Inotec

- Offer Profile

- The inotec team of highly

motivated staff has many years of experience in the barcode and Auto ID

sector. inotec is your trusted partner, for planning logistics concepts,

through to implementation of individual Auto ID solutions. inotec works in

accordance with the quality management system tested and certified in EN ISO

9001:2008.

We use photocomposition, thermal transfer and digital printing processes to produce sequential barcode and 2D code labels. Our range includes RFID smart labels, blank labels, metal labels and signs, ceramic labels and library cards.

Product Portfolio

Barcode labels

-

Barcodes are by far the most established and proven technology for

automating fast and accurate data capture. Wide usage has resulted

in a range of very affordable readers and terminals making barcode

hardware the most cost effective.

As a printed technology, innovative label designs and specialist materials, offered by inotec, give barcodes labels outstanding flexibility and durability in harsh and complex environments. The technology is well proven with a range of international standards supporting global adoption. As a printed technology Barcodes can however only carry a limited amount of data and usually rely on a remote database to provide more detailed information. Apart from very basic systems, they cannot therefore be stand alone data carriers, but in combination with other technologies, like 2D and RFID they are a versatile and reliable data capture tool. digital printing

-

Using the latest digital printing technology with our new ‘hp

indigo’ presses, we have been able to revolutionise the new design

options for sequential barcode labels. With our state of the art

presses we can print unlimited colours and fonts.

With a print resolution of 800 dpi, we can represent photographic quality images. Using these additional colour features can make label identification even easier.

Under surface printing makes these labels extremely scratch-proof and resistant to oils and weak chemicals.

Diomaster

-

Our Diomaster label is our premium digitally printed product, making

it an ideal choice for identification of pallets, containers,

racking and assets.

Under surface printing technology makes this label extremely robust and resistant to mechanical abuse.

Our range of adhesives guarantee optimum adhesion to any surface.

Multilevel/Multicolour

-

Our Multilevel/Multicolour labels identify multiple levels all

within one label design – ideal for ID of pallet racking spaces and

shelving. The coloured level identifier directs the warehouse

operator immediately to the correct level.

Utilising oblique (angled) barcodes, scanning of incorrect barcodes can be eliminated - ensuring a 100% correct first reading rate. These labels are a perfect alternative to expensive long-range labels and scanners in any warehouse system.

FloorBlock

-

Our FloorBlock Kits are the ideal solution for semi-permanent

identification of bulk stack floor locations, indoor or outdoor.

They can be easily applied to and removed from concrete flooring

using specialist screws supplied in the kit.

Our top of the range, under surface printed Diomaster label is applied into the recess of a rigid aluminium or high density plastic plate giving it greater protection from heavy traffic.

A range of kits are available to suit any application.- Resistant to high traffic of vehicles and cleaning processes

- Designed to withstand mechanical damage

- Quick and easy installation by your own engineers

- Available with Aluminum or Durable Printed Synthetic labels

- Can be repositioned and reused in new locations and with new labels

Diocard

- Our Diocard is a non adhesive digitally printed rigid card available in various thicknesses. Benefitting from all the durable characteristics of our under surface printed digital range, they are ideal for mechanical fixing using staples, screws or rivets to pallets, containers and stillages.

Diotough

-

The Diotough label is extremely durable. The materials and

manufacturing process mean they can withstand extreme weather

conditions and are fully water-resistant.

This means they can be used indoor or outdoor in harsh environments. They can be used on hire equipment, outdoor assets and will withstand repeated washing and weathering. This makes them the preferred product for the identification of ski hire equipment – where our special adhesives guarantee that the labels do not come off even at temperatures significantly below zero and in extreme wetness..

Diosecure

-

Diosecure is the next generation in tamper evident security

labelling.

Both the face and reverse of the label can be printed digitally in colour, with sequential information – even Pictures, Barcodes, QR Codes and serial numbers.

When the face is removed, a custom-made imprint is left on the surface to show evidence of tampering or even to offer proof of originality.

thermal transfer printing / photocomposition process

Barcode labels, thermal transfer printing

-

Specialist selection of hard-wearing label materials and printing

ribbons, make our thermal transfer labels extremely robust – even at

operating temperatures between -40°C and +400°C.

These labels are smear-proof, scratch resistant, UV light-fast and are also resilient against oils and chemicals.

We offer a range of materials so suit any project and budget from paper labels, scratch-proof plastic films or temperature-resistant Kapton, depending on the application.

Barcode labels, photocomposition process

-

inotec photocomposed labels are extremely resilient data carriers,

ideal for long term identification projects – with guaranteed image

retention lasting over 25 years.

In contrast to conventional printing processes, in the photocomposition process, the barcode information is not printed onto the surface but exposed into photosensitive material surfaces. These come in various material options including paper, polyester and aluminium and can be tailored to suit your individual requirements and applications. We also offer unlimited options with regard to the label size, shape and design.

In-mould labels

-

Diobond in-mould labels provide permanent identification for

injection moulded plastic pallets, containers and totes.

Using inotec‘s state of the art printing techniques and patented manufacturing technology, full-colour logos, barcodes and even RFID enabled inlays can be injection moulded into the wall of a container. Metal Labels

- We supply a range of metal labels in various

thicknesses of steel and aluminium, which can be laser etched or

photocomposed with variable barcode information.

A new colouring process enables us to offer colour coded metal labels. RFID Labels

- INOTAG is the name of our flexible RFID label range,

which we offer in a range of label materials including: paper, polyester and

polycarbonate.

Combined with an RFID inlay (antenna + chip) and an adhesive adapted for your application, inotec RFID labels allow fast accurate automatic identification of objects without the need for contact or ‘line-of-sight’ scanning.

The data can be read, transmitted and modified wirelessly even over large distances, depending on the type and frequency of the inlay antennas and readers used. Credit-card-sized high frequency (HF) labels have a reach of approx. 30 – 100 cm. Ultra high frequency (UHF) labels can be read from several metres away. The anti-collision mechanisms in UHF technology also allow multiple sets of RFID label data to be accurately captured without disrupting each other.

Our RFID labels can be supplied fully printed in full colour and encoded or blank for subsequent in-house printing and encoding, using RFID enabled thermal transfer printers. The format needed depends on the inlays used. We handle inlays from renowned providers in the frequencies HF 13.56 MHz or UHF EPC Claas 1 Gen 2 860 – 960 MHz. RFID on metal

- The topic RFID on metal is well known and so inotec

put a focus on this topic in the Research and Development laboratory to

develop solutions that fit to the market and work in an excellent manner.

Following criteria were determining:

- Fixation on different metallic surfaces

- The shape / type of the objects to be labelled requires flexible labels

- Environmental conditions and application fields

- The reading range / frequency

- The economic life-time and efficiency of the tags as well as

- Cost-effective purchasing

inotag Flex on metal

- With inotag Flex on metal inotec has developed a

very flexible RFID label with a thin inlay suitable for direct application

on metal. The label’s surface resists even to harsh environmental

conditions. The adhesive is optimised for metallic surfaces and compensates

irregularities, vibrations and mechanical interactions. The readability is

up to 3 metres.

Applications: industrial on metal applications, metal containers, pipes and tubes

Chip types: UHF EPC Class 1 Gen 2 (Impinj, NXP, Alien), HF ISO 15693 (z.B. NXP I-Code SLI-X)

inotag Flex on metal Spacer

- An even stronger adhesive RFID label is launched with

inotag Flex on metal Spacer: a flexible and smart label with an UHF

inlay and characterised by an extraordinarily robust industry adhesive for

metallic surfaces. This RFID label is wash resistant, resistant to heat and

cold as well as strong shearing forces, vibrations and mechanical

interactions. Thus the label suits to several applications.

Applications: Pump motors, metal containers, pallet cages, transport trolleys, band conveyors, gas bottles, tubes and pipes

Chip types: UHF EPC Class 1 Gen 2 (Impinj, NXP, Alien)

RFID labels - digital printing

- Using the latest digital printing technology with our new ‘hp indigo’ presses, we have been able to revolutionise the new design options for RFID labels. With our state of the art presses we can print unlimited colours and fonts. With a print resolution of 800 dpi, we can represent photographic quality images. Using these additional colour features can make label identification even easier. Under surface printing makes these labels extremely scratch-proof and resistant to oils and weak chemicals.

INOTAG Diomaster HUW

- Inotag Diotough HUW labels are constructed from 50µ (micron) polyester

foil. Reverse printing makes these labels extremely scratch resistant, wipe

and wash proof and highly resistant to UV weathering. Our HUW adhesive

offers excellent grab strength on various surfaces.

Applications: Crates, Pallets, Asset ID

Standard Size: 103x20 mm

Chip Types: UHF EPC Class 1 Gen 2 (Impinj, NXP, Alien)

Chip Types: HF ISO 15396 (NXP I-code SLI-X)

INOTAG Diomaster 250 PC HUW

- Inotag Diomaster 250 PC HUW Labels are constructed from

250µ (micron) polycarbonate foil. Reverse printing makes these labels

extremely scratch resistant, wipe and wash proof and highly resistant to UV

weathering. An additional polyester layer can be added in various

thicknesses to give extra strength. This special construction protects the

RFID inlay from mechanical damage, whilst leaving the label flexible enough

to fit shaped profiles. A range of adhesives are available to guarantee a

strong adhesion to any surface.

Applications: Crates, Pallets, Asset ID

Standard Size: 103x20 mm

Chip types: UHF EPC Class 1 Gen 2 (Impinj, NXP, Alien)

Chip types: HF ISO 15693 (NXP I-code SLI-X)

INOTAG Dioclassic

- Inotag Dioclassic labels are made using a digitally,

surface printed paper. All colour and adhesive options are available to

match any application. These labels offer a cost effective RFID tagging

solution, where on-metal and highly damage resistant specifications are not

required.

Applications: Documents, Asset ID

Chip types: UHF EPC Class 1 Gen 2 (Impinj, NXP, Alien)

Chip types: HF ISO 15693 (z.B. NXP I-Code SLI-X)

INOTAG Diobond Inmould

- Diobond RFID labels consist of

an in-mould label material combined with a UHF inlay. A special surface

treatment makes these RFID labels particularly resistant to wear and tear,

UV light, cleaning products, weak acids and chemicals. The label is bonded

to the container during the injection moulding process, leaving a smooth,

rimless surface. With no adhesive edge and no gap for dirt or moisture to

get in underneath the label, this makes the in-mould label and in-mould RFID

the perfect solution for the food and pharma sector.

Applications: crates, pallets

Chip types: UHF EPC Class 1 Gen 2 (Impinj, NXP)

Chip types: HF ISO 15693 (z.B. NXP I-Code SLI-X)

RFID Labels, thermal transfer printing

- Our thermal transfer RFID labels are supplied in

various TT films, such as polyester or PE. These can be supplied with a

range of specialist adhesives to ensure a strong bond to any surface and can

be delivered pre-printed and encoded or blank.

Use:- Identification of containers

- Inventory markin

Ino-Tag TT HUS, Ino-Tag TT HL2, Ino-Tag TT Pet 7

-

Our thermal transfer RFID labels are supplied in various TT films, such as

polyester or PE. These can be supplied with a range of specialist adhesives

to ensure a strong bond to any surface and can be delivered pre-printed and

encoded or blank.

Standard sizes: HF area 50x80 mm and 30x65 mm. UHF 103x20 mm

Applications: crates, pallets, asset ID, libraries, cable identification, documents

Chip types: UHF EPC Class 1 Gen 2 (Impinj, NXP, Alien)

Chip types: HF ISO 15693 (z.B, NXP I-code SLI-X)

Ino-Tag TT Paper

- RFID labels combining a UHF inlay with thermal transfer printed paper. These

are supplied with an excellent permanent adhesive and can be delivered

pre-printed and encoded or blank.

Standard sizes: 4x2 inch, 4x4 inch, 4x4 inch, 50x50 mm and 50x80 mm

Applications: Logistic (pallet identification), identification of products, libraries, documents

Chip types: UHF EPC Class 1 Gen 2 (Impinj, NXP, Alien)

Chip types: HF ISO 15693 (z.B. NXP I-code SLI-X)

RFID in-mould labels

- Diobond RFID labels consist of an in-mould label material and a UHF inlay. A

special surface treatment makes these RFID labels particularly resistant to

wear and tear, UV light, cleaning products, weak acids and chemicals.

The label is bonded to the container during the injection moulding process, leaving a smooth, rimless surface, which means that no dirt or moisture can get in underneath the label. This makes the in-mould label and in-mould RFID the perfect solution for the food and pharma sector.

Use:- Permanent identification of reusable containers

- Permanent identification of plastic palettes

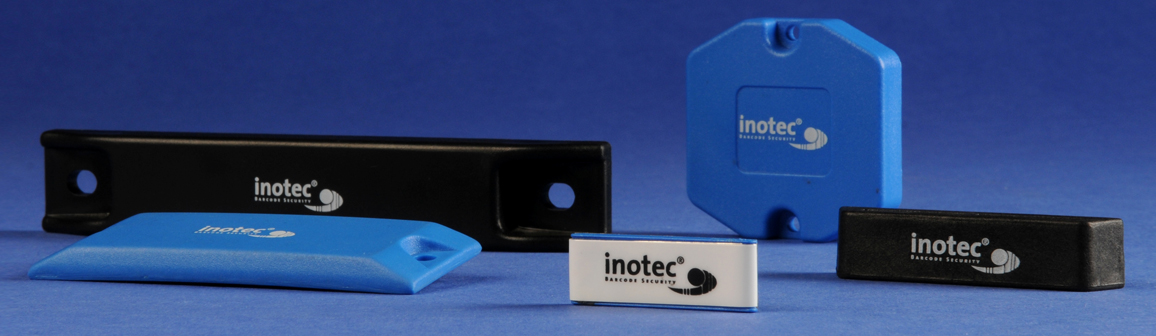

RFID hard tags

- We offer a wide range of RFID Hard Tags in all

frequencies and to suit any RFID application – even on-metal. Our

transponders are protected by a special rugged plastic casing, which can

also be supplied with printed human readable and barcode information. These

Tags can be supplied with blank chips or fully encoded with your data.

Use:- Container or Pallet identification, Warehouse applications or Inventory and Asset marking

INOTAG Pallet tag

- Technology RFID / UHF

Working frequency: 860-960 MHz EPC Class 1 Gen 2 compliant

Chip type: Alien Higgs 3

EPC: 96 bit

User memory: 512 bit

Reading range: depends on reading devices

Use: pallet identification, container identification

INOTAG M-Crown-Tag

- Technology RFID / UHF

Working frequency: 865-869 MHz EPC

Class 1 Gen 2 compliant

Chip type: Alien Higgs 3

EPC: 96 bit

User memory: 512 bit

Operating temperature: -25°C to +70°C

Use: Identification of metallic objects; inventory, container identification, warehouse applications

INOTAG M-Prince-Tag

- Technology RFID / UHF

Also available as HF/high temperature

Working frequency: 865-869 MHz EPC

Class 1 Gen 2 compliant

Chip type: Alien Higgs 3

EPC: 96 bit

User memory: 512 bit

Operating temperature: -25°C bis +70°C

Use: Identification of metallic objects/inventory/warehouse/containers

INOTAG M-Warrior-Tag

- Technology RFID / UHF

Working frequency: 865-869 MHz EPC

Class 1 Gen 2 compliant

Chip type: Alien Higgs 3

EPC: 96 bit

User memory: 512 bit

Operating temperature: -25C to +70°C

Use: Identification of metallic objects; inventory, container identification, warehouse applications

INOTAG M-Shield-Tag

- Technology RFID / UHF

Working frequency: 856 - 869 MHz EPC Class 1 Gen 2 compliant

Chip type: Alien Higgs 3

EPC: 96 bit

User memory: 512 bit

Operating temperature: -25°C to +70°C

Use: Identification of metallic objects, inventory, identification of tools

INOTAG M-Nano-Tag

- Technology RFID / UHF

Working frequency: 865-869 MHz EPC

Class1 Gen 2 compliant

Chip type: Alien Higgs 3

EPC: 96 bit

User memory: 512 bit

Operating temperature: -25°C to +70°C

Use: Identification of metallic objects, inventory, identification of tools

INOTAG Laundry Tag

- Technology RFID / HF

Working frequency: 13,56 MHz ISO 15693

Chip type: I-Code SLI, 1024 bit

Operating temperature: -25°C to +120°C

Use: Identification of hired laundry

INOTAG Jewellery Tag

- Technology RFID / UHF also available as HF

Working frequency: 865-869 MHz EPC

Class 1 Gen 2 compliant

Chip type: Alien Higgs 3

EPC: 96 bit

User memory: 64 bit

Operating temperature: -25°C to +85°C

Use: Identification of premium jewellery and accessories

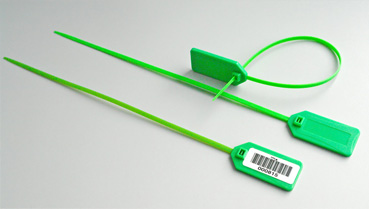

RFID safety seal and RFID cable tag

- inotag RFID cable tie; inotag RFID safety seal, inotag RFID cable tag

Applications: industry, logistics; inventory, product protection

E.g. safety seal for containers, trucks or trolleys. Security seal for products, doors and shipping units. Animal identification.

With the RFID cable tie even metallic objects can be identified as well as objects that cannot be labelled.

inotag RFID cable ties are particularly suitable for the identification of big bags, tubes, metal boxes, small containers and recycled material.

The RFID cable tag cannot be removed without destroying it.

The RFID cable tie and the RFID safety seal can be printed on. The additional identification with a label is possible, too. The chip can be programmed beforehand.

These RFID cable ties are a cost-efficient alternative to RFID hard tags. Complete Auto ID Solutions: RFID and Barcode

- For: Warehouse, Logistics Food, Transport, Production

and Industry

First Class integration of bespoke Auto ID solutions fo any application - using inote premium products and our specialist selected partners!

Consultation - Installation - Integration:

Consultation: Demand Analysis; Proof of Concept; RoI advice

Installation and Integration: Contact and functional specifications, technical evaluation, system installation and integration, on-site Training and Workshops

Software: Standard or bespoke software, interface programming, software and hardware integration: State of the Art Solutions

Hardware: We'll help you choose the right tools for the job - with hardware selected to suit your application, produced, installed and supported by one of our Premium Partners.

Labels & Tags: Barcode and RFID: With more than 30 years experience in the Auto ID industry, we will work with you to specify and deliver the perfect identification solution for any application. In-mould Labels

- Diobond in-mould labels provide permanent

identification for injection moulded plastic pallets, containers and totes.

Using inotec‘s state of the art printing techniques and patented manufacturing technology, full-colour logos, barcodes and even RFID enabled inlays can be injection moulded into the wall of a container.

The bond between label and crate becomes permanent, offering a smooth edgeless surface, which eliminates contamination behind the label. This makes In-mould the ideal choice for food and pharmaceutical industries. Diobond has gained (FDA) certification for use on food containers which come into direct contact with food.

A specialist treatment of the label material gives the printing ink a super strong adhesion. Then a special protective lacquer is applied which makes the labels resistant to wear and tear, UV light, cleaning products, weak acids and other chemicals.

With no need for adhesives, this also makes the labels highly resistant to heat as well as being completely waterproof - especially important for returnable plastic containers which still require fast accurate identification even after repeated wash cycles.

inotec‘s unique and patented manufacturing process enables RFID chips to be moulded into plastic products. In recent tests up to 300 in-moulded tags were read in a couple of seconds.

Using the in-mould process, the labelling becomes fully automated, without consuming extra production time. Costly printing processes such as hotfoil and silkscreen can also be eliminated.

Our in-mould labels are suitable for plastics including PE, PP, ABS, PS, nylon and polycarbonate, among others.

In-mould Barcode Labels

- Diobond

labels consist of an in-mould label material. A special surface treatment

makes these labels particularly resistant to wear and tear, UV light,

cleaning products, weak acids and chemicals.

The label is bonded to the container during the injection moulding process, leaving a smooth, rimless surface, which means that no dirt or moisture can get in underneath the label. This makes the in-mould label the perfect solution for the food and pharma sector.

Use:- Permanent identification of reusable containers

Permanent identification of plastic palettes

- Permanent identification of reusable containers

In-mould RFID Labels

- Diobond

RFID labels consist of an in-mould label material and a UHF inlay. A special

surface treatment makes these RFID labels particularly resistant to wear and

tear, UV light, cleaning products, weak acids and chemicals.

The label is bonded to the container during the injection moulding process, leaving a smooth, rimless surface, which means that no dirt or moisture can get in underneath the label. This makes the in-mould label and in-mould RFID the perfect solution for the food and pharma sector.

Use:- Permanent identification of reusable containers

Permanent identification of plastic palettes

- Permanent identification of reusable containers

In-mould Decorative Labels

- Our Diobond in-mould Decorative labels provide a full-colour labelling solution which can be permanently moulded into the surface of plastic products. High-resolution six colour printing offers extremely high quality results and combined with special protective lacquers the labels become resistant to wear and tear, UV light, cleaning products, weak acids and other chemicals. With no need for adhesives, this also makes the labels highly resistant to heat as well as being completely waterproof. Using the in-mould process, the labelling becomes fully automated, without consuming extra production time. Costly printing processes such as hotfoil and silkscreen can also be eliminated. Our in-mould labels are suitable for plastics including PE, PP, ABS, PS, nylon and polycarbonate, among others.

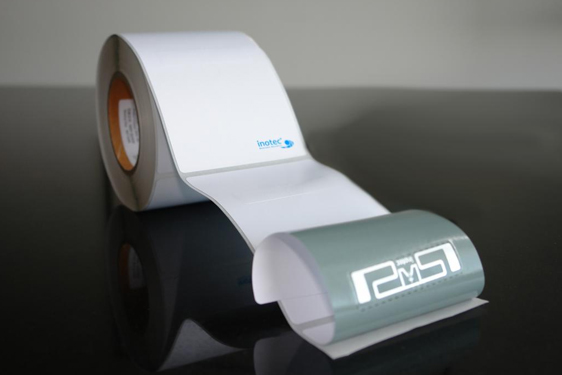

Blank labels for in-house printing

- We offer blank labels in a huge range of options,

giving you complete flexibility of design, and format to fit any application

or printer.

You can choose between labels on rolls, fan folded, sheets or continuous forms with or without perforations. Bespoke die cut shapes and formats are possible.

We can pre-print all or part of the label for you, giving unlimited flexibility in the graphic design of your labels and logos.

Labels can be supplied in a number of standard materials:- Polyester

- PP

- PE

- Thermal transfer paper

- Direct thermal paper

- Heat-resistant up to approx. 400°C

- Special freezer adhesive

- Extremely strong adhesive labels for car tyres and pallets

- Destructible vinyl labels

- Resistant to oily surfaces and weak chemicals

- Food grade adhesive

Digital decorative labels

- For smaller runs, digital print labels are a

cost-effective alternative to the usual letterpress, flexo or offset

printing processes. Digital printing offers the opportunity to react quickly

to a constantly changing market. Short runs of full colour labels with

variable data, images and text can be produced with a very short lead-time.

The digital processing means that printing can be done using data-base

management and last minute changes even to printed images can be made at the

touch of a button.

Decorative labels are available in a wide range of materials and adhesive labels. High-resolution six colour printing offers extremely high quality results.

Labels can be protected for outdoor use using specialist preparation, coatings and laminates.

Our labels can also be supplied with permanent, removable and washable adhesives.

These labels have a variety of applications for medical, cosmetics, glass and PE bottles, cardboard boxes, food, containers, inventory marking.

Special effects:

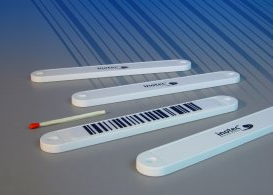

Metallic representations of gold, silver, bronze and other colours are available. Ceramic labels / Ceralabel

- inotec ceramic labels are used for extreme environment

applications where conventional labelling could not survive. These labels

are available in a range of designs and formats to suit various extreme

conditions, for temperatures up to 1,400°C, and prolonged exposure to

chemical, acids and aggressive solvents.

Applications:

A steel ceramic label consists of a special stainless, heatproof steel covered with a layer of ceramic. The ceramic layer is printed in a thermal transfer process and applied to the steel substrate. The steel background compensates for the fragility of the ceramic material and allows the label to be fixed mechanically using screws, rivets or welding.

Because of their robust, durable properties, these labels are often used for marking racks, containers and workpiece carriers permanently in a wide range of thermal and/or chemical processes.

Steel and aluminium industry: identification of annealing baskets in extrusion plants, identification of racks, tools or moulds in foundries, identification of containers in metalworking

Automotive: identification of workpiece carriers in lacquering and ‘paint and bake’ processes and containers in degreasing equipment

Pharma: identification of containers in the production process, autoclaves and other sterilisation processes

Food industry: identification of smoking and cooking trolleys, containers in pasteurisation plants and machine parts for cleaning and sterilisation schedules

Ceralabel SL 600/800/1000

- This steel ceramic label consists of special stainless, heatproof steel, covered with a layer of ceramic. The ceramic layer is printed in a thermal transfer process and applied to the steel substrate. The steel background compensates for the fragility of the ceramic material and allows the label to be fixed mechanically using screws, rivets or welding.

Ceralabel Green

- The Ceralabel Green ceramic labels are available on rolls in a wide range of formats. They are very flexible labels which are particularly suited for shaped or curved surfaces. These labels are printed in a thermal transfer process and are available in blank or printed formats. Following a special firing process, the labels are permanently bonded to the surface. These labels are used primarily in the glass industry for marking tubes, cylinders and other glass products and are available for various temperatures, from 400°C to 1200°C.

Ceralabel Laser

- This label is produced specifically for on-site laser engraving of your data. The type LSL600/800/1000 compound labels are extremely resilient and can withstand heavy mechanical damage immediately after marking. They are suitable for identifying hot surfaces and/or chemical processes.

Full ceramic

- Labels made from full ceramic are suitable for temperature ranges of up to 1650°C. Temperature ranges from 1000°C to 1650°C can be achieved. These labels are used in manufacturing processes which require extremely high temperatures, such as the production of cements or granulates.

Steel labels

- Our etched steel labels provide a reliable solution for the most extreme mechanical and chemical loads. These labels can be manufactured in any format and with any type of coding. The barcode is either completely cut out or engraved into the surface. Individual formats and different material strengths are available.

Thermal Transfer Printing Unit with RFID writer

- Specially designed for use in Production and Logistics. The perfect workstation for Just in Time, on-site, label and smart label production.

inotec Flexible Thermal Transfer Printing Unit with RFID writer

- Large rolls of labels – up to 350mm – can be processed

with ease, thanks to the custom made wind up and wind down unit.

Precise and problem free processing of barcode and RFID smart labels. Print and RFID encoding data, can be processed through the built in PC workstation or by integrating the unit directly into your own IT-network. An optional barcode scanning unit can capture and verify all printed data, in line - enabling continuous post-production verification, quality control and traceability. The advanced oscillating wind on facility, allows a continuous workflow, even when printing and encoding at the same time. Built from rugged stainless steel, the base construction is ideal for use in clean room, Medical, Hospital and Pharma facilities, as well as the Food industry and high demand production areas

Applications

Warehouse Logistics

- Flexibility, speed and accuracy in the handling of

goods are the cornerstones of modern warehousing and high performance

freight forwarding. To remain competitive in these sectors, providers must

be able to guarantee smooth-running internal processes and immaculate

adherence to deadlines.

Container Identification

- inotec labels are designed to offer durability and

accuracy in the harshest of environments. Our labels stand up to wind and

weather, cope with extreme temperature changes, are scratch-resistant and

unbreakable. Our labels guarantee effective handling and enable the fast

accurate identification which is so critical to the transport and logistics

industries.

Container ID

We are specialised in container management and can provide you with all solutions for identifying reusable containers, whether in a container pool or in open circulation. We also offer in-mould labels, which are bonded directly to the plastic container during the manufacturing process. The bond between label and crate becomes permanent, offering a smooth edgeless surface, which eliminates the risk of contamination behind the label. This makes in-mould the ideal choice for food and pharmaceutical industries.

Inventory

- For accurate Inventory control, all items must be recorded precisely. Our versatile labels make this task easier. With durable barcodes applied to the items, fast, accurate identification leads to extremely accurate stocktaking.

Libraries

- inotec

is a leading supplier of labels, membership cards and RFID tags to the

library industry.

We offer a choice of print technologies from archivable photo-composed labels and digitally undersurface printed labels to economic thermal transfer or laser printed labels with or without coloured logos.

Using our specialist materials and print processes, we can match our labels to your scanners and guarantee 100% readability of your labels. With adhesives and laminates designed for the library market, our labels will be hard to remove but will not deface or look untidy.

The product- High quality stick-on barcode labels from photosetting polyester

- Specialist adhesives to protect the surface of the books

- Improvement in service

- No waiting times when borrowing and returning items

- Fast processing of large quantities of data

- Easy integration of old stocks and new additions

- Protection against manipulation and theft using EM security strips

- All kinds of book and media identification (e.g. on the back cover, inside or outside)

- Identification of CD ROMs, audio CDs and DVDs

- Membership Cards

Industry

- Rugged labelling for industrial applications

Harsh environments require particularly high standards of quality and durability in barcode labelling. For these applications, inotec offer a huge range of scratch-proof and colourfast labels which are also resistant to oils, chemicals and acids.

inotec high-temperature labels asre used for extreme applications fpr which conventional labels are not sufficiently long-lasting or robust.- Ceramic labels, metal labels or film labels

- Temperature range up to max. 1,400°C

- Robust and long-lasting data carriers for extreme harsh environments

- For mechanical fixing, welding, branding or adhesive

- A variety of materials are available, supplied pre-printed or blank for in-house printing

- Offering multiple print processes and marking techniques

- Tool identification

- Factory equipment identification

- Conveyor marking (racks, containers, stillages, drums, hoppers, pallets etc)

- Circuit board marking

- Product identification (steel and aluminium industry)

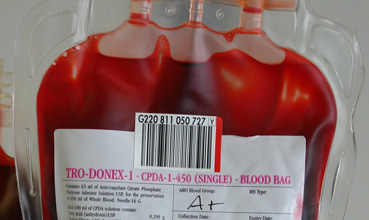

Medical labelling

- Barcode and RFID labels can be lifesavers –

identifying blood bags in blood donation centres, patients in hospitals or

samples in medical laboratories. The speed and accuracy of identification

achieved by using Barcode labels, has made them an irreplaceable tool in the

healthcare sector.

The product- Photocomposed labels with medically approved (FDA) and diffusion-free adhesives

- Available for multiple application in ‘piggy back’ sets

- Colour coding options available

- Thermal transfer labels also available for in-house printing

- Secure identification of patients and sample material

- Immediate access to complex disease patterns

- 100 % Accuracy

- 0% Duplication

- Effective organisation of laboratory processes

- Fast medical supply ordering systems

- Labels are also available for use in freezers or Autoclaves