- Offer Profile

-

Today, DENSO is one of the most renowned suppliers of systems and components and is expanding its business to non-automotive fields, such as Home Energy Management Systems (HEMS), industrial and medical robots, and agricultural support.

DENSO Corporation operates in more than 38 countries across 5 continents. Powered by approximately 170,000 associates specializing in Sales, Product Development, and Design Manufacturing, DENSO works alongside regional manufacturers and suppliers to provide the most suitable solutions to regional requirements.

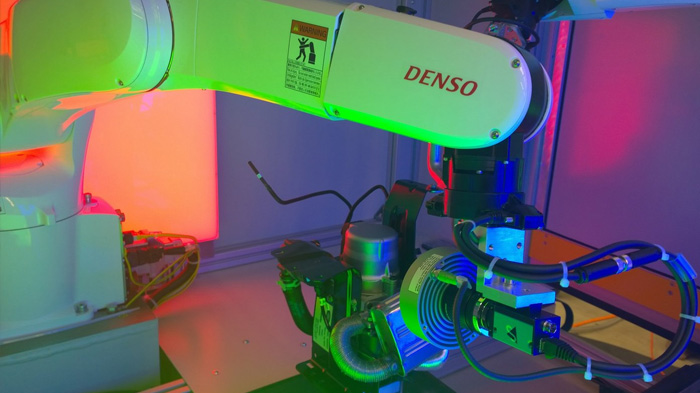

DENSO Robots

- outstanding speed, precision and quality. DENSO robots can move a weight of up to 20 kg and thus offer a high degree of functionality. Each model was developed to the highest quality standards. DENSO robots are not only compact, light weighted and require minimal maintenance, they also come with a two-year warranty. For more cost-effectiveness and user-friendliness, there is a unified controller type RC8A for all robot models from DENSO.

DENSO robot arms can be used in assembly applications, processing, pick & place, inspection, machine tending, screwing and other applications.

DENSO robots also work in dusty, damp or clinical environments and have correspondingly required protection classes. Thus, DENSO kinematics can be used in almost any environment.

In addition, DENSO Robotics deals with solutions related to logistics and IoT tasks. Collaborative Robots

Collaborative Robot COBOTTA

-

Anywhere, anytime, always safe.

- Arm length: 342.5 mm (TCP 385 mm)

- Payload: 0.5 kg (*0.7 kg wrist direction downward within ± 10 degrees)

- Position repeatability: ± 0.05 mm

- Total arm weight: 4 kg

- Options:

Built-in Electrical Gripper (force controlled)

Built-in Electrical Vacuum Generator / Vacuum Gripper

Built-in A/F 2D Camera

Cobotta Pro

-

- Arm lenght: 908 and 1303 mm

- Payload: up to 12 kg

- Max TCP Speed:2.100 mm/s2.500 mm/s

- Repeatability: from ±0.04 mm

- Protection: Standard IP54 / Cleanroom ISO5

- ISO Standards: EN ISO 10218-1:2011, EN ISO 13849-1:2015, ISO/TS 15066:2016

Benefits

Safety

-

Inherently safe design - No sharps or pinch points

Functional safety- Safety-rated monitored function (all axis)

Power and force limiting concept rel. to ISO / TS15066 and ISO 10218-1

Safety level PL d / Cat 3 (ISO 13849)

TÜV Rheinland certified acc. to int. standards for the safety of industrial robots

Built-in controller integrated

-

Robot arm weight with controller only 4 kg

Small space needed: approx. 200cm²

Easy transportation

Ext. Communication: Ethernet TCP/ IP, 2 x USB, Field Network: EtherCAT, ProfiNET, EtherNet IP External I/ O: 20 Input/ 20 Output

Open Platform

-

Wide possibilities to use COBOTTA - from first time user to robot expert

Individual development environment

(Linux+ROS)Usable with all TCP/IP devices

Portable Body

-

Transporting and installing COBOTTA anywhere anytime is simply easy.

Easy to install e.g. on trolley or AGV/mobile robot

No additional wiring between arm and controller

Easy to Use

-

Easy to teach the movement with direct teaching

Easy operation with Remote TP or COBOTTA world

Easy adjustment with built-in electrical gripper and built-in AF camera function

Easy Programming

-

Easy programming with tablet based App Cobotta World

Set up a new program within minutes

Teach COBOTTA by moving it directly and selecting tasks from the preset job items

5/6-Axis Robots

VP-5243 / 6242

- Ideal for use in confined areas

Key Features

- Arm Reach: 430 mm /432 mmmm

- Payload: up to 3 kg

- Cycle Time: 0.99 s

- Repeatability: ±0.02 mm

Benefits:

- Only 13 kg robot arm weight (for 5-axis model).

- Compact design: Small robot's base installation area: 160 x 160 mm. Slim robot arm: width of 65mm Flexible movement even in a small space

- Repeatability accuracy: ±0.02 mm Consistency in production

- Global Service organization

- Low maintenance

- Low energy Consumption

VS-050/060

- The compact body has outstanding power and speed.

The 6-axis VS Series is a simpler version of the New VS Series. VS Series robots are an excellent solution for basic applications.Key Features

- Arm Reach: 653 and 854 mm

- Payload: up to 7 kg

- Cycle Time: 0.49 s (with 1 kg)

- Repeatability: from ±0.02 mm

- Mounting Options: floor and ceiling

- Options available: IP40, IP65/54, cleanroom class ISO 5 and ISO 3, and UL specifications

Benefits:

- Employ robots in many industries and applications thanks to a wide variety of options available.

- Deploy robots worldwide thanks to ANSI, CE, and optional UL certifications.

- Save money by providing a minimum amount of service and upkeep.

- Operate robots using any standard 230V power outlet.

VS- 068/ 087

- The compact body has outstanding power and speed.

The VS-068/087 series provides high speed and high power in a compact, slim body. A wide range of options are also available that allow operation in a wide range of environments.

Thanks to it's high speed performance, accuracy and diverse options available the VS-068/087 can be used in almost all industries including appliances, automotive, chemicals, consumer products, electronics, food, greenhouse, machine tools, medical devices and pharmaceutical, semi-conductor, plastics and metal.Key Features

- Arm Reach: 710 and 905 mm

- Payload: up to 7 kg

- Cycle Time: 0.33 s (with 1 kg)

- Repeatability: from ±0.02 mm

- Mounting Options: floor, wall and ceiling

- Options available: IP40, IP65/54, IP67 and cleanroom class ISO 5 and ISO 3

Benefits:

- Handle parts at high-speed by using 6 DOF (until 11.000 mm/s).

- Connect devices such as servo grippers and Ethernet-based cameras directly to the robot’s flange (optional feature).

- Use robots in wet environments thanks to its optional IP67 class.

- Save additional space by connecting all cables such as motor and encoder cable from the robot’s bottom (optional feature). This feature also enables to sport dirt and clean the robot easier since all cables are “hidden”.

- Employ robots in many industries and applications thanks to a wide variety of options available.

- Deploy robots worldwide thanks to ANSI, CE, and optional UL certifications.

- Save money by providing a minimum amount of service and upkeep.

- Operate robots using any standard 230V power outlet.

VM- 6083/ 60B1

- Meet our largest 6-axis robot. The VM Series is ideal for robust payloads of 7–13 kg and an arm reach of up to 1.3 m.

Key Features

- Arm Reach: 1021 and 1298 mm

- Payload: up to 13 kg

- Cycle Time: 0.89 s (with 5 kg)

- Repeatability: from ±0.05 mm

- Mounting Options: floor and ceiling

- Options available: IP40, IP65/54 and cleanroom class ISO 5

Benefits:

- Covers bigger work areas than any other DENSO 6-axis robot (up to 1.3 m)

- Handle higher payloads than any other DENSO 6-axis robot (up to 13 kg)

- Employ robots in many industries and applications thanks to a wide variety of options available.

- Save money by providing a minimum amount of service and upkeep.

- Operate robots using any standard 230V power outlet.

VS-6556 / 6577

- The compact body has outstanding power and speed.

Key Features

- Arm Reach: 653 and 854 mm

- Payload: up to 7 kg

- Cycle Time: 0.49 s and 0.59

- Repeatability: from ±0.02 mm

- Options available: Dust & splash proof (IP65/54) Protected (IP67) Cleanroom (ISO 5 & 3) UL specifications

Benefits:

- Repeatability accuracy: ±0.02 mm Consistency in production

- Compact design: Small robot's base installation area: 200x200mm. Slim robot arm: width of 110 mm. Flexible movement in a small space.

- Mounting Possibilities

- Global Service organization

- Low maintenance

- Low energy Consumption

VMB-2515 / 2518

- Meet our largest 6-axis robot. The VM Series is ideal for robust payloads of 7–13 kg and an arm reach of up to 1.3 m.

Key Features

- Main arm lenght: 1395 and 1695 mm

- Payload: 25.0 kg

- Max. reach (TCP): 1506 mm and 1804 mm

- Repeatability: from ±0.05 mm

- Options available: IP40(Standard type) / IP67(Protected type)

Benefits:

- Eliminated External Wiring / Piping

- Full-coverage Structure

- Mounting possibilities:Floor-mounted Ceiling-mounted Wall-mounted* Sloping-mounted*

- Global Service organization

- Low maintenance

- Low energy Consumption

VLA-4025 / 6022

- They are suitable for transportation and palletizing operations which makes workers free from hard labor.

.

Key Features

- Main arm lenght: 2085.5 and 1835.5 mm

- Payload: up to 60 kg

- Max. reach (TCP): 2503 mm and 1804 mm

- Repeatability: from ±0.06 mm

- Options available: Wrist IP67/Unit IP65

Benefits:

- Higher Payload and Longer Arm Reach

- Environmental Resistance

- Mounting Possibilities:Floor-mounted Wall-mounted Cloping (max 45°)

- Global Service organization

- Low maintenance

- Low energy Consumption

4-Axis Robots

HSR-048 / 055 / 065

- SCARA robot HSR-series - speedy start, speedy continuation of motion, and accurate stopping.

The HSR Series delivers high-performance during continuous operation over long periods thanks to a reengineered and improved design that makes the robot arm ligther, stronger and faster.

As a result of pursuing high-speed performance, high-speed picking systems can be realized with small, space-saving robots not only in conventional parts assembly processes, but also in packaging processes of food, medical supplies, and cosmetics, which is bringing about a revolution in performance.

The HSR series robot is available in 480, 550 and 650 millimeters arm reach. All three SCARA models offer a maximum payload of up to 8 kg.Key Features

- Arm Reach: 480, 550 and 650 mm

- Payload: up to 8 kg

- Vertical Stroke (Z): Vertical Stroke (Z) 100, 200 and 320 mm (with bellow 170 and 290 mm)

- Cycle Time: 0.28 s (with 1 kg)

- Repeatability: from ±0.012 mm

- Mounting Options: Floor and ceiling

- Options available: IP40, IP65 and cleanroom class ISO 3

Benefits:

- High performance even during long periods of continuous operation.

- Handle heavier payloads than the HS Series (up to 8 kg).

- Cover bigger work areas than the HS Series (up to 650 mm).

- Advanced interlocking design assures highly effective vibration dampening.

- Save money by providing a minimum amount of service and upkeep.

- Operate robots using any standard 230V power outlet.

HS-035 / 045 / 055A1

- SCARA Robot HSA1 Series - High Speed and Accuracy

Key Features

- Arm Reach: 350, 450 and 550 mm

- Payload: up to 5 kg

- Vertical Stroke (Z): 100, 150, 200 and 320 mm

- Cycle Time: 0.35 s (with 2 kg)

- Repeatability: from ±0.015 mm

- Mounting Option: floor and ceiling

- Options available: IP40, IP65, cleanroom class ISO 3, and UL specifications

Benefits:

- Install robots in small places and save space thanks to its compact design.

- Employ robots in many industries and applications thanks to a wide variety of options available.

- Deploy robots worldwide thanks to ANSI, CE, and optional UL certifications.

- Save money by providing a minimum amount of service and upkeep.

- Operate robots using any standard 230V power outlet.

HM-40** / 4A**

- Long arm reach and high payload

Key Features

- Arm Reach: 600 to 1,000 mm

- Vertical Stroke (Z): 200, 300 and 400 mm

- Payload:10 / 20 kg

- Cycle Time:0.29 sec 0.31 sec

- Repeatability: from ±0.02 mm

- Mounting Option:±0.02 mm / ±0.025 mm

- Options available: Dust & splash proof (IP65) UL specifications

Benefits:

- Max. payload 20 kg Max arm reach 1,000mm

- One cycle time is the time taken to move an object at a height of 25 mm between two points 300 mm apart

- Repeatability accuracy of ±0.02 mm, High rigid Z-axis design

- Global Service organization

- Low maintenance

- Low energy Consumption

LPH-040 4-Axis SCARA Robot

- High-performance, low-priced and compact SCARA robot..

Key Features

- Arm Reach: 400 mm

- Payload: 3 kg

- Vertical Stroke:150 mm

- Position repeatability:± 0.02 mm

Benefits:

- Gripper Design with High Degree of Freedom

- Reduction in Work Time without the Use of PLC

- Enables Control from PLC with No Programming Knowledge Required

- Global Service organization

- Low maintenance

- Low energy Consumption

Pharmaceutical & Medical Robots

VS – 050S2

-

The New VS – 050S2 Series features a hygienic and easy-to-clean design, making it particularly suitable for cleanrooms.

Sterile environment resistance/ Resists contamination

Robot for use in sterile environments and clean environments that employ H2O2 gas 35% density (dry / wet) and UV exposure.

Smooth surface prevents adherence of dust and dirt.Isolation (suitability for sealed environments))

Cables and other connector panels are positioned on the bottom for compatible installation in sealed and quarantine environments

Key Features

- Arm Reach: 520 mm

- Payload: up to 4 kg

- Cycle Time: 0.35 s

- Repeatability: ±0.02 mm

- Mounting Options: floor, wall and ceiling

- Options available: H2O2/UV-resistant, cleanroom class ISO 5, UL specifications, and H1 grease

Benefits:

- Easy to clean and to spot dirt thanks to its hygienic design

- Connect devices directly to the robot’s flange and prevent destroying wires with strong cleaning chemicals.

- Seal cables in and keep bacteria out by connecting all cables from the robot’s bottom.

- Avoid the accumulation of bacteria thanks to its round forms.

- Inhibit bacteria from accumulating under screw heads; no screws on the robot’s surface.

- Certified by Fraunhofer IPA.

- Save money by providing a minimum amount of service and upkeep.

- Operate robots using any standard 230V power outlet.

Small Gantry Robot

XR Series

- Thanks to its X-R design, this robot series cover larger work areas than conventional SCARA robots. The XR Series is ideal for applications where the robot has to be mounted on the ceiling.,

Key Features

- Working Area: 850, 1160, 1260, 1360, 1460, 1560 and 1660 mm

- Payload: up to 5 kg

- Repeatability: ±0.015 mm

- Mounting Option: ceiling

- Options available: IP40

Benefits:

- Cover bigger work spaces than 4-axis robots thanks to its special X-R structure (up to 1660 mm)

- Faster than cartesian robots thanks to its combined movement of coordinated slide (X-axis) and swivel motion (R-axis)

- Ideal for applications where the robot must be mounted on the ceiling

- Save money by providing a minimum amount of service and upkeep.

- Operate robots using any standard 230V power outlet

Robotics Functions

Extended joint tracking

- Simultaneous control of conveyor and robots enables high tracking accuracy.

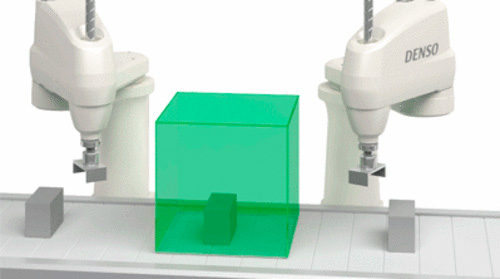

Dual Arm Control

- Allows a single controller to control two SCARA robots. Saves space and simplifies operations

External axis control

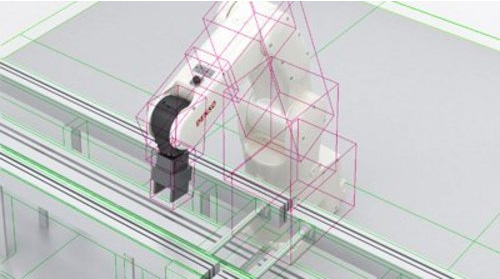

- By adding an extended joint board (EtherCAT), servomotors of various capacities can be controlled.

Circular tracking

- This function enables the robot to track workpieces on an arc path, achieving operation without stopping the index table, etc. Setup can be performed with the wizard-type GUI, achieving easy introduction.

High-precision calibration

- The high-accuracy calibration function improves the absolute accuracy to reduce differences between robots, significantly decreasing the man-hours required for teaching.

Extended-joint support specification

- Extended joints can be controlled by the same interface as the robot. They can be easily adjusted using the Auto Gain Tuning function.

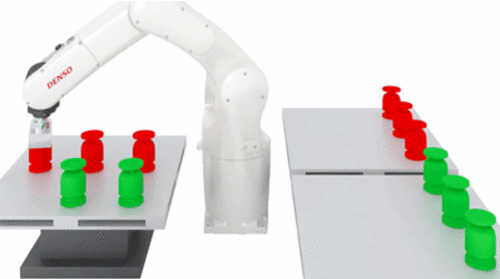

Conveyer tracking

- Since a robot can track workpieces, workpieces can be conveyed and aligned without stopping the conveyer.

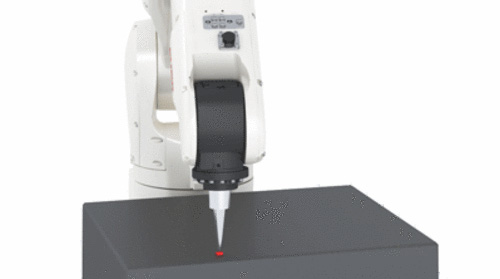

Compliance Control Function with Force Sensor

- Constant control of a pressing force of a tip of the robot hand with force sensor. Stable operation on assembling, grinding and other work by using this function.

Cooperative Control

- By using two or more robots, heavy loads and long loads can be conveyed and assembled.

Exclusion control

- This function can prevent more than one robot from entering the exclusive area.

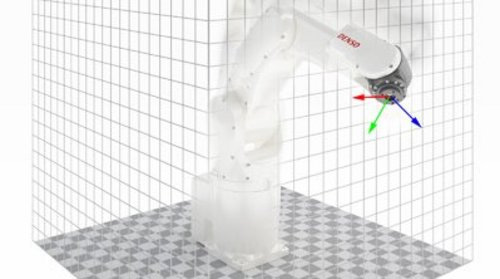

Virtual fence

- The virtual fence prevents the robot from colliding with surrounding facilities.

External TCP

- The external TCP function enables rotation about the coordinate origin of a workpiece, making it possible to easily teach the robot with reference to the object.

EtherCAT Slave motion

- Allows centralized robot path generation from an IPC with EtherCAT Master installed.

Autofig

- Automatically calculates the optimal “figure” for motion to a designated position resulting in reduction of setup time.

Motion Skip

- This function enables the robot to change the target point without stopping operation in the automatic mode.

High-accuracy Path Control

- This function decreases any change in the path due to change in speed, to improve path accuracy in the arc motion and the free curve interpolation motion.

Singular Point Avoiding Function

- When the robot passes through points in proximity to a singular point or other points where the posture of the robot changes, which requires linear interpolation, use of the singular point avoiding function enables the robot to move smoothly.

Collision detection

- When the robot collides with a peripheral device or workpiece, this function detects the collision and brings the robot to an emergency stop.

Compliance control function

- The compliance control function protects workpieces and hands from excessive load by adjusting the pressing force.

Optimal Speed Setting

- Optimizing motion speed and acceleration according to the load on the tip of the robot arm shortens the tact time.

Command Slave

- Robots can be controlled with PLC languages (ladder programs). Function blocks that support 107 robot commands are offered.

b-CAP (communications protocol)

- By directly sending packets of motion commands to the robot from a PC, PLC or other device, the robot can be controlled.

Provider

- A provider enables the direct control of various factory automation products (image processing apparatuses, sensors, hands, etc.) using PacScript (DENSO robot language).

Applications

Assembling Automotive Control Sensors: How DENSO Robots Enable a Flexible and Precise Soldering Process.

-

CHALLENGE

Modern control sensors are essential for today’s automobiles. Supporting safety control features in automobiles, these sensors have an important function. In many cases, their manufacturing has only been made possible with the introduction of automated production systems. Due to the required, highly precise installation of sensors in miniature spaces, a manual assembly is impossible. Their assembly is carried out in an (half) automated wave soldering process of fixating the sensor to a sensor carrier.

The challenge: Despite a pre-set solder wave height, deviations of this value are an unavoidable technical issue that has to be compensated for individually, depending on the varying degrees of deviation. Thus the sensor carrier has to be passed over the wave solder flexibly in order to adjust to the deviation.

SOLUTION

The sensors are installed in sensor carriers by using a wave soldering process in an automated production system developed by Erwin Quarder Systemtechnik GmbH & Co. KG for an automotive industry supplier. Quarder is a specialist for automated solutions based on injection molding technology. Relying on innovative engineering know-how and computer science, the company is developing tailor-made production systems. In providing a high level of functionality, quality, safety and usability, these are meeting the requirements of today’s industry.

The automated production line features 12 modules – from the production of the plastic sensor carriers in an injection molding machine, their subsequent transfer onto the assembly line, to the removal and insertion of sensors, the preparation with a fluxing agent and the soldering of the sensors to the sensor carriers and finally to the quality check as well as their palletizing into trays.

Test cell by handke industrial solutions

-

CHALLENGE

For automotive suppliers, quality management is one of the key factors determining a company’s technical and economic success. In this industry, for both quality and safety reasons, the high-precision installation and fitting of a large number of very different, pre-fabricated components into a specific mechanical setting are particularly important.

In the past, manual quality checks have been too costly and time-consuming, as well as being relatively unsafe, given the likelihood of human error. In addition, today’s extensive variety of models and components would present a real challenge to any employee. And fitting delicate components into relatively inaccessible areas is almost impossible without the adequate tools.

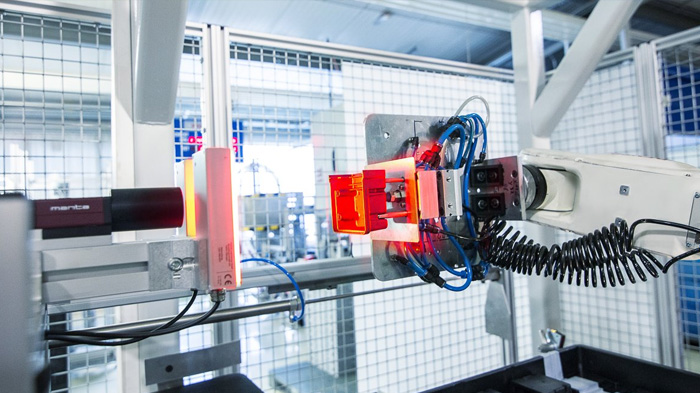

SOLUTION

Automotive suppliers are therefore relying increasingly on fully automated, robot-based test cells, where components are quality-checked and then correctly assembled using image processing and software to ensure precise integration and functionality.

Such a test cell has been developed by Handke Industrial Solution GmbH (HIS GmbH) for a client in the automotive supply industry. HIS GmbH, based in Garbsen near Hannover in Northern Germany, has been distributing und manufacturing products and software for the automation and electronics markets since 1979.

The test cell has been in operation since late 2016. It inspects the correct assembly of parking heaters (each component measuring up to 60x60x60 mm) for vehicles and trucks. While the actual base component is always quite similar, its mechanical fittings, i.e. the mounting, the waste gas extraction and the vacuum exhaust, vary widely, depending on the vehicle model. In total, the test call has to master 250 different versions. It currently manages a total of 1,500 components each day (in a three-shift cycle).

The assembled component carriers are transported automatically into the 3x3 m test cell where they are inspected by cameras mounted on two VS-087 DENSO robots. ...

DYMACO, Italy

-

CHALLENGE

To develop a very compact and flexible Workstation for In-line Automatic Measuring with the latest Manufacturing Equipment Capabilities. A new programmed Dimensional Measuring Machine capable to compare a large variety of components to be measured based on comparison between the item to be measured and its Master Sample that are normally used in the control of Headlamps for the Automotive Lighting Industry.

SOLUTION

Against this background the DM Series emerged, based on the new revolutionary DENSO robot VS087 – that could be described as a type of Automated Lighting Inspection System Workstation, which is connected to the Manufacturer In-line Systems.

The Dimensional Measuring Machine robot receives its order data to carry out the measurements brilliantly assisted by DENSO robot VS087 according to its principle based on comparison through the Master Sample with the target measuring points located according to the Lamp’s CAD and the results obtained are then compared with the calibration values previously configured by the manufacturer ensuring all the times its precise performance and estimated manufacturer working cycles. DENSO robot VS087 gives to the DM401 a great speed and precision when calculates the points to be measured.

Great attention has been paid to the dimensions of the equipment to accomplish the World Class Manufacturing requirements where the DENSO Robot VS087 fits perfectly helping to minimize as much as possible the floor space usage when designing the DM401 Serie

RENGER Kunststoffspritztechnik

-

CHALLENGE

Traditionally, the automotive supplier industry has been one of the most important branches for using compact robots, which are being employed in the manufacturing of various components. One of the companies in this area relying on DENSO robots is Renger Kunststoffspritzteile GmbH & CO. KG in Inzigkofen north of the Lake Constance in the Southwest of Germany. The company primarily manufactures plastic components in injection-moulding technology for the automotive industry. In this case study, we are looking at their production of cases for airbag control units, undoubtedly one of the most safety-related components in cars.

The challenge: In the past, the company had assembled the components by relying on traditional linear systems, quality control was carried out by employees. With the introduction of DENSO robots, however, the cycle time could be reduced significantly while also realising a zero defect figure. It is this 100-percent quality that really matters when it comes to delivering these crucial car components.

Thus the manufacturer had to develop a robot-based system, which would combine a fast pick-and-place performance with an outstanding quality control.

SOLUTION

Renger has been working with DENSO robots since 2009 as the company appreciated the robots’ flexibility and the possibility of combining various tasks even later in the process. In light of growing quality and cost requirements of plastic components demanded by the car industry, these were two decisive advantages.

DENSO robots convinced the company also with their high speed, simple handling and the programming approach. Renger is using the VS-6577 and the VM-60B1G (among others), which were selected due to their arm length and payload capacity. Until then, Renger had only worked with linear robots, which offer only a fraction of operation capabilities a six-axis robot can cover.

At Renger, DENSO robots are primarily used in the manufacturing and quality control of cases for airbag control units; these manufacturing system are quite complex, as they are fully integrated with an injection moulding machine and a PLC system.

DeROBÓTICA, Spain

-

CHALLENGE

The future of an optimized industrial automation lies in efficient, safe and reliable Industry 4.0/IoT applications. The key to any successful Industry 4.0/IoT solution in so-called smart factories is a simple, fast and highly user-friendly interaction between all parts of the system: Users have to be able to monitor and control processes at any time, from anywhere and with as many different devices as they wish. Central tools for facilitating these applications are cloud services functioning as a platform for the actual automation application and the user control. But how can robot-assisted industrial automation, cloud services and user friendliness be integrated into one system today – relying on already existing software and technologies, thus making automation even more efficient?.

SOLUTION

A solution was presented at Microsoft’s.Net conference in Madrid (Spain) in 2016 through a cutting-edge project called "DENIoT". The project aimed at showing how Industrial IoT applications can be made more efficient and safer by using already existing software and technologies. “DENIoT” was coordinated by DeROBÓTICA, the Iberian sales organization for DENSO Robotics, and supported by ENTRESISTEMAS, an industrial automation and system integrator specialist, as well as ENCAMINA, a Spanish consultancy company specialized in Microsoft products.

The central elements of the solution were the software development interface ORiN (Open Resource interface for the Network), which is part of DENSO’s robot controller RC8, a DENSO VS-060 6-axis robot and the cloud platform Azure by Microsoft. Azure is a collection of integrated cloud services, such as analytics, computing, database, mobile, networking, storage and Website. ORiN is a powerful tool that enables the interaction with DENSO robots using high-level programming languages such as C#, C++, VB, etc. This unique capability of programming permits a very easy integration of the software platforms with the DENSO robot and with Microsoft’s Azure.

The cloud platform was connected to the DENSO robot controller in order to collect and interpret data using big data analytics and other techniques. These data were turned into actionable information. In the actual demonstration, the VS-060 had been programmed to perform up to 9 different movements, mostly pick-and-place. By monitoring and analyzing the robot data, it is not only possible to interact with and control the robot from virtually anywhere, but it also facilitates machine learning, which further enhances efficiency and performance. The data monitored included parameters such as the robot arm's speed, acceleration, positions and (joint) angles.

During the “DENIoT” demonstration, the robot was also controlled via Microsoft's intelligent voice command system Cortana: Basically, it translates verbal commands into robot movements (through the cloud). In the demonstration, each of the nine movement commands was assigned a number. The command "move", for example was assigned the figure "10", which was sent to the robot in order to perform this specific movement. Voice command interaction will become more important as the human-robot-collaboration will be increasing in the future.

Marvel Studios, USA and UK

-

CHALLENGE

For the release of its highly successful blockbuster string of “Avengers” movies, the production company Marvel Studios needed futuristic-looking robots for one of the movie’s key scene showing a dramatic turn of events in the movie plot. “Avengers: Age of Ultron” is the epic follow-up to the biggest super hero movie of all time. When Tony Stark tries to jumpstart a dormant peacekeeping program, things go awry and the “Avengers” are put to the ultimate test as the fate of the planet hangs in the balance. As the villainous Ultron, an artificial intelligence, emerges, it is up to the “Avengers” to stop him from enacting his terrible plans. .

SOLUTION

DENSO Robotics provided three robots, two VS 050 and one VS 087, for the dramatic, turning-point scene set in a futuristic medical lab meant to be in Seoul of movie character Dr. Helen Cho (played by Claudia Kim), a geneticist helping the Avengers. “For this scene, we were not looking for industrial robots that would have fitted Stark’s lab, but rather for medical ones”, explains movie set designer Richard Roberts, one of the world’s leading sci-fi and fantasy set designers. “After some research we found images of DENSO robots, which had the right, white color and the high-tech design we were looking for. We wanted to show the cutting-edge technology in Dr. Cho’s lab – and the robots reflect that image. The DENSO robots definitely had the best look suiting the existing set design.”

The robots were lent to the production by DENSO Robotics, a DENSO service representative was on site programming the robots in PacScript to perform regular pick-and-place functions with several position variables, which were easily obtained by using the functions within the controller.

The actual filming of the scene took place over three days last year at the Shepperton studios near London.

AIRBUS , Germany

-

CHALLENGE

Airbus studies and tests the flow behaviour and the flight capability of diverse airplane types- especially wings and engines- that are essential components for the development and manufacturing of new aircraft types. The Airbus Low Speed Wind Tunnel (LSWT Bremen) has been designed to analyse the performance of aircrafts during take-off and landing. It also studies factors such as pressure, stress and temperature at speeds of up to 85 m/s. Multi-hole pressure probes play a decisive role in this process because they are efficient and reliable tools to precisely measure flow conditions. As expected, all probes used for this purpose have to be calibrated accurately.

SOLUTION

Probes are checked with the support of a DENSO VM-60B1G-V robot either before or after every test or during a flight simulation.

“Contrary to most robotic applications, in this case, the most important is not speed but absolute accuracy”, explains Airbus’ project manager. “In this way, it is easy to decide whether or not a new calibration is necessary or whether additional tests can be performed.” In order to decide this, the probes are exposed to a flow field with known speed and direction. The robots carry out the movements of the probes within the measuring grid and the results obtained are then compared with the calibration values.

“The simplicity to operate the robots and the free choice to communicate with them using our own software is a great advantage.” says the responsible engineer at Aerodynamics Testing at Airbus. “Additionally, with its six axes, the robot is extremely flexible when operating in a three-dimensional grid with 1,000 measuring points. You have the opportunity to control the robot in such way that it is possible to check the same measuring point for one minute.” Previously, inflexible rotating discs inconveniently carried out these tasks.

SINTEF, Norway

-

CHALLENGE

In one of the few industries where automation seems to have leveled out, a breakthrough application has now successfully demonstrated how robots can perform even the most challenging food handling usually done manually by human operators.

SOLUTION

At SINTEF, Scandinavia’s biggest independent research center, engineers developed the “Gribbot”, a specially designed system using a DENSO VS 087 robot for processing chicken breasts.

“This part of the chicken is the most costly one, so meat producers are naturally concerned about the yield", explains SINTEF’s research leader for the Gribbot, Dr. Ekrem Misimi. "However, automating this process, as any procedure that relies on human hand-based operations, is very challenging. With the Gribbot, we wanted to show to manufacturers and food retailers that this kind of automation is possible today.”

The Gribbot is based on the center’s experiences with several robot-based projects such as RoboTrim project, also using a DENSO VS 087, which was used to trim objects in a salmon fillet. This experience with the DENSO V087, primarily because of its flexibility and the ease of use, has opened up a sea of opportunities in robot-based automation in the food industry for handling and processing operations.

The main goal but biggest challenge was to generate a satisfactory yield comparable to that of human operators - not an easy task, given the slippery surface, soft texture and the high variation of the chicken breasts as such. “We had to implement the scraping of the fillet from the carcass along the rib cage so that a minimal amount of rest meat was left on the carcass. This was an even bigger challenge for the entire system - from the detection of the gripping point with machine vision as well as creating an optimal path movement for the robot arm”, says Dr. Misimi. The biggest challenge, however, consisted in the development of the gripper. The chicken fillet had to be handled with care so that it would not be teared off or squeezed too hard.

SINTEF, Norway

-

CHALLENGE

The processing of fish and meat is subject to strict regulations: The production process has to be completely hygienic. It must be possible to track the origin of every product. Fish and meat have to have a consistent quality.

SOLUTION

The research company SINTEF from the Norwegian city of Trondheim is currently working to automate and optimize the way these foods are processed. For the processing, SINTEF uses the highly efficient six-axis robot of the model VS-087 produced by DENSO Robotics. With over 2200 employees SINTEF is one of Norway’s biggest research facilities.

"Our robot fillets the fish and operates the cutting blades”, Lars Wirenfeldt, Sales Manager of DENSO Robotics in Scandinavia, explains. The fish is measured with the help of sensors, so it can then be analyzed at which exact points the blade has to cut around the skin and the bones. Another advantage for the consumer is that unwanted bloody spots can be identified by the sensors and can be removed by the robot. The use of robots ensures that the weight and shape of the filets is close to identical when they go into sale. The process is also intended for portioning chicken breasts.

Demanding work environment

“The biggest challenge when processing fish and meat is that all pieces are different but are still supposed to look identical when they go into sale”, Harry Westavik, Research Manager for automation and product efficiency at SINTEF, says. But the processing of fish and meat is a difficult field to operate in. Westavik: “The work environment is cold and yet very wet, which is corrosive to all objects made of metal. DENSO robots are very robust and operate extremely fast. This is why we have chosen one.”

ROFOBOX, Germany

-

CHALLENGE

Folding napkins is one of the most labor consuming processes in the gastronomy and hotel industries. Each year, around 400,000 napkins are folded in larger hotels. It was witnessed that it takes about 30 seconds to fold a napkin but the 3,333 hours of folding can quickly become monotonous and demotivating for the worker. In addition to this, in food courts, napkins fall under special hygienic requirements as they come into contact with the mouth.

SOLUTION

Designing and developing a cost-effective, efficient and hygienic automatized system could replace this monotonous manual task.

The company ROFOBOX (RobotFoldingBox) together with partners developed a fully automatized machine that uses, combined with other devices, DENSO robots for the handling, folding and palletizing of napkins.

The DENSO technology that is being utilised by the ROFOBOX is the best robotics technology available on the market. “The robots are compact, fast, relatively light and have a long arm reach. In addition, the small floor area required for the robot allows for easy installation- whether it is on the ground, or mounted on the ceiling. The VS087 DENSO robots that we use have an attractive design and their white color portrays the purity of their design. These are precisely the skills we need for our innovative napkin machine,” says Kartal Can. CEO of Rofobox.

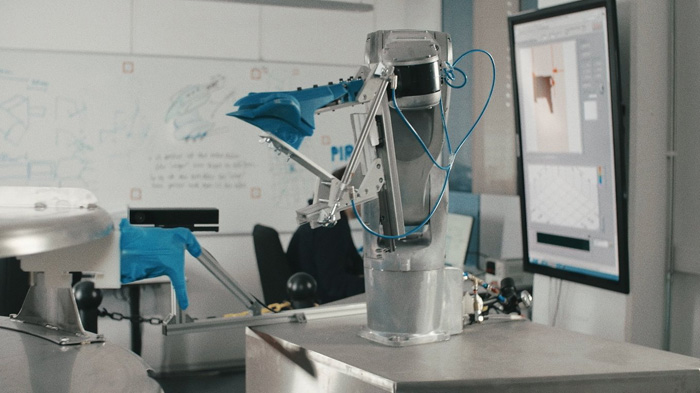

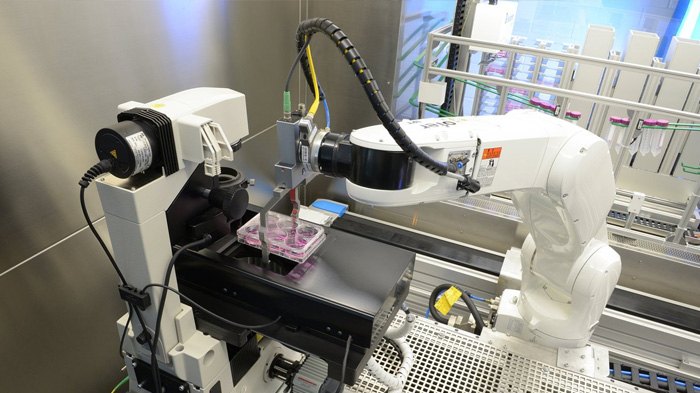

Fraunhofer Institute for Production Technology IPT, Germany

-

CHALLLENGE

Stem cell research is one of the most innovative areas in current medical research and plays a decisive part in developing new agents and drugs. Research is thereby based on cultivated stem cells, in particular mesenchymal stem cells, or MSCs. These are mature stem cells extracted from adult human tissue, which means that isolation (unlike embryonic stem cells) can be done in an ethically acceptable way. Due to their capability to differentiate into new cell types, stimulate cell growth and influence the human immune system, they hold much promise for regenerative cell therapy.

The expansion of these cells, however, is a long and labor-intensive process. What is more, researchers have to deal with variations in the biological material that originates from many different donors. This variability is further increased by deviations in the cell treatment in manually produced cultures. At the same time, human interaction raises the risk of error and limits reproducibility. Additionally, as cell cultures are living organisms, a cleanroom environment is essential, which requires special standards for instruments and devices.

SOLUTION

The solution is the development of a fully automated, self-contained yet flexible system for cultivating stem cells. StemCellDiscovery is a globally leading pilot project launched by the Fraunhofer Institute for Production Technology (IPT) in Aachen, Germany. The Aachen facility aims at growing and researching MSCs, and implementing various lab processes – from cultivating cells to generating experimental data. The facility features the easy integration of devices; consistent and accurate reproducibility; an individual, modular-based control of processes; high-quality cell products; and the use of advanced measuring technology for quality assurance and analysis.

A DENSO robot plays a central role in the facility. The robot, a VS-087 model, serves as a flexible handling unit for all transportation steps in the platform: transporting cell cultures in multititer plates, moving falcon tubes between different processing and measuring devices, and ensuring highly accurate positioning. Precision is particularly important at the microscope, where the robot first grips the cell culture container and then positions it in the designated holder. The robot’s flexibility also is useful for pre-positioning resources, such as transporting pipette tips from the storage to the liquid handling unit.

In addition, the robot provides the service for shaking the cell cultures with the same speed and movement in order to distribute the cells equally. This is key, as an inconsistent movement could result in cells accumulating at the edge of the container, leading to suboptimal conditions for cell growth. To achieve a consistent distribution of cells in the container, it is important that the robot applies constant acceleration to the cultures...

HEALTH ROBOTICS, Italy

-

CHALLENGE

To develop a very compact and flexible system able to manipulate a large variety of objects (i.e.: drug vials, syringes, and IV bags of different shapes and dimensions) that are normally used in the manual process of drugs compounding.

SOLUTION

Against this background the i.v. Station emerged, based on a DENSO robot – that could be described as a type of automated medicine distribution system, which is connected to the hospital prescription system. The appliance receives its order data from the prescriptions for the treatment specific to the patient. This information includes the medicine preparations that have to be made available in a selected time period and in a special form. At the point in time that a new bottle, a new syringe or a new bag is introduced almost nothing on the machine's hardware has to be changed. It is enough to readjust the software or the modalities to handle and administer the object. Among others the i.v. Station allows the preparation of medicines such as antibiotics, painkillers and anti-inflammatories for inpatient treatments.

A DENSO 6-axis robot of the VP-G2 series takes the syringe and positions it on a mechanical dosing feeder.

Then it takes the top off the syringe and takes the bottle that has to be filled with the medicine out of the repository, which had previously checked by an image processing system.

After the needle has drawn off the desired quantity the robot lifts the syringe into the weighing system.

A gravimetric check is carried out there that makes it possible to make an independent check of the dosage. During these procedures the machine is continually provided with a constant air flow that guarantees sterility in the interior. This system guarantees that the air is completely exchanged practically every two seconds.

Before discharging, the syringe is provided with a protective cap so that the contents do not come into contact with the outside air. Then it is labelled by the labelling machine, which provides information about the medicine preparation and a barcode for identification purposes.To avoid errors when filling materials the i.v. Station has two image processing systems with medium resolution cameras (three megapixels). These check if the bags and syringes have been correctly positioned and they also scan the bottle labels that appear to prevent the operator from accidentally confusing the medicines during the filling phase. This is supplemented by a control phase – which takes place during filling - that is done by a barcode reader placed on the front panel of the machine. The final check is done by the computer monitoring system, but through the barcode reader the machine already knows what to expect.

Great attention has been paid to the dimensions of the equipment, because there is normally little space in hospitals. “Large equipment,” emphasises Giribona, “means nothing less than sacrificing part of the market, because many hospital do not have enough space to install it. It is for precisely this reason that we drafted the i.v. Station to be the size of a large fridge, a cuboid one metre by two metres high that can be easily set up." The compact design of the DENSO robot met this aim.

Safety has top priority

To be able to guarantee an appropriate safety level in terms of functionality and operator access the i.v. Station is equipped with certain capabilities. For example, it guarantees that access by unauthorised people is prevented during working procedures. These measures extend from profiling the user using user names and passwords, reader modules to identify RFID badges, up to biometric recognition.

NewIcon, Spain

-

CHALLENGE

The manual retrieval of medications is a time-consuming task, requiring millions of man hours in hospitals and pharmacies each year. In Germany alone, pharmacies sell some 1.3 billion medication packages annually, or roughly 68,000 packages per pharmacy.* Yet medication retrieval is also an error-prone process, for error rates as high as 15% have been reported by some studies. This is a pressing problem, because errors in filling prescriptions can endanger patient health.

To address these issues, the Finnish company NewIcon has developed automated, robot-assisted systems that make medication storage and retrieval safer, faster, and more efficient. DENSO robots lie at the heart of the solution.

SOLUTION

Previously, NewIcon employed linear robots in its medication retrieval systems. Since 2010, however, the company has been using DENSO robots, which offer more axes for faster storage and retrieval as well as light-weight components in a compact housing. NewIcon also opted for DENSO because DENSO´s open architecture could be flexibly integrated with its existing software and machine vision system.

NewIcon offers two interlocking systems: a storage system for sorting and registering medications, and an input system for retrieving and delivering medications that have been stored. The DENSO VP-6242G is used in most applications, although the VS-068A2 is also employed when there is a need for faster speed and longer reach. The robots are controlled through an Ethercat bus connection. Robot programming is carried out in Visual Basic and C# using WINCAPS, DENSO´s offline programming, monitoring, and simulation software.

The information for picking and delivering a package can be manually entered by staff on a PC or communicated by scanning a barcode. In both cases, the control system directs the robot to grab the appropriate package and drop it into a container, which is then forwarded to a collection tray. When sorting packages, the robot performs scanning autonomously, without human interaction.

The robot arm is equipped with vacuum pumps and special suction cups to ensure reliable grip. The PC software knows the dimensions of all packages, enabling it to specify exact coordinates for robot pick-up.

Controllers

- The next generation RC8 controller is significantly smaller than its predecessor, the RC7. Compact yet robust, the RC8 can be installed almost anywhere.

RC8A Standard Controller

- RC8A Standard Controller - The world’s smallest high-performance controller.

- Size: W 357 x D 320 x H 94 mm

- Programming: Java, C++, C#, VB, LavVIEW etc. or PLC

- Certifications:TÜV Rheinland, ANSI, CE, UL and CSA

RC8A Safety Motion Controller

- For Human-Robot-Collaboration. Convince yourself of the performance of the RC8A Safety Motion Controller.

- Size: W 411 x D 320 x H 94 mm

- Programming: Java, C++, C#, VB, LavVIEW etc. or PLC

- Certifications:TÜV Rheinland, ANSI, CE, UL and CSA

SOFTWARE

PROGRAMMING & DEVELOPMENT

- DENSO Robotics Europe offers you a wide range of software for programming you DENSO robots and peripheral devices from a PC or PLC, simulating actual production lines and maintaining your robot's performance with support tools.

WINCAPS III

-

Software for programming DENSO Robotics(PacScript,PAC) and creating simulations on the PC.

FeaturesWINCAPS III is a software application that supports all processes from consideration of introduction to maintenance of DENSO robots. With its abundant functions, it helps users with operation of DENSO robots, such as robot programming, controller data backup and robot posture checking on a 3D screen.

ORiN2 SDK

-

ORiN2 SDK is a middleware application for developing application programs and providers based on ORiN2 specifications.

FeaturesORiN ® 2 SDK is a software tool kit used to develop an application program or provider based on ORiN2 specifi cation.

- It provides a standard communication interface for robots as well as various FA peripherals and databases.

- ORiN®2 SDK is mounted with a variety of functions (including a CAO engine, test program, sample program and skeleton provider auto generate tool) to support evelopment.

- The superior expandability of ORiN®2 supports not only industrial robots, but a variety of devices (including PLC, CNC machine tools, bar code readers and RFID) to enable application development that is independent of manufacturer or model.

Robot Tools

-

Robot Tools is a software application for helping streamline maintenance work and the operations of DENSO robots.

Features

Robot Tools is a fully featured suite of utility tools created for optimum maintenance and operation of DENSO Robotics.

The software streamlines daily maintenance workflow and reduces the running costs of a robot after installation.

RC Vision

-

RC Vision is a robot vision application software package that utilizes DENSO Robotics and cameras to support equipment startup.

EVP Easy Vision Picking

EVP (Easy Vision Picking) is an image processing application that specializes in Pick & Place without using a program.

Image processing settings are configured using an application (EVP Guidance) on the PC. When executing (EVP Runtime) can be run by RC8 and the camera connected to RC8 only.EVP also includes a calibration wizard that can perform robot calibration and calibration between camera and robot.The picking device has built-in functionality to output the location of parts that are within the field of vision of the robot, allowing control of parts movement via a feeder or other device.

EMU

-

Software that enables simulation of multiple DENSO Robotics.

Features

- EMU (Enhanced MUlti-robot simulator) is software that allows you to run simulations for multiple DENSO Robotics.

- EMU allows you to use projects created in WINCAPS® III, coordinating with peripheral devices (models) and testing functionality in a state that is both virtual and real.

- EMU helps you achieve vertical startup for preliminary testing and production systems at the design stage for equipment centered on DENSO Robotics.

VRC

-

VRC is an emulator that provides a virtual environment for the RC8 on a PC by imaging the RC8 (robot controller) itself.

Features

As an RC8 (robot controller) virtual robot module, VRC provides an RC8 virtual environment on the PC.

- When programming in a universal language (Visual C++, Visual BASIC, Delphi, LabVIEW, etc.) on the PC, connecting to the VRC lets you control DENSO

- Robotics and monitor their statuses in a virtual environment.

Being able to simulate the operation of actual robots without actually using them dramatically improves development efficiency

Mobile Tools

- Mobile Tools is a set of application software for smart devices that support equipment startup or maintenance using DENSO robots.

ACCESSORIES

PENDANTS

- All DENSO robots come with a robot controller inclusive. However, there are many other accessories that allow you to increase the functionality of your robots. We have a wide range of products such as:

Teach Pendant

-

- Allows programming, operating, teaching and maintaining the robot

- Provides a simple, clear and user-friendly interface

- Provides a full colour 7” touchscreen

- Safe and secure

Light:- Weighs less than 1.3 kg

- 198 x 290 x 104 mm

- DC24V (supplied from robot controller)

- IP65

- Japanese, English, German, Korean, Chinese

Mini Pendant

-

Allows operating, teaching and simple maintenance of the robot (not able to create & edit programs)

Maintenance functions:

- Performing CALSET

- Resetting the motor encoder data

- Setting the calendar clock built in the robot controller (date setting)

- Setting the next battery replacement

- Releasing and locking brakes

Light:- Weighs approx. 0.3 kg

- 242 x 102 x 75 m

- Performing CALSET

- Resetting the motor encoder data

- Setting the calendar clock built in the robot controller (date setting)

- Setting the next battery replacement

- Releasing and locking brakes

- DC24V (supplied from robot controller)

- IP65

- Japanese, English, German, Korean, Chinese

Communication Boards, Fieldbus and Network

Extension Boards

-

- CONTEC Serial Comm.

- Analog I/O

- Digital I/O

Fieldbus

-

- DeviceNet Master

- DeviceNet Slave

- CC-Link RD

- PROFIBUS Slave board

Fieldnetwork

-

- PROFINET I/O Device

- EtherNet/IP board

- EtherCAT Slave Board

- EtherCAT Slave Board (Motion)

Motor & Encoder Cables

Encoder & Motor Cables

-

- Standard cable (lengths: 2m, 4m, 6m, 12m & 20m)

- Standard L-Shape (lengths: 2m, 4m, 6m, 12m & 20m)

- Standard Dust & Splash proof (lengths: 2m, 4m, 6m, 12m & 20m)

- L Shape Dust & Splash proof (lengths: 2m, 4m, 6m, 12m & 20m)