- Offer Profile

-

EUROSORT PERFECTING THE SCIENCE OF UNIT SORTATION

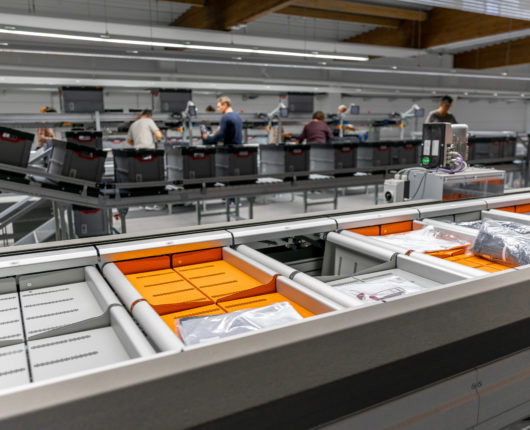

EuroSort specializes in manufacturing high speed unit sortation systems for a variety of warehousing and distribution applications including e-commerce order fulfillment, buy online pickup in store, returns processing (reverse logistics), postal sorting, kitting, central fill store replenishment, and more.

Our automated sortation systems use a variety of induction methods and our patented sorting trays in the process of identifying and sorting items into their correct destination. Our automated sortation systems have an array of applications, from batching individual orders to consolidating multiple orders into a manual or automated putwall, and even to sorting returned items back into putaway groupings by aisle or product type.

High Speed & High Capacity Unit and Shipping Sorters

-

EuroSort is a recognized industry leader in state of the art high-speed and high-capacity unit sorter technology. We offer a large selection of customizable Bomb Bay (Split Tray), Push Tray, Cross Tray, Push Bar and Sweeper sorters that can handle your toughest unit sortation challenges. EuroSorts high speed unit sorters are constantly improving the productivity, accuracy, and efficiency of companies specializing in pharmaceuticals, apparel, books, postal, third party logistics, jewelry, e-commerce, and more.

At EuroSort, our mission is to increase productivity, efficiency, and the bottom line of our customers core business by providing innovative and modular high-speed unit sorters for our customers automated sortation challenges. From our Cross Tray Sorter that allows for automated sorting of non-conveyable, hard-to-handle items to our Push Bar Sorter that excels where other linear sorters fail by handling everything from business cards up to 50 lb. cartons, our high-capacity unit sorters are capable of performing any automated sorting task which will reduce your labor costs, free up space in your facility, and make your unit sorting operation more efficient and effective.

WHICH SORTER IS RIGHT FOR YOU?

- At EuroSort, our mission is to increase productivity, efficiency, and the bottom line of our customers’ core business by providing innovative and modular high-speed unit sorters for our customers’ automated sortation challenges. From our Cross Tray Sorter that allows for automated sorting of non-conveyable, hard-to-handle items to our Push Bar Sorter that excels where other linear sorters fail by handling everything from business cards up to 50 lb. cartons, our high-capacity unit sorters are capable of performing any automated sorting task which will reduce your labor costs, free up space in your facility, and make your unit sorting operation more efficient and effective. Contact us now with your requests and questions!

SPLIT TRAY SORTERS

- Designed from the ground up as the product that launched the company, the EuroSort Split Tray Sorter (also called a Bomb-Bay (bombay) Sorter or Flat Tray Sorter) has undergone many revisions and improvements over the years, but has never lost the simple functionality that makes our unique Bomb-Bay sorter a favorite in the postal, pharmaceutical, retail, and apparel industries.

PUSH TRAY SORTERS

- The EuroSort Push-Tray Sorter was designed from the ground up to be one of the most versatile and flexible unit sorters in the industry. Whether you need to handle apparel and shoeboxes at the same time, or microwaves and giftcards, the EuroSort Push Tray Sorter can handle it with ease. This sorter truly subscribes to our philosophy “If it Fits, It Sorts.”

CROSS TRAY SORTER

- After years of EuroSort’s Cross Tray Sorter was designed after years of watching cross-belt sorters across the industry continue to have the same problems, year after year. We set out to create a sorter that around fixing the major problems with many cross-belts on the market today, namely their high cost, and lack of a pocket on the tray which allows items wont roll or slide off of the trays when going around turns. Our Cross Tray Sorter can easily sort the smallest, lightest, and least conveyable items and can handle small to medium parcels, e-commerce items, fashion, shoe boxes, sportswear and pharmaceutical products.

PUSH BAR SORTER

- First installed in 2004 and fully overhauled in 2019, the EuroSort Push Bar Sorter (also called a pusher sorter or push sorter) is a proven tool in the EuroSort toolbox for operations looking to automate manual processes. The wide range of sortable products, extreme layout flexibility, and easy scalability allow our pusher sorters to achieve a quick ROI and significantly increased productivity in all operations.

SWEEPER SORTER

- Simple, Efficient, Reliable. The EuroSort Sweeper Sorter is THE solution for sorting polybags and small items under 5 inches tall and under 5 lbs. It has a modular design that allows for extreme flexibility and scalability should your operational needs change, and it’s compact design allows it to fit in spaces never considered for automated sortation in the past.

Split Tray Sorters

-

OFTEN IMITATED, NEVER DUPLICATED

The EuroSort Split Tray Sorter (also called a bombay sorter or flat tray sorter) is named after the iconic way that the bay doors on the bottom of an aircraft split open. On the EuroSort Split Tray Sorter, the bottom tray panel is split into two sides that are connected by our patented linkage technology which allows for the quick and simultaneous release of both sides of the tray bottom, dropping the sorted item perfectly flat into the outbound tote or carton.

With our patented technology, the EuroSort Split Tray Sorter has the smallest discharge pitch in the automated sortation industry, creating up to a 50% space savings in your facility when compared to other bombay sorters on the market. The increased accuracy of our Split Tray Sorters over other types of bombay sorters means less incorrect orders, less rework, and a higher sort density. Increased accuracy, along with their many other benefits, make our bombay sorters a perfect choice when designing and implementing a sortation system for store fulfillment, e-commerce, or omni channel distribution.

The EuroSort Split Tray Sorter comes in three different tray configurations: single split tray, dual split tray, and a unique quad tilt tray. All of our split tray sorter configurations provide multiple solutions for sorting round objects, odd-shaped items, and other non-conveyable products that can be challenging for other bombay sorters. Additionally, our modern take on the bombay style unit sorter is offered in 17 unique tray sizes, opening the door to endless customization, modularity, and throughput options.

With three different tray configurations and 17 unique tray sizes, the EuroSort Split Tray Sorter can be optimized to your product and desired throughput. Learn more by selecting one of the sorter trays above.

Single Split Tray Sorter

-

Designed from the ground up as the product that launched the company, the EuroSort Single Split Tray Sorter has undergone many revisions over the years, but has never lost the simple functionality that makes our unique bombay sorter a favorite in the postal, pharmaceutical, retail, and apparel industries. Unlike similar single bombay sorters on the market, our single split tray sorter allows items to drop flat and maintains the quality and protection of any item sorted.

The EuroSort Single Split Tray Sorter (or single bombay sorter) is unique among split tray/bombay sorters on the market today because of our patented linkage technology that connects both tray blades and allows for the most accurate discharge of any available split tray sorters, enabling smaller destinations and a reduced overall footprint for your sorting system.

Our Single Split Tray Sorter features a concave tray surface that allows it to sort non-conveyable items and other odd-shaped objects such as loose apparel, pharmaceutical bottles, polybags, or even round items by containing them within the single split tray.

SINGLE SPLIT TRAY SORTER FEATURES- Flat-Drop Technology – Our single split tray sorters are designed to ensure that products stack safely and securely without damage.

- Manual Induction Ease – Our collection of sortation technology, including our single split tray sorters, allows for easy, safe manual induction to attain the high throughputs required by many of our customers.

- Flex Drive Functionality – With the elimination of wheel-style turns and the utilization of our distributed system of small electric motors, our single split tray sorters can easily handle inclines, declines, and positive and negative turns.

- Safe Tray Design – Safety and utility are crucial for all of our customers, so we designed our trays to be extremely close to each other, enabling high throughput with a lower sorter speed.

- No-Touch Pack-Out – Our split tray sorters allow for the sorting of items to their destinations without using a second touch during pack-out.

- No-Weld Framework – EuroSort’s Single Split Tray Sorter utilizes an 80% aluminum framework that eliminates the need for welding, allowing easy installation, expansion, and modularity of your sortation system.

- Heavy Duty Tray Options – Our single split tray sorter is capable of heavy duty use with the capacity to hold up to 25 lbs on a single tray.

- Smallest Drop Zone – Compared to other bombay sorters today, our single split tray sorters have the smallest drop zone in the sortation industry.

Dual Split Tray Sorter

-

The EuroSort Dual Split Tray Sorter continues to be a consistent favorite among customers with a large variety of products in different shapes and sizes. Our dual split tray sorters are used to meet the high throughput needs of major retailers, distributors, and suppliers that also need to use the least amount of floor space possible. Like every unit sorter in our product line, our dual split tray sorters were designed around the ideas that high-speed unit sortation systems could be much simpler and more cost-effective than what was on the market already, and that unit sorters don’t need to occupy unnecessary amounts of valuable facility space.

With the EuroSort Dual Split Tray Sorter, we have created the ability to sort one large item or two smaller items using the same dual split tray. This double tray sorter (sometimes called a dual bombay tray sorter) eliminates the hassle of sizing trays according to the dimensions of the largest item being sorted. By removing this sizing obstacle, our dual split tray sorters are able to double the possible throughput of sorted items without increasing the overall size of the sorter, sorting up to 17,280 trays per hour from just one induction area.

At EuroSort, we work each day with purpose, dedicated to simplifying the complexities involved with the implementation of automated sortation systems in a variety of industries. From the unique sorting needs of the post and parcel industry to the intricate sorting systems of the apparel and retail industries, EuroSort Dual Split Tray Sorters are used all over the world, providing customizable and modular solutions for an array of automated sorting applications.

DUAL SPLIT TRAY SORTER FEATURES- Dual Tray Our patented dual tray allows for double the throughput capacity of our single split tray sorter, and the highest throughput of any split tray sorter on the market.

- Flat-Drop Technology – Our dual split tray sorters are designed to ensure that products stack safely and securely without damage.

- Manual Induction Ease – Our collection of sortation technology, including our dual split tray sorters, allows for easy, safe manual induction to attain the high throughputs (up to 600,000 items/day) required by many of our customers.

- Flex Drive Functionality – With the elimination of wheel-style turns and the utilization of our distributed system of small electric motors, our dual split tray sorters can easily handle inclines, declines, and positive and negative turns.

- Safe Tray Design – Safety and utility are crucial for all of our customers, so we designed our trays to be extremely close to each other, enabling high throughput with a lower sorter speed.

- No-Touch Pack-Out – Our split tray sorters allow for the sorting of items to their destinations without using a second touch during pack-out.

- No-Weld Framework – EuroSort’s Dual Split Tray Sorter utilizes an 80% aluminum framework that eliminates the need for welding, allowing easy installation, expansion, and modularity of your sortation system.

- Smallest Drop Zone – Compared to other bombay sorters today, our dual split tray sorters have the smallest drop zone in the sortation industry.

Quad Tilt Tray Sorter

-

The EuroSort Quad Tilt Tray Sorter is our answer for operations handling large amounts of small products and requires extremely high throughputs to maintain productivity and efficiency. Our quad tilt tray sorter is able to maintain these high throughputs by utilizing four independently controlled multi tilt trays that use a gentle tilting motion to discharge the product quickly and accurately into its designated chute. This ensures that every sorted product is handled with care throughout the entire sorting process.

From its initial inception, the EuroSort Quad Tilt Tray Sorter (also called a multi tilt tray sorter) was designed to be durable, quiet, and require very little regular maintenance. The four independent trays on each of our quad tilt tray sorters allow for exponentially higher throughput than other tilt tray sorters on the market today. With its modular design and all-aluminum framework, our multi tilt tray sorters allow for easy customization, flexible layouts, and future expansion.

The EuroSort Quad Tilt Tray Sorter is unique in the automated unit sorting industry because it is the only tilt tray sorter that can sort jewelry and other miscellaneous small items accurately and gently at high throughput rates of up to 39,600 items per hour. Currently, EuroSort Quad Tilt Tray Sorters are being used in a variety of diverse industries, such as pharmaceuticals, retail, jewelry, and small accessories, helping to simplify and improve any automated sorting needs.

QUAD TILT TRAY SORTER FEATURES- Quad Tray = Quadruple the throughput capacity of our Single Split Tray in the same footprint.

- Manual Induction Ease – Our collection of sortation technology, including our quad tilt tray sorters, allows for easy, safe manual induction to attain the high throughputs (up to 600,000 items/day) required by many of our customers.

- Flex Drive Functionality – With the elimination of wheel-style turns and the utilization of our distributed system of small electric motors, our quad tilt tray sorters can easily handle inclines, declines, and positive and negative turns.

- Safe Tray Design – Safety and utility are crucial for all of our customers, so we designed our trays to be extremely close to each other, enabling high throughput with a lower sorter speed.

- No-Touch Pack-Out – Our split tray sorters allow for the sorting of items to their destinations without using a second touch during pack-out.

- No-Weld Framework – EuroSort’s Quad Tilt Tray Sorter utilizes an 80% aluminum framework that eliminates the need for welding, allowing easy installation, expansion, and modularity of your sortation system.

- Smallest Drop Zone – Compared to other bombay or tilt tray sorters today, our quad tilt tray sorters have the smallest drop zone in the sortation industry.

Push Tray Sorter

SINGLE PUSH TRAY SORTER

-

CARTON AND POLY-BAG SORTING ON ONE MACHINE

The EuroSort Push Tray Sorter was designed from the ground up to be a new solution to an age-old problem and represents a unique product for the industry.

At its heart, it is a high-speed unit sorter, capable of sorting up to 13,300 items/hour and can handle everything from polybags/apparel/odd-shaped items to heavy cartons, all at the same time.

This single push tray sorting unit was designed to help eliminate the need for multiple sorters saving cost and space, increasing productivity, and enabling a more efficient pick.

SINGLE PUSH TRAY FEATURES- Gentle Push Product Handling – Our single push tray sorters use a positive divert to gently push items off the tray and slide them into the chute allowing for sortation of fragile or odd shaped items.

- Manual Induction Ease – Our collection of sortation technology, including our single push tray sorters, allows for easy, safe manual induction to attain the high throughputs required by many of our customers.

- Flex Drive Functionality – With the elimination of wheel-style turns and the utilization of our distributed system of small electric motors, our single push tray sorters can easily handle inclines, declines, and positive and negative turns.

- Safe Tray Design – Safety and utility are crucial for all of our customers, so we designed our trays to be extremely close to each other, enabling high throughput with a lower sorter speed.

- No-Weld Framework – EuroSort’s Single Push Tray Sorter utilizes an 80% aluminum framework that eliminates the need for welding, allowing easy installation, expansion, and modularity of your sortation system.

- Heavy Duty Tray Options – Our single push tray sorter is capable of heavy duty use with the capacity to hold up to 25 lbs on a single tray.

- Smallest Drop Zone – Compared to other push tray sorters today, our single push tray sorters have a smaller discharge pitch and a higher accuracy

TWIN PUSH TRAY SORTER

- Our award winning Twin-Pushtray sorter is designed around

flexibility and throughput. This is our response to the typical use of a

cross-belt or tilt-tray at a much lower cost and significantly reduced

footprint.

Sorting anything from a business card to a 50lb carton on the same tray, the twin-pushtray is incredibly useful in the e-commerce, postal, and retail worlds. It can handle polybags and cartons on the same sorter, reducing the need for two sorters, and can do so at rates of up to 13,300 items/hour.

TWIN PUSH TRAY FEATURES:- Twin Tray – Our twin tray allows for double the throughput capacity of our Single Push Tray, and the highest throughput of any push tray sorter on the market

- Gentle Push Product Handling – Our twin push tray sorters use a positive divert to gently push items off the tray and slide them into the chute allowing for sortation of fragile or odd shaped items.

- Manual Induction Ease – Our collection of sortation technology, including our twin push tray sorters, allows for easy, safe manual induction to attain the high throughputs required by many of our customers.

- Flex Drive Functionality – With the elimination of wheel-style turns and the utilization of our distributed system of small electric motors, our twin push tray sorters can easily handle inclines, declines, and positive and negative turns.

- Safe Tray Design – Safety and utility are crucial for all of our customers, so we designed our trays to be extremely close to each other, enabling high throughput with a lower sorter speed.

- No-Weld Framework – EuroSort’s twin push tray sorter utilizes an 80% aluminum framework that eliminates the need for welding, allowing easy installation, expansion, and modularity of your sortation system.

- Heavy Duty Tray Options – Our twin push tray sorter is capable of heavy duty use with the capacity to hold up to 50 lbs on a single tray.

- Smallest Drop Zone – Compared to other push tray sorters today, our twin push tray sorters have a smaller discharge pitch and a higher accuracy

Cross Tray / Push Bar / Sweeper Sorter

Cross Tray Sorter

-

FLAWLESS SORTING OF FRAGILE CONSUMER GOODS, LIGHTWEIGHT PACKAGES AND NON-CONVEYABLE ITEMS

EuroSorts Cross Tray Sorter can easily sort the smallest, lightest, and least conveyable items and can handle small to medium parcels, e-commerce items, fashion, shoe boxes, sportswear and pharmaceutical products.

The trays are enclosed on all four sides, meaning every product – large, small, flat or round – remains in place throughout its entire journey on the sorter. The cleats on both sides of this enclosed tray sorter provide a forced discharge, increasing sort accuracy, and while making two-sided sorting possible.

CROSS TRAY SORTER FEATURES- Enclosed Sorter Tray – The EuroSort cross trays are enclosed on four sides so items stay in place around turns

- Two-Sided, Forced Discharge – maintains a compact footprint and eliminates sort errors and rework

- Works well with small, lightweight, smooth and cylindrical items

- Flex Drive Functionality – With the elimination of wheel-style turns and the utilization of our distributed system of small electric motors, our cross tray sorters can easily handle inclines, declines, and positive and negative turns.

- Manual Induction Ease – Our collection of sortation technology, including our cross tray sorters, allows for easy, safe manual induction to attain the high throughputs required by many of our customers.

- Safe Tray Design – Safety and utility are crucial for all of our customers, so we designed our trays to be extremely close to each other, enabling high throughput with a lower sorter speed.

- No-Weld Framework – EuroSort’s cross tray sorters utilize an 80% aluminum framework that eliminates the need for welding, allowing easy installation, expansion, and modularity of your sortation system.

- Lower Investment Costs – no motors in the carriers, and no expensive automatic induction system require

Push Bar Sorter

-

First installed in 2004 and fully overhauled in 2019, the EuroSort Push Bar Sorter (also called a pusher sorter or push sorter) is a proven tool in the EuroSort toolbox for operations looking to automate manual processes. The wide range of sortable products, extreme layout flexibility, and easy scalability allow our pusher sorters to achieve a quick ROI and significantly increased productivity in all operations.

The EuroSort Push Bar Sorter’s precise bi-directional sorting allows for the accurate discharge of a large variety of products into an extremely tight destination such as an outbound carton or mailsack. Like our other automated sortation systems, our Push Bar Sorter is designed to be space conscious and require minimal maintenance.

When it comes to bi-directional sorting, the EuroSort Push Bar Sorter accurately sorts items from as small as a single business card or individual polybag, all the way up to a 30-inch carton at rates of up to 3,000 items/hour. Our Push Bar Sorter is starting to become the go-to solution for reliable linear sortation at a more affordable price point than any other pusher sorter on the market. With the EuroSort Push Bar Sorter, if you can convey it, we can sort it!

PUSH BAR SORTER FEATURES- Performance – Our pusher sorter can sort up to 4,000 items/hour.

- Accuracy – With a positive push divert, the push bar ensures that all items are discharged correctly regardless of shape, weight, or material.

- Flexibility – Inclines, declines, left and right turns, even floor changes and spirals are all possible for our Push Bar Sorter.

- Handling Variety – From a single piece of mail up to a 50 lb. carton, if it can be conveyed, our push sorter can sort it.

- Modularity and Simplicity – Based around a simple diverting concept, our pusher sorter is extremely modular and easy to extend or re-configure as your business evolves.

- Cost – Simple mechanisms and no extra fluff make the EuroSort Push Bar Sorter one of the most cost-effective sorting solutions on the market.

SWEEPER SORTER

-

Originally developed as a sweeper for no-reads during auto-induction, the EuroSort Sweeper Sorter has developed into a compact, low budget sorter, with a dense sort, and throughput designed for medium sized operations .

The Sweeper Sorter is ideal for applications involving items under 5 inches and 5 lbs. With the ability to add destinations and track with ease, this sweeper belt modular system is ideal for products such as books, pharmaceutical products, small packages, polybags, mail, multimedia and jewelry.

A great alternative to loop sorter equipment, its small, linear footprint is great for existing facilities that cannot fit a loop sorter, and need to increase throughput.

SWEEPER SORTER FEATURES- Small Discharge Zone – The EuroSort Sweeper Sorter has an extremely dense sort due to it’s space saving design and tight divert centers.

- Low investment – Simple modules and common parts make this sorter extremely cost efficient, and decreases lead time

- High accuracy – Trusted by central-fill operations around the country, the EuroSort Sweeper Sorter is extremely accurate, and has the ability to create a fully traceable sort with no manual QC.

- Low maintenance – Simplicity means less to go wrong

- Easily Expandable – The Sweeper Sorter is designed around common modules that allow for easy expansion in the future with minimal or no downtime

- Small Item Master – Able to sort anything from a greeting card to a cell phone to a polybag or small carton, the sweeper sorter excels where other linear and loop sorters struggle.

APPLICATIONS

Retail Sortation

-

To remain competitive in the fast-paced, modern retail fulfillment landscape, order fulfillment and distribution centers are relying on unit sortation systems to ensure accurate and fast sortation of retail goods. With hundreds of thousands of products moving through just one retail fulfillment center on a daily basis, automated retail fulfillment systems utilizing unit sortation can help improve the sort accuracy and reduce the number of touches required for the sort, which are two of the most common customer pain points when using outdated manual or semi-automated systems.

EuroSort’s retail fulfillment sorting systems are installed in nearly 100 order fulfillment centers, so we have the experience, knowledge, and specialized unit sorters to help you solve any automated sorting problems and inefficiencies. Our unique and flexible dual split tray sorters and push tray sorters offer benefits not found in any other unit sorter on the market today.

E-commerce

-

E-Commerce is the fastest growing segment of the material handling industry, and with fewer items per order and more numerous orders, the traditional unit sorter with destinations designed to accept 15-20 items no longer makes sense. EuroSort’s suite of e-commerce sorting equipment can provide a space efficient solution that allows for a large enough pick wave to maintain or increase the efficiency of your pickers, with the throughput to keep up with your busiest days.

E-Commerce also comes with the dreaded R-word Returns. EuroSort distribution center sorting machines offer the flexibility to handle incoming returns and outgoing orders at the same time on the same Twin Push Tray EuroSort Sorter, eliminating the need for two machines, two processes or two shifts.

From 10 destinations to 3,000, EuroSort has the experience and knowledge in designing and building e-commerce focused sorters for some of the largest names in the retail and e-tail industries.

Omnichannel

-

The ability to do store fulfillment, e-commerce, and returns on the same sorter using different styles of chutes opens up the world of omnichannel fulfillment and commerce. The ability to handle an ever-changing variety of products is crucial to this and the Split Tray, Push Tray, and Cross Tray sorters excel at this. We subscribe fully to the theory if it fits, it sorts. No more worrying about whether your product will roll off the tray, or not divert correctly.

As long as that product makes it on the tray, it will get diverted into the correct destination. We take the worry out of sorting with our omnichannel sorter.

Third Party Logistics (3PL) Sortation

- The third party logistics sortation market is getting ever more vast as companies are asking to sort more and more quantity and variety of items which may be completely different from the next customer. You need 3PL sorter equipment that offers the flexibility to use one sorter to sort it all. Thats why we designed our Push Tray sorter around the philosophy If It Fits It Sorts. Offering throughput up to 13,300 items/hr from one induction area, and maintaining the ability to sort anything from a business card to a 50 lbs carton this sorter can keep up with your ever-changing clients and demands with a lower cost and smaller footprint than comparable cross-belt and tilt-tray sorters.

Returns

-

COVID-19 has changed retail as we know it. E-Commerce is a convenience until stores are closed and customers physically cannot come to try on/purchase their items. This led to a significant increase in e-commerce purchases and, because up to 40% of all items purchased online are returned, an equal and opposite increase in returned items. No longer can these items be ignored until there is a convenient time to process, it needs to be a concurrent process to get those items either back onto shelves/inventory, back to the manufacturer, or out to be trashed.

The EuroSort Push Bar Sorter is designed to be an extremely cost effective way to automate a previously manual process, and with a short lead time can be implemented quickly and with minimal disruption to your operation. The flexibility in being able to handle your entire product range (down to the size of a gift card) means that your returns process can remain where it is, but requires less labor, and less time, leaving you with more time to get those e-com orders out the door.

Shipping Sortation

-

Everyday, EuroSort shipping sorters process millions of items for our customers around the world. Whether you are shipping polybags, mailers, cartons, or even letters, EuroSort has a wealth of knowledge and experience in designing and implementing sorters that reduce touches, increase the number of shipped items/day and ultimately save you money. We understand that getting items out the door is the key to your operation, and our shipping sortation systems are proven tough in the harshest environments, running 24 hours a day, 7 days a week in facilities around the world.

At EuroSort, we take pride in our vast experience handling any and all of your automated parcel and packet sorting needs, from dimensioning and weighing to pre-sorting and post sorting, we have done it all. Regardless of whether your path to ROI is in increasing your pre-sort to take advantage of significant USPS/Fedex/UPS savings, or in being able to compete in this post-Amazon world of two day shipping, a EuroSort Split Tray or Push Tray Sorter could be the technology you need.

INDUSTRIES

Apparel Sortation

-

When you are considering a unit sorter for your apparel and/or accessories operation, trust in the experts in apparel. Millions of pieces of apparel are sorted by our apparel sorting systems around the world every hour.

At EuroSort, we got our start in the apparel sorting industry and we have 16 years of experience sorting everything from the smallest of socks to the largest of wedding dresses for the biggest names in apparel. With the smallest drop-zone in the industry and the ability to sort direct to box or to a custom-designed chute, the EuroSort Split Tray allows for the flexibility you need day in and day out.

Book Sorting

-

EuroSort book sorting equipment should be your only consideration when looking at how to automate your book handling operation.

Our Split Tray Sorter excels in book sorting because our patented tray linkage enables a completely flat discharge of the book, preventing damage and allowing for the largest accumulation of items in a destination, and the tight discharge pitch allows for a large number of destinations in a small area. Our discharge is so good at preventing damage, even books sorted 100s of times in our demo center look brand new.

Whether your operation needs to sort 1,000 or 16,000 items/hour, EuroSort has the book sorting technology, the experience, and the knowledge to get it done right.

Jewelry Sortation

-

EuroSort is proud to be the only unit sorter company that can sort individual jewelry items, without damage, at rates of up to 39,600 items per hour with our jewelry sortation system.

Our Quad Tilt Tray Sorter handles small items gently and efficiently, allowing for high capacity and accurate sorting every time, and its industry-leading small drop zone and creative chute design allows for a large amount of chute destinations in a small area.

Perfect for e-commerce and store replenishment applications, our automated jewelry sorter equipment makes your operation more efficient and effective, increasing your throughput, decreasing labor hours, and increasing accuracy.

Pharmaceutical and Central-Fill Sortation

-

EuroSort sorters are the proven standard in the pharmaceutical industry and are used by all 3 of the top PBM’s in North America. Regardless of whether you need to sort pharmaceutical bottles for batching orders, or are sorting polybags for your PBM or central fill operation, EuroSort has a sorter that can fit your needs. With the concave tray design of our split tray sorter and industry leading tight drop zone, we can handle both your polybags and your non-conveyable bottles on one sorter within your existing facility footprint.

Utilizing small, clean, electric motors and with noise levels below 70 dB, they are proven successful in clean rooms and automated bottling facilities. Some of the biggest names in pharma are using our Sweeper Sorters, and Split Tray Sorters shouldnt you?

Garment & Laundry Sorting

-

The ability to sort loose items without polybags allows us to extend into the world of industrial laundry facilities, whether it is sorting soiled laundry incoming from major hotel chain, clean wet laundry heading to the proper dryer, or outgoing folded clean laundry heading back to the hospital, EuroSort automated garment sorting will handle it all at rates of up to 6,200 items/hour.

The use of RFID tracking and identification allows for an unprecedented level of accountability and tracing all the way through the cleaning process, and the EuroSort industrial laundry facility sorting machines ensure that every customer always gets the back their same garments.

Parcel and Package Sortation

-

EuroSort has extensive expertise in automated mail sorting and parcel sortation, with over 100 of our parcel sorters installed in locations all over the world, sorting everything from small bubble mailers or polybags, all the way up to large cartons. Our parcel sortation systems are proven tough in the harshest environments, running 24 hours a day, 7 days a week. At EuroSort, we take pride in our vast experience handling any of your automated parcel and packet sorting needs, from dimensioning and weighing to pre-sorting and post sorting, we have done it all.

Our heavy-duty, non-magnetic sorter trays are designed specifically for the rigors of the automated parcel sorting environment. EuroSort’s packet sorting machines offer the most flexible solutions in the automated mail sorting industry by enabling a sort directly to postal containers, such as postal bags, wiretainers, metal carts, and gaylords, reducing the number of touches required to complete the sort. The flexibility of our parcel sorting systems also helps you save time, lower costs through decreased labor hours, and increase the sorting accuracy without increasing the total footprint of the parcel sorter.

EuroSort’s parcel sortation systems have the key element of providing extremely low downtime by having a small number of easy and quick-to-change parts.