Navigation : EXPO21XX > MATERIAL HANDLING 21XX >

H18: Construction Equipment

> Hoesch Schwerter Profile GmbH

Hoesch Schwerter Profile GmbH

Videos

Loading the player ...

- Offer Profile

- Hoesch Schwerter Profile GmbH develops special steel profiles. In close cooperation with individual companies or entire branches, we develop products that always serve to solve a specific production or construction problem. At its site in Schwerte, the company provides all that is required in order to provide branches and companies all that they require from a competent development partner

Product Portfolio

Shaping steel at its best

- Hoesch Schwerter Profile GmbH is the development partner and systems supplier for companies. Our customers already contact us with their initial idea for or requirement of, a new profile solution. The early cooperation enables us to economically balance out all of the end production aspects in an optimal form, together with our customers. The increasingly customised system and product requirements with the efficiency pressure that is applied at the same time, not only places demands on us as the manufacturer, but also on our customers as suppliers of highly technological complete solutions. Together, we can succeed in uniquely positioning ourselves in the market. We see ourselves as being a system supplier and partner for our customers starting with the research and development and proceeding through the design and production and terminating with the on time delivery.

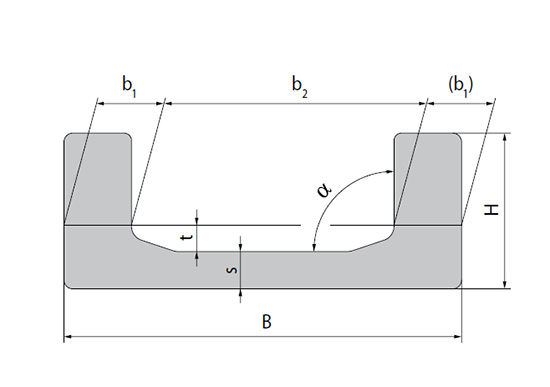

Hot rolling

- Whether in the automotive, transportation or railway industries – our hot rolled profiles provide numerous branches and companies with innovative solutions.

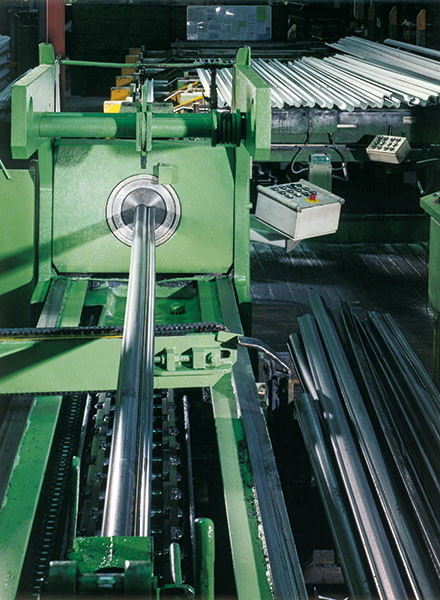

Cold-drawing

- The cold-drawing process considerably enhances the dimensional accuracy and surface quality of rolled or pressed profiles, without any material loss whatsoever.

Independent company for our pressing plant

- The pressing plant activities of the Calvi Holding have been bundled at the “Hoesch Schwerter Extruded Profiles GmbH“ site in Schwerte since August 2016.

Hoesch special steel and custom profiles

- Competent development partner

Hoesch Schwerter Profile develops customised profile solutions. Our company has all of the requirements for supporting other companies as a competent partner at the Schwerte site:- Leading quality standards

- A high degree of engineering know-how

- Innovative capabilities

- Modern production facilities

A consistent closeness to customers is one of the most important three mainstays of our strategy, the others being cost efficiency and globalisation.

Hoesch special profiles - Custom solutions

-

Profiles from Schwerte

Hoesch Special profiles are used as construction elements in almost all segments of the steel processing industry. The diverse profiling procedures at the site in Schwerte makes it possible to form the material in such a way that it meets the respective economical, construction and optical conditions. Hoesch Schwerter Profile GmbH is also an interesting partner for many industrial branches and companies as not only does it offer diverse production processes, but also processing steps such as sawing, milling, drilling, heat treatment and surface treatment.

Production

-

Three processes – best quality

- Hot rolling

- Cold-drawing

- Independent company for our extrusion plant

SE-|M|®

-

Up high with Hoesch

Hoesch Schwerter Profile GmbH has been working on a process that would enable lift mast profiles to be manufactured with a greater wear resistance in addition to them being designed for greater heights since 2003. The “specially engineered milled process“, or SE-|M|® was patented in 2008. The result of these years of work: The combination of the classic hot rolling process with a suitable material and an efficient mechanical processing makes it possible to meet the high demands.

SE-|M|® offers numerous benefits that take our customers higher and further:

- the lowest possible tolerances (0.2 mm) in the main functional surface of the profile

- improved wear resistance through the material selection and removal of the surface decarburisation

- reduced costs when compared with cold-drawn profiles for example, due to a high degree of automation

Standard steel profile range

- Hoesch Schwerter Profile GmbH has constructed profiles that are repeatedly requested and ordered for diverse branches. Refer to our datasheets in order to see whether you can find a solution to your construction concern.

Solutions

-

We provide these branches with a profile

Hoesch Schwerter Profile GmbH develops special steel profiles in close cooperation with individual companies. Contrary to the mass production offered by other suppliers, the plant in Schwerte supplies products that have properties that are specified by the customers according to their needs. Our special profiles always solve a special production or construction problem.

Materials handling

-

Warehousing and logistics solutions

Warehousing systems and industrial trucks manufacturers have been relying on the know-how and experience of Hoesch Schwerter Profile GmbH for many years. The designing of special profiles for these branches not only requires profound knowledge of logistical requirements, the profiles also need to be able to withstand extreme loads.

Durable joints, lifting tools for heavy loads, good visibility and stability are specific functions within the industrial trucks branch that can often only be met by special profiles from Schwerte.

We produce special profiles for everything from the smallest stock vehicles to heavy industrial trucks or large high-bay warehouse systems.

Mechanical and plant engineering

-

Production with a precision

Precision and load-bearing capacities are fundamental criteria for components that are used in the mechanical and plant engineering industries.

Whether for highly technical tools or production plants, whether guide rails for machines in the textile industry or the woodworking industry – only highly innovative production technology is able to meet the extreme demands of the various machine manufacturers.

Power industry

-

Full power ahead

Germany’s plant and power station engineering companies have been defending their top position in a global comparison for many years. The projects are economical and reliable.

Hoesch Schwerter Profile GmbH has a reputation as being a competent partner when it comes to the development and production of special components for large industrial plants or power stations for the generation of power.

Construction engineering

-

Precision and functionality

Precision and a variety of shapes – special profiles from Schwerte place the construction industry in an advantageous position in many areas.

Components for the most diverse building and civil engineering constructions leave the Schwerte plant on a daily basis: whether interlock sections for technically demanding sheet piling designs or expansion joint profiles for bridges or road joints.

The same is valid for all of the profiles: a minimum weight with a maximum bearing capacity.

As there is also no need for complex welding work and mechanical processing, architects and engineers are able to appreciate the cooperation with Hoesch Schwerter Profile GmbH.

Ship building

-

Profiles fora perfect launch

Hoesch Schwerter Profile GmbH develops customised profile solutions in close cooperation with renowned companies from the industrial trucks industry, the automotive industry and the shipbuilding industry. As a system supplier, we develop the right profile solutions in cooperation with the experts from our customers, before delivering the profiles just in time for direct processing

Reduce the time you require for the manufacturing of your assemblies by directly installing our special ready for installation profile solutions. This saves you the manual, time-consuming and therefore cost-intensive treatment and finishing of norm standard profiles.

Railway engineering

-

Everything to do with Rails

Hoesch Schwerter Profile GmbH has been an innovative partner for “everything to do with rails“.

Whether the high precision of running rails for automatic doors in trains or trams, whether as a rail fastener or as technological applications in the field of rail track construction, special customised profiles are provided for all areas in order to meet requirements.

Automotive

-

In the fast lane

The highest level of endurance, low weight, exact processing throughout, no superfluous material.

Our customers in the automotive industry know how to value these benefits. They have been using the benefits provided by our special profiles for years, in order to continue in the fast lane in this highly competitive market.

Hoesch Schwerter Profile GmbH has a reputation as being an innovative partner for the automotive and automotive supplies industry.

Aviation

-

Above the clouds

Our experts are repeatedly faced with demanding material-related requirements in the aircraft construction industry – the large number of possible cross-section dimensions and the use of an extensive range of materials makes the profiles plant in Schwerte a sought-after and competent point of contact for many companies in this industrial branch.

Protection systems

-

Always on the safe side

Another area of use for special profiles is so-called “protection systems“. This concerns itself with protection-related components and system solutions that are mainly used in a military environment, including in armoured vehicles, submarines and frigates.

Differentiations are to be made here between:- conventional profile solutions

- system components

- sandwich gratings

Sandwich gratings are systems, with which special combinations of composite materials prevent the penetration of projectiles or fragments through the air inlet and outlets of armoured vehicles.