- Offer Profile

-

The ALFOTEC Group develops, designs, manufactures and supplies durable conveying elements and conveyor systems for internal material handling, automation of manufacturing processes and warehousing. With this range of products and services, which is complemented by comprehensive customer-oriented services, the ALFOTEC Group is successful throughout Europe.

A big advantage of the group of companies is the flexibility and the know-how, even for complex projects, which we accompany from consulting to after-sales service.

ALFOTEC Conveyor systems & conveyor elements

-

Tailor-made solutions from one source

For more than two decades we have been dealing with the subject of conveyor technology for general cargo. Our goal is to increase the efficiency of our customers’ internal material flows. ALFOTEC’s range of services extends from individual conveying elements and plant segments to customer-specific, turnkey conveyor systems. We accompany you holistically from the first consultation, through all planning and production steps up to commissioning, training and maintenance.

ALFOTEC stands for: Customer-oriented thinking, high consulting competence, individual complete solutions, fairness, precision, speed, know-how and internationality.

OUR PROJECTS

-

You need an efficient conveying solution?

We build them tailor-made to your requirements

Here we show you realized projects with which we have promoted the success of our customers e.g. from the tire, steel and electrical industry as well as plant and mechanical engineering

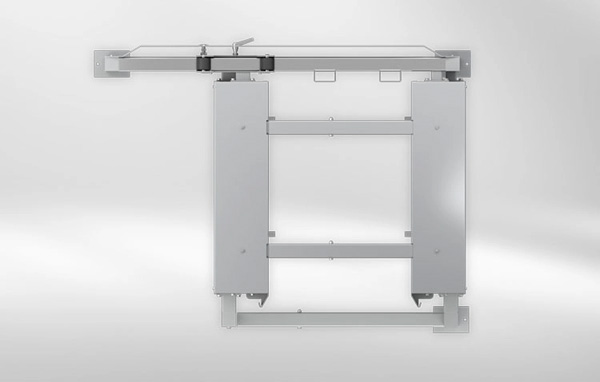

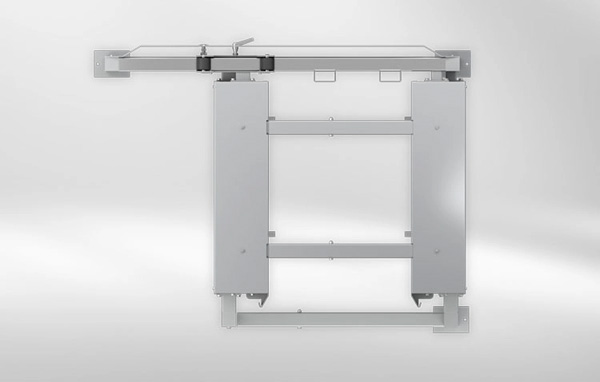

Assembly line assembly of office desks

-

The task: An ergonomic assembly line

In a new plant, which the REISS company built in Lausitz, the innovative but also ergonomic idea of the company was to be continued. For this reason, a work-friendly assembly line was conceived as a production line, on which the heavy tables were to be assembled, tested, packed and assembled ready for dispatch step by step.

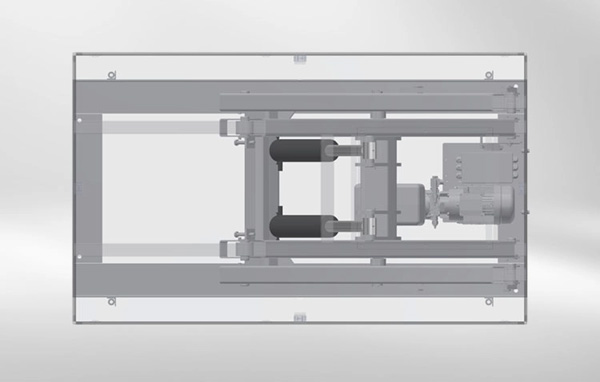

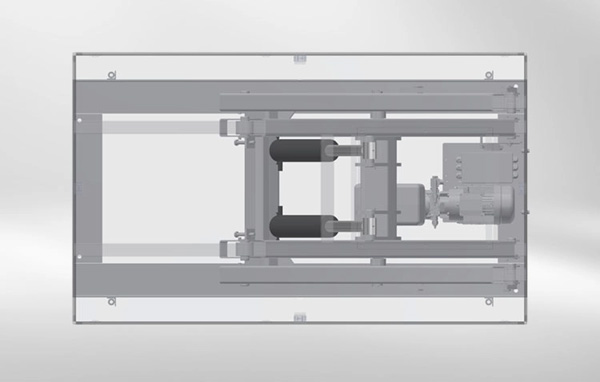

Integration into a test cell

-

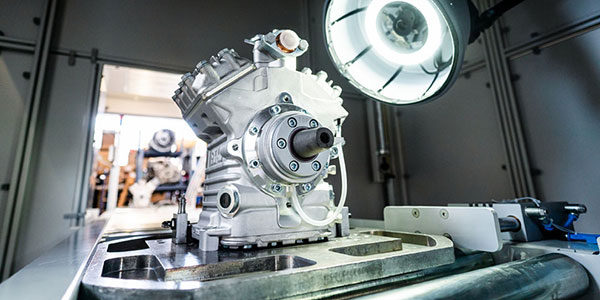

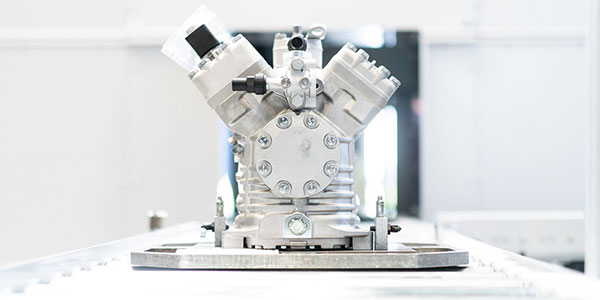

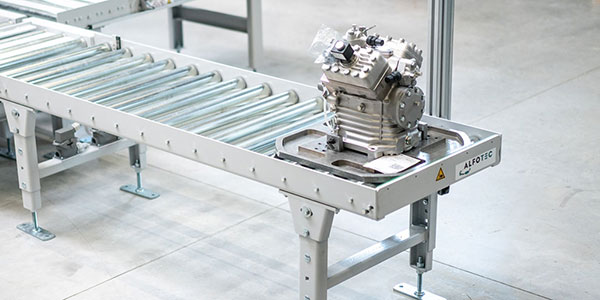

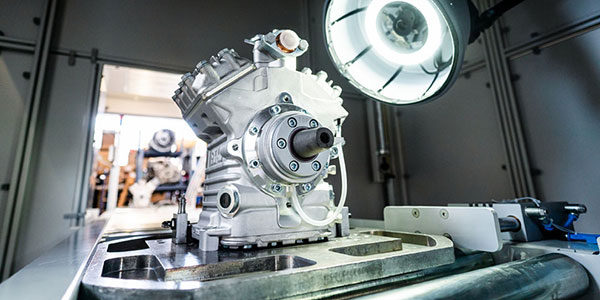

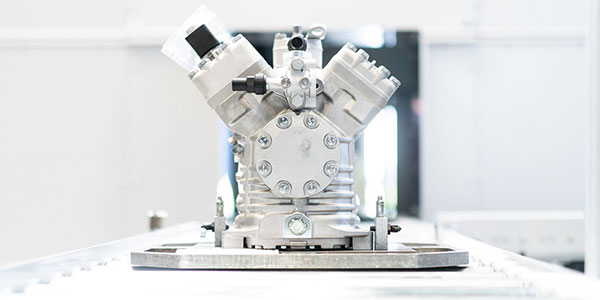

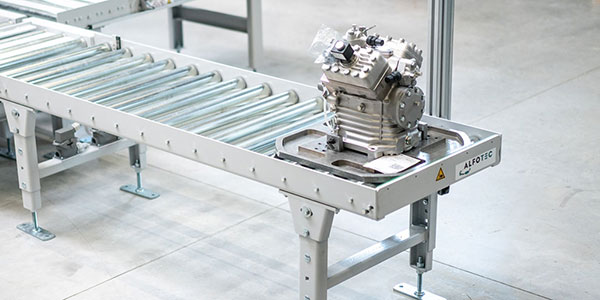

The task: Synchronisation of measuring and conveyor technology

The challenge of the project was the synchronization of the measuring and conveying technology. The task was to check various compressors or compressors for transport refrigeration in the automotive industry in the planned plant for completeness of the installed components. Subsequently, the compressors were to be distributed according to the result in an area for correct and incorrect ones in order to divide them up for further transport or for reworking.

Malaysia refreshed

-

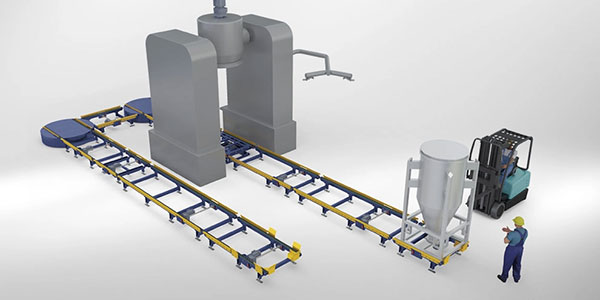

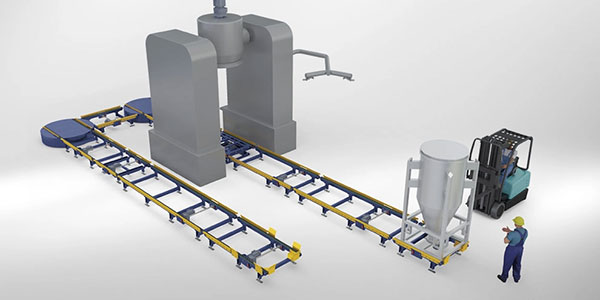

The task and special challenges

The task was to supplement an existing mixer station with a conveyor system to be developed by us in such a way that the mixing process and the transport of the material to be conveyed between the feed and take-off station could be fully automated in future – without the need for expensive conversions at the mixer station.

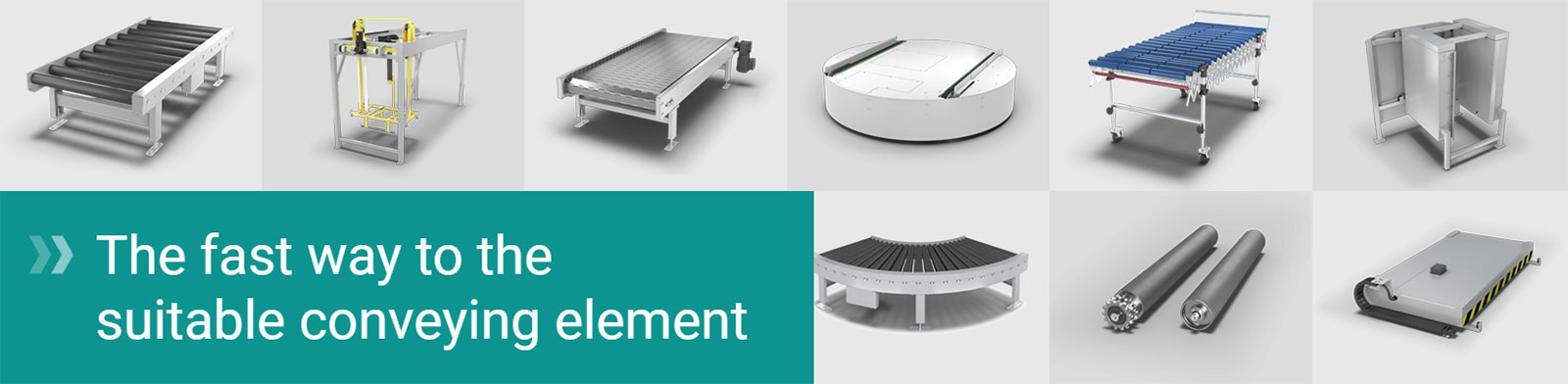

CONVEYER ELEMENTS

-

You would like to expand or optimise your conveyor system?

Find the right conveyor element now!- roller conveyer

- strand conveyer

- belt conveyer

- lifters

- converter and change of direction

- lift table

- storage techniques

- rollers, castors and factory equipment

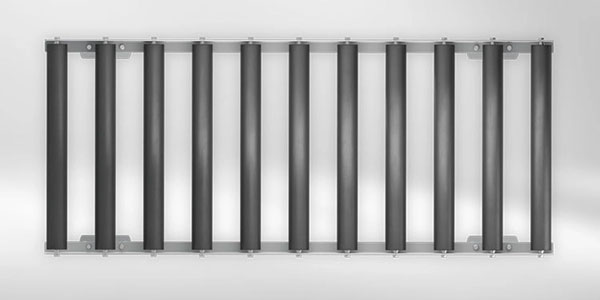

ROLLER CONVEYER

- Conveying technology

We move your goods to the millimetre With more than two decades of experience in conveyor technology, we develop, design and manufacture conveyor elements for light and heavy materials of various kinds. Such as pallets, lattice boxes, containers, bins, racks, barrels, plate stacks, workpiece carriers, glass plates, castings, motors, order-picking containers, cardboard boxes, trays, cans, perfumery articles, automotive spare parts, beverage crates, packaged food, etc.

ALFOTEC conveyor systems are produced with high precision and quality. We develop millimetre-precise, individual and practical conveying solutions that offer you maximum benefit. We manufacture ourselves and are therefore not bound to any particular system. We are also extremely flexible in terms of the number of conveying elements, whether a single piece, many identical elements or a large overall system with many different elements – with us you will always find the right partner!

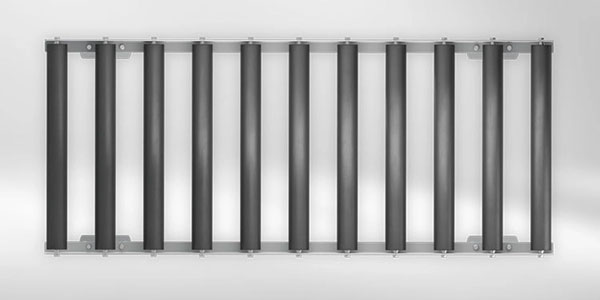

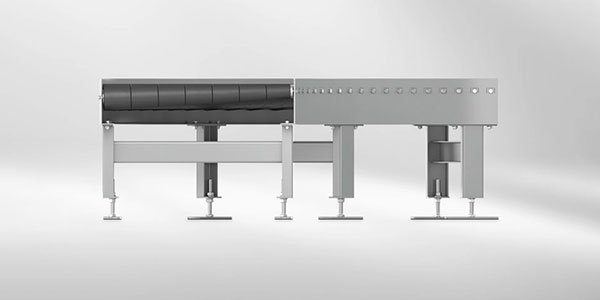

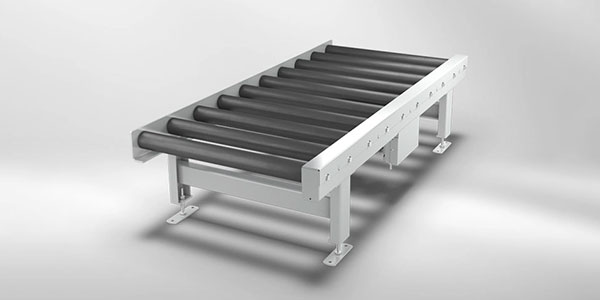

Roller conveyor non-driven

-

We find roller conveyors – non driven – almost everywhere. In the warehouse, during packaging, in incoming goods, outgoing goods, everywhere where people still want to pick up and move parcels and other goods. All roller conveyors consist of three basic components: frames, support rollers and, if required, supports. In order to ensure good stability, the idlers are always bolted together, which means that the conveyor rollers can carry maximum loads and can be easily replaced during maintenance.

Suitable for:

- Pallets

- Cardboard boxes

- Plastic crates

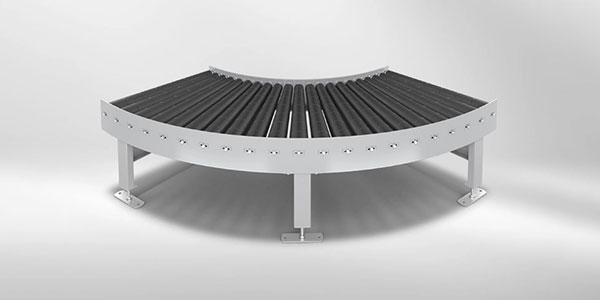

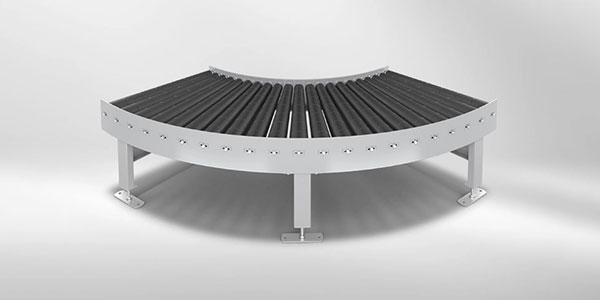

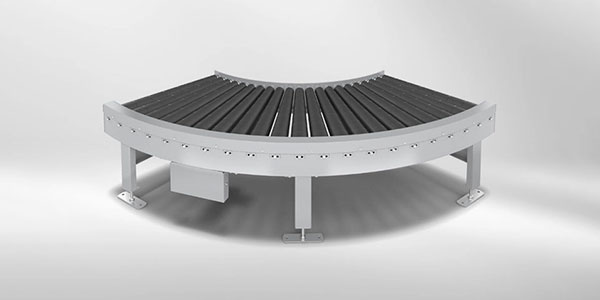

Roller conveyor curve non-driven

-

Curves – non-driven – complete the roller conveyor program and are ideal for the use of light conveyed goods, such as cardboard boxes, plastic crates, tires and various other transport items. The curves are adapted and designed in size according to the goods to be conveyed and the weight, as well as the elements in front and behind them. Possible are 45°, 90°, 180° or any other degree. As with roller conveyors, the curves consist of 3 basic components: frames, support rollers and, if required, supports.

Suitable for:

- Cardboard boxes

- Plastic crates

- Bucket

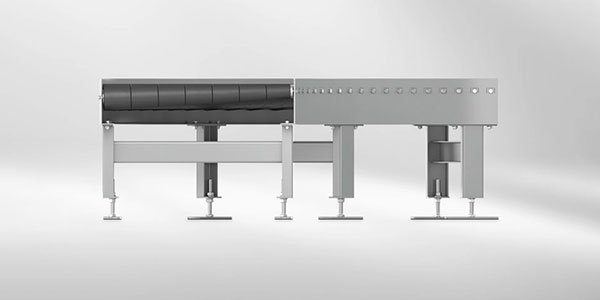

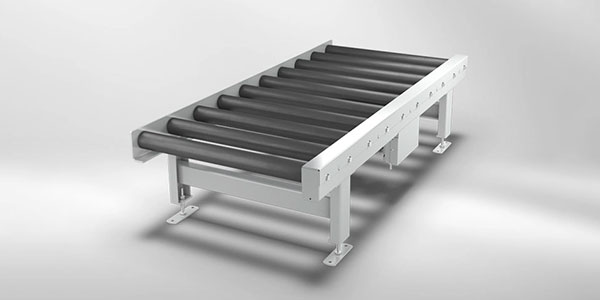

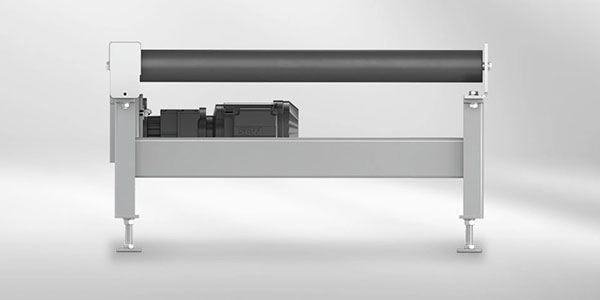

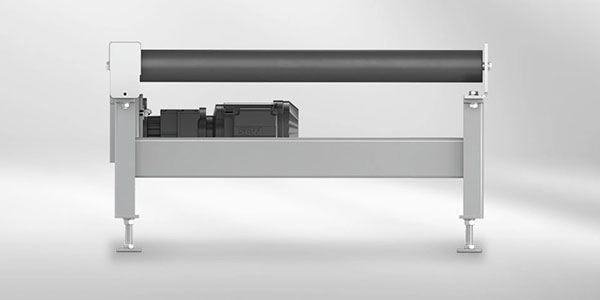

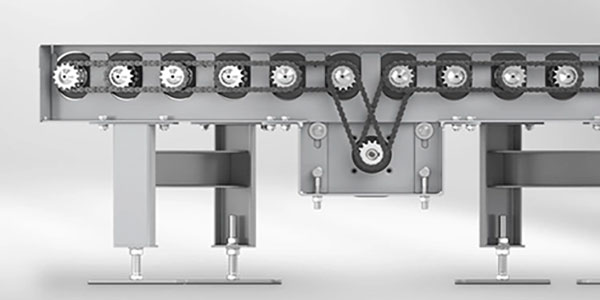

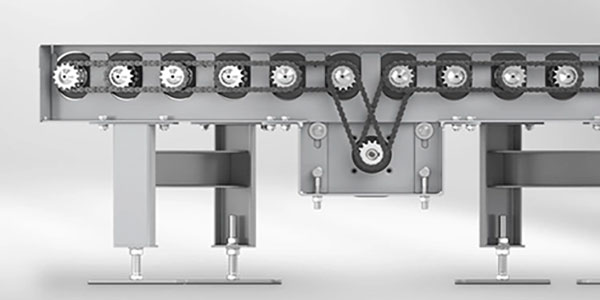

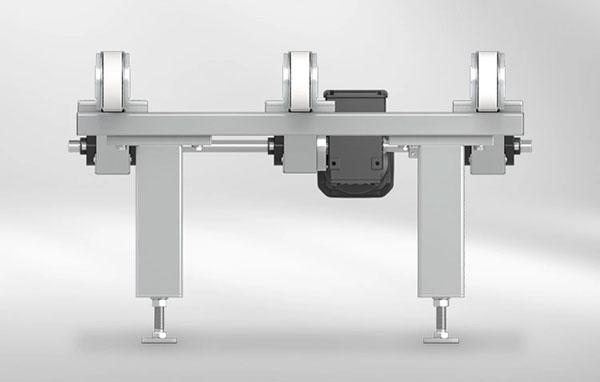

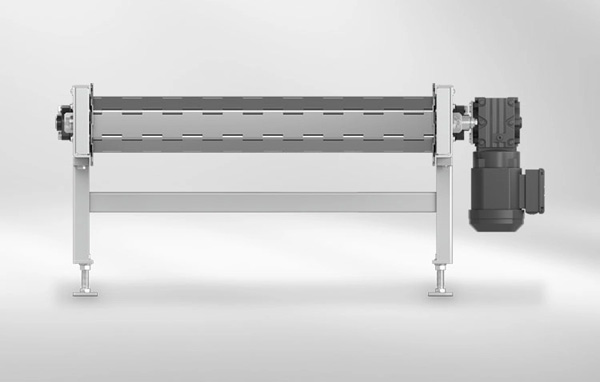

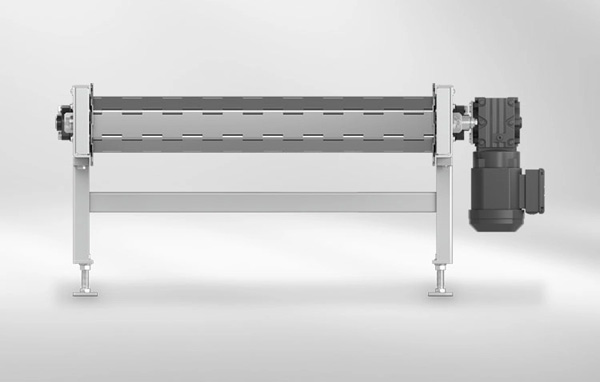

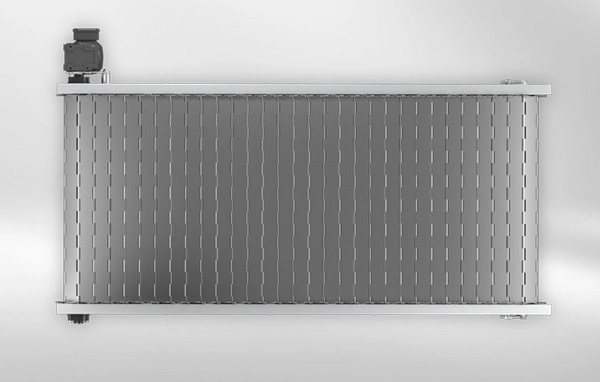

Roller conveyor chain drive

-

Due to their efficiency, roller conveyors are very often used in conveyor technology. Pallet transport is typical, provided that the pallets are transported in longitudinal direction. Depending on the dimensions and weight of the goods to be conveyed, the optimum design is constructed. The basic model is the same for all roller conveyors: frame, supports, support rollers, and motor station with gear motor. The carrying rollers are driven by double chain wheels from roller to roller and guarantee an optimal power transmission via chain circuits.

Suitable for:

- Pallets

- Workpiece carrier

- Cardboard boxes

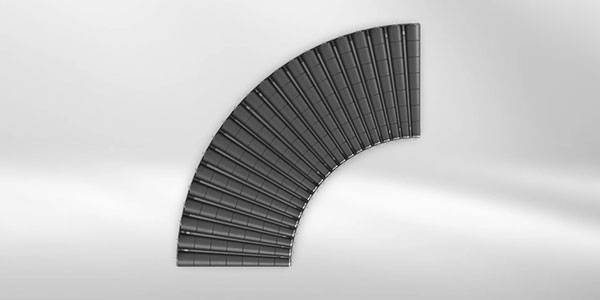

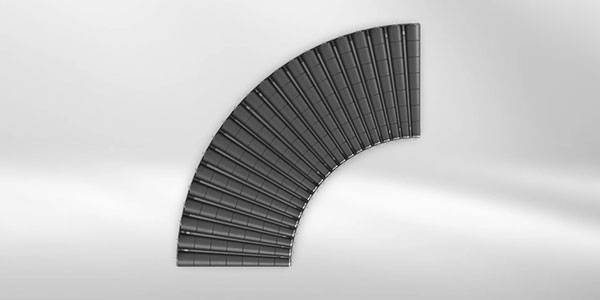

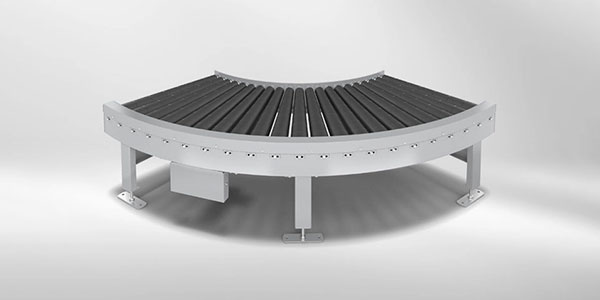

Roller conveyor curve chain driven

-

Curves – with drive – complete the ALFOTEC roller conveyor programme. Optimal for the use of light goods to be conveyed, such as cardboard boxes, plastic crates, tyres, various other transport items. The curves are adapted and designed in size according to the goods to be conveyed and the weight, as well as the elements in front and behind them. Possible are 45°, 90°, 180° or any other degree. The carrying rollers are driven by double chain wheels from roller to roller and guarantee an optimal power transmission via chain circuits.

Suitable for:

- Cardboard boxes

- Plastic crates

- Barrels

Scissor roller conveyor

-

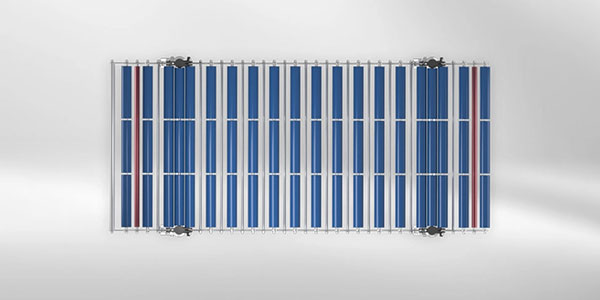

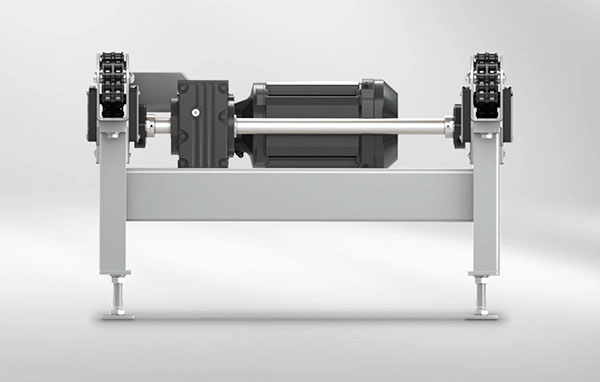

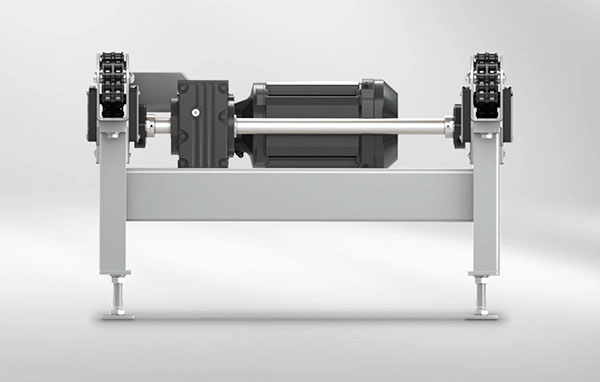

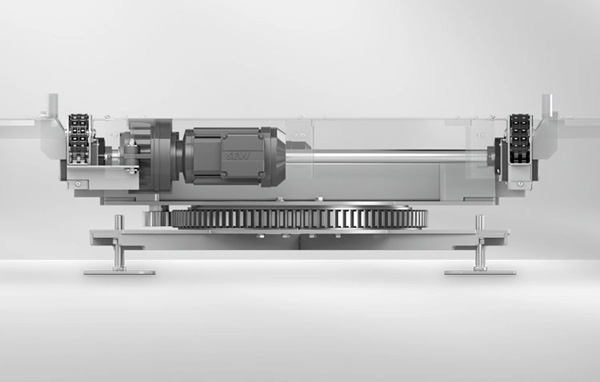

Strand conveyors are continuous conveyors. They are used, for example, for the (transverse) transport of heavy unit loads such as pallets, mesh boxes, crates or large plastic canisters. We offer robust chain conveyors, toothed belt conveyors with two strands and more (depending on customer requirements) and a round belt conveyor. All ALFOTEC strand conveyors are driven by a three-phase asynchronous geared motor.

Depending on the load, we use single, duplex and triplex steel chains with a material thickness of 1/2″ to 2″ as standard. If the strands do not need to be adjustable in width or height, we connect them together with a shaft. For extremely heavy designs we use cardan shafts or equip each strand with its own motor.

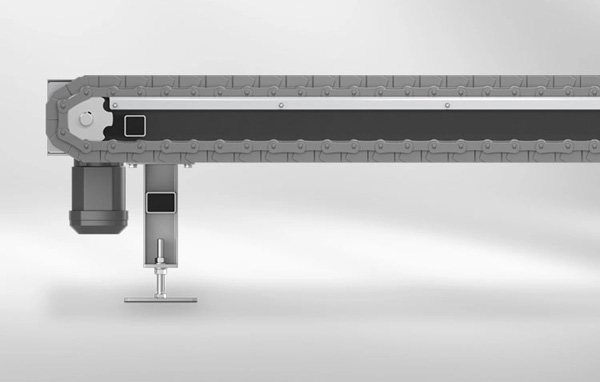

STRAND CONVEYER

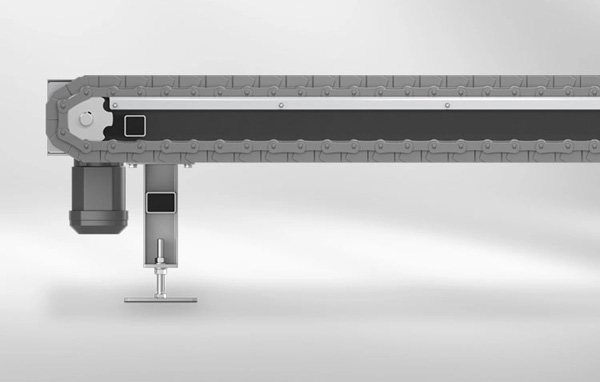

Chain conveyor

-

Suitable for the cross transport of pallets and other conveyed goods

Chain conveyors are typical for the transverse transport of pallets and other conveyed goods with small contact surfaces, such as mesh boxes or steel frames with only a few support points. Double or multiple strand chain conveyors with different roller chains are used. As a rule, duplex chains according to DIN 8187 / ISO 606 are used, and triplex chains are also used for particularly heavy duty applications. The dimensioning of the chains is individually designed according to the mass of the transported goods, the number and size of the support points or according to special applications.

Suitable for:

- Box pallets

- Workpiece carrier

- Long materials

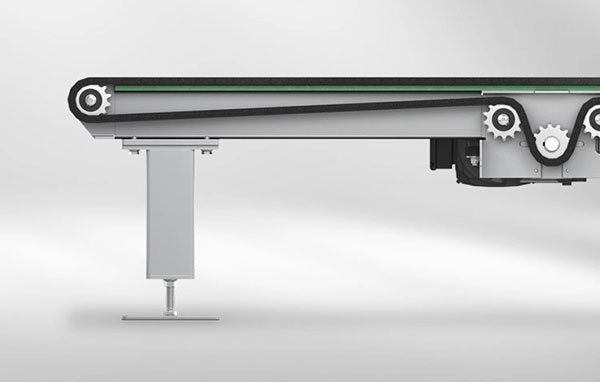

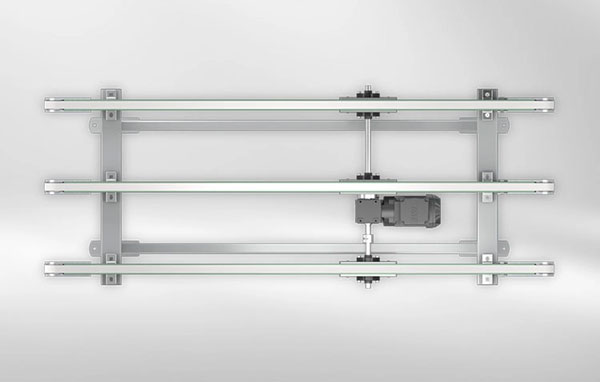

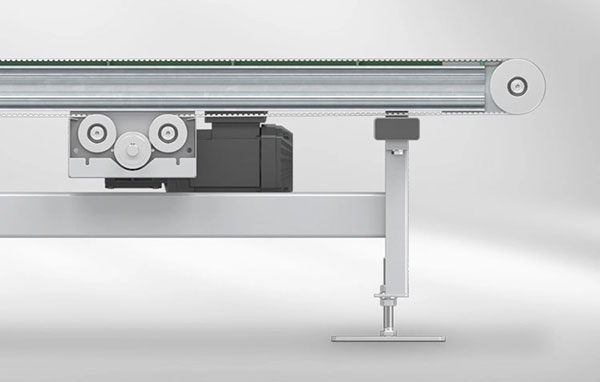

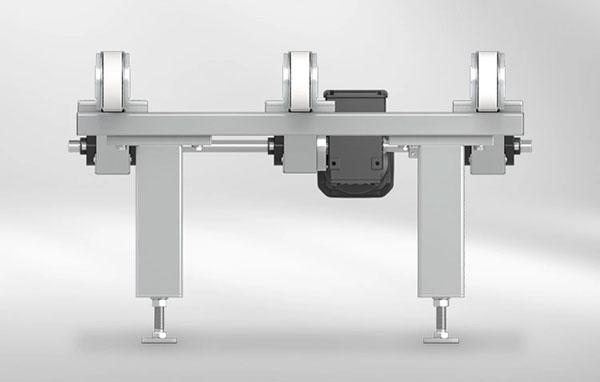

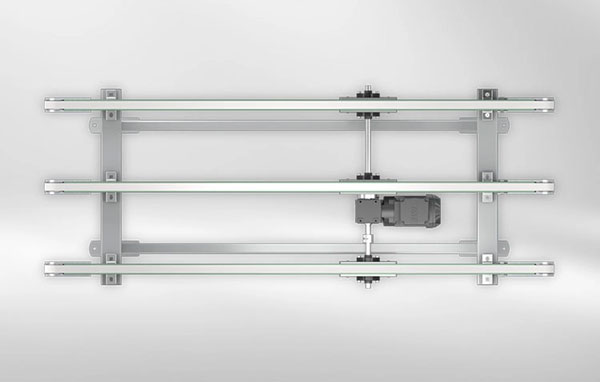

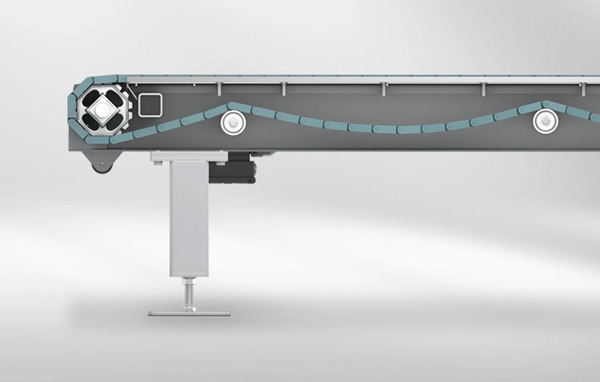

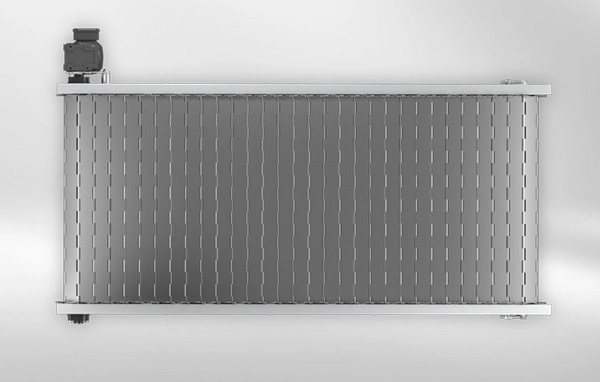

Toothed belt conveyor

-

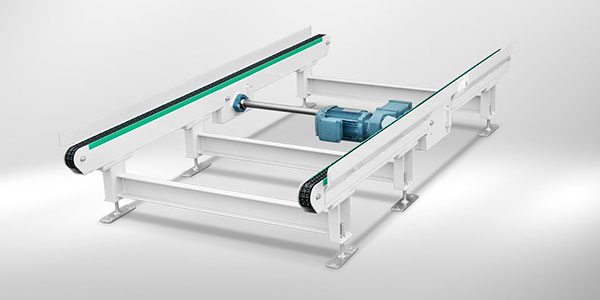

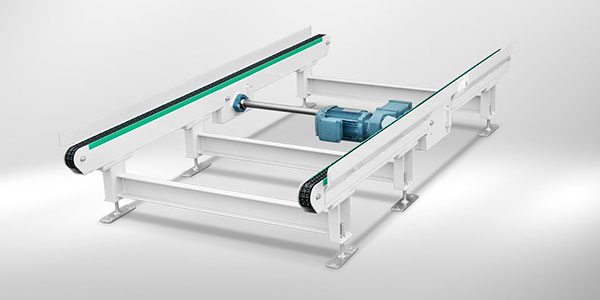

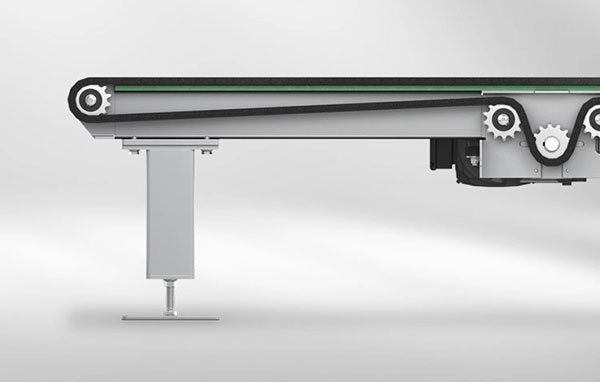

Belt conveyors are continuous conveyors. We offer belt conveyors in three designs: as belt conveyors – also double-deck – for loads of up to 200 kg per metre, as apron conveyors with open and closed plastic apron belts and as apron conveyors.

All ALFOTEC belt conveyors are driven by three-phase asynchronous geared motor and chain.

BELT CONVEYER

Belt Conveyor

-

Belt conveyos with closed plastic fabric belts transport your goods quickly and quietly. Whether uphill or downhill, they are universally applicable for all light and medium-heavy goods to be conveyed. Especially small, curved and differently sized parts, which cannot be moved on a roller conveyor or a string conveyor, find their optimal transport route here. Possible transport goods include small hand tools, cans, bags and furniture as well as smaller items such as screws or nuts.

Suitable for:

- Small parts

- Tyres

- Furniture

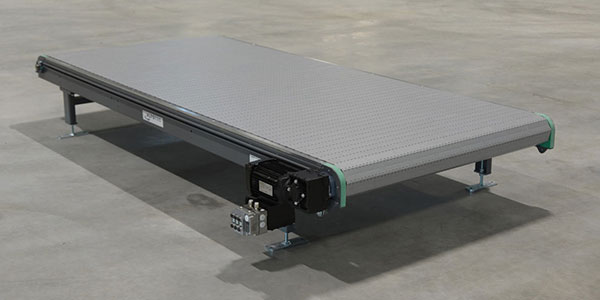

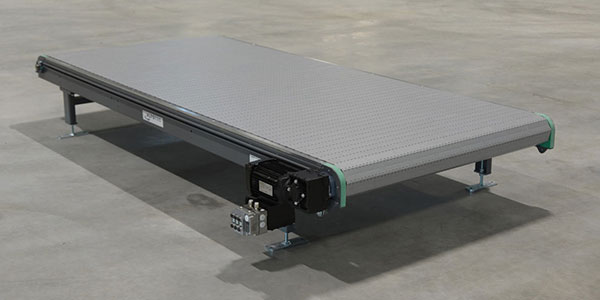

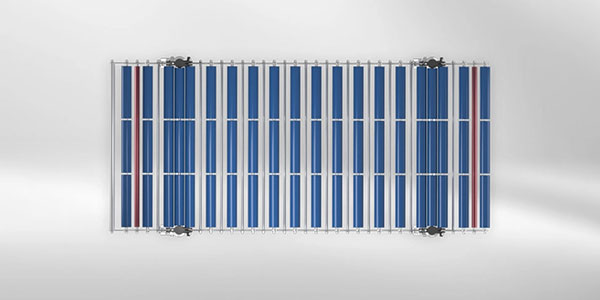

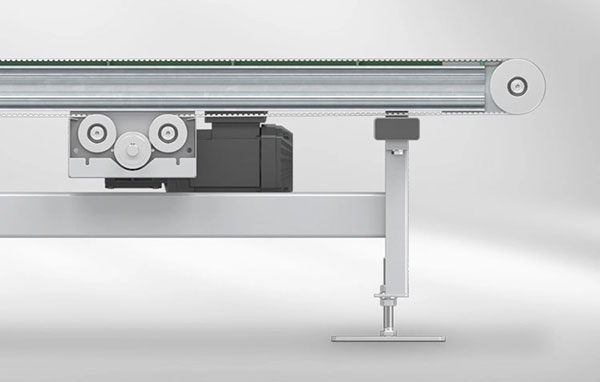

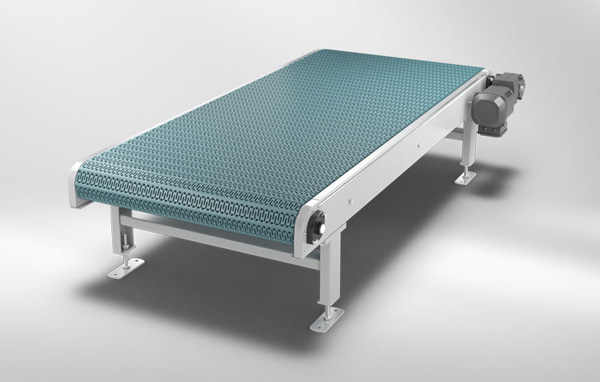

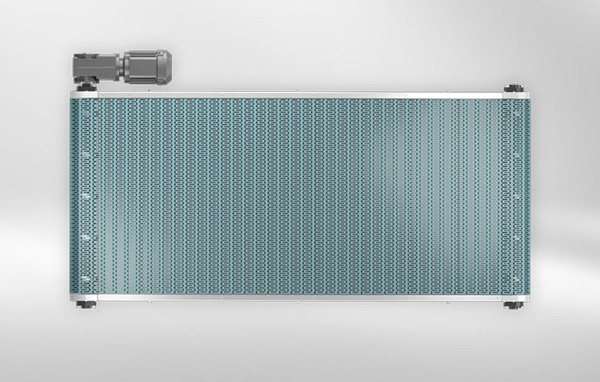

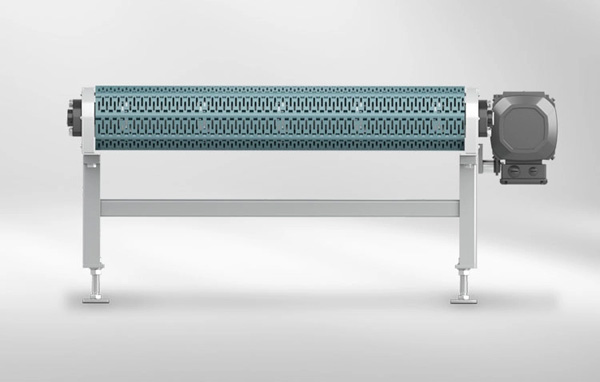

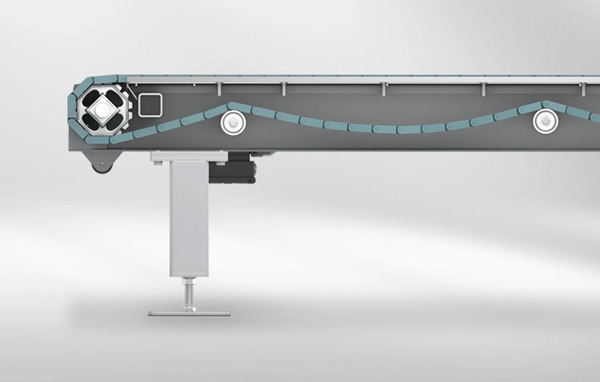

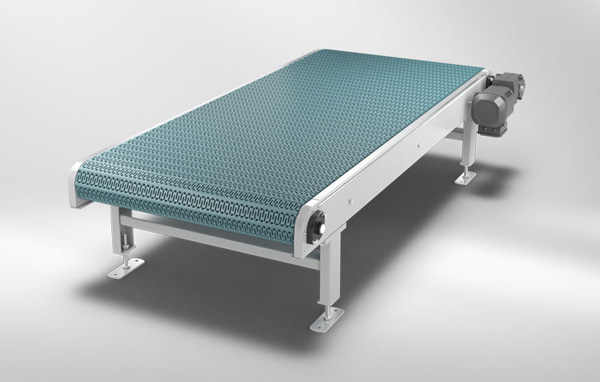

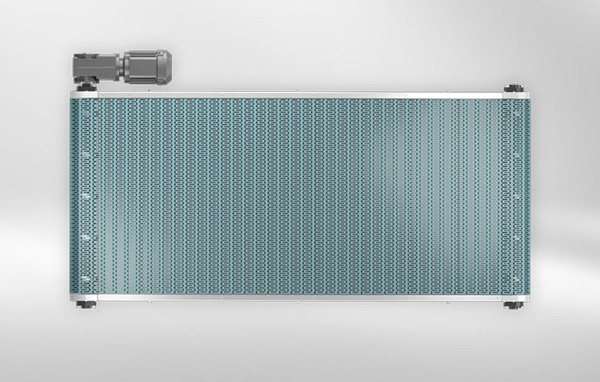

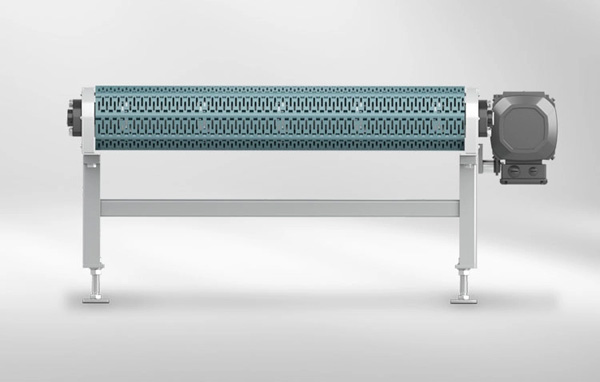

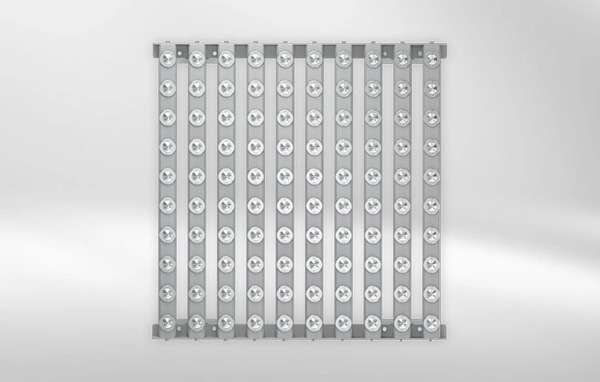

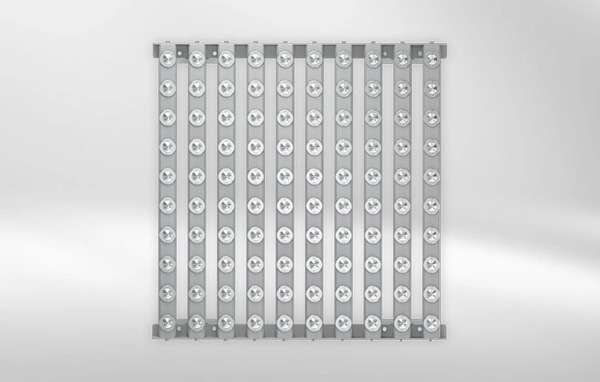

Plastic modular belt conveyor

-

Plastic modular belt conveyors are universally applicable, no matter whether light or heavy goods, area or point loads are involved. Whether cold or hot, small or large – almost any goods can be transported. Wherever the ALFOTEC belt conveyor reaches its limits, the ALFOTEC steel plate conveyor can usually provide the solution. Plastic modular belt conveyors can transport uphill or downhill and are truly multi-talented. In addition to a harmonious appearance due to the selection of different belt colours, these conveyors are very low-maintenance.

Suitable for:

- Big Bag

- Oily small parts

- Conveyed goods with heavy point loads

Steel plate conveyor

-

Steel plate conveyors are designed for special applications and complete the ALFOTEC programme. The belts consist of several steel plates connected by hinges and are suitable for materials with extreme properties: e.g. high temperatures, heavy soiling, sharp-edged contours, contaminated with milling chips, moisture or emulsions. The belts are driven on both sides by single chains, sprockets and three-phase geared motor.

Suitable for:

- Oily small parts

- Hot conveyed goods

- Sharp-edged stamped parts

CONVERTER AND CHANGE OF DIRECTION

-

In conveyor technology, it is not always possible to go straight ahead. That’s why our range of services includes conveying elements that guarantee that every conveyor system gets around the bend. Like our revolving platforms, driven by roller conveyors, or two- or three-strand chain conveyors or toothed belt conveyors.

In addition, we offer roller conveyor curves, ball roller tables and transfer cars for the purpose of changing direction.

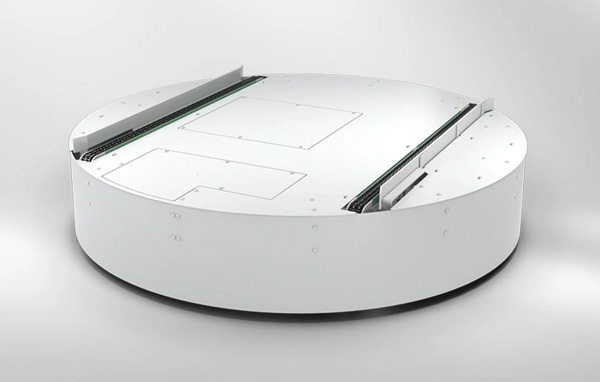

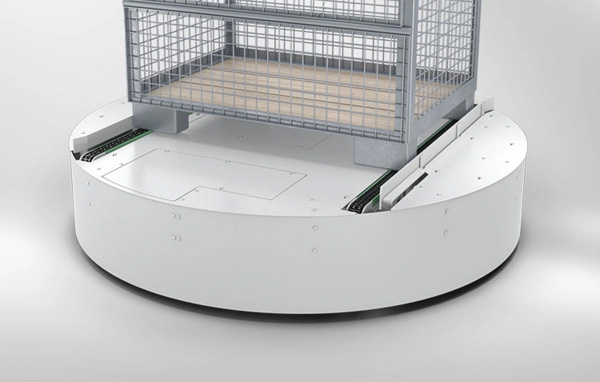

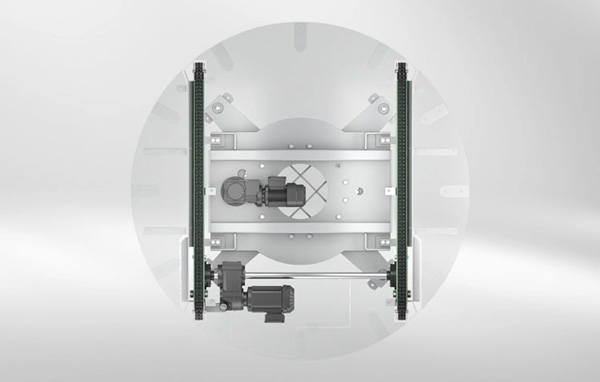

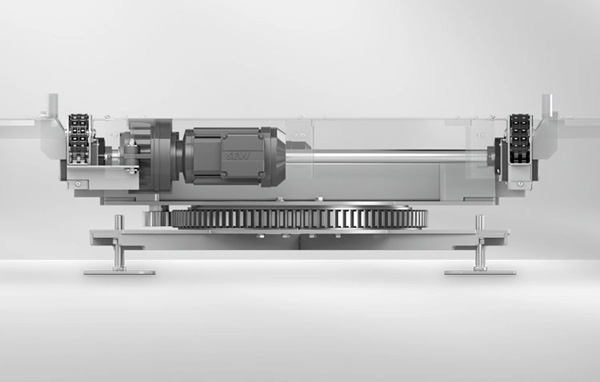

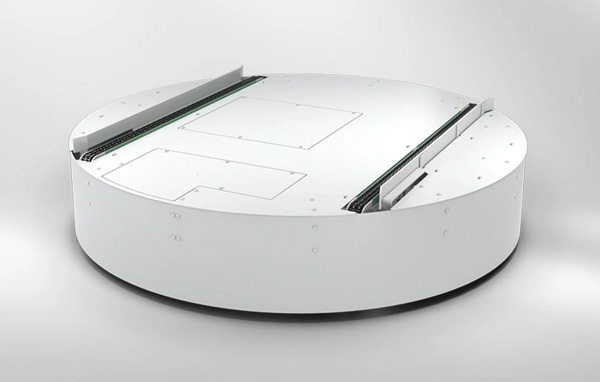

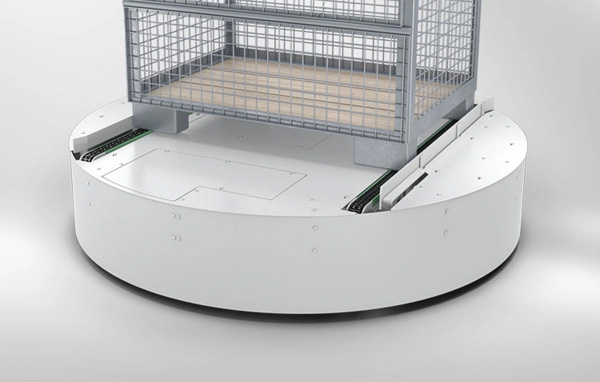

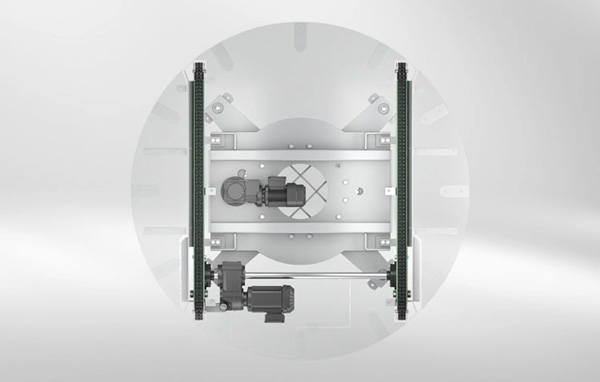

Turntable conveyor

-

Turntable conveyors are characterized by their ability to turn even heavy goods weighing several tons and thus change the direction of transport. The suitable conveying element (e.g. roller, strand or belt conveyor) is placed on the turntable or integrated. Turntable conveyors do not require a lot of space, they can be set up in the tightest of spaces. Where necessary, a full enclosure guarantees safe turning. A simple operation by handle is possible for manual revolving platforms, but a motor-driven version can also be realized.

Suitable for:

- Changing device for e.g. robotic cell

- Structure of various conveying elements

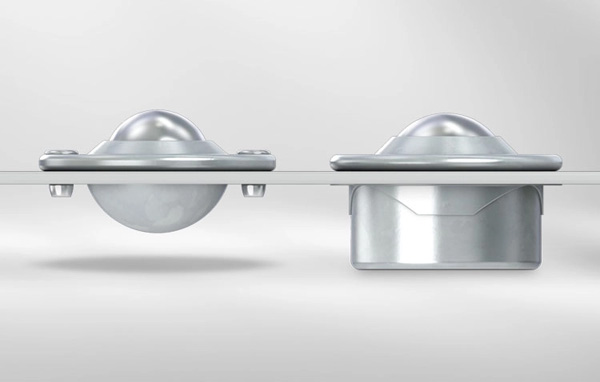

Ball transfer table

-

On a ball transfer table, the conveyed material can be moved in all directions – provided it has a smooth, closed and even running surface. Ball transfer units move on all sides and are mostly used for cardboard or plastic boxes during order picking, packaging or manual discharge. Furthermore, even large-area products can be simply turned or pushed by hand.

Suitable for:

- Plastic boxes

- Cardboard boxes

- Tool Changing Device

Pallet transfer shuttle

-

With the layer palletizer and the protal system, we offer you a comprehensive range of services for the most varied tasks for the formation and further processing of palletized load units. For particularly heavy demands on a buffer store in “LiFo” or “FiFo” principle, we offer a flexible and robust pallet shuttle.

Our FlexShuttle is also suitable for particularly high loads. The pallet magazine enables the stacking and unstacking of pallets onto a roller conveyor, belt conveyor or string conveyor and rounds off our range of services in the field of palletizing systems.

STORAGE TECHNIQUES

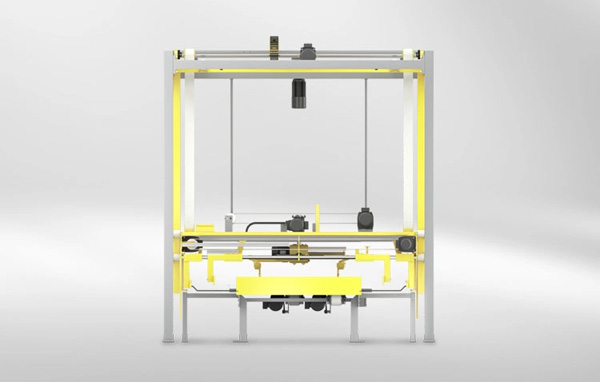

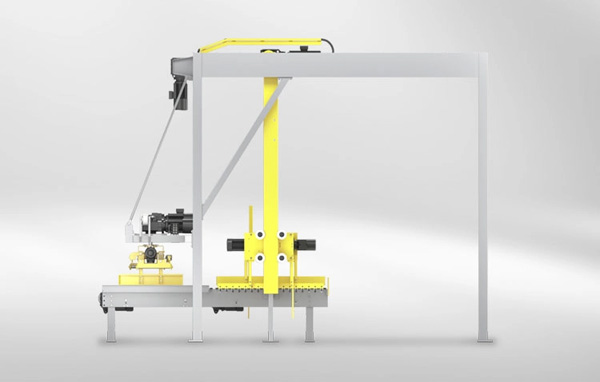

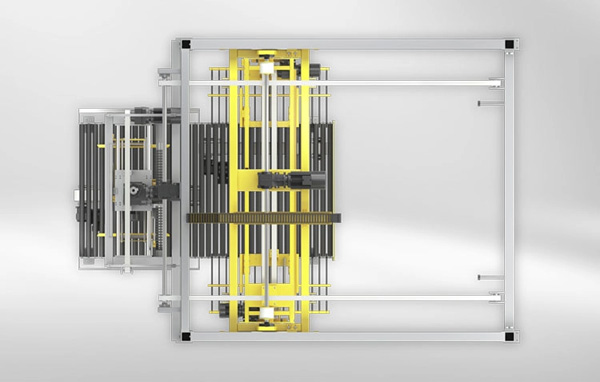

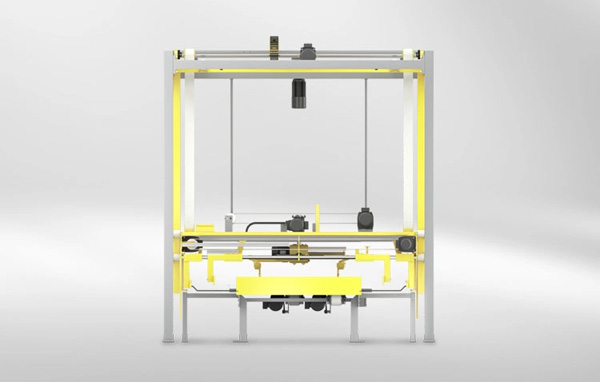

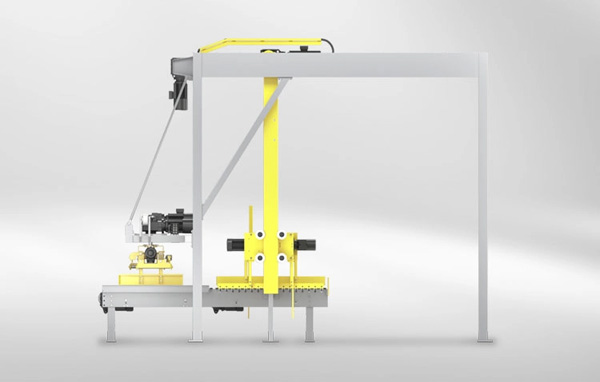

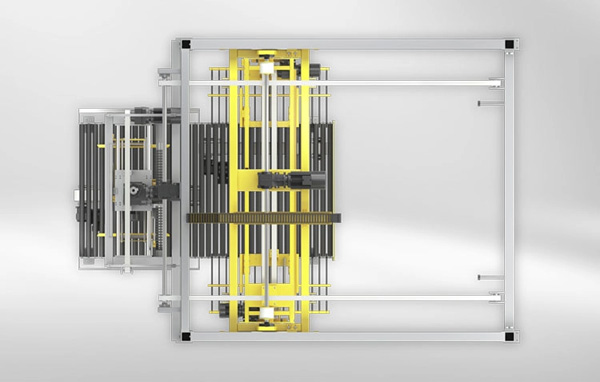

Portal system

-

The gantry system is a flexible modular system for stacking or unstacking different goods and can be used for machine loading or palletizing. The linear system consists of a stable steel construction, which can be adapted according to customer requirements and equipped with up to 4 axes. Driven by three-phase motors or pneumatic drives, power is transmitted by means of belts, running wheels or toothed rack. Individual grippers are available, whether driven by pneumatic, hydraulic, electromechanical or vacuum components.

Suitable for:

- Plastic crates

- Plasterboards

- Cardboard boxes

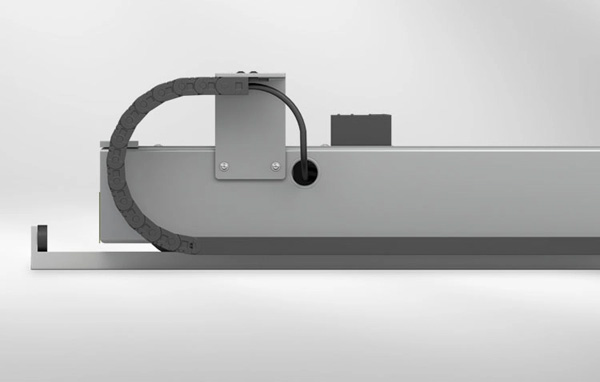

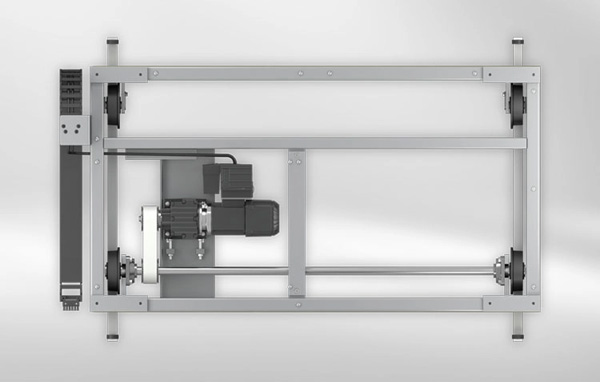

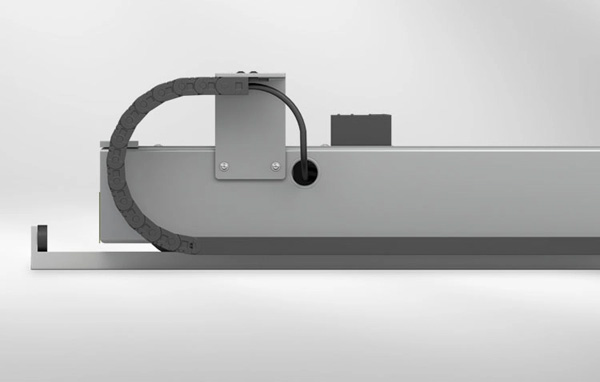

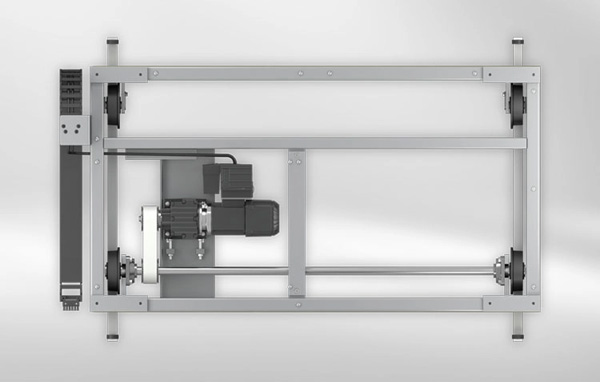

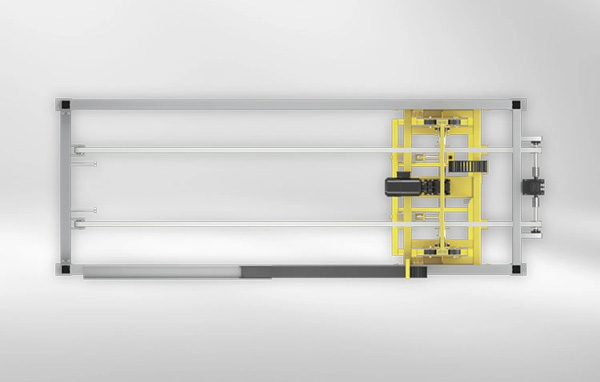

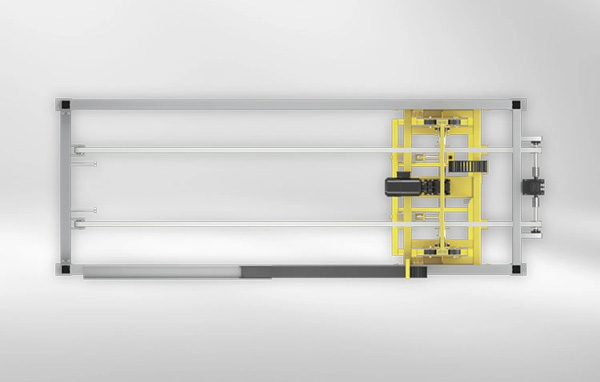

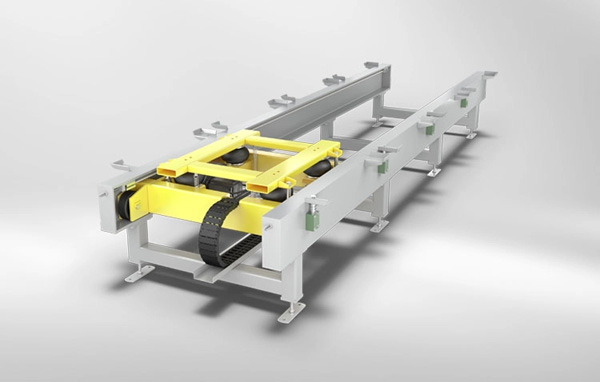

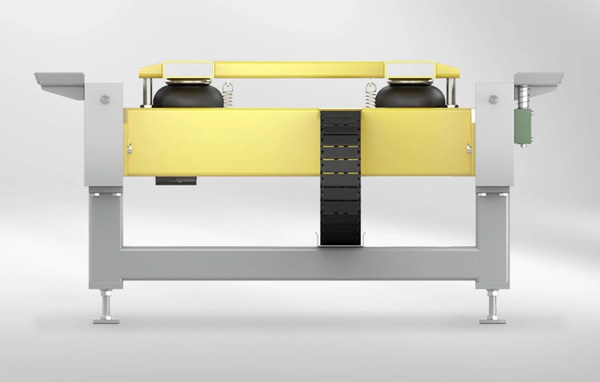

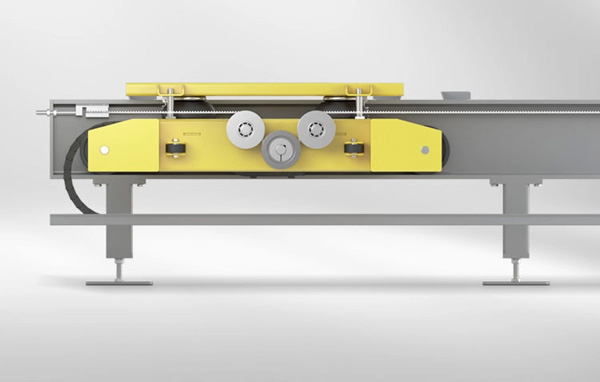

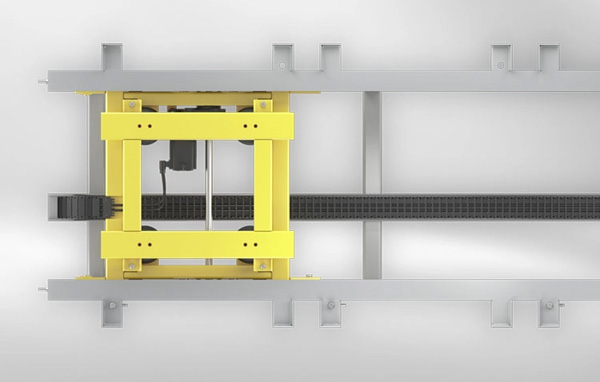

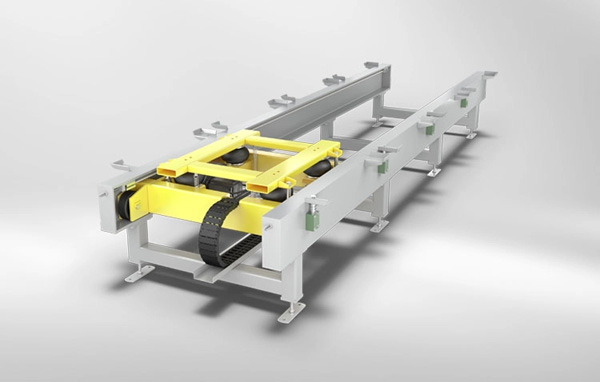

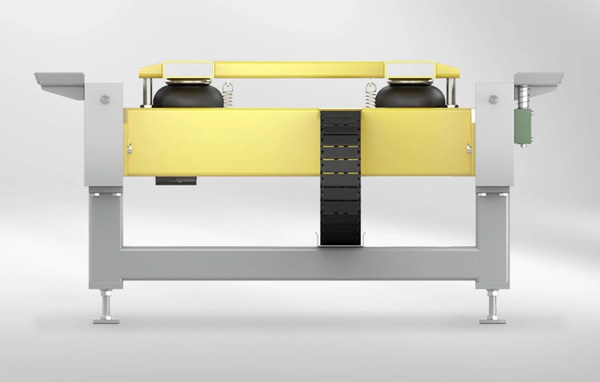

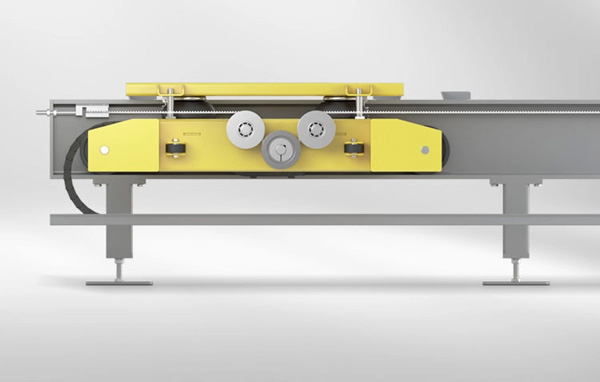

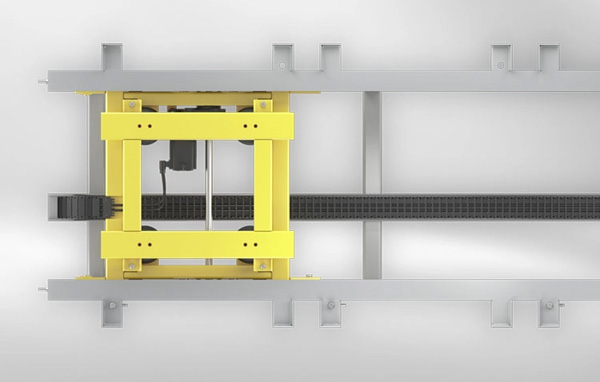

FlexShuttle

-

The Flexshuttle transports goods on an integrated carriage. Robustly designed profiles and bearings enable the transport of large loads. The servo drive of the carriage enables high transport performance and precise positioning with low noise levels. Suitable for pallets, workpiece carriers, grid boxes with single feet or other conveyed goods that are difficult to transport on other conveyors due to their contact surface.

Suitable for:

- Pallets

- Box pallets

- Steel tanks

Palletizer

-

With our palletizer we offer you a comprehensive range of services for the most varied tasks for the formation and further processing of palletized load units. Due to its multifunctional design, it can handle almost all palletising tasks in your company. A multitude of additional components, e.g. for the transport of packages, empty and full pallets, for labelling and for special functions, such as a press belt for bags, complete the product range.

Suitable for:

- Grain bags

- Bags with building materials

- Cardboard boxes

Pallet magazine

-

The pallet magazine is always in connection with conveyor technology. This device can optionally have the function “unstacking” or “stacking” of pallets. Originally designed for special pallets, Euro pallets, industrial pallets and many other pallets can also be stacked without any problems. Prerequisite are open and loadable anchor points into which the gripper can enter. The loading is carried out by means of a forklift truck in longitudinal or transverse direction. During operation, the pallets are picked up or dropped off individually, the pallet dispenser is controlled by the existing conveyor system.

Suitable for:

- Special pallets

- Euro pallets

- Industrial pallets

LIFTERS

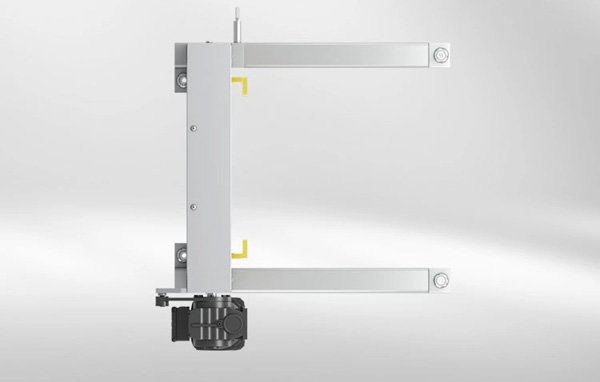

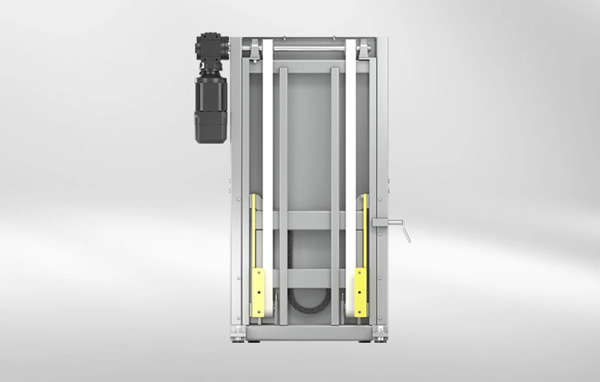

Column lifter

-

Whether with toothed belt or pneumatic drive, the universal lifter is always used when conventional lifters are too slow or the conveyor section has a too low overall height. The mounting plates allow a variety of attachments, from a support fork, to angle rails, to attached roller, string or belt conveyors, almost anything is possible. Using the example of a feed line, the lifter can be used to lift a goods carrier onto the return or to separate conveyed goods. Furthermore, the transfer from an AGV to a conveyor line is possible.

Suitable for:

- Roller, strand or belt conveyors

- Pallets or racks

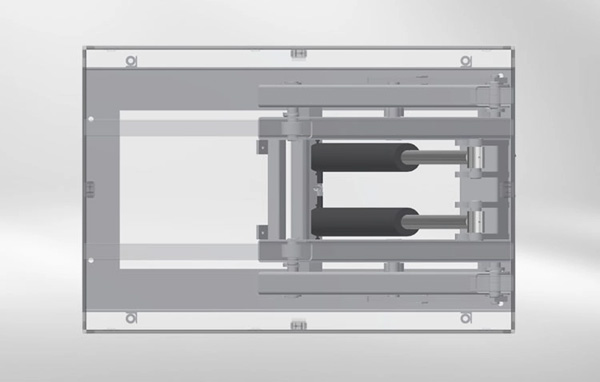

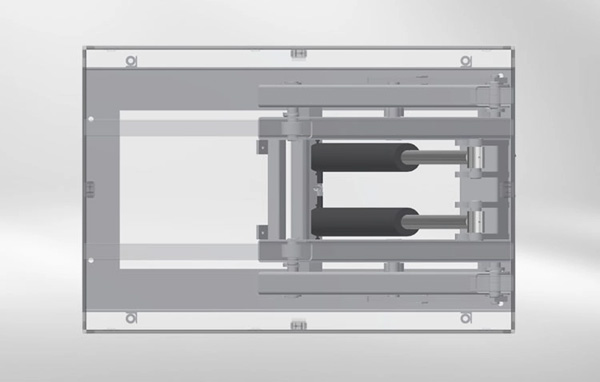

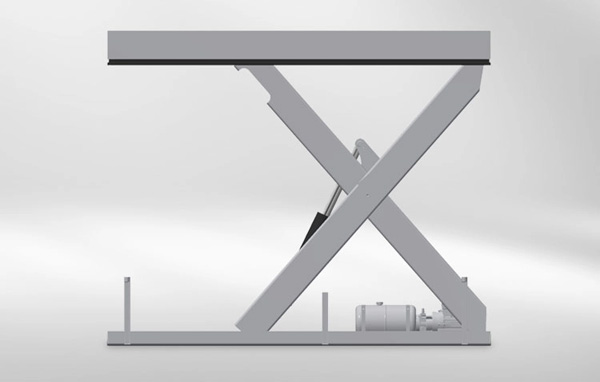

LIFT TABLES

-

ALFOTEC lifting tables adapt to their purpose, we distinguish between single, multiple and tandem lifting tables, which differ in platform length and lifting height. In addition, our car lift tables are designed for lifting motor vehicles. Our loading lift tables are suitable for the robust use at the loading ramp. U-shaped and flat-shaped lifting tables round off the range. We integrate lifting tables very often and gladly into our conveyor solutions.

An important reason for this is the improvement of work processes from an ergonomic point of view, which in turn avoids health problems and unnecessary costs. Numerous additional options make it possible to adapt our hoists exactly to your requirements. High-quality materials and components, solid workmanship and intelligent product details add up to a convincing product quality. Convince yourself of the quality features of the electro-hydraulically driven scissor lifts.

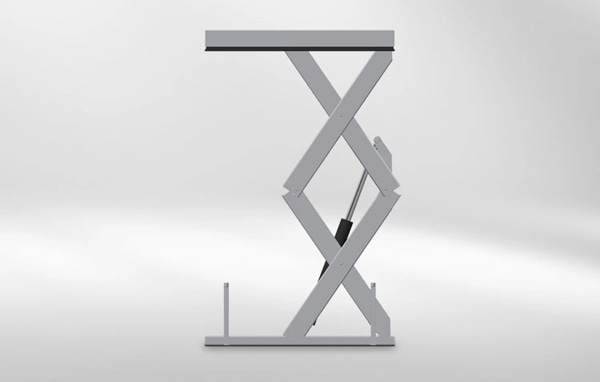

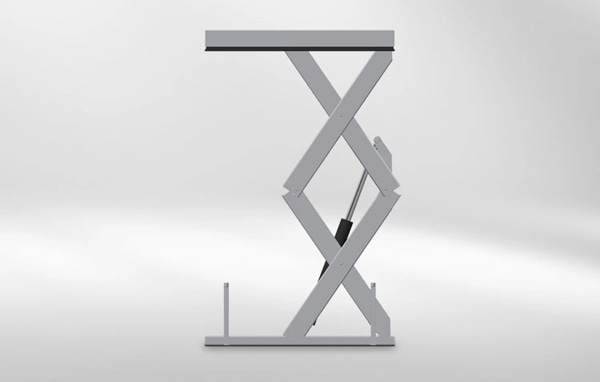

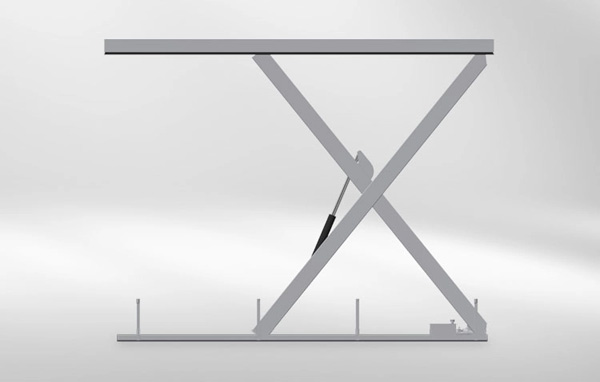

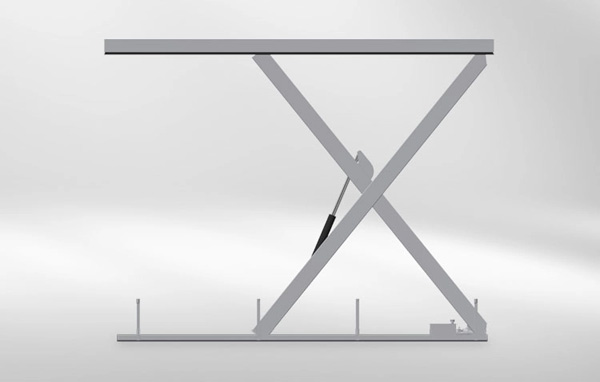

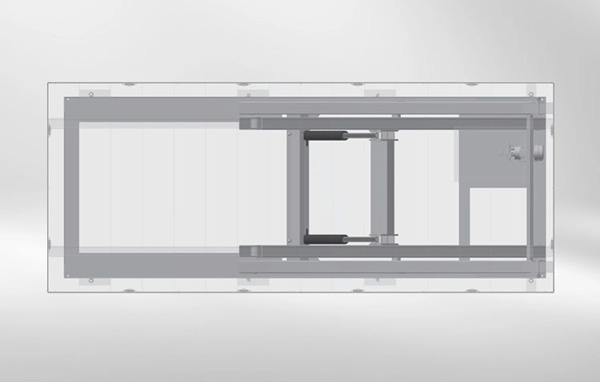

Single scissors lift table

-

The electro-hydraulic single scissors lift table is a lifting unit with a scissors package and is the basic model of the lift table series. The scissors lift table has a wide range of applications and is used, for example, in production and logistics when height differences have to be compensated. As standard, this lift table is designed for a maximum of 25 cycles per hour in 1-shift operation. On request, we can supply and install the optimum solution individually according to your requirements and application.

High lift scissor lift table

-

The electro-hydraulic high lift scissor lift table is a lifting unit with superimposed scissors packages. This has the advantage that if the stroke is doubled, the platform dimensions do not need to be changed. This lifting table can be used as a working platform (assembly platform, no passenger transport), pallet loader or freight elevator, for example. Compared with a traditional lift, this lift table is a rational and cost-effective solution.

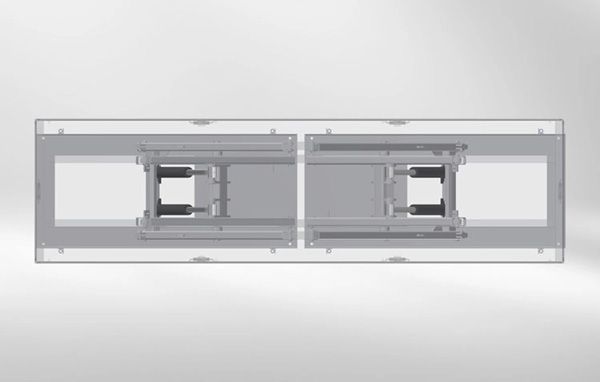

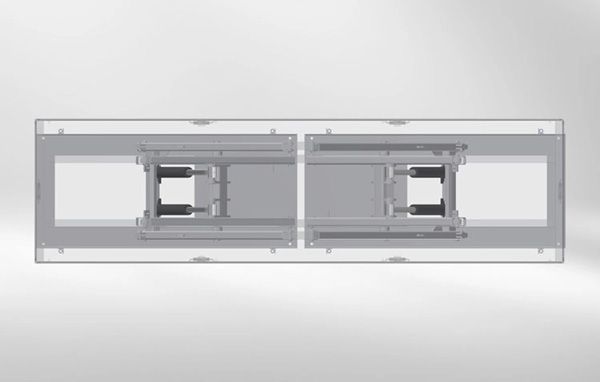

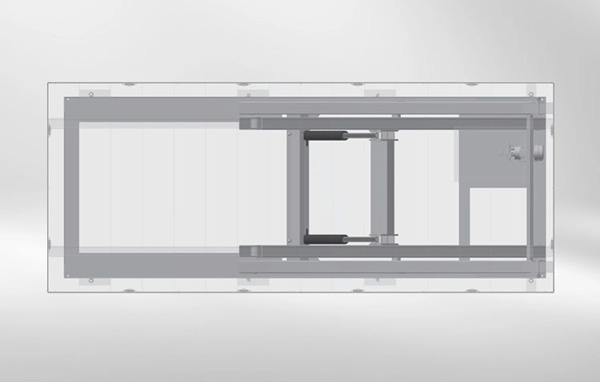

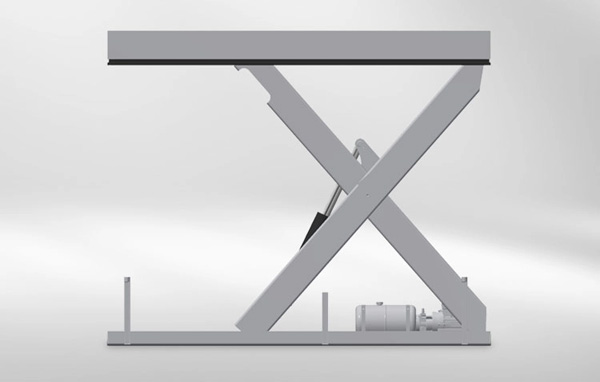

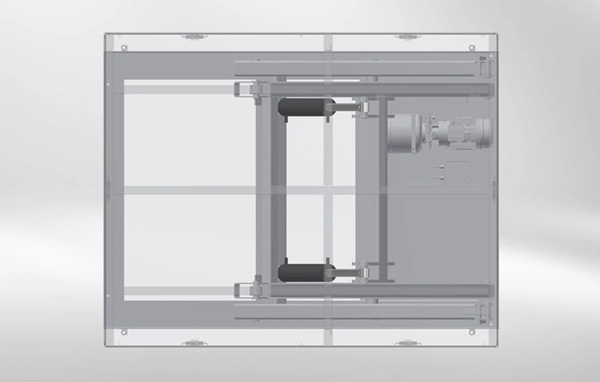

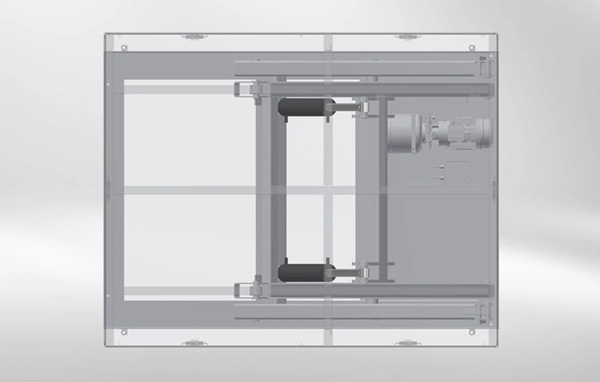

Twin scissor lift table

-

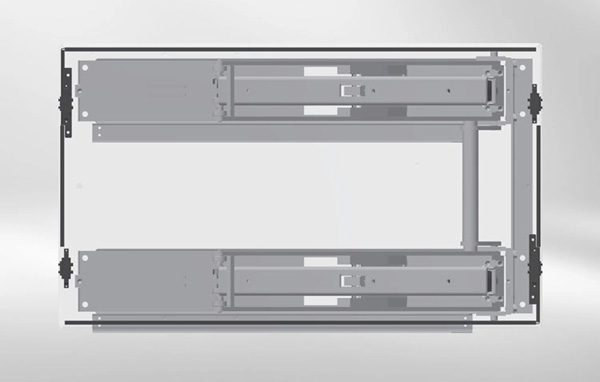

The electro-hydraulic twin scissor lift tablet is a lifting unit with adjacent scissor packages. This allows long platform lengths and high load capacities to be achieved. The use of such a lifting table is always necessary when long and unwieldy goods have to be moved. In this case this lifting table, also called tandem lifting table, is the best solution. The pairs of scissors are controlled synchronously and thus a parallel lifting movement is guaranteed.

Car lift table

-

The electro-hydraulic car lift table was specially developed for lifting motor vehicles. Due to reinforced profiles under the platform in the lane area, they are ideally suited for vertical vehicle transport, e.g. in multi-storey car showrooms or production levels in production halls. In addition, they are equipped with a practical maintenance hatch and with crane eyes for installation. All in all, they represent a flexible and cost-effective alternative to conventional car lifts.

Loading dock lift table

-

The electro-hydraulic loading dock lift table is mainly used for loading and unloading, especially on loading ramps, and is characterised by a particularly robust design. This scissor lift achieves high stability by a reinforced platform with additional profiles. Additional loading flaps enable easy passage with pallet trucks. Furthermore, this loading lift table has a maintenance hatch, crane eyes for insertion in a pit and differential cylinders for outdoor use.

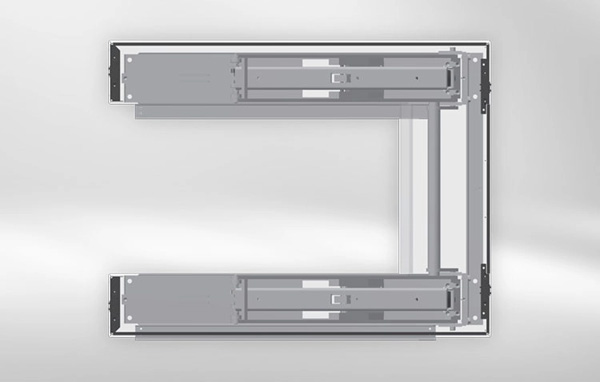

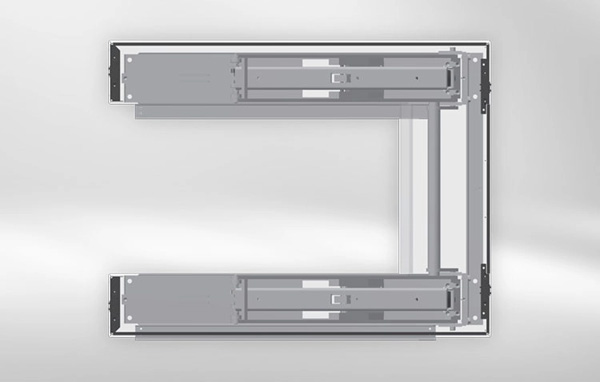

U-shaped lift table

-

The electro-hydraulic U-shaped lift table is characterised by a very low overall height and is designed for working with palletised goods. These can be placed directly on the lift table from the floor using a pallet truck and lifted to an ergonomically advantageous working height. Due to the U-shape and the low overall height of only 80-100 mm, the use of an access ramp is not necessary. U-shaped lift tables are ideal working equipment for the production area and warehouse.

Low-built lift table

- The electro-hydraulic low-built lift table is characterised by an extremely low overall height and is suitable for the transport of pallets, mesh boxes and containers. It can be used as an assembly table, packaging station and stacking table. Ergonomic working is ensured by steplessly moving to the desired position. Depending on your requirements, we equip our low-built lift tables with the options required specifically for your application, such as foot switches. The task by pallet truck is carried out via an access ramp.

ROLLERS; CASTORS AND FACTORY EQUIPMENT

-

If you are looking to make your internal material flow more flexible, to optimise sub-processes integrated into it and thus accelerate it, then you have come to the right place. Whether heavy-duty rollers, support rollers or fixed and steering rollers, flanged ball rollers, ball cup rollers or roller strips – we have the right conveyor element for every application. Thanks to high-quality materials, different designs or additional components, there is a solution for every conceivable application and every difficult working environment.

For example, our galvanized swivel or heavy-duty castors are also ideally suited for humid environments. Or our ball cup rollers, for fast longitudinal and transverse movements that require little effort. Ask us, together we will find the most efficient conveying solution for you.

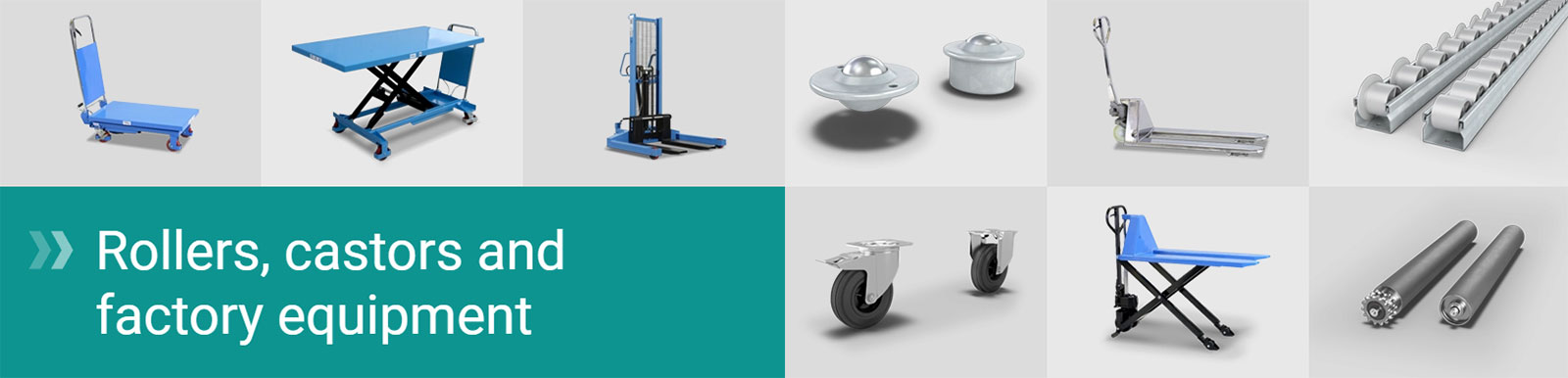

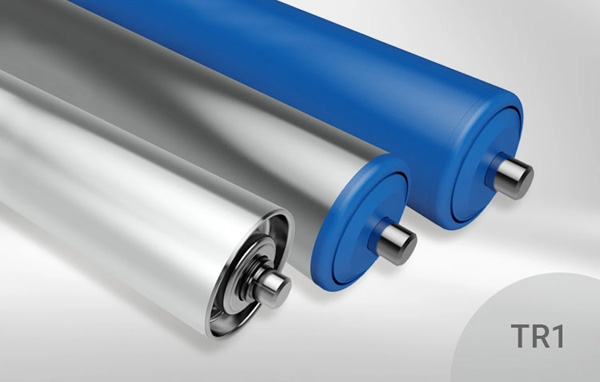

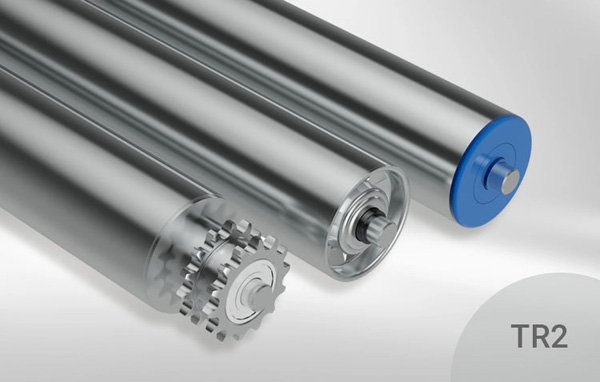

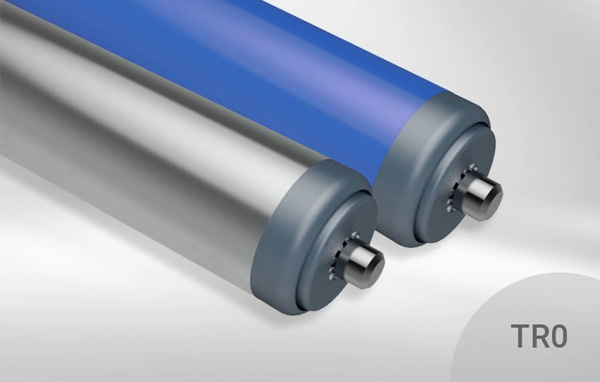

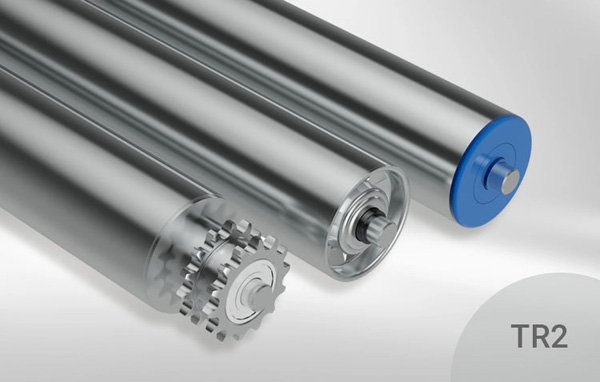

Conveyor rollers

- It is hard to imagine conveyor technology without conveyor rollers. We offer numerous variants made of plastic, steel and stainless steel – ball bearings with one or two rows of balls (TR0) or with cone ball bearings (TR1). Both variants are convincing due to their very smooth running and are ideally suited for gravity drive. In addition, we offer idlers with deep groove ball bearings according to DIN 625 (TR2) for heavy loads, such as the transport of pallets. These conveyor rollers are available with drive (sprocket, toothed belt, …) or without drive. For this type, deep groove ball bearings are either pressed into the tube or welded to it using circular blanks – depending on the application and load.

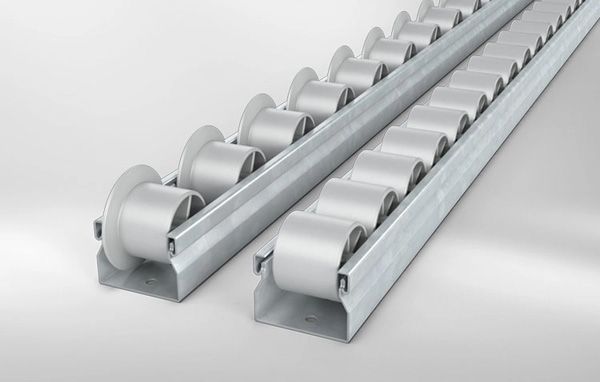

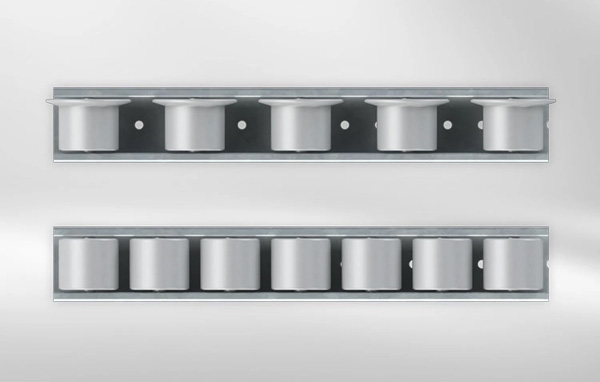

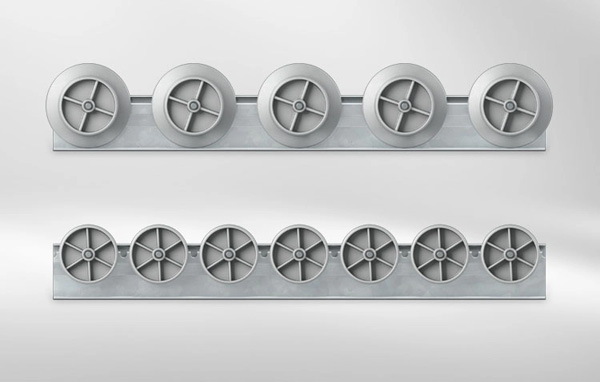

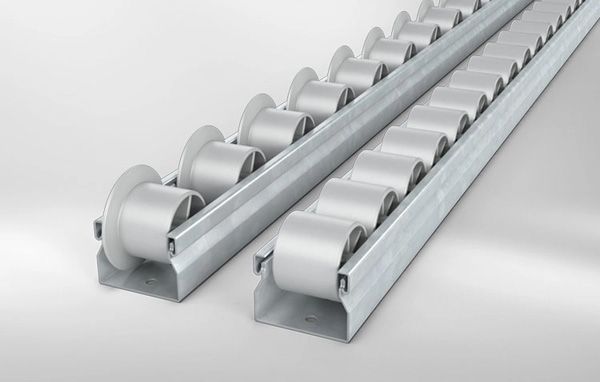

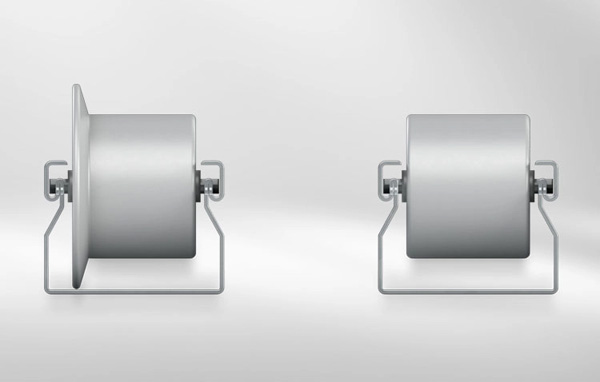

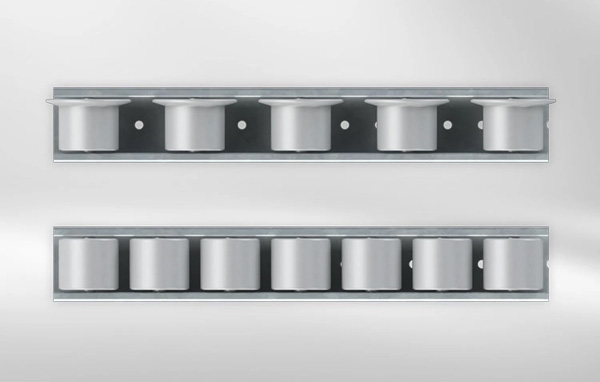

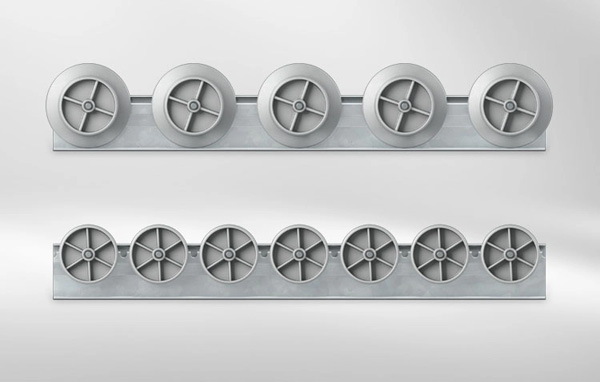

Roller rails

- We offer our roller rails according to DIN 9033 in two versions: with flanged rollers or cylindrical plastic rollers. Both versions are suitable for light goods to be conveyed, such as cardboard boxes or light order picking and storage containers, and convince with their very good running characteristics. Compared to roller conveyors, our roller rails are unbeatably favourable and are available in any desired length up to 4,500 mm – also in antistatic design. Thanks to their regular drill holes on the underside, they can be easily mounted and do not require any maintenance due to their plain bearings.

Swivel castors and fixed castors

- Swivel castors and fixed castors normally consist of galvanised sheet steel fork, bolted wheel axles and wheels. The wheels in turn consist of a wheel body (steel or polypropylene), depending on the type, various bearing units and the wheel tyre made of low-noise solid rubber or break-proof, acid and alkali-resistant polyamide. Swivel castors contain a ball bearing turntable as a further component and, if required, additional brakes.

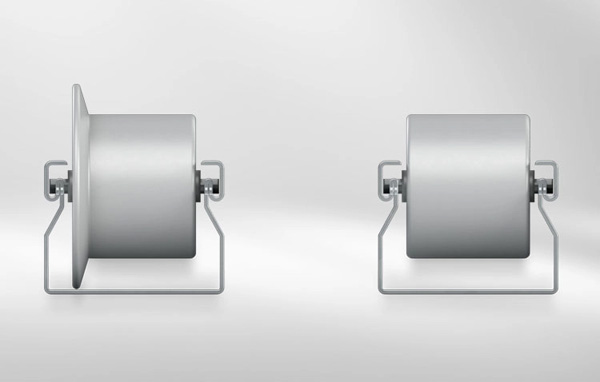

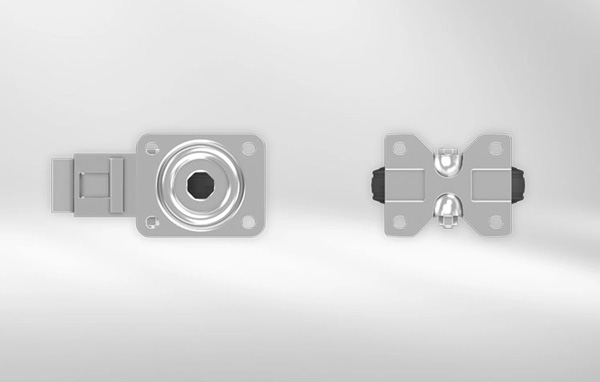

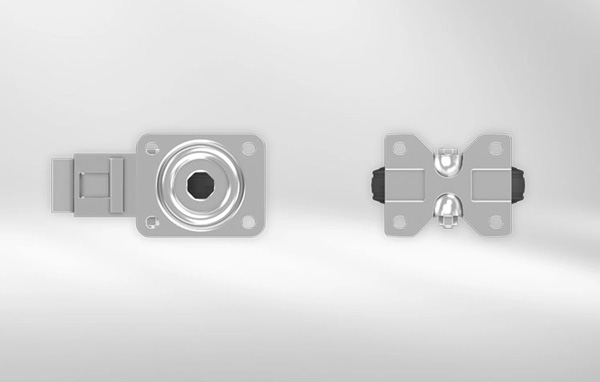

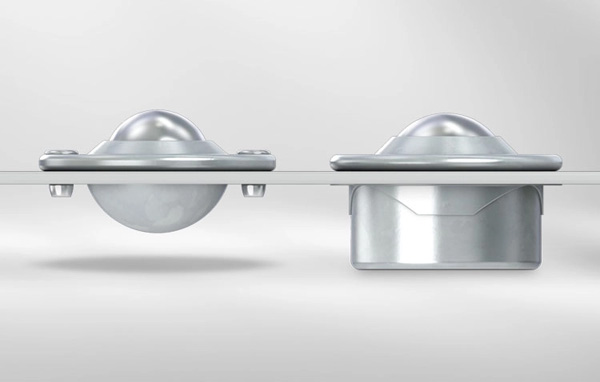

Ball Transfer Units

- They are suitable for goods to be conveyed with a smooth and load-bearing underside. Due to their very low frictional resistance, they reduce the amount of work and effort required for unit load handling and enable transport in all directions. Ball cup rollers are attached and secured to a carrier plate with clips, flanged ball rollers are attached by means of rivets or screws.

The ball transfer unit consists of the load ball and a number of small supporting balls mounted in a shell. This design allows the load ball to rotate with low friction in all directions. Heavy loads can be easily moved without much effort.

Pallet truck

-

Our manual pallet trucks with great manoeuvrability and high mobility are ideal for moving palletized goods efficiently and easily. Due to their compact design, they serve as practical helpers for the transport of all common euro pallets in goods receiving, storage and shipping.

In addition to their use in production plants, the pallet trucks are also firmly established in the wholesale and retail trade as well as with forwarding agents. In addition to the standard models, we also offer high-quality special models with scales or even with scissors. With the scissor lift trucks, pallets can be loaded and unloaded much more ergonomically, as they can be lifted to the appropriate height.

High lift truck

-

Our stable and loadable high-lift trucks are used almost everywhere in the warehouse. They facilitate the daily work routine in professional warehouse work or loading and unloading trucks. They lift heavy loads without problems and transport them safely from A to B.

Electric high lift trucks are a great relief, but manually operated high lift trucks often offer a better alternative, in line with the requirements of the company. We offer a range of semi-electric and manual models.

Mobile lifting table

-

Our high-quality, movable or mobile lifting table can be used in many different ways and thus offer additional flexibility. They are ideal for back-friendly support during loading and unloading or filling of e.g. machines, storage racks and production lines. Another field of application is the use as transport trolley for working materials or for tools.

The movable lifting tables convince by their robust workmanship and the high quality of the installed components. The powder coating of the entire unit provides ideal protection against premature corrosion.

Available as a simple scissor lift table, manually or electrically operated as well as an all-terrain version.