel'

has stood for innovative solutions in automated records and materials

handling. Today we are one of the world's leading providers in the industry.

Thanks to the continuous refinement of our products and software, the

solutions we offer today will meet the requirements of tomorrow.

Hänel was, for example, the first producer of vertical lift technology to develop an EcoDrive® system, which converts the kinetic energy of the descending extractor into electrical energy and feeds it back into the electrical supply system.

Product Portfolio

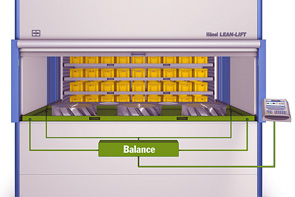

Hänel Lean-Lift®

- Flexibility, efficiency and cost-effectiveness

Economy, efficiency and ecology – these are the demands that modern-day intralogistics must meet

With the Hänel Lean-Lift® we offer you a first-class, high-tech system for storage organization and materials handling that saves time, storage space and costs, and

enables a much more efficient workflow:- Over 60% more space

- Efficiency

- Ergonomic and safe

- Work time slashed

- Optimal parts management

- We are committed to environmental protection

The principle

- The automated ‘high-bay warehouse in a cabinet’

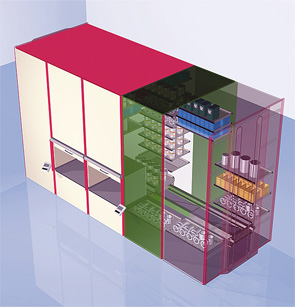

The Hänel Lean-Lift® is both storage rationalization and goods protection in one: At the center of this closed system is a computer-controlled positioning lift – the ‘extractor’.

In front of it and behind it are the storage shelves. This is where the articles are stored in containers in height optimized positions. The storage locations are accessed automatically under electronic control by means of the extractor, which stores or retrieves the requested container. The goods are then delivered to the retrieval area at the correct ergonomic height.

This ingenious principle finds applications in a wide variety of industries. Used in the medical technology and electrical engineering sectors (for which ESD versions are possible) and also in the automotive, aircraft and pharmaceutical industries or in mechanical engineering, the mail-order and wholesale trades – the Lean-Lift® is the ideal buffer, dispatch, production or tool store, to name but a few sectors that demonstrate its versatility.

Our specialists would be happy to show you references from your line of business – just send us an inquiry.

The pluses:- Fast storage and retrieval times.

- High storage density, even when articles have different heights.

- Goods to man is the motto instead of man to goods: this saves time.

- Improved order-picking performance.

- High economic efficiency and cost savings.

- Protection of inventory.

- Storage and handling of bulky and heavy parts.

- Load-bearing capacity of up to 1,000 kg per tray.

- Load-bearing capacity of up to 60,000 kg per Lean-Lift® (higher payloads on request).

- Integrated storage management.

- The automated ‘high-bay warehouse in a cabinet’

Features

Storing with intelligence

- An ingenious development!

The Hänel slot profile in 75 mm or 90 mm steps offers a multiplicity of options:

The slot profile is a built-in fixed wall with integrated slots in 75 mm or 90 mm steps, and is the ultimate solution for achieving optimal space-saving storage.

Convincing simplicity:

the high-stability Hänel profile wall!

Hänel is the inventor of the profile wall – with over 15 years of experience!

The profile wall with its high stability and precision is fixed to the rectangular profiles at the factory.

On the outside the typical Hänel design, on the inside a stable slot system!

Less warehouse is more

- The Hänel Lean-Lift® offers over 60 % more storage

capacity than a miniload system/rack store on the same footprint

One glance in the Hänel Lean-Lift® shows the advantages clearly: Optimum storage of highly varied parts without any loss of space! Key points speak in favor of the Hänel Lean-Lift®:

Distinct advantages over conventional rack storage and MLS- Storage capacity can be adapted step by step.

- More than one person at a time can operate the lift and process jobs.

- Retrieval times are considerably shorter.

- Units can be added, expanded or separated at a later time.

- Better utilization of storage volume thanks to height-optimized storage.

- Decentralized storage right in the production hall.

The access point

- It protects the user and it weighs, measures,

photographs and identifies the storage items. The smooth-action rollers make

storage and retrieval operations a breeze. Shelf retrieval and put-away can

also be performed automatically.The interior lighting makes sure you can 'keep an eye on things'. A

compartment sublevel indicator or the Pick-o-Light® system guarantee

error-free retrieval.

Hänel offers individual equipment variants for every need.

All these are ideas the Hänel specialists have developed over their many years of experience – and from which you benefit.

The Hänel light curtain guarantees maximum safety for the operators as they pick and put.

Optimum storage assignment based on precise height measurement of goods

Accurate height measurement for storing containers in the optimal packing density. Height-measuring light barriers spaced at 25 mm, 37.5 mm, 75 mm, 90 mm or 125 mm.

When the container is drawn in, the highly accurate light barriers measure the articles, and the Hänel microprocessor control system finds the optimum storage location in the Hänel Lean-Lift®. At the same time a protruding goods check is carried out. With its height sensors, profile wall and Hänel container technology, the Hänel Lean-Lift® provides vertical optimization and height optimization in one!

Accurate weights recorded with the Hänel weighing device

The Hänel Lean-Lift® is equipped with a weight management system as standard. As an option, an electronic 4-point weighing system can be used to weigh each container in the access point without any loss of time. The current weight is then shown on the keyboard display.

The weighing device allows the maximum load of the individual containers and that of the entire lift to be recorded. The additional payload is determined with the tare function.

Secure access

The compartment indicator ensures error-free access and quick storage and retrieval

- The LED display can be positioned above or below the

access point as required. The compartment and sub-level indicators ensure

the right article is accessed.

The compartment and sub-level are displayed on the LED strip as either one or two digits.

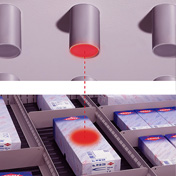

The Hänel Pick-o-Light® system for quickly finding the required articles

- An LED array is integrated into the panel above the access opening of the lift. A colored LED directs a beam of light onto the requested article so that it is identified unmistakably and unequivocally. This ensures maximum efficiency and reliable selection during order picking.

Hänel Pick-o-Light-Vario® for variable container divisions:

- Alternatively, if container divisions are variable, items can be identified via a free-moving Vario unit with 4 integrated LEDs.

Crosshair reticle

- As an option, the Pick-o-Light-Vario® can be fitted with a crosshair reticle. This is used to clearly identify very small items

Integrated camera

- A camera integrated in the Lean-Lift® takes a photo of

the container each time a transaction is carried out.

A fixed number of pictures is archived per container so that inventory changes on the container can be tracked.

With the photographic information, an article on a container can be identified directly from the control unit and brought to the access point.

Variable and ergonomically

The Hänel high-speed door

- The Hänel high-speed door enables several operators to

work simultaneously at a Lean-Lift® with more than one access point. The

access areas are blocked off from each other.

Travel speeds of up to 1 m/s make for quick access. The aluminum profiles are highly robust and have a long lifecycle. A frequency converter ensures optimal flow of movement.

The fold-down support rail from Hänel

- The support rail at the access point can be raised and

folded down as required. Storage containers can then be pulled out of the

access point on smooth-running plastic rollers.

This makes work at the Hänel Lean-Lift® even more ergonomic. Heavy parts can also be removed with a crane.

The Hänel transporter

- With the Hänel transporter, complete containers can be taken out of the Lean-Lift®, as they can with the fold-down support rail. This means that even with particularly heavy parts (up to 1,000 kg per container) the container can be transported effortlessly to the required destination.

Multifunction containers

- Different sizes of Hänel

multifunction containers

Hänel offers a variety of container widths and depths. This means the containers can be adapted individually to the stored goods!

Width: 840/1,300/1,640/1,860/2,060/2,300/2,460/2,860/3,060 or 3,260 mm

Depth: 635/825/1,047 or 1,270 mm

And a wide range of accessories are available, such as tool inserts, molded trays for small parts, holders for milling cutters, and other separators, which compliment the Hänel Lean-Lift®, turning it into a complete intralogistics system that saves costs, makes optimum use of space, makes work easier and minimizes distribution times!

Our specialists would be happy to develop a tailored solution for your storage requirements. Hänel offers special-purpose solutions to hold, for example, arbors, bars, rollers, sheet material, boards, SMT reels, hanging garments, rollable storage goods, sleeve rolls, and drawings of all formats right up to A0 size. Solutions for the electronics industry. The Hänel Lean-Lift® offers the electronics industry further advantages: The containers can be given an antistatic coating, if necessary, to protect sensitive electronic components. And Hänel supplies containers that can be electrified with an electronic plug-in contact at the rear.

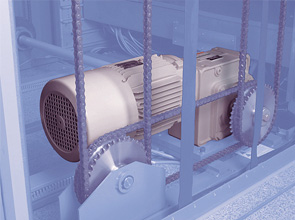

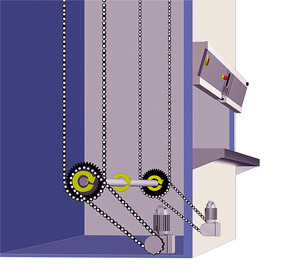

Drive components

- The Hänel Lean-Lift® is available in a high-speed

version. The vertical speed of travel, for example for containers with a

load capacity of up to 500 kg, is 2.3 m/sec with an empty extractor, and 1

m/sec with a loaded extractor. Horizontally the extractor travels jolt-free

at a speed of 0.5 m/sec.

Moreover each Hänel Lean-Lift® is equipped with a soft start control with frequency converter.

The advantage: Gentle and rapid acceleration and braking.

The vertical carriage (extractor) has 4-point suspension...- No tilting of the extractor.

- No problems with certain load imbalances, especially with

heavy loads, and therefore a longer lifecycle. - Easy maintenance access from the side.

- Easy attachment of the arresting device for the extractor.

- Roller chains are durable, so no fatigue failures.

- Long lifecycle.

- No replacement necessary at fixed service intervals.

- Roller chains have a high rate of efficiency (98%).

- Accurate positioning because of high rigidity.

- No slip on emergency stops.

Highly efficient and powerful motors allow the extractor to achieve travel speeds of up to 2.3 m/sec

The Hänel EcoDrive® –CO2 reductions thanks to efficient energy recovery

In the Hänel Lean-Lift® EcoDrive®, a frequency converter converts the kinetic energy of the descending extractor into electrical energy and feeds it back into the electrical supply system. Depending on the traversing rate, up to 40% of the energy fed in for the upward run can be returned to the supply network.

Cool systems

Automated storage in a controlled atmosphere

- Optimum solutions for storage in

temperature-controlled and dry-air

environments.

The quality requirements that consumer and industrial goods have to meet are becoming increasingly stringent and far-reaching. Many products today, ranging from highly sensitive components in the electronics industry (such as the delicate surfaces of semiconductor products) to sensitive substances in the chemical and pharmaceutical industries, need to be stored under very specific, defined conditions.

With its automated DryStore® and ClimateStore® systems, Hänel offers future-oriented solutions that are suitable for all air-controlled environments. The systems are flexible and can be free-standing or installed so that they dock into existing rooms.

Illustrated on the opposite page is a Hänel ClimateStore® Lean-Lift®, networked with other Lean-Lifts®.

It is used to stock temperature-sensitive medicines at a constant 5 degrees Celsius. The efficacy of the climate chamber is ensured by an automatically closing door and the Hänel high-speed door.

Maximum efficiency

EcoDrive®

DualDrive®

Pre-Store-Buffering®

Pick-o-Light®-System

Camera solution

Multi-Space®

- Whether it’s a stand-alone solution, or networked

with other Multi-Space® systems, or used in combination with Lean-Lifts® and

Rotomats® – the Hänel Multi-Space® offers another innovative solution for

your intralogistics!

With the rollout of the Multi-Space®, Hänel optimizes the principle of 3-axis storage systems. In addition to the many benefits of Hänel’s Lean-Lift® technology, the Hanel Multi-Space® offers maximum flexibility, speed, and space utilization.

Maximum flexibility. Thanks to its cutting-edge technology, Hänel is able to offer a 3-axis storage system that is over 9 m wide.

The Hänel Multi-Space® can even vary its width and height to meet later needs – a new feature from Hänel!

Even the number of access points is variable and can be altered at any time. Along with the different container widths and depths, this results in the most versatile of combination possibilities.

Optimum space utilization. The variable positioning of the access openings makes optimal integration into already existing storerooms possible. Previously inaccessible areas can be integrated into a storage concept without difficulty. And the Hänel slot profile combined with the Hänel multifunction containers are the ideal prerequisites for compact, heightoptimized storage. The new definition of vertical lift technology from Hänel!

The principle

- The Hänel Multi-Space® principle:

With simultaneous horizontal and vertical movement, the articles are stowed away in the Hänel Multi-Space® by the quickest route

Modular design- Modular scalability with the use of additional storage units (payload up to 40 tons per unit)!

- Extractor can be widened at any time!

- Height can also be increased through multiple floors!

- Number and position of access points freely selectable!

- The variable design of the extractor with its lightweight construction, including elements used in bridge engineering, guarantees maximum stability and rigidity!

- Later adaptation of the extractor width is possible!

- High running speeds ensure quick access to the stored items!

- Roller chains are durable, no fatigue failures!

- Long life cycle!

- No replacement at service intervals necessary!

- Roller chains perform with optimum efficiency!

- Exact positioning thanks to maximum rigidity!

- Inspection doors on both sides as standard!

Rotomat® Industrial Carousels

- Rationalization –

cost-cutting – efficiency: these are

all demands that modern-day storage

organizations must meet!

Quality and leading-edge technology ‘Made by Hänel’

In 1953 Gerhard Hänel founded the office equipment company 'Hänel Bürosysteme'. By 1957 Hänel was series-producing filing carousels based on the Ferris wheel principle – the first manufacturer in Europe to do so. Today Rotomat® carousels and Hänel Lean-Lifts® are produced in three manufacturing plants – and exported worldwide. Hänel has distributors in over 50 countries across the globe. Innovation and performance, dynamics and ideas, new technologies and team spirit have made Hänel one the leading providers of storage and organization systems. With the Hänel Rotomat® industrial carousel, we offer a flexible storage and provisioning system that adapts optimally to your needs.

The principle

- The principle is simple. The applications are

brilliant!

The compact design of the Hänel Rotomat® enables up to 60% more storage area to be created on a minimal footprint by making use of the available room height.

The operating principle

The Hänel Rotomat® creates an enormous amount of storage space on a small footprint. It works on the Ferris wheel principle, i. e. the archives come to the operator, not the operator to the archives.

The structural design

Self-supporting steel plate casing, comparable to the cellular structure used in the aircraft industry. Lockable, smooth-action sliding doors. Environmentally friendly powder coating, as well as impact-resistant and shock-proof stove enamel finishes. There are five attractive colors to choose from. Customized finishes are possible.

The drive system

Most Hänel Rotomat® industrial carousels are powered by two 400-V three-phase motors. Pole-switching three-phase motors are used as standard, enabling gentle but powerful acceleration and braking even under different load conditions.

The intelligent Hänel control systems

Powerful Hänel microprocessor control units offer the possibility of hooking up to computers and other peripheral devices, giving you an optimal overview at all times.

The safety

Hänel ensures maximum safety by using the Hänel safety threshold switches and light-barrier curtains compliant with DIN EN 15095. The Hänel Rotomat® carousels have the German GS mark and the Swiss SUVA inspection certificate attesting to their safety.

The pluses- Optimum use of floor space. There are no upper limits to the Rotomat®.

- The Rotomat® is as flexible as you need it to be. Even systems with multiple access points on different floors are possible.

- Goods to man is the motto instead of man to goods. Time is saved and access times reduced.

- High-performance controllers and interface with IT systems make the Rotomat® flexible and adaptable to customized applications.

- The requested part or tool is brought automatically to the

ergonomic retrieval height. - Safety has top priority. No ladder-climbing, no risk of accidents.

- The Rotomat® protects all the parts from dust, light and unauthorized access.

- Elegant design and five modern colors to choose from. Customized finishes are possible.

The access point

Non-wearing V2A work counter

- The V2A stainless steel work counter used on the Hänel

Rotomat® is virtually wear-proof and not only looks good but enables users

to pick, put and slide the storage bins with minimal effort.

Behind it is the Hänel safety threshold which allows level-sweep access to the inventory while ensuring optimal personal protection at the same time.

The compartment indicator ensures error-free access and quick storage and retrieval.

- The LED display is integrated elegantly into the work

counter. The sub-level indicator in front of each storage compartment

ensures error-free retrieval.

The compartment and sub-level are displayed on the LED strip as either one or two digits.

Lockable sliding doors

- The Hänel Rotomat® is fitted with a smooth-action,

lockable sliding door. This protects the goods from dust and dirt as well as

from unauthorized access.

The sliding door is split, with the upper and lower halves providing a counterbalance to each other. This makes the door easy to open without the need for additional counter-weights.

Multifunction carriers

- The task defines the fittings

We provide customized interior fittings, tailored to the individual demands of production systems and storage logistics. The mechanical parts and carrier sets are configured according to the size and weight of the storage goods. It's this flexibility that makes the Hänel Rotomat® so cost-effective. The Hänel multifunction carriers offer you customized, variable interior fittings that can be adapted effortlessly to your personal needs and the different article heights. This achieves maximum compaction of the storage volume. And a wide range of accessories are available, such as plastic boxes, tool inserts, molded trays for small parts, holders for milling cutters, etc., which complement the Hänel Rotomat®, turning it into a complete logistics system that saves costs, makes optimum use of space, makes work easier and minimizes distribution times. Hänel also offers customized special-purpose holders for SMD reels, cable drums, printing rollers, rods and tubes.

The pluses:- Hänel multifunction carriers are absolutely stable and distortion-free.

- Variable fittings can be altered at a later date.

- Compartment dividers, bins, drawers or loose goods – the possibilities are endless.

- Long lifecycle and high load-bearing capacity up to 750kg per carrier, depending on the model.

- Multifunction carrier with different front edge variants

- Multifunction carrier with intermediate shelves slotted into punched holes and with movable dividers

- Multifunction carrier with front wall – trough version with movable dividers

- Multifunction carrier with drawers of different heights slotted into punched holes

- Multifunction carrier with lowerable front walls

Drive components

Twin-motor design

- The drive systems of all Hänel Rotomat® carousels are housed inside the carousel casing. This ensures optimal freedom of movement in front of the carousel. Almost all Hänel Rotomat® industrial storage carousels are equipped with twin motors. This guarantees less wear and quieter running. The right and left drive motors are controlled synchronously. The simultaneous acceleration and braking of the two drives means that the multifunction carriers are moved without distortion. The twin motor design also ensures optimal balance if the load on the carrier is distributed unevenly.

Stable carrier suspension on 4-point sliding carriage principle

- The Hänel Rotomat® carrier suspension is designed according to the sliding carriage principle so that the carriers are suspended from 4 levers on 4 rollers on left and right.

Safety Bypass System

- Hänel Rotomat® industrial carousels work reliably and

failure-free. If a malfunction should arise, however, Hänel's optional

Safety Bypass System comes into effect in certain cases.

If a light barrier curtain or door switch is defective, for example, the user can continue to operate the Hänel Rotomat® until the Hänel service technician arrives by activating the Safety Bypass System and closing the sliding door.

Special features

Automated storage in a controlled atmosphere

- The quality requirements that consumer and industrial

goods have to meet are becoming increasingly stringent and far-reaching.

Many products today, ranging from highly sensitive components in the

electronics industry (such as the surfaces of semiconductor products) to

fragile substances in the chemical and pharmaceutical industries or medical

supplies in hospitals and pharmacies, need to be stored under very specific,

defined conditions.

With its automated DryStore®, CleanStore and ClimateStore® systems, Hänel

offers future-oriented solutions suitable for air-controlled environments.

The systems are flexible, can be free-standing and operate as stand-alone solutions, or be integrated into existing rooms with air-controlled environments.DryStore® humidity-controlled:

For articles that need to be stored in humidity- and corrosion-protected conditions.

CleanStore particle-controlled:

Low-particle storage of components in clean-rooms.

ClimateStore® temperature-controlled:

Whether it's in the plus or minus range, goods are stored at a constant temperature.

Solutions

Distribution warehouse

Heavy-duty lifts

Small parts storage

Electronics industry

Medical technology

Rotomat® Office Carousels

- Productivity

– cost reduction – efficiency: these

are the challenges faced by today’s

office organization!

Quality and leading-edge technology ‘Made by Hänel’

In 1953 Gerhard Hänel founded the office equipment company ‘Hänel Bürosysteme’. By 1957 Hänel was series-producing filing carousels based on the Ferris wheel principle – the first manufacturer in Europe to do so. Today Rotomat® carousels and Hänel Lean-Lifts® are produced in three manufacturing plants – and exported worldwide. Hänel has distributors in over 60 countries across the globe. Innovation and performance, dynamics and ideas, new technologies and team spirit have made Hänel one the leading providers of storage and organization systems. With the Hänel Rotomat® office carousel, we offer a flexible organ- ization and filing system that adapts optimally to your needs.

Up to 60% more storage capacity

The Rotomat® office carousel from Hänel makes use of the available room height, so its compact design creates up to 60 % more filing capacity. This means expensive office space is used more efficiently.

Work time slashed

The Rotomat® office carousel from Hänel brings the required files to the retrieval point in just a few seconds.

Ergonomics

No more bending, ladder-climbing or walking long distances to search for and archive records. The required files are brought automatically to the optimum ergonomic retrieval height.

The right decision

If you want to improve your office organization methods and cut costs, you should first speak with our specialists – together we can work out a tailor-made system concept.

The principle

- The principle is simple. The

applications are brilliant!

The days when walls were lined with filing cabinets and when archives gathered dust in the cellar are over. The legwork and ladder climbing involved in searching for files are a thing of the past – they cost too much time and money! The compact design of the Rotomat® allows up to 60% more storage capacity to be accommodated on minimal floor space by making use of the available room height.

The operating principle

The Hänel Rotomat® creates an enormous amount of storage space on a small footprint. It works on the Ferris wheel principle, i. e. the archives come to the operator, not the operator to the archives.

The structural design

Self-supporting steel plate casing, comparable to the cellular structure used in the aircraft industry. Lockable, smooth-action sliding doors. Environmentally friendly powder coating, as well as impact-resistant and shock-proof stove enamel finishes. There are five attractive colors to choose from. Customized finishes are possible.

The drive system

400-V three-phase motors (other voltages and Hertz values, as well as AC connection are possible). Pole-switching three-phase motors are used as standard, enabling gentle but powerful acceleration and braking even under different load conditions.

The intelligent Hänel control systems

Powerful microprocessor control units offer the possibility of hooking up to computers and other peripheral devices, giving you an optimal overview at all times.

Hänel service worldwide

Hänel operates internationally and has branches and distributors on all continents. It is supported by an extensive service network under centralized control.

The safety

Hänel ensures maximum safety by using patented safety threshold switches and light-barrier curtains compliant with DIN EN 15095.

The pluses- Optimum utilization of floor space. The term upward mobility takes on a new meaning with the Rotomat®.

- The Rotomat® is as flexible as you need it to be. Units can extend through several floors.

- Files to user is the motto, not user to files. Personnel costs and retrieval times can be dramatically reduced.

- High-performance controls and computer interfacing ensure that the Rotomat® can be put to use flexibly and on an individual basis.

- The required files are brought automatically to the ergonomically positioned retrieval point.

- Safety has top priority. No ladder-climbing, no stretching, no bending.

- The Rotomat® protects all the files from dust, light and unauthorized access.

- Elegant design, five attractive colours to choose from. Individual finishes are possible.

Versions

Rotomat® 300

- Smart, space-saving file management for large-scale

needs

When the problem you face is how to store large quantities of hanging folders in the most space-saving way while guaranteeing quick access, the Hänel Rotomat® 300 comes into its own.

You can cut your office space requirements by up to 60 %. Hänel performance at its best!

The simplicity and quick access afforded by Hänel office carousels are highly appreciated by office staff.

Tailored management and control systems plus interfaces with PC workstations make the Hänel Rotomat® the ideal partner in commercial and administrative offices.

Rotomat® 400

- Maximum usage of filing capacity in a minimum of space

The Hänel Rotomat® 400 offers maximum filing capacity on a minimal footprint.

Because the carousel adapts to the height of the room, the floor space required can be reduced by up to 60 %.

The efficient way in which it works – the required lateral folders are retrieved automatically by the microprocessor control – cuts the work time involved considerably!

Rotomat® 500

- Efficient, secure storage of files on a minimal footprint

while guaranteeing rapid access

The days of walls lined with box files or binders on shelves gathering dust are gone forever! Nowadays the demands placed on modern office organization include ensuring that costly office space is reduced, capacity is optimally used and files can be accessed quickly.

The Rotomat® principle has decisive advantages over conventional filing systems: the files are brought to the user, not the other way around.

This brings benefits: Workflow is speeded up, and so becomes more efficient and cost-effective. Full utilization of the room height can reduce the office space required by up to 60 %!

The Rotomat® 500 is the cost-effective filing carousel for ring binders.

Rotomat® 600

- Efficient management of

hanging folders in a minimum of

space

Wherever files are in constant use and must be actively managed, the Hänel Rotomat® 600 is the ideal solution.

The hanging folders are stored neatly in space-saving frames that are pulled out on high-quality telescopic runners for easy access.

The user-friendly microprocessor control with numeric keypad is integrated in the work counter. A mere touch of a button brings the required folder to the retrieval zone. It couldn’t be easier or quicker!

And of course the Hänel Rotomat® can be connected to your PC system without difficulty.

This is office organization at its best!

Rotomat® 700

- Efficient

management of archives with maximum cube capacity on a minimal

footprint

The Hänel Rotomat® 700 offers abundant space on a minimal footprint. Its huge capacity results from its ability to adapt optimally to the available room height.

The versatile fittings inside the Rotomat® 700 allow it to be used for a wide variety of applications. It is ideal for cards of all sizes, computer disks, microfilm jackets, microfiche, letters and legal folders, press photos and X-ray pictures to name but a few!

Any required item is automatically brought to the user in seconds – conveniently, at the right ergonomic height, without any legwork or physical effort.

Rotomat® 7-600

- Cost-efficient

archiving of vertical files and

index cards for administrative

offices

The medical service of a health insurance company.

When several departments were recently merged, reorganization became necessary. The first job was to transfer folders from about 100 filing cabinets to a central archive. Space was in short supply, the fileroom was bursting at the seams!

The solution: Hänel carousels! More than 100,000 vertical folders (stacked in a line they would stretch half a kilometer) are now neatly stowed in 10 Hänel Rotomats®, ready for immediate access!

All of the administrative staff enjoy working with the Rotomat® system, and particularly appreciate how easy it is to use.

Special-purpose solution

- The Hänel Rotomat® is an ideal filing system for disabled

users

Integration of the disabled at the workplace is more important today than it has ever been. The right measures need to be taken, however, if proper integration is to be achieved. Hänel offers custom-made solutions with regard to workstations suitable for the disabled.

Special solutions have been designed in cooperation with the German association for self-help for the physically handicapped in Krautheim:- The ergonomic recess at the retrieval area allows wheelchair users to get close to the carousel, thus enabling easy processing of the files.

- Each stop position of the carrier set can be defined individually by the Hänel multifunction positioning system.

- The control panel is placed in the center of the work counter. Rotomats® with no work counter have the control panel in an easy-to-reach keyboard housing.

Lockomat®

- Compartment

doors that are closed manually or

automatically guarantee error-free

retrieval and protect the stored

articles from unauthorized access.

The user proves his authorization by means of an ID card, password or transponder, and the user interface set up for him personally appears on the display. All booking operations can then be traced to a specific user. Multiple users can be set up with different authorizations.

Article management

Articles are requested or put into storage by entering an article number or using a barcode scanner. The digital LED display on the work surface indicates the compartment door behind which the article is stored. All pick and put operations are logged, which makes later verification and tracking easy. Similar-looking articles can’t be confused.

Inventory control

Continuous inventory control means that shortages in the supply of materials can be avoided. The intelligent microprocessor control system can be easily integrated into the customer's own IT system. This ensures you have an overview of the stock situation at all times.

Protection of inventory

The closed storage system protects your stock from unauthorized access.

Space and time savings

Optimum use of floor space. There are no upper limits to the Lockomat®. Systems can even span multiple floors.

The Lockomat® is designed according to the tried-and-tested vertical carousel principle. That means:

Goods to man is the motto instead of man to goods. Access times are slashed.

The principle

- Chemical industry, banks, pharmaceutical industry .

. .

when items that look identical on the outside but are very different on the inside need to be stored and retrieved quickly and without mistakes

The Hanel Lockomat® is highly versatile

- The principle is simple.Its applications are

brilliant!

Each Hänel Lockomat® is designed according to the tried-and-tested Ferris wheel principle (vertical carousel system) which means the goods are brought to the operator, not the other way around.

The compact design means that up to 60 % more storage capacity can be created on a minimal footprint by using the available room height.

The advantages of the Hanel Lockomat system at a glance:- Error-free access. Only the requested item is brought to the access point for the user.

- Computerized storage. with full tracking of all retrievals, users and inventory.

- Space and time saved. Goods to man is the motto, not man to goods. Staffing levels can be cut and cycle times reduced.

- Optimization of workflow.No time lost ‘searching’ – the requested item is brought to the access point at an ergonomic work height without any mix-ups.

- Safe and secure access. Items can only be withdrawn after authorization is verified.

Controllers & Software

- Flexibility,

efficiency and cost-effectiveness –

these are the demands that

modern-day intralogistics must meet!

Up to 60% of the available floor space saved and drastic reductions in the time taken to access the stored goods.

The operating procedures of Hänel storage systems are optimally designed to create additional space and time savings

of up to 2.3 m per second! Numerous add-on modules and the various options for integrating the controllers into existing IT systems offer you optimal, customized

storage management for your intralogistics.

The right decision

If you want to improve your intralogistics concept and reduce costs, you should talk to the specialists at Hänel first. They will work with you to develop your own ‘tailor-made intralogistics concept‘.

Be sure to choose the intelligent control and software solutions from Hänel, as so many renowned companies worldwide have done!

MP controllers

MP 0 N

The MP0N is designed as a single-lift controller for the Hänel Rotomat® with one access point.

It offers three different operating modes:- MP0N-StandAlone

- MP0N-HOST

- MP0N-BARCODE

MP 12 N

- Whether you use the Hänel storage

systems as stand-alone solutions with integrated inventory management or want to integrate the control units into a higher-level ERP system – the top controller MP12N from Hänel has every-thing already built in.

MP 100 D

- high-performance central control system for up to 99

storage units

Hänel developed the central control system MP100D so that a large number of storage units can be managed effortlessly with the integrated storage management packages from Hänel. It manages the data of up to 99 storage units.

Storage Management Packages

- Intelligent inventory control with the storage

management packages from Hänel

Hänel file management

All three packages boast easy-to-handle user interfaces and maximum storage management functionality.

Software solutions

HänelSoft®

- HänelSoft® is a powerful software package that offers practical configuration options and numerous add-on modules enabling it to be individually tailored to every customer’s needs. The smooth interaction between HänelSoft® and the Hänel lift controllers guarantees efficient storage operations.

WebClient

- A modern and intuitive user interface guides the user through the software and can be operated directly from the Hänel microprocessor controllers via touchscreen. The browser functionality of the MP 12 N-HostWeb control system allows HänelSoft® to bring the intuitive functionality of a tablet PC or smartphone straight to the lift controller. All booking dialogs for the pick and put operations are available where the materials are being moved – directly at the lift!

HänelSoft® Picture

- A picture (drawing, photo, etc.) can be assigned to the item in the article master record.If a digital camera is connected to the HänelSoft® PC, the picture can be taken with this module and integrated directly in the article master data. This photo is available in all the article and storage lists as well as in the graphical container view.

AutoIdent®

- Three cameras above the access opening record every storage and retrieval operation. Just before the operation and immediately after it a high-resolution photograph is taken of the storage situation on the relevant tray. Intelligent image analysis detects the storage location from which an item was removed or to which it was returned. This procedure is then compared with the HänelSoft® storage management.

Wireless terminal

- Portable mobile terminals with W-LAN technology connect conventional storerooms online to the HänelSoft® server. The supplementary module HänelSoft® MobileClient makes work easy and user-friendly. Storage and retrieval operations are recorded directly at the racks with the wireless terminal and transferred straight to the HänelSoft® server. This ensures that a complete inventory overview is always available in real time. Terminals with integrated barcode scanner offer quick and secure data collection and prevent input errors.

MP-Link

- Process Transactions from the DMS at the Hänel Unit. A direct link between inventory stored in Hänel units and the DMS. Direct Communication with DMS Terminal Pick orders and receiving reports are sent from the DMS terminal to the MP Link. Connectivity between Hänel Unit and Off-site DMS Synchronize transaction reports and inventory values between DMS and Hänel units.

Hänel TDM-Software

- Tools are requested or put

into storage by entering an article

number or using a barcode scanner.

This means similar-looking tools

can’t be confused.

In addition to the numerical data, Hänel TDM processes and stores other information about components, complete tools and tool lists in all the customary data formats. All storage and retrieval operations are logged, which makes later verification and tracking easy, and ensures traceability to the respective user. This practical tool data management system can be adapted flexibly and effortlessly to different user environments. The modular design and high flexibility of Hänel TDM means that this well-engineered tool management system can be efficiently used in small, medium and large production plants in a very short time.

WMS

- The Warehouse Management System WMS controls and

optimizes the entire logistics chain, including the Hänel vertical lift and

Rotomat® systems in both office and storeroom.

Thanks to its collaboration with the viastore company, Hänel Office and Industrial Storage Systems is able to offer solutions for complex intralogistics requirements with the viad@t software.

viad@t works with innovative technologies for real-time process monitoring and control: wireless data transmission, pick-by-light, pick-by-voice, RFID, automatic weighing, control of conveyor systems, roboting, automated warehouse.

Energy efficiency

- Energy-efficient systems are the key to lowering

energy consumption in your warehouse.

The effective energy consumption of automated material and file handling systems has a major impact on operating costs, amortization and not least on environmental protection.

For this reason we have always placed great emphasis on continually optimizing the energy efficiency of our storage systems. This brings our customers many benefits, both from an economic and an ecological perspective!

Optimizing the energy balance with intelligent concepts

The goal of continually optimizing the energy balance of the Hänel storage systems is a challenge we embrace every day. Under the heading Hänel EcoConcept we constantly develop components that contribute to improving energy efficiency.

- The built-in frequency converter converts the kinetic energy of the descending extractor into electrical energy and feeds it back into the electrical supply system. This enables up to 40% of the required energy to be recovered depending on the rate of travel.

- Continuous monitoring of the load situation in the Rotomat® and adherence to the storage recommendations ensures that an even load distribution is achieved. This means only minimal energy is needed to start the storage carousel rotating.

- All systems that consume energy even when in standby mode are closed down by the control system in 4 EcoMode® levels (energy-saving levels). This reduces the energy intake of the Hänel storage systems to a minimum when they are not being used.