- Offer Profile

- BARTEC is the leading global

provider of high-quality industrial safety technology for applications in

explosion-hazardous areas.

BARTEC specialists develop, produce and sell component solutions and system solutions for all areas where hazardous substances such as combustible liquids, gases and dusts are worked with.

BARTEC is a competent partner for manufacturers of devices, apparatus and machines, for constructors of plants as well as for operators in the sectors of chemical, oil and gas industry, petrochemical industry, mining, pharmaceutical industry, energy and environment.

Analyzers and Measurement Technology

Analyzers and Analyzer Systems

-

Engineering

- Feasibility studies

- Cost/benefit aspect

- Basic/detail engineering

- Budget planning

Production, Procurement, Delivery- Process analyzers

- Physical property analyzers

- Modular Gas Analyzer

- Sample conditioning systems

- HVAC/Cooling systems

- Recovery systems

- Procurement: enquiry requisition, tender comparison, preparation of documents ready for ordering, placing of orders and purchasing

- Delivery

International certificates- ATEX

- CSA, C & US

- others on request

Service- Commissioning: connection, functional testing, calibration, performance test, instruction, final documentation

- After Sales Service: spare parts supply, training courses, maintenance contracts

rapiDist-4 Analyzer

- To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly.Distillation is a physical method of separating the component substances from a liquid mixture by selective vaporization and re-condensation. Distillation is based on differences in volatilities of the components of the liquid mixture. The distillation curve is one of the most common quality parameters of liquid hydrocarbons such like naphtha, gasoline, kerosene, diesel and gas oil.

Features- Cycle time 10 to 15 minutes (for diesel 10 min. and for gasoline 15 min.)

- Results within ASTM D86 requirements

- Measuring points from IBP to FBP, free programmable

- Core components meet ASTM D86 design

- Optical level measurement for dosing unit and receive

Distillation Process Analyzer DPA-4

- To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly.Distillation is a physical method of separating the component substances from a liquid mixture by selective vaporization and re-condensation. Distillation is based on differences in volatilities of the components of the liquid mixture. The distillation curve is one of the most common quality parameters of liquid hydrocarbons such like naphtha, gasoline, kerosene, diesel and gas oil.

Features- The only ASTM D86 compliant design with flask – condenser – receiver

- Capability to reduce cycle time by Rapid Analysis Mode (RAM)

- Complete boiling curve can be measured from IBP to FBP

- Suitable for operation at pressure below atmospheric pressure

- De-coking feature

- Network and fieldbus communication

Cold Filter Plugging Point Process Analyzer CFPP-4

- The cold filter plugging point (CFPP) is the lowest temperature at which diesel and domestic heating fuels will pass through a filter in a given time when cooled under certain conditions. CFPP is supposed to give an estimate for the lowest temperature at which these fuels will flow in fuel systems without problems. This temperature is important especially in cold temperature regions where high CFPP of diesel fuel could result in clogging up vehicles’ fuel systems.

Features- The only ASTM compliant CFPP process analyzer

- Identical test mesh filter as used in the laboratory

- Stepped and linear cooling

- Network and fieldbus communication

Flash Point Process Analyzer FPA-4

- To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly.

The flash point temperature is defined as the lowest temperature at which application of an ignition source causes the vapor of specimen of the sample to ignite under specified conditions of test.

Features- Flash point temperature continuously measured

- No coking of measuring cell

- Wide temperature range from 25 to 180°C

- ASTM correlation based on catalytic reaction

- Network and fieldbus communication

Freezing Point Process Analyzer FRP-4/CPA-4

- The freeze point as well as the cloud point are both important cold properties which need to be monitored by operators. A matter of fact is that cloud point and freeze point can be detected with one analyzer as the principle of detection is identical. The di erenc between the two properties is defi ned by the actual sample behavior. The sample e.g. gasoil is cooled down and below a certain limit small crystals start to appear, which results in a certain degree of cloudiness of the sample. At that point the so called Cloud Point temperature is determined via reduction of light intensity through an optical path. The cooling process is stopped and the crystals dissolve again. At that point the sample becomes clear and transparent again. As soon as all crystals have dissolved the so called Freeze Point temperature has been reached.

Features- ASTM compliant optical measurement

- Suitable to also measure cloud point temperature

- Typically no chiller required for cloud point applications

- Network and fieldbus communication

Pour Point Process Analyzer PPA-4 Ex

- The pour point of a liquid is the temperature at which it still flows but starts losing its flow characteristics by becoming semi solid. For hydrocarbons the pour point temperature depends on the content of paraffin in the liquid but also on the viscosity that changes with temperature. The pour point temperature is an important quality parameter especially for lube oils but also for gas oils and fuel oils.

Features- ASTM compliant measurement based on tilting mechanism

- Low and high temperature applications

- Opacity independent measurement

- Network and fieldbus communication

Vapor Pressure Process Analyzer RVP-4

- To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly. The vapor pressure is an indication of a liquid evaporation rate and relates to the tendency of volatile components to escape from the liquid. To assure safe storage and transportation of petroleum products, minimize environmental pollution and assure proper functioning of combustion engines it is important to measure the vapor pressure.

Features- ASTM compliant cylinder piston design with 4:1 expansion

- Suitable for high pressure applications (LPG)

- Suitable for high viscous samples (Crude Oil) without flushing cycles

- No maintenance approach

- Integral temperature control unit

- Network and fieldbus communication

Viscosity Process Analyzer VISC-4

- To remain competitive, today’s refiners must employ all optimization and product control techniquesavailable. The use of online physical property analyzers is one of the key features to reach thoseobjectives because they measure important quality properties in the process directly.

All fluids that fulfil the conditions of Newton’s friction law are referred to as Newtonian fluids. Their viscosity is a material constant, which is only dependent on pressure and temperature. The viscosity for incompressible and Newtonian fluids can be derived from the so called Hagen-Poiseuille law. The fluid is assumed to flow under laminar conditions.

Features- The only ASTM compliant capillary type viscometer

- Kinematic viscosity directly and continuously measured

- Integral measurement of density

- Calculation of dynamic viscosity

- Unparalleled temperature stability of ± 0.02K

- No maintenance approach (no oil bath, no pump)

- Hagenbach correction not necessary

- Network and fieldbus communication

Viscosity Index Process Analyzer VI-4

- To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly.

All fluids that fulfil the conditions of Newton’s friction law are referred to as Newtonian fluids. Their viscosity is a material constant, which is only dependent on pressure and temperature. The viscosity index is a widely used and accepted measure of the variation in kinematic viscosity due to changes in the temperature of a petroleum product between 40 and 100°C. A higher viscosity index indicates a smaller decrease in kinematic viscosity with increasing temperature of the product.

Features- The only ASTM compliant viscosity index analyzer

- Kinematic viscosities directly and continuously measured

- Integral measurement of density

- Integral calculation of viscosity index

- Unparalleled temperature stability of ± 0.02 K

- No maintenance approach (no oil baths, no pumps)

- Hagenbach correction not necessary

- Network and fieldbus communication

Near-Infrared Analyzer NIR-4

-

The BENKE NIR-4 Analyzer measures near-infrared (NIR) absorption spectra of the samples to predict additional parameters, e.g. RON, MON, Aromatic content, Olefin content, FAME, PIONA, Cetane number etc, via chemometric models. BENKE developed a unique true dual beam flow through cell for the NIR- analyzer, which contains a full-fledged reference channel. Only this concept assures the best possible drift compensation. An optionally available automated cleaning system removes the requirement for regular wash and validation cycles. This leads to industry-leading performance and robustness of the measurement. With the freely configurable, easy-to-use software and the optional 6-port mechanical multiplexer and 5-port optical multiplexer it is the perfect addition for even the most challenging multiple component measurements. Applications for the NIR-4 are e.g. monitoring the streams at Atmospheric Distillation Units, Naphtha Steam Cracker and Catalytic Reformer as well as monitoring at final product blending and terminal blending stations.

MWD XRF

Features- Industry-leading performance

- Simultaneous determination of multi-properties

- Freely configurable with an easy to use software

- Optional mechanical 6-port and optical 5-port multiplexer

- Optional automated sampling of outliers for subsequent laboratory measurement

Analyzer Systems

-

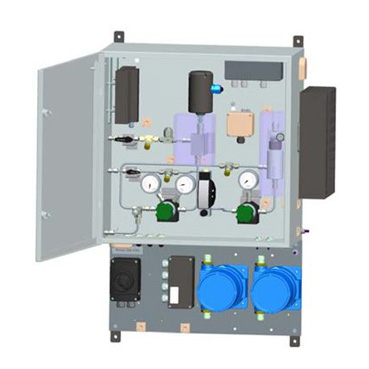

Sample Conditioning Systems, Turn-Key Analyzer Shelters

Capital is employed right from the planning phase to the time of delivery. BARTEC BENKE engineers and technical staff contribute that your production process will be faster and more cost efficient. The portfolio comprises complete analyzer shelters according to DIN EN 61285 / IEC 1285 as well as complete solutions with integration of systems and instruments of other manufacturers.

Typical Process Units Cover:- Terminals

- Distillation units

- Blending units for motor gasoline, gas oil and fuel oil

- FCC units

- Cracking units

- Natural gas pipelines

Production, Procurement, Delivery of Turn-key Analyzer Shelters:- On-site sample conditioning and fast loops

- Sample conditioning

- Analyzer shelters (Concrete, Glass-fibre reinforced plastic, steel, stainless steel, aluminium)

- Auxiliary and supply systems

- HVAC/Cooling systems

- Recovery systems

Model P-500 Flash Point Analyzer

-

To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly. The flash point temperature is defined as the lowest temperature at which application of an ignition source causes the vapor of specimen of the sample to ignite under specified conditions of test.

Features- Complies with ASTM

- Capable of handling high sulfur samples

- Rapid measuring cycle of 5 minutes

- Independent sample and flash chamber temperature control

- Micro-processor controlled

- External programming

- Color graphics screen

- Remote diagnostics over IP

Model P-600 Salt In Crude Analyzer

- To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly.

Salt in crude is the amount of chloride based salts found in the sample in weight per volume.

Features- Micro samples

- Low solvent consumption

- Cell temperature control

- Enclosed solvent tanks

- Fully automatic

- Local interface

- Supports Modbus

- Remote stand by option

Model P-700 Reid Vapor Pressure Analyzer

-

To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly.

Reid Vapor Pressure is a common measure of the volatility of gasoline. It is defined as the absolute vapor pressure exerted by a liquid at 100°F (37.8°C) as determined by the test method ASTM D323. The test method applies to volatile crude oil and volatile nonviscous petroleum liquids, except liquefied petroleum gases.

Features- Correlates with ASTM

- Optional validation sample system

- Optional stream switching

- TVP Output Available

Model P-800LT Freeze Point Analyzer, Low Temperature

-

To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly.

The freeze point is the temperature at which the last of the wax crystals disappear when warming the sample, after first reaching the Cloud Point temperature.

Application

Given today’s highly competitive environment, oil refiners are demanding instrumentation that aids in the optimization of the refining process. Therefore, refineries require a reliable and accurate analysis system of the Freeze Point temperature to meet the required specifications. This analysis will allow the operators to optimize the refining process and therefore lower production costs while improving product quality.

Features- Operating range -125 to 25 °C (-193 to 77 °F)

- Straight path absorbance & 90° back-scatter detection

- Rapid analysis cycle of 15 minutes or less

- Superior repeatability of less than 0.5°F (0.25°C)

- Internal Cryo chiller cools to -125°C without external cooling system

- No Sample Recovery System needed, can return directly to process

- Stream switching and validation

- Remote diagnostics over IP

Model P-820LT Cloud Point Analyzer, Low Temperature

-

To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly.

The cloud point is the temperature at which wax crystals form in a sample as it is cooled giving the sample a cloudy appearance.

Features- Measuring range -125 to 25 °C

(-193 to 77 °F) - Rapid measuring cycles less than 10 minutes

- Superior repeatability of less than 0.5°F (0.25°C)

- Internal Cryo chiller cools to -125°C without external cooling system

- No Sample Recovery System needed, can return directly to process

- Stream switching and validation option

- Measuring range -125 to 25 °C

Model P-840/P-840LT No Flow Point Analyzer

-

To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly. The no flow point (correlating to pour point) is the temperature where a product (as it is cooled) stops flowing.

Application

Given today’s highly competitive environment, oil refiners are demanding instrumentation that aids in the optimization of the refining process. Therefore, refineries require a reliable and accurate analysis system of the No Flow (Pour Point) temperature to meet the required specifications. This analysis will allow the operators to optimize the refining process and therefore lower production costs while improving product quality.

Features- Operating range -100 to 25 °C (-148 to 77 °F)

- Rapid analysis cycles of 10 to 45 minutes

- Superior repeatability of less than 0.5°F (0.25°C)

- High pressure sample detection cell eliminates the need for atmospheric recovery

- Stream switching and validation

- Remote diagnostics over IP

Ex Compact Air-Conditioning Unit FKS-CLM

- To remain competitive, today’s refiners must employ all optimization and product control techniques available. The use of online physical property analyzers is one of the key features to reach those objectives because they measure important quality properties in the process directly. It is therefore of the utmost importance that the analyzers operate as reliably as possible and with the best performance. An important prerequisite for this is a constant and reliable ambient temperature for the analyzers, since fluctuations can lead to measurement errors and malfunction of the analyzer in the worst case. However, this source of error is often underestimated and is therefore not taken into account when choosing the air conditioning. Here the FKS-CLM is the perfect solution to keep the risk as low as possible. Another application area are converter control cabinets or small generator houses that are set up, for example, on drilling rigs in potentially explosive areas.

Features- Optimized for robust and reliable operation

- -20 ° C to +55 ° C ambient temperature

- High cooling capacity

- Compact design, suitable also for Ex p cabinets

- Easy retrofit in systems that are in operation

- Two different variants with 2 kW and 4 kW available

- Simple Maintenance

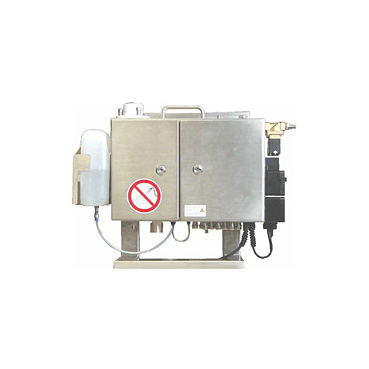

Ex Closed Loop Chiller FKS-KWS

- The BARTEC BENKE closed loop chillers consist of an air-cooled high performance condenser combined with an encapsulated compressor and are suitable for the installation in explosive gas atmospheres defined as zone 1. The electrical control system is supplied with its own Ex d housing. Optionally, with a BARTEC BENKE analyzer, the control system can be placed inside the Ex p housing of the analyzer.

Problems on site where utilities supplying cooling water is of a lower quality or special requirements of cooling water are needed, BARTEC BENKE closed loop chillers can be supplied to meet these applications. The chillers can be supplied with diverse refrigerating capacities which allow the chillers to be used on single analyzers up to complete analyzer houses, peltier elements and heat exchangers. They can be supplied suitable for indoor or outdoor use. Depending on the flow rate required, different pump capacities are also available.

Features- Compact design

- ATEX/CSA certified

- Ambient temperature range of -20 °C to +55 °C (-4 °F to +131 °F)

- Various refrigerating capacities

Trace Moisture Measurement for Gases

-

Stable Measurement for Process Safety

The measuring principle of HYGROPHIL F 5673 is patented and has established in many different markets, based on the low service and maintenance efforts required. The analyzer was originally designed for the natural gas market. Today it is being used in a wide variety of markets to determine trace moisture contents for different gas and liquid hydrocarbon process streams.

Moisture and Hydrocarbon Dew Point Measurement in Natural Gas

HYGROPHIL HCDT is to protect natural gas and pipeline networks and to maintain failure-free operation. There are wo measurements of Quality Control of natural gas:- Water dew point

- Hydrocarbon dew point

HYGROPHIL F, Moisture Analyzer, Type 5673-10, -11, -12, -13

-

HYGROPHIL F 5673 works with a combination sensor which by means of a fibre optical method measures the moisture content and by means of a PT100 measures the temperature in the medium. The very robust construction of the sensor and the measurement procedure itself offer several decisive advantages.

Among the advantages of this measurement principle which is protected by patents are the following:- high measurement safety including accuracy, reproducibility and low hysteresis

- long-term stability of the sensor (no drift!)

- measurement directly in the pres-sured pipe is possible (pressured dew point!)

- sensor can be placed in hazardous locations (class I/div. 1)

- simple installation and integration (Swagelok, Parker, …)

HYGROPHIL F 5673 was particularly designed for the natural gas industry. In the meantime it is used for moisture measurement in a diversity of gases and liquids. Due to the high-quality materials re used the sensor is extremely robust and resistant to almost all mediums.

Applications HYGROPHIL F 5673- Calculation of moisture content in accordance with DIN EN ISO 18453

- Moisture Measurement in Natural Gas

- Moisture Measurement in the Recycle Gas of a Reformer

- Moisture Measurement in hydrocarbon

HYGROPHIL HCDT

-

Measuring System for Determination of Hydrocarbon Dewpoint in Natural Gas

HYGROPHIL HCDT has been designed especially for the field of natural gas. As the materials that are applied are of very high quality, the sensors are extremely robust.

Application

Hygrophil HCDT combines the established water dewpoint measurement and the hydrocarbon dewpoint sensor to detect the moister content, the temperature and the hydrocarbon dewpoint of the measured medium. Apart from the very robust construction of the sensors, it is the measuring method itself that provides a number of decisive advantages.

Some advantages of this measurement principle protected by patents are:- High measuring certainty including precision, reproducibility and low hysteresis

- Long-term stability of sensors

- Measurement of HCDT at the cricondentherm point (pressure reduction)

- Measurement of DT on high pressure side (pressure dewpoint)

- Application in explosive area

- Simple installation (standardized connections)

Gas Moisture Measurement

- BARTEC BENKE's moisture measurement systems for gases has been a fixed term of analyse measurement for decades. Maximum accuracy, long term stability and reliability underline the success of our measurement devices and systems. We support you with our competence in solving your measurement problems. BARTEC BENKE offers system solutions for absolute gas moisture measurement under high temperatures, in dusty environments and aggressive gases. BARTEC BENKE also offers solutions for applications in Ex zones.

HYGROPHIL H 4230-10

-

Continuous moisture measurement in industrial processes

System solution including gas withdrawal sensor, heated gas pipeline und measurement device.- Long-term stable psychrometer

- Measurement range 0 to 100°C dewpoint

- Profibus DP

- Analogue Outputs

Field of Application-

Food Industry

Control of the water vapourisation in the baking industry, Hot air chain cookers, Monitoring the drying of cereals, coffee, milk powder etc. - Combusters and cogeneration plants

Emission measurement according to 13. and 17. BimSchV, Early detection of pipe bursts in boiler Systems, Fire-power control in waste incinerators - Building material industry

Dryers for sand, loam, kaolin, Dryers for plaster boards and wood fiber plates, Process control in brick production - Gas analyses technique

Flue gas analyses, Exhaust fumes analyses of engines, Mobile emission measurements - Ceramics and porcelain manufacturing

Control of burning process, Control of the gas according to German TA air - Chemical industry

Measurement of absolute humidity for accurate process management, Dryers for detergents, Dryers for fertilizers - Environmental measurement techniques

Sludge drying, Humidity Measurement in biogas and digester gas - Glass manufacturing

Monitoring the drying process e.g. fire protection glass - Pharmacy

Humidity control in coating, agglomeration or granulation processes - Metal industry

Control of the sinter process, Control of the coke drying

HYGROPHIL H 4230-12

-

Process Hygrometer for Ex zone 2

HYGROPHIL H 4230-12 is explosion proof. It can be used in Ex zone 2 area. To guarantee the explosion protection the enclosure is continually perfused by a saving gas.

Continuous moisture measurement in industrial processes. For very high demands in terms of being resistant to corrosion and dirt. Particularly suitable for cases where the air to be measured contains oil vapours, dust, water-soluble gases, solvents, acids and aggressive chemicals.- Measurement range: 20 to 100 °C DT

- Secondary standard method in accordance with DIN 50012

- Tragbare Ausführung für mobile Anwendungen

- Continuous measurement

- Constant scavenging

Field of Application- Hot-ait tunnels for cooking

- Foodstuffs

- Fertiliser dryers

- Various chemical processes

- Copper-nickel works

- Large combustion plants

- Combined heating and power stations

- Waste incineration plants

HYGROPHIL Z 1701-41

-

Measuring probe for moisture and oxygen in gases

The process hygrometer HYGROPHIL Z 1701-41 is designated as a measuring probe in gases according to the patented dual-element-operation based on zirconoxid sensors.

Monitoring and controlling of the moisture in gases results in equal high quality. Efficient energy use and under-passing admissible emission limits in many industrial processes are easily achieved.

Due to no need of maintenance for the process hygrometer HYGROPHIL Z 1701-41, it is suitable for continuos operation in industrial processes.

Applications- Textile dryers

- Baking ovens

- Drying covers

- Hot air tunnels

- Ceramic dryers

- Smoke chambers

- Food industry

- Pet food dryers

- Roasting plants

- Calcinating furnaces

- Plasterboard dryers

- Rotary kilns

- Kaolin dryers

- Sand and mineral dryers

HYGROPHIL K 4326-31

-

Multifunctional moisture and temperature transmitter

HYGROPHIL K 4326-31 is a combination of a high quality capacitive humidity-sensor and the newest microprocessor technology. These are the guarantee for best accuracy, excellent long-term stability, small hysteresis and high resistance to pollutants.

Easy installation and on-site adjustment guarantee a simple service and a high availability even in harsh industrial applications. The actual measured or calculated data can be indicated on the display.

Applications- Chemical industry

- High end HVAC

- Drying processes

- Open processes

- Meteorology

- Green house

HYGROPHIL DTP 1500-10

-

Optical dew-point sensor for online measurement

HYGROPHIL DTP works according to the patented method

of internal total reflection. The sensor can be installed

directly into the compressed-air line and thus determins

the exact pressure dew-pont.- LC display

- On site configuration

- Process connection and registration via analog current output and RS 232 interface

- Usable for online measurement in the range from 0 to 16 bar overpressure

- No conversion in case of varying pressure conditions is required

- Short response time

Applications- Compressed-air networks

- Monitoring, controlling and regulating tasks

- Sensor reaction tool

Seismic Instrumentation

-

Earthquakes can not be forecasted or predicted. The primary damages at buildings, plants and infrastructure, and especially secondary damages caused by fire, explosion and pollution are a high risk for human beings and environment.

The risk increases by earthquake hazard, density of population and industry as well by the vulnerability of buildings, lifelines and industry.

Higher risk industry and lifelines get a basic design including the estimated additional earthquake load of the location. This design is based on standards such as the German KTA 2201, the European Code 8, the US Regulatory Guide or the Uniform Building Code.

BARTEC SYSCOM`s seismic instrumentation measures continuously the vibration level at the sensor location and provides alarms if limiting values get exceeded. Based on these alarms immediate inspections can be initiated or high risk processes can get shut down. The automatically performed analyses compares design with measured values and allows further decisions. The video below provides you with an interesting application of our seismic instrumentation:

MR3000C

- MR3000C is a compact vibration/motion measurement system built in a rugged SYSCOM RED BOX.

The MR3000C is equipped with a new generation of electronic components, keeping the best features of the MR2002, but adding new ones, such as a reduction in size and weight and an increased computing power.

MR3000C has been designed for different temporary and fixed measurements in the civil engineering and strong-motion surveys.

Features- IP65 compact unit containing sensor, digital recorder and communications

- Internal or external sensor

- Accelerometers and geophone available

- External battery pack

- External display showing the most important information

- Removable memory SD Card

- Precise timing (GPS or NTP)

- Power over Ethernet (PoE)

- Wired & wireless connectivity

- Embedded Web Server for the configuration

- Event recording principle with multiple level triggers

- DDNS, OpenVPN, FTP push network capabilities

- Automatic sending of SMS and E-Mail in case of event

MR3000TR

- The MR3000TR is a new set dedicated to the monitoring of vibration induced by traffic and railways.

Features- 1 trigger input to start the measure with an external trigger

- 2 relay outputs for the connection to external devices

MR3000BLA

- The MR3000BLA is a new high-end instrument dedicated to the monitoring of explosion-induced vibrations. The MR3000BLA is an all-in-one autonomous motion recorder integrated in a rugged housing for field measurements. The three channels for vibration and the channel for air overpressure make it perfect for a complete blasting monitoring.

The MR3000BLA linked with the SCS (Syscom Cloud Software) offers a near real-time reporting solution with graphical norm comparison.

The MR3000BLA is equipped with an internal 3G module for wireless data transfer.

Features- Vibration and air pressure acquisition (4 channels) with band-pass filter from 2 to 250 Hz

- External triaxial velocity sensor MS2003BLA with extended measuring range ±250 mm/s (±10 in/s)

- High pressure microphone from 2 to 2000 Hz, up to 150 dB(L)

- Heavy duty IP66 Peli Box

- Wi-fi connectivity

- Embedded 3G module

- Long-life internal battery

- Compatibility with SCS (Syscom Cloud Software) for automatic blast event reporting

MR3000DMS

- SYSCOM MR3000DMS seismic monitoring system is the most compact, integrated and reliable system for dams, ensuring highest level of safety and sustainability. Automatic earthquake detection and structural monitoring will ensure the full integrity of the dam over its lifetime.

MR3000DMS is extremely versatile and easy to install, thanks to its state of the art Ethernet master-slave connectivity and the command & control access through embedded web server.

Three relays output (alarm 1, alarm 2 and device error) can be directly connected to the dam control room for a centralized overview and an automatic logic response in case of any seismic event that might occur.

Features- IP66 compact unit containing tri-axial MEMS sensor, digital recorder, battery and communications

- No need of periodic calibration

- Internal terminals as junction box, AC/DC & Over Voltage Protection (OVP)

- Removable memory SD Card

- Up to 32 MR3000DMS in an Ethernet master-slave configuration network with common triggering and alarming

- Embedded Web Server for the configuration

- Fiber optics (FO) for long distances and highly reliable data stream

- Event recording principle with multiple level triggers

- Three configurable output relays for dam control monitoring system integration

- DDNS, OpenVPN, FTP push network capabilities

- Automatic sending of E-Mail in case of event

MR2002BMS

- SYSCOM MR2002BMS seismic Building Monitoring System provides a complete strong-motion and vibration monitoring network inside a building. The system can be used not only for earthquake monitoring, but also to evaluate structural damage and human comfort in case of construction sites close to the building.

Typical installations include a daisy chain network of three or more stations at the foundation, middle and top floor of the building, in compliance with most of the international standards.

Features- IP67 compact unit containing tri-axial MEMS sensor, digital recorder, battery and communications

- No need of periodic calibration

- Digital interconnection with minimal noise

- Common timing and common triggering

- Trigger on accelerations or Cumulative Absolute Velocity (CAV)

- Automatic alerting and self-test

- Remote control and data retrieval

- VIEW2002 comprehensive analysis software

MR3000SB

- SYSCOM MR3000SB Structures & Buildings Monitoring System provides a complete strong-motion and vibration monitoring network inside a building. The system can be used not only for earthquake monitoring, but also to evaluate structural damage and human comfort in case of construction sites close to the building.

Typical installations include a daisy chain network of three or more stations at the foundation, middle and top floor of the building, in compliance with most of the international standards.

Features- IP67 compact unit containing tri-axial MEMS sensor, digital recorder, battery and communications

- No need of periodic calibration

- Digital interconnection through Fiber Optics or Ethernet copper type cable with minimal noise

- Common timing and common triggering

- Automatic alerting and self-test

- Remote control and data retrieval

- VIEW2002 comprehensive analysis software

Contactless Temperature Measurement

-

BARTEC's "contactless temperature measurement" has been dealing with infrared-measurement for more than 30 years.

The success of numerous installed measurement devices and systems underlines the high competence as your partner for solving measurement problems.

OEM solutions for up to 250 °C environmental temperature and sensors for hazardous areas are components of the product range.

Applications- moving objects

- measurement with a short measurement period >100 ms

- objects, that require contactless measurement (foils, lacquers, glass surfaces, etc.)

- objects >1500 °C

- objects in high frequency fields

Thermophil INFRAsmart R 300/ 301 / 302

-

Contactless measurement of temperature for all applications

Stationary pyrom-eter for contactless and quick measurement of temperature for objects in motion, under current or with poor conduction of heat, e.g. plastic films, paper or bulk materials.- compact, sturdy pyrometer

- integrated electronics up to 70 °C

- two-wire techniques 4 - 20 mA

- HART interface

- spectral range for plastic, glass, metal

- optic options for different measures

- punctual temperature registration with good price-/performance ratio

Applications- plastics: thermoforming, foil production

- textiles: textile drying

- asphalt: mineral temperature of rotary run-out, asphalt temperature when silos are filled

- asphalt temperature when asphalt is loaded

- glass: glass forming, flat glass treatment

- chemical industry: rotary kilns

- automobile industry: brakes, lacquering

- baking: regulation of hotplate temperature

Thermophil INFRAht R 310 / 311 / 312 / 320

-

Contactless measurement of temperature at high ambient temperatures

- pyrometer for environmental temperature up to 125 °C

- without extra cooling

- separated electronics

- two-wire techniques 4 to 20 mA

- HART interface

- spectral range for plastics, glass, metal

- optic options for different measures

Applications- plastics: thermoforming, foil production

- textiles: textile drying

- asphalt: mineral temperature of rotary run-out, asphalt temperature when silos are filled

- asphalt temperature when asphalt is loaded

- glass: glass forming, flat glass treatment

- chemical industry: rotary kilns

- automobile industry: brakes, lacquering

- baking: regulation of hotplate temperature

Thermophil INFRA R 271

-

Contactless measurement of temperature at high ambient temperatures

Stationary and robust measuring sensor for contactless temperature measurement at high ambient temperatures.

- robust and tight stainless steel casing IP65

- two-conductor-technology 4 to 20 mA

- Measuring head is pluggable

- continuous furnaces for lacquer drying

- textile and paper drying

- and others

Automation & Enterprise Mobility

Human Machine Interface

POLARIS PROFESSIONAL

-

The POLARIS Panel PC is an innovative further development of the POLARIS PROFESSIONAL Serie. High-resolution displays with LED technology and touchscreen for intuitive as well as comfortable operation are available now in the standard variant.

State-of-the-art LED display technology ensures the optimum contrast even with a large viewing angle. This Panel PC has been equipped as standard with the latest generation processor, the Intel® AtomTM with 1.6 GHz. The pre-installed operating system is Windows® XP and Windows 7® is optionally possible. Thanks to the integrated keyboard customisation for Windows®, Siemens WinCC flexible® , RS View® or BMSGraf- pro, the POLARIS Touch Panel can be used for all visualisation tasks. They can be connected to the control or the process control system through Ethernet, PROFIBUS-DP or various serial COM interfaces.

POLARIS REMOTE

-

The POLARIS Remote unit by BARTEC is a display with keyboard and mouse with which a PC can be operated in safe areas of hazardous areas.

Distances of up to 10,000 m are possible. POLARIS Remote 19.1" offers the user the possibility of using any currently available PCbased process control system, without any restrictions in the Ex area.

POLARIS COMFORT

- The POLARIS Touch Panel is an innovative further development of the POLARIS Panel PCs 5.7". High-resolution displays with LED technology and touchscreen for intuitive as well as comfortable operation are available now in the standard variant. State-of-the-art LED display technology ensures the optimum contrast even with a large viewing angle. The proven LX800 offers sufficient computer capacity for presenting HTML pages or functioning as a remote client.

POLARIS BASIC

- With the Panel PC, process visualizations can be directly connected in explosive areas without the need for additional intrinsically safe isolation cards. The laying of blue lines for intrinsically safe circuits is dropped. A separate wiring of the data line is not necessary. The Panel PC can be directly connected to the PROFIBUSDP or the communication interface of the control station. We offer e. g. RS422/485 or PROFIBUSDP as well as an optional supply module for handheld scanners.

POLARIS SMART HMI

-

The POLARIS SMART HMI 7" W is an innovative further development of the POLARIS series. The high-resolution display with LED backlighting and touchscreen allows intuitive and comfortable operation. It is optionally available in a capacitive or in a resistive version. The state-of-the-art LED display technology offers optimum contrast even with large viewing angles or in poor lighting conditions. As standard, the Panel PC is equipped with a third-generation processor, the Intel® AtomTM with 2 x 1.46 GHz. The open Windows operating system makes the device series unique on the market. It is also possible to work with the BMS-Graf-Pro. Connection to the control or to the process control system is facilitated by Ethernet. The front-panel insertion allows easy installation. On request, the devices are also available as ready-made system solutions in stainless-steel enclosures for wall or floor mounting. The intrinsically safe USB interfaces are accessible on the back. Intrinsically safe input devices are connected also.

Features- Open operating system

- Slim and modern industrial design

- Clean-room-compliant version (gap-free)

- Optimized connection technology

- Sunlight readable display

- Low-reflective (the capacitive design)

- Optionally available as a resistive touch display

Bus Technology

Remote I/O Systems ANTARES

- The hot swap capability allows the electronic unit to be replaced without disconnecting from voltage even in an Ex atmosphere. The internal and galvanically isolated bus connection is established by simply joining the modules to the RCU. A bus rail is not necessary. Line break/short-circuit monitoring can be programmed for each channel. The bus status messages and individual messages per channel are displayed through the LEDs. This facilitates diagnosis at the module as well. The module is programmed with Software ANTARES Designer. See the system description for installation instructions.

MODEX Bus System

-

PROFIBUS-Interface 16 x digital out

This module allows the activation of 16 actuators in the hazardous area via PROFIBUS-DP.

For example, encapsulated solenoid valves or indicator lamps can be directly activated with 24 V/500 mA.

LEDs on the front of the module output bus status as well as output states.

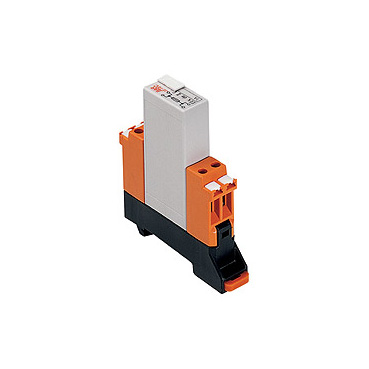

Control Unit MODEX

-

Fused modules are required to protect equipment and power circuits in areas in which an explosion hazard exists. The increasing automation of functions and processes make it necessary to install the standard protective devices on-site.

An advantage of MODEX fuses is that they are fitted in explosion-protected enclosures with integrated double terminals. This allows the input and output voltage to be used further by the MODEX component.

Please indicate the desired current value with your order (see selection chart).

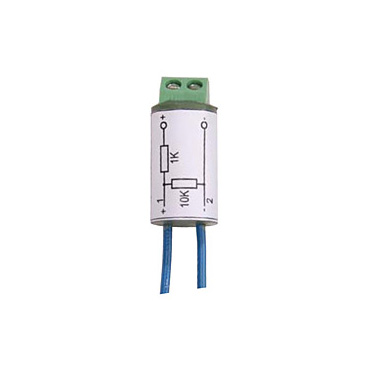

Resistive Coupling Element

-

The 1 kOhm/10 kOhm resistive coupling element is used to monitor open and short circuits in isolator amplifier circuits controlled by mechanical contacts. The coupling element is installed directly to the control contact or inside its terminal box.

Function

Numerous isolator amplifiers can monitor the connected sensor line for open or short circuit conditions thanks to the employment of electronic proximity switches to which current can be applied in both damped and undamped status DIN EN 60947-5-6. Current values outside the specified range are identified as open or short circuits. If simple mechanical contacts are used, it is not possible to identify a short circuit. Neither can be distinguished between open circuit and open contact.

Industry Tablets/Tablet PCs

Agile X IS

- The BARTEC Agile X IS is an rugged and highly flexible industrial tablet PC for rough environments. Agile X IS has a large number of international certifications and can be used throughout the world. It is certified for ATEX and IECEx Zone 1, Zone 0 and NEC 500 Class I Division 1. Further national certifications are possible on customer request. Thanks to its broad range of functions, the Agile X IS is the perfect assistant to service technicians, engineers and project managers in the field and in industry.

Features- Highly flexible industrial tablet PC with powerful Quad-Core processor for rough and hazardous environments

- Ergonomic positioned high quality 1D/2D imager SE4500 from Zebra and RFID reader HF/NFC

- Brilliant, high-resolution, bonded 10.1" touch LED display, sunlight readable, rain useable

- High quality 5 MP camera

- Integrated Bluetooth 4.1 LE, WLAN and optional LTE module

- Unique expansion port for customer specific applications

- Great amount of accessories supporting Productivity and operator safety

Agile S NI

- The Agile S NI from BARTEC is a rugged and highly flexible industry tablet PC for rough environments. TheAgile S NI has a large number of international certifications and can be used throughout the world.It is certified for ATEX and IECEx Zone 2/22 and to UL Class I Div. 2. Further national certifications are possible on customer request. Thanks to its broad range of functions, the Agile S NI is the perfect assistant to service technicians, operating staff, engineers and project managers in the field and in the industry.

Features- Rugged and highly flexible industry tablet PC 10.1”

- Powerful Intel core i5 processor for high working speed and long battery life

- Robust through military specification according to MIL-STD-810G

- Integrated Bluetooth 5.0, WLAN and optional LTE radio modules

- Easy integration into your company through Windows 10 operating system

- Data acquisition with barcode and NFC/RFID scanner

- Wide range of accessories

Agile S

- The Agile S from BARTEC is a rugged and highly flexible industry tablet PC for rough environments. Thanks to its broad range of functions, the Agile S NI is the perfect assistant to service technicians, operating staff, engineers and project managers in the field and in the industry.

Features- Rugged and highly flexible industry tablet PC 10.1”

- Powerful Intel core i5 processor for high working speed and long battery life

- Robust through military specification according to MIL-STD-810G

- Integrated Bluetooth 5.0, WLAN and optional LTE radio modules

- Easy integration into your company through Windows 10 operating system

- Data acquisition with barcode and NFC/RFID scanner

- Wide range of accessories

Smartphones & Mobile Camera Systems

Pixavi Phone

- Built to provide top performance while ensuring your safety in hazardous areas. Highly ruggedized, yet elegant and pocket friendly. The ultimate intrinsically safe Android smartphone.

Weighing in at 293 grams, the Pixavi Phone is the lightest and slimmest Intrinsically Safe smartphone in the market. Its low weight and slim design, combined with the market-leading 5.5″ Full-HD AMOLED display, provides the user friendliness of a consumer smartphone – without compromising safety or ruggedness.

Features- AndroidTM 9.0

- 4G (LTE)

- Bluetooth® 5.0

- Dual-SIM or Single-SIM + SD Card

- Qualcomm Snapdragon 660 Octa-Core 2.2 GHz

- Lightest & Slimmest Intrinsically Safe Smartphone

- 5.5”, 1920x1080 AMOLED Display

- Replaceable battery

- Magnetic charging po

Pixavi Cam

- Higher quality photos, 4K video capturing: Pixavi Cam is the successor of the market leading explosion proof camera Gravity X.

Whether it’s documenting, live-streaming, or routine inspection, capturing images and video in a hazardous area must always be easy and hassle-free. That’s why the intrinsically safe Pixavi Cam is designed to be user friendly – a 5.5″ AMOLED display makes capturing images and video simple and easy, even while wearing gloves. Its low weight and compact size means it can always be at the ready – either in a pocket, or easily carried with a dropped safety strap.

Features- 12.2 MP Camera

- 4K recording

- 5.5” 1920x1080 AMOLED Display

- 64 GB storage

- Support optional SD Card

- Dedicated programmable button (e.g. camera button)

- Replaceable battery

- Qualcomm Quickcharge w/magnetic charging po

Orbit X - Explosionproof Wi-Fi Camera

- Orbit X is the toughest, most intelligent and smallest explosion-protected camera. It has an HD image sensor, two LED lamps and a laser pointer. This means in potentially explosive atmospheres it is also possible to take photos and record videos, hold live wireless video conferences and use video streaming for monitoring. Using 1080p Wi-Fi, the camera with its compact and robust design can record, stream and display videos and 8 megapixel stills. Images and videos recorded in the field can then be transmitted via USB to any computer. Orbit X offers the option of remote management using the Collaboration X Device Management System. The camera can be connected by Wi-Fi to any Android device. The SIPIDO app is also included by way of standard, permitting video conferencing by Wi-Fi in full HD.

Features- HD video streaming

- High end imaging

- Light and flexible

- Powerful LED

- Make better decisions

- Increase flexibility

- Decrease travel expenses

- Improve work routine

Touch & Mobile Computers

Touch Computer TC75Xex

- Your workers in the field need a mobile computer to communicate with others and to access information. Only in this way can they work with maximum efficiency and improve service to customers. You would like to provide your staff with an enterprise-class hand-held device that has been designed for field use your employees, however, expect a device that has the same level of development and which is as easy to use as their own smartphone. The touch computers in the TC75Xex series meet all of these requirements because they have been optimised for use in business. A tough design for reliable, everyday operation. Access to practically all information in your back-end systems wherever and whenever you need it. The ability to collect more types of data quicker than ever before. Immediate Push-to-Talk communication with field staff, line managers, despatch coordinators and colleagues in the office. 4G LTE support for robust, wireless connections in the fastest mobile phone networks in the world. And an extensive range of accessories which meets the unique demands of practically all mobile employees. The TC75Xex series a simple way of equipping your field team with a true mobile office now also in a potentially explosive atmosphere.

Features- Extreme rugged

- Dual Sim Slot

- Exchangeable strong battery

- Integrated scan functionality

- High quality integrated camera

- Professional accessories

Touch Computer TC77ex-NI

- Your workers in the field need a mobile computer to communicate with others and to access information. Only in this way can they work with maximum efficiency and improve service to customers. You would like to provide your staff with an enterprise-class hand-held device that has been designed for field use – your employees, however, expect a device that has the same level of development and which is as easy to use as their own smartphone. The touch computers in the TC77-NI series meet all of these requirements because they have been optimised for use in business. A tough design for reliable, everyday operation. Access to practically all information in your back-end systems wherever and whenever you need it. The ability to collect more types of data quicker than ever before. Immediate Push-to-Talk communication with field staff, line managers, despatch coordinators and colleagues in the office. 4G LTE support for robust, wireless connections in the fastest mobile phone networks in the world. And an extensive range of accessories which meets the unique demands of practically all mobile employees. The TC77-NI series – a simple way of equipping your field team with a true mobile office – now also in a potentially explosive atmosphere.

Features- Extreme rugged

- Dual Sim Slot

- Exchangeable strong battery

- Integrated scan functionality

- High quality integrated camera

- Professional accessories

Mobile Computer MC 92N0ex

- In close cooperation with Zebra, BARTEC has developed the MC 92 Mobile Computer for global use in potentially explosive areas, based on the successful MC 9000ex range. The device range enables complex applications to be executed, processes to be simplified and productivity boosted. Whereas barcode scanners are used for the classic collection of data, the MC 92 also offers wireless data exchange and direct further processing of data in the field. The MCs are available with a choice of different barcode scanners in order to read 1D, PDF, 2D and DPM (Device Part Marking) barcodes. The selection permits a customised adjustment that also enables barcode scanning at a distance of up to 12 m (long range). In the RFID reader area, a UHF version is also available in addition to the LF and HF versions. The RFID reader is available as internal solution without barcode scanning. Three versions of operating system are available. These are the familiar environment of Windows® Embedded Handheld and Compact, as well as Android, the innovative, most commonly used operating system in the world. This means the user can easily adjust the devices to meet his requirements. The real time data exchange via Wi-Fi or Bluetooth is convenient, saves time and improves work processes. International approvals such as ATEX/IECEx and UL certificates as well as other national approvals such as for Brazil, South Africa, Russia etc., guarantee the worldwide use of the devices. The optimised power management and automatic shutdown via a motion sensor both guarantee long operating times.

Features- Wi-Fi IEEE 802.11

- Proven, robust design for demanding environments

- 3.7" touchscreen made from tempered special glass with excellent readability, also in direct sunlight

- Scan engines for all barcode application areas

- Supports RFID standards LF/HF/UHF

- Interchangeable keypads offer considerable scope for individual features with customised designs

- Compatible with existing accessories from the MC 9000 range

- Can be individually adjusted to customer infrastructure by means of three operating systems available in the factory (Windows®/Android)

Mobile Computer MC 93ex-NI

- BARTEC has developed in close cooperation with Zebra Technologies the next evolution of the world’s best selling and most trusted enterprise mobile computer – the MC93ex-NI for worldwide use in hazardous areas.

Users get simplicity with Android, ultimate processing power, a larger touch display, and much more.

New data capture capabilities include an extraordinary scan range of up to 21.4 m.

The new battery runs twice as long as the MC9200ex series on a single charge. The MC93ex-NI is the most rugged mobile computer ever created, ready to outlast virtually every device in its class in any environment. The new software solutions from Zebra “Mobility DNA” help you get more value out of the MC93ex-NI by adding functionality as well as simplifying deployment and management, while delivering better-than-ever robust wireless connections.

Features- Users get simplicity with Android, ultimate processing power, a larger touch display, and much more.

- New data capture capabilities include an extraordinary scan range of up to 21.4 m.

- The new battery runs twice as long as the MC9200ex series on a single charge.

- It is the most rugged mobile computer ever created, ready to outlast virtually every device in its class in any environment.

- The new software solutions from Zebra “Mobility DNA” help you get more value out of the MC93ex-NI.

Control and Connection Equipment

ComEx Control Stations

Actuating elements

-

A large number of variants and versions of actuating elements are available for the ComEx control and indicator units. All actuating elements are made of high-quality thermoplastic and conform to the IP 66/IP 67 type of protection.

To complete the actuating elements, there are useful accessories such as e. g. label holders, marking tags, metal shroud or nut wrench. Actuating elements for increased resistance to oil are available too.

The actuating elements are mounted quickly and easily onto the ComEx control and indicating devices. Use in Zone 1 and 21 is certified.

Modules with Terminals for Rail-mounted Installation

- The ComEx lamp module signals command statuses by illuminating or extinguishing a light signal. It is suitable for use in almost all potentially explosive areas in which the functional status of machinery needs to be visibly displayed The lamp modules are executed according to the requirements of type of protection “e increased safety” and “d flameproof enclosure”. The lamp module can be combined with various lamp module actuators. A junction box is provided for the safe and convenient installation of the module in a control panel. Conductors are connected using terminals with increased safety on the back of the module. The simple installation of the lamp module actuators without tools guarantees the high IP protection type.

Modules for Local Control Stations

-

The ComExflex lamp module indicates command modes by means of a light signal lighting up or going out. It is suitable for use in almost all explosive areas in which a visual indication of a machine’s functional status is required.

The lamp module can be combined with various lamp module actuating elements. A junction box is available to facilitate a safe and convenient installation of the module into a control panel.

The conductors are connected by means of terminals on the back of the module which have an increased safety level. The lamp module actuating elements can be fitted easily without tools, which ensures conformance to the high IP degree of protection.

ComEx Actuating Elements, Accessories

-

Actuating elements - Accessories

Fixing nut

- Fixing nut

- Printed pushbutton labels

- Spanner

- Label holder

- Contrast plate

- Label

- Marking tag

- Label (without marking)

- ComEx flange set

ComEx Actuating elements for complete enclosure- Cable gland

- Locking device

- Protective metal shroud

- External earth stud

- UL adapter

- Earth plate ComEx

ComEx Control Stations Complete Devices

-

ComEx is a flexible system offering standard as well as customer-specific local control and indicating units.

You have the choice between three standard enclosures which can accomodate up to three different control and indicating devices. Combinations of up to three ComEx enclosures are possible.

Either stuffing box glands in M20 x 1.5 and M25 x 1.5 made of plastic or cable glands made of metal are available for the electrical connection. The plastic glands require no lock nuts. Metal glands are screwed into a metal earth plate sheet inside of the enclosure. Maximum amount of cable clands: two off M20.

To ensure easier operation on site, each enclosure can be equipped with an individual info-label. For offshore applications special oil-resistant attachments are available.

Control Panels

Local Control Stations

-

BARTEC produces local control stations for use in areas with flammable gases and dusts. Depending on the application area, the control stations are designed

with the type of protection “Increased safety” or “Protection by enclosure”.

The explosion-protected local control stations are available in aluminium, polyester or stainless steel. When selecting the version, you can choose between a cabinet with door and an enclosure with screw cover. Control, signalling and display devices and remote I/O systems are installed according to customer specifications. The installation of industrial standard equipment in controls for Zone 21, type of protection tb “Protection by enclosure” is possible.

The control elements can also be mounted on a mounting rail or in the front wall. Free installationa reas can be designated for the subsequent installation of BARTEC control and signalling devices, which are then sealed using blanking plugs. All explosion-protected local control stations are supplied prewired on terminals.

Fields of application

Chemical and petrochemical industry, process and plant engineering, pharmaceutical and food industry, OFF SHORE areas.

Limit Monitor

- The limit value transmitters of Types 07-31..-.../... are deployed in conjunction with pneumatic actuators on valves and fittings. They serve to signal the "open/closed" status of a fitting. This end position is communicated by means of up to a maximum of 6 limit switches in the “Ex d” type of protection or by means of 6 proximity initiators in conformance to NAMUR in the “Ex i” type of protection. In intrinsically safe proximity initiators there is a choice of slot initiators or V3 initiators. The limit monitors are available in polyester, aluminium and stainless steel. The metal versions can be used in temperatures down to -60 °C – depending on the fitted components. To ensure mechanical adaptability to the pneumatic actuators, we supply 4 consoles according to VDI/VDE 3845. The BARTEC limit monitors can be used in hazardous (potentially explosive) areas in Zone 1 and 2 in accordance with the certified explosion sub-groups IIA, IIB and IIC and the temperature classes T5/T6 and in Zone 21 and 22 in accordance with the certified max. surface temperature.

Flameproof Control Panels

-

As flameproof control unit, this Ex d enclosure from BARTEC provides a compact solution for the installation of standard industrial products, whereby components such as contactors and relays are installed in a flameproof enclosure.

The enclosure is light, flexible with respect to wiring systems, may be flange mounted and can be equipped with electrical or mechanical line bushings on the sides and in the lid. The different versions of lids enable the installation of display units or devices with control buttons. The installation of Ex i assemblies is also permitted.Types of connection:

Flameproof control units may be connected either with direct cable entry by means of Ex d cable glands or indirectly using an Ex e junction box. The electrical connection between Ex d and Ex e area takes place using Ex d line bushings with terminals. Control devices and display units can be installed in the junction box.Note:

The use of an empty enclosure requires an acceptance inspection by a notified body.

Control, Regulating and Display Devices

- These up to 4 W potentionmeters show that Ex potentiometers can be small and compact. The external dimensions are approximately the same as those of standard industrial potentio-meter enclosures. Central fixing in a single hole and the standard size of shaft have been includend. From the variety of resistors on the market we have chosen cemented wire-wound resistors and carbon film resistors and developed a standard-program range.The metal Ex d enclosures are tailored to the dimensions of the resistors and feature a standard 30 mm diameter. The potentiometers have been designed so that the stated nominal capacities can be fully exploited at temperature class T6 or T5 and be deployed in zones 1 and 2. The potentiometer is fitted into an enclosure that meets the requirements of an approved type of protection in conformance to IEC/EN 60079-0.

Standard Motor Control

-

The standard motor controls consist of an enclosure in the “flameproof” type of protection and a junction box in the “increased safety” type of protection. The motor starters are fitted into the enclosure with the “flameproof enclosure” type of protection. Depending on the order, controls are fitted into the junction box with the “increased safety” type of protection.

The motor control units are supplied with a main switch and controls as standard. The standard versions with control transformer conform to EN 60204

requirements. However, it is also possible to order the motor controls without a control transformer, main switch or controls.

The contactor for switching ohmic consumers and motor starters is equipped with thermal overcurrent tripping. The nominal voltage must be specified separately if it deviates from 400 V. The transformer is adapted accordingly then.

Installation Systems

Plug-and-Socket

-

BARTEC’s plug-and-socket devices for areas in which an explosion hazard exists are particularly well-suited for use in raw atmospheres because of their high degree of IP protection and their resistance to chemicals. Their integrated switch function gives them the ability to switch overloads as per IEC/EN 60947-3 Cat. AC 22 or AC 23.Silver-plated butting contacts ensure a constant contact pressure with low transfer resistances.

Plugs/couplers:

The modular design of the plug-and-socket system allows both plugs and couplers to be supplied. They are supplied in unmounted state.

Wall socket:

BARTEC supplies both a fully certified wall socket and a socket with a 30° adapter to flange onto housings.

Plug-and-socket devices from BARTEC are approved in accordance with the European directives not only for Zone 1 and 2, but also for Zone 21 and 22. Likewise for Class I Div. 2 Groups A, B, C, D and Class II Div. 2, Groups E, F, H in accordance with the American standards.

Enclosures and Distribution Boxes

-

Polyester enclosures have proven their worth in many industrial plants. They offer safe protection even when they are used under extremely unfavorable conditions, on exposure to aggressive chemical media or hard mechanical conditions.

The inside base of the enclosure has at its sides, threaded bushings for the fastening of mounting rails or panels. The enclosure is mounted by means of insulated screws outside of the lid seal.

Terminals

-

The continuous demand for increased nominal insulation voltage and current carrying capacity in Ex e terminals made us these larger BARTEC terminal blocks.

Terminals for 4 mm² and 16 mm² conductors are available in 2- and 3-pole versions. Terminals for 35 mm² conductors are available in a 3-pole version. The terminals can be fitted directly onto a metal base or onto a 10 x 5 mm mounting rail.

Cables and Wires

- Replaces the traditional RFOU but have only 1/3 of the weight and thickness. Extremely flexible and can be installed in flexible installations like drag chains/cable carriers etc. DNV approved and meets the mud resistant requirements in NEK TS 606:2009.

One range only that cover both signal and power (0,6/1kV). All cables are with screen/armour that can be used as earth in accordance to NEK606 and IEC 61892-4. Excellent mechanical properties - DNV tested and approved according to TAP 6-827.11 incl. cold impact/bend, scratch and tensile tests.

Sheath: RADOX Elastomer SFH (SHF2, SHF mud). Color: black. Multicore/twisted pairs/twisted pairs with individual screen 0,5-6mm².

Switches

Insert switch

- This switching element can be universally used for switching, controlling and regulating operations within Ex-areas. The insert switch is audited by the PTB according to the latest EC guideline 94/9/EC. Devices equipped with these insert switches have to be approved by a testing authority, the switch itself needs not be retested. The cores are cast-in at the back of the switch. Their standard length is 500 mm; other lengths are available on request. To connect the cores we recommend the miniterminals from BARTEC.

Limit switch

-

The limit switches have been developed for Ex-areas where safe and reliable signalling is required, for example on pumps, petrol pumps, as well as in mechanical and high-tec engineering.

The switches must be mounted into the respective devices or systems in such a way as to guarantee mechanical protection. No further tests are required. The connection cable is cast in on the back of the switch. For the connection in Ex-areas BARTEC provides a large variety of terminals and terminal boxes.

Miniature limit switch

-

BARTEC miniature switches are used in areas with of limited space for a flameproof switching element. They are especially suitable for applications in valves, thermostats, push switches, servo components, level metres and switching gears. The smallest Ex d miniature switch in the world is encapsulated in a plastic enclosure. The leads or cable tail are potted in at the base. The standard version of the BARTEC miniature switches contains fine silver contacts. Other contact materials such as gold plated silver or solid gold are available for low currents and voltages.

Switches with connector cables have been approved by PTB with EC model test certification. The switches can therefore be mounted at any time into devices and systems which offer mechanical protection – no further testing is required. The connector cable is cast into the back of the switch. The wires are colour-coded. The (standard) cable length is 3 m; other lengths are available on request.

Miniature insert switch

-

BARTEC miniature switches are used in areas with of limited space for a flameproof switching element. They are especially suitable for applications in valves, thermostats, push switches, servo components, level metres and switching gears. The smallest Ex d miniature switch in the world is encapsulated in a plastic enclosure. The leads or cable tail are potted in at the base. The standard version of the BARTEC miniature switches contains fine silver contacts. Other contact materials such as gold plated silver or solid gold are available for low currents and voltages.

The insert switch with wires is available as a building block for your explosion-proofing solution. These insert switches are tested and approved by PTB (the Federal Physical-Technical Institute) according to Ex Guideline 94/9/EC. After installation, the complete device is tested by an authorized institution. Thanks to its PTB approval, the microswitch itself needs not be individually tested. The leads are individually marked. The length of the cable is 50 cm (standard). Other lengths can be supplied on request. For the connection of the cores we recommend our BARTEC Ex Mini-terminals.

Limit switch plastic encapsulated

-

Besides the metal-enclosed precision switch of the RET series, BARTEC also offers a series of limit switches with plastic bodies. The enclosure is made of shock impact resistant proof plastic providing an IP 65 protection class according to IEC/EN 60529. Due to its format several limit switches can be mounted in tandem formation requiring very little space. This allows a multiple triggering of switching operations. The connection cable is equipped with a strain relief device, prewired and safely cast into the enclosure by means of epoxy resin. We supply this robust limit switch with a standard length of 3 m; special lengths are available on request.

The integrated switching element changes over via NC contact with positive break operation. Operator protection corresponds the the GS-ET 15 requirements. Its high vibration resistance and long life are the result of a most extensive laboratory research. The certification for hazardous areas and the high protection class granted thanks to its structural characteristics are the ideal prerequisites for its use in almost all fields of automation, mechanical and high-tec engineering.

Limit switch metal encapsulated

-

Limit switches of the RET range are metalencapsulated precision switches with a robust and compact explosion-proof structures.

Our connection cable comes prewired, is equipped with a strain-relief device and safely cast into the enclosure.

We supply this robust limit switch with a standard cable length of three meter. Special cable lengths and switches with lateral cable outlets are available on request. The integrated basic switch has a single-pole changeover contact with high switching accuracy and a precise repeatability of the switching point.

Its high vibration resistance and long mechanical life are the result of extensive laboratory tests. The high protection class, IP 67, allows the switch to be used in nearly all fields of automation, mechanical and high-tec engineering.

Position switch Aluminium

-

All dimensions and actuating elements of the Ex d position switch correspond to the DIN EN 50041 standard.

Its 30 x 60 mm mounting dimensions make the switch directly compatible to the position switch corresponding to the same DIN standard. The switch is equipped with snap-action contacts with several switching element versions. A microswitch with connection cable Type 07-2511 is mounted as switching element.

Different actuators are available for the variety of actuating possibilities. After the removal of four screws these knobs can be rotated by 90 °C allowing so four different directions of actuation. Gold-plated or gold-nickel contacts are available for the switching of low currents of voltages.

Standard length of the connection cables are 3 m. BARTEC has designed a very extensive range of Ex e terminal boxes of polyester and aluminium for the connection of the position switch within the Ex area.

Cable Entries, Line Bushings

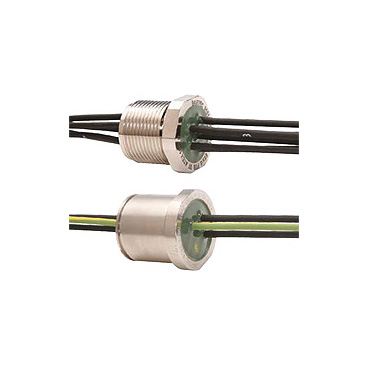

Line bushings

-

A line bushing is a component for the electrical connection between a flameproof “d“ enclosure and an increased safety “e“ terminal box. The bushing consists of a threaded or non-threaded metal sleeve encapsulating one or more cores providing a flameproof barrier. The lengths of these leads vary according to their applications. The depth of engagement of the threaded sleeves and the joint length of the cylindrical sleeve in the wall of the “d“ enclosure must correspond to the EN 60079-0 and EN 60079-1 standards. After installation the bushing must be protected against rotation and accidental loosening. Recommendations are given under “Accessories“. Our standard bushings come with threaded sleeves from M10 to M48 or with cylindrical sleeves. They are equipped with cores with a 0.2 to 95 mm2 csa. and approved for nominal voltages between 250 V and 3 000 V. See also table “Electrical data“.

For the connection of intrinsically safe circuits in the “d“ area with the terminal strip in the connection compartment we provide line bushings with blue cores for “i“ low power circuits.

Bushing conductor studs 690, 1000 and 1600 Volt

-

A bushing conductor stud is a component with which the electrical connection between an enclosure in type of protection “Flameproof enclosure d“ and its connection enclosure in type of protection “Increased Safety e“ is established. The cable bushing includes a threaded metal sleeve, a ceramic insulation, terminals and a stud. Standard threaded sleeves from M16 to M42 are included in the delivery of bushing conductor studs.

The diameter of the stud depends on current and the terminal size on the cable diameter. Thanks to different types of terminals, vertical as well as horizontal cable connection is possible. Special terminals are available on request. After installation, the bushing conductor stud needs to be secured by means of a nut or adhesive to prevent self-loosening.

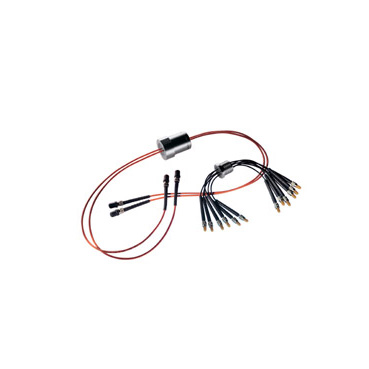

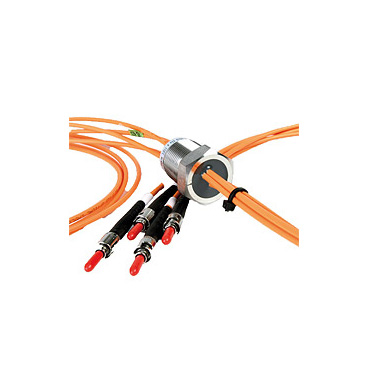

Optical fibre bushings

-

The optical fibre bushing is used as an optical fibre cable entry into flameproof enclosures located in hazardous areas. They can also be supplied with plug-in connectors.

The optical waveguiders - also known as fibres - are made of glass and resist to mechanical, climatic, chemical and electromagnetic influences. The optical waveguide is most commonly used for carrying signals in the form of electromagnetic waves in the frequency range of visible light.

The type and structure of the cable determines its transmission properties.

Electrode line bushing explosion-proof and pressure-sealed

-

Waste water pumps can be fully submergible units. The pump assembly and motor are often separated from each other by an oil fore-chamber sealed by mechanical seals. Any leaks in the shaft seals need to be registered in order to prevent malfunctions or failure of the motor and to arrange for inspections in good time.

BARTEC’s electrode line bushings Ex + sealed allow signals to be reliably transmitted through the walls of pressure-proof enclosed operating equipment, even in areas in which an explosion hazard exists. Only electrical circuits certified as intrinsically safe may be connected to the electrode line bushing.

Bushing explosion-proof and pressure-sealed

-