- Offer Profile

- Racking systems made by GALLER – the perfect fit for all your storage needs

We use our versatile racking solutions to build your custom storage system. Each of our racking systems can be modified to perfectly suit your requirements: surface area, building height, conveyor equipment, storage goods, logistics processes – no matter what your requirements are, our experienced specialists will create the most efficient racking system for your storage needs.

Case Studies

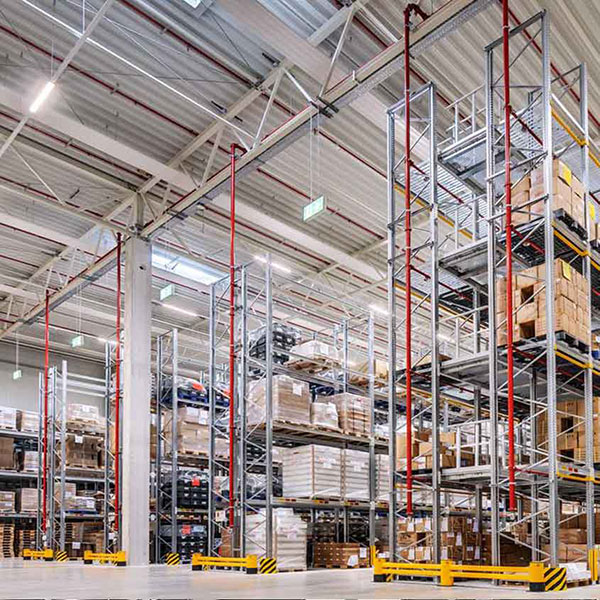

GALLER pallet racks - Individual warehouse solutions

-

Racking systems made by GALLER – the perfect fit for all your storage needs

We use our versatile racking solutions to build your custom storage system. Each of our racking systems can be modified to perfectly suit your requirements: surface area, building height, conveyor equipment, storage goods, logistics processes – no matter what your requirements are, our experienced specialists will create the most efficient racking system for your storage needs.

Manual racking systems

-

The GALLER pallet racks for manual operation are manufactured from the proven system components of the OMEGA profile. All of the essential components are profiled, welded and surface treated at the production facilities in Kulmbach.

Flexibility and a rational design make the multi-storage pallet rack an indispensable component for intralogistics.

An improved utilisation of space and the storage of particularly heavy goods are the most important reasons for using a single-storage pallet rack.

For the non-stackable unit loads with low turnover, the drive-in pallet rack is a particularly space-saving storage type

In hot-dip galvanised design and, if required, with roof and wall cladding, these systems are also perfectly suitable as storage systems for outdoor installation.

Multi-storage pallet racks

- Multi-Storage Pallet Racks

Multi-storage pallet racks – the backbone of intralogisticsThe OMEGA pallet rack is the basis of our versatile rack systems. Its flexibility and the rational design make it a core element for your individual storage solution.

- Enables the storage of a wide variety of load carriers (pallets, containers, pallet cages, corlettes, barrels, etc.)

- Lengthwise and crosswise storage of the load carriers

- Up to five pallets next to each other in one compartment

- Optionally in a welded model for additional stability and load capacity

- Surface treatment for each of your requirements: Sendzimir-galvanised, hot-dip galvanised, powder-coated or OR6000 for the highest level of corrosion protection worldwide

Pallet rack in steel construction

For the storage of particularly heavy or bulky loads – as they are often found in steel construction – GALLER specially customised pallet racks. In this way, semi-finished products or even entire assemblies can also be stored in a space-saving and efficient manner.Outdoor pallet rack/with roof and wall

Do you need a pallet rack system for your outdoor storage area? This is no problem with the robust OMEGA pallet rack! It also meets the significantly higher technical and structural requirements of outdoor use.For outdoor installation, we deliver OMEGA pallet racks with welded uprights and hot-dip galvanised as standard.

You can choose from various roof and wall elements for protection against the weather.

Single-storage pallet racks

-

Single-Storage Pallet Racks

When compared with multi-storage systems, GALLER pallet racks provide a better load distribution (support load). This makes them particularly suitable for the storage of heavy goods.- Also well suited for direct order picking from the pallet or pallet cage

- Very good utilisation of space using angle profiles instead of beam profiles

- GALLER OMEGA pallet racks carry the highest loads with the lowest tolerances

- Quick and easy assembly

- High degree of flexibility via 50 mm adjustment

- Flexibly adjustable due to the broad range of variable front-to-back supports

Drive-Inpallet racks

-

Drive-In Pallet Rack

GALLER also provides drive-in pallet racks for a particularly high degree of space utilisation. The industrial truck enters the channels for this purpose. These racks provide efficient storage, particularly for the same type of bulk goods.Drive-in pallet rack

- Best possible utilisation of space (nearly) as in block storage

- Ideal for non-stackable unit loads with low turnover

- Drive-in pallet racks for lengthwise and crosswise storage

- Loading and unloading are carried out via one and the same work process

- Drive-in pallet racks enable the Last In – First Out principle

- Individual pallets are not directly accessible

- Floor guide rails for more than four storage spaces in a row facilitate manoeuvring of the forklift

- Homogeneous goods are stored very compactly and economically

- Comprehensive range of accessories from the multi-storage pallet rack system

- Very low profile height for pallet rails guarantee low loss of space

Drive-through pallet rack

- Almost identical in design to the drive-in pallet rack, but with an open construction at the end

- A forklift can drive through the rack aisle

Storage from one side, removal from the other side of the rack - Easy realisation of a First In – First Out strategy

- Higher turnover rate than with the drive-in pallet rack

Dynamic Storage Systems

-

We bring movement into your warehouse with our dynamic storage systems!

With this storage technology, you can store your goods particularly compactly without the need for a forklift to manoeuvre laboriously in rack aisles. This is because the goods are automatically transported to the removal position via rollers or trolleys using gravity. This can save you a lot of time compared to conventional compact storage.

Movable racks are a special feature of dynamic storage systems: here, the complete rack row moves – this enables the combination of highly compact storage with targeted access to individual storage locations.

Flow Rack / Push-Back Rack Trolley

-

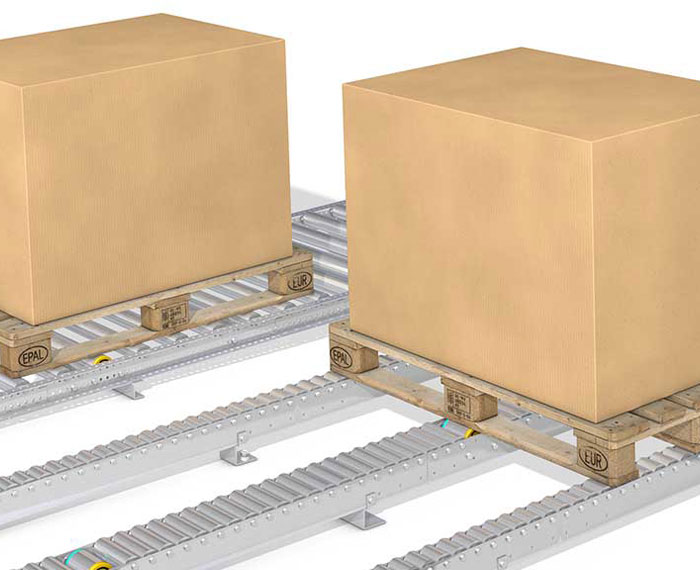

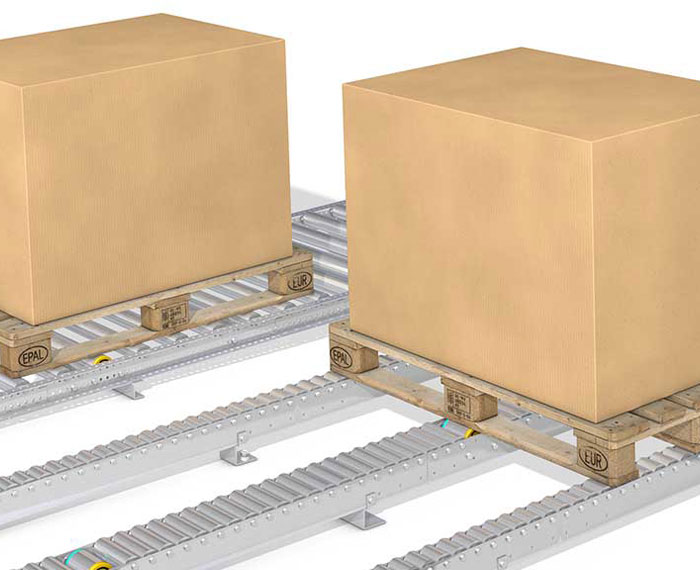

Push-back and flow racks with our pallet roller conveyors enable optimum space utilisation by means of dynamic block storage. This also allows convenient monitoring of your inventories.

Highly suitable for fast-moving items due to extremely efficient order picking

Push-back rack: Last In – First Out

Flow rack: First In – First Out, which is, for example, required for batches, expiry date and product series

Our OMEGA pallet racks are optimally coordinated with the flow and push-back racks.

Also available for outdoor applications.

Due to their optimum utilisation of space, flow racks are frequently used in cold storage and freezing facilities.The smooth running support rollers of the roller conveyors from GALLER guarantee you trouble-free processes and a high degree of operational safety. Pallets weighing between 200 and 1,200 kg can run mixed in the same channel. If you use special pallets: We adjust our systems to them and test the smooth function in our GALLER test centre.

- Centrifugal brakes provide optimum regulation of the running characteristics of all pallet types and loads.

- The spring-loaded brake bearing guarantees optimum and constant braking performance.

- Every pallet is sure to reach the end stop thanks to the “dynamic pre-stopper”.

- Mechanical and pneumatic separators enable the pallets to be removed without dynamic pressure.

- The particularly stable design prevents damage from forklift tines.

- All components are suitable for low temperatures: brakes, ball bearings, rollers, gearboxes.

- The triple-divided floor mounted unloading section allows removal using a hand pallet truck.

- We also provide you with guaranteed operationally safe solutions for pallet cages, metal pallets, plastic pallets, half pallets and special pallets.

Functional sequence

The basic principle of both systems is a compact rack block comprising channels that are side-by-side and above one another. The channels are equipped with support rollers that have a gradient of 4% so that the goods run through the channels automatically via gravity. Flow racks are loaded from one side and unloaded from the other side (First In – First Out). In the case of push-back racks, loading and unloading are carried out from the same side (Last In – First Out).

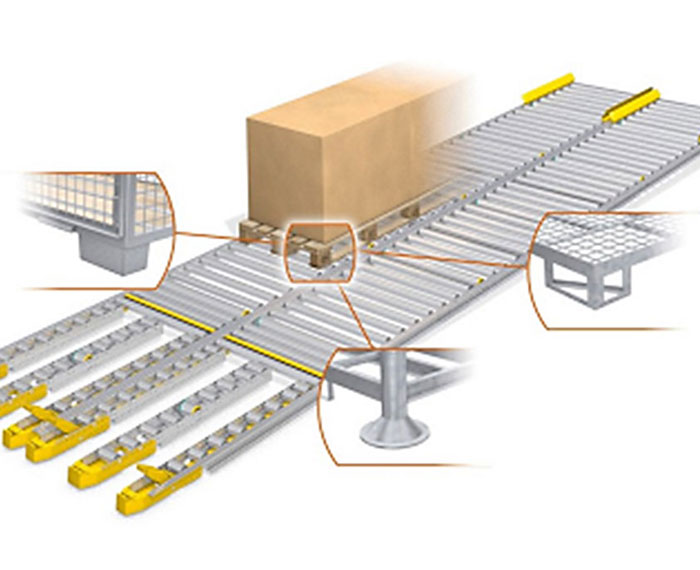

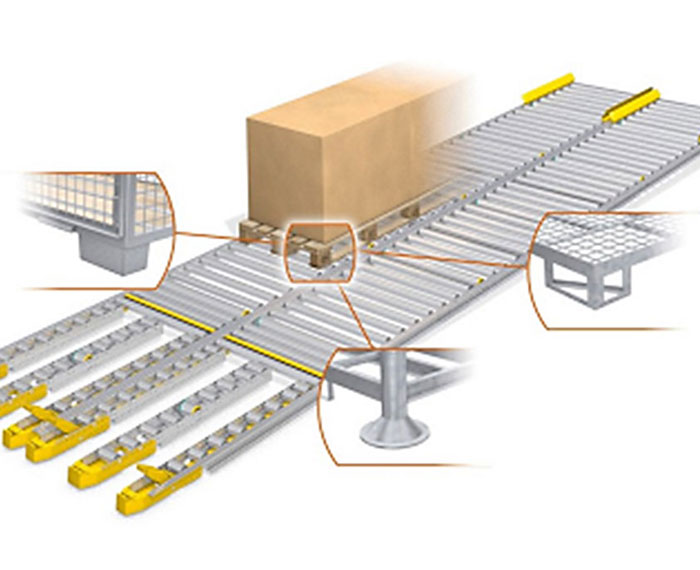

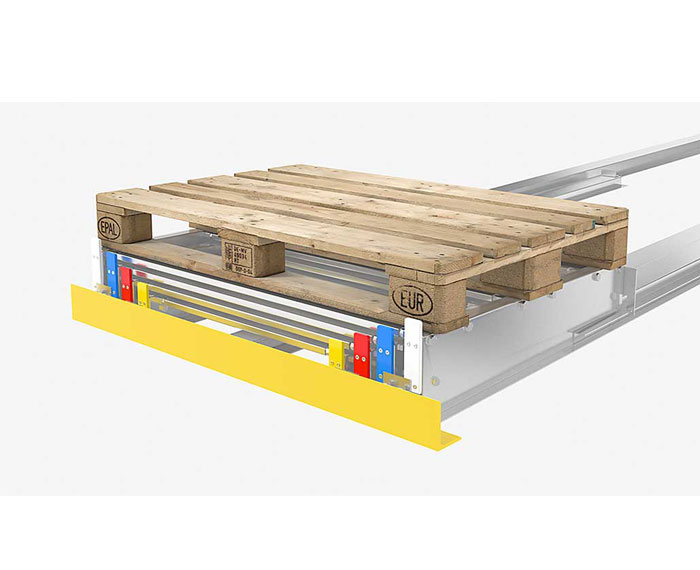

Pallet floor roller conveyor

-

Pallet floor roller conveyor

GALLER also provides roller conveyors for mounting on the floor. The elements can be installed with or without a slope and are used, for example, in provision zones or picking areas.The smooth-running conveyor rollers of the floor roller conveyors from GALLER guarantee you trouble-free processes and a high level of operational reliability. Pallets with weights from 200 to 1,200 kg can run mixed in the same channel. If you use special pallets: we adapt our systems to them and test the smooth functioning in our GALLER test centre.

- Centrifugal brakes provide optimum regulation of the running characteristics of all pallet types and loads.

- The spring-loaded brake mounting guarantees optimum and constant braking performance.

- Thanks to the “dynamic pre-stop”, every pallet really reaches the end stop.

- Mechanical and pneumatic separators enable the pallets to be removed without accumulation pressure.

- The particularly stable design prevents damage from forklift tines.

- All components are suitable for low temperatures: brakes, ball bearings, rollers, gearboxes.

- Removal using a hand pallet truck is possible due to the floor discharge divided into three parts.

- We provide you with guaranteed operationally reliable solutions also for pallet cages, metal pallets, plastic pallets, half pallets and special pallets.

Your advantages with floor roller conveyors from GALLER

longitudinal and – NEW – transverse transport of pallets possible- three-lane tracks minimise deflection and maximise operational reliability.

- excellent operating characteristics due to short roller pitch and length

- convenient removal of the pallets due to separator with foot release

- easy cleaning between the tracks

Multi XXL roller conveyor for all conceivable load carriers

-

Multi XXL roller conveyor for all conceivable load carriers

With the Multi XXL roller conveyors from GALLER you have maximum flexibility for the loading aids used. You can use up to seven different pallet types on the same lane – whether made of wood, plastic or steel. Even load carriers with small plate feet or narrow skids run reliably on the rollers with precision bearings. Use the Multi XXL roller conveyors, for example, as provision storage in production, incoming goods or despatch. They have also proven themselves as a link between work stations or internal intermediate storage.- Load capacity of up to 3 t per storage space

- removal without accumulation pressure

- precise separation and isolation technology

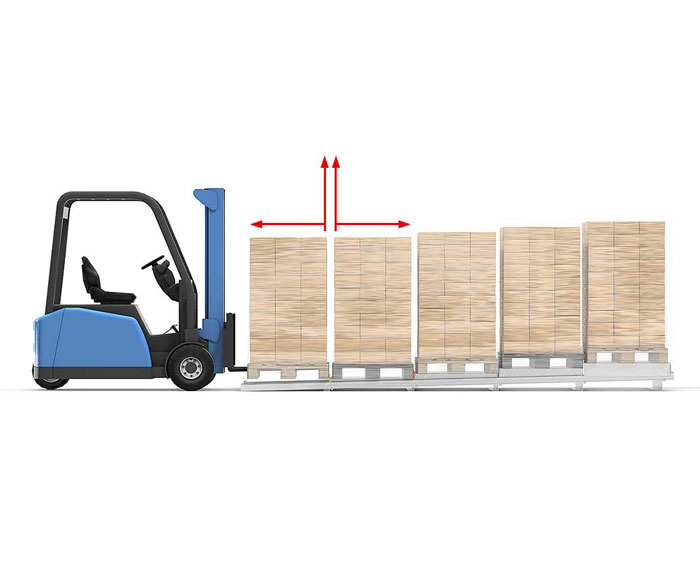

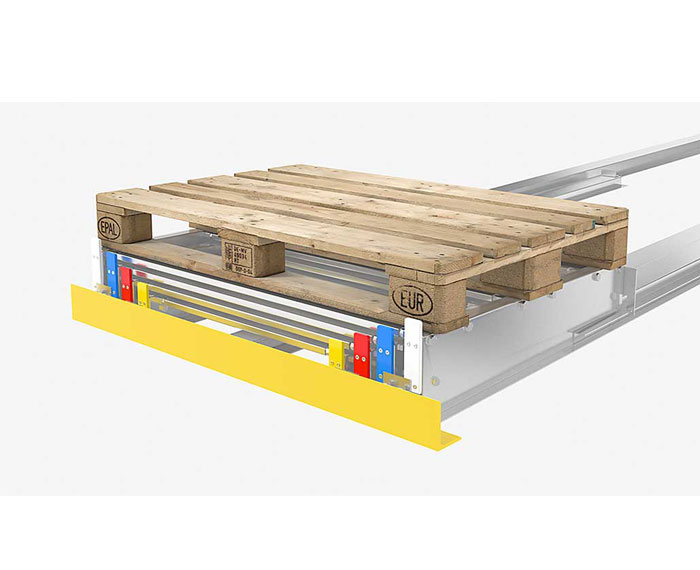

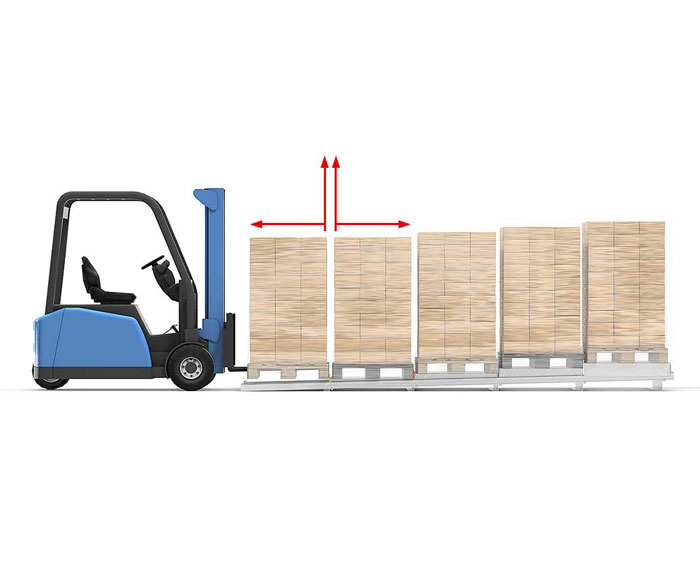

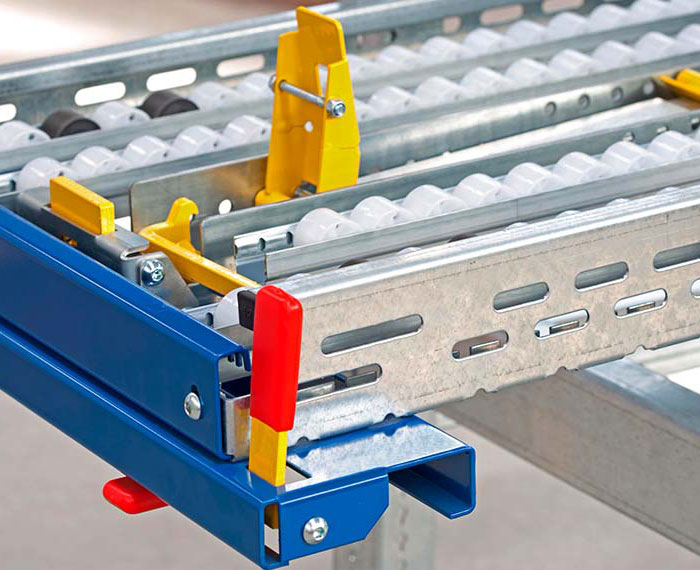

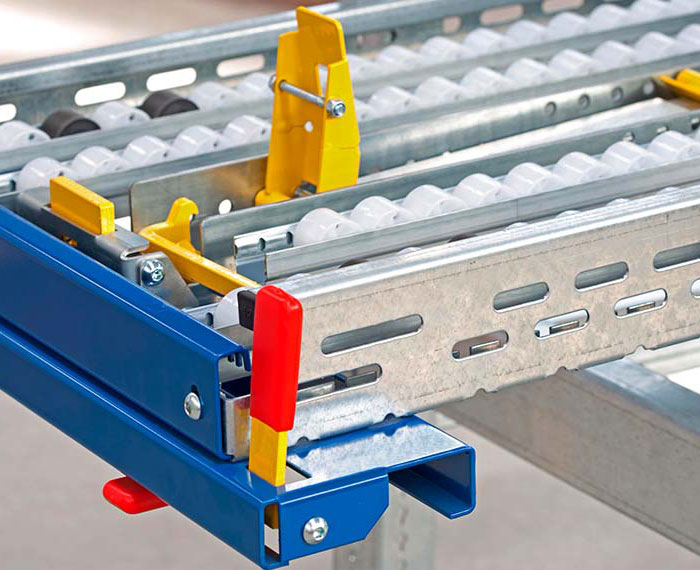

Push-Back Trolley

-

The push-back trolley system is an alternative to push-back racks that is gentle on goods. It provides the same benefits and range of possible applications, but in addition, it allows the storage of goods without dynamic pressure. This is because the unit loads are put on trolleys with a level load deck. This also makes the push-back trolley system independent of the quality of the pallets. Due to the inclination of the tracks, the trolleys automatically travel back in the direction of the loading side.

- Efficient solution for the storage of the same types of articles according to the “Last In – First Out“ principle (LIFO)

- Also suitable for damaged or shrink wrapped pallets

- Equally suitable for pallet cages, steel pallets or pallets stored crosswise

- Lengthwise and crosswise storage of load carriers is possible

- Mixed storage of different pallets and pallet cages in one channel

- Particularly suitable for use in deep-freeze areas

1. Rail system

2. Push-Back Trolley

3. Top-hat profile

4. IPG beam (angle bracket)

Additional accessories such as collision guard elements, protective fences or roofing and wall cladding comply with the multi-storage rack systemBenefits of the GALLER Push-Back Trolley System

- No dynamic pressure during removal – pallets do not touch each other

- The pallets always stand horizontally during storage and removal

- Sensitive goods or goods stacked unstably remain intact at all times.

- Operation also possible with devices WITHOUT mast inclination

- The trolleys run particularly smoothly on steel rollers with ball bearings.

- Thanks to the low 2.5 degrees inclination of the rail track, only a small amount of push force is required for storage – even for heavy pallets.

- Quick information on the filling level via colour-coded limit plates.

- Extremely low maintenance system components that are easy to replace

- Easily mounted – existing pallet racks can be retrofitted without problems

- Special dimensions and higher load capacities possible for special pallets

Order picking flow rack

-

When picking small parts or packages of any size, order picking flow racks from GALLER enable you to achieve a significant gain in efficiency. The flow racks provide you with continuous availability, very compact storage and a particularly high order picking rate for a very large number of items. The order picking flow racks allow the use of cartons, boxes or crates. We configure your individual order picking flow rack from different levels and channels that are equipped with roller rails. Our experts optimise the number and design of the levels ergonomically for the respective articles or containers and work tasks. Typical applications of our order picking flow racks are in shipping and web retailing, in the food industry, in white goods distribution centres or in provisioning in manufacturing and assembly.

- Flow racks basically work according to the First In – First Out principle.

- The flow channel is loaded on one side of the rack and unloaded on the other side.

- A flow rack can also be automatically loaded by automated storage and retrieval systems.

- The order picking flow racks can be designed as a standalone solution or – also retrofitted – integrated into pallet racks.

- Fatigue-free work thanks to accessories such as picking tray, handrail or step

GALLER flow racks provide you with these advantages

- Rollers are mounted on steel axles: best running properties, long service life, particularly quiet running with high load capacity (12 daN).

- 28 mm roller pitch: best running properties also with the smallest stored goods

- Highly conductive rollers (ESD version) available on request.

- Rack depths of up to 20 metres

- Brake rollers enable diverse applications: e.g. sorter buffers, supermarket applications, particularly high inclination or deep flow racks

- Brake rollers can be retrofitted

- The weight range provided by GALLER is unique on the market.

- individual guide rails for special applications

- very easy to assemble thanks to tool-free insertion of the beams, roller and guide rails

Function Description

- The stored goods automatically advance to the pick-up point via roller rails.

Mobile racks

-

Mobile racks enable you to make excellent use of space and area in the warehouse, while allowing direct access to each stored pallet.

Particularly suitable for rather low turnover rates

Ideal in the cooling/refrigeration area, as the air is able to circulate freely between the goods

´Frequency-controlled motors enable smooth start-up and braking.

The aisle width depends on the ability of the forklift to manoeuvre.

Space saving up to 50%, and an increase of storage capacity of up to 100%

Lower investment costs in buildings and operating costs due to the compact designFunctionality

Mobile racks are OMEGA multi-storage pallet racks mounted on trolleys. They are driven by an electric motor. In this manner, the racks can be moved close together. In order to access a pallet, the forklift driver only opens a single rack aisle. This enables extremely compact storage, yet each individual pallet can still be accessed directly.Cantilever racks on trolleys

Instead of pallet racks, trolleys can also be equipped with cantilever racks.

The trolley is adapted to the individual designs.

If the arm levels are connected by cross beams and shelves, then the result is a continuous storage level.

Automated Storage Systems

-

In the field of automated storage systems, GALLER provides racking and shelving equipment for the systems commonly used in intralogistics. From AS/RS / shuttle warehouse, AMS to high-bay racking silo, GALLER meets your customer requirements based on the system components of the OMEGA profile.

Customers from a wide range of industries rely on our rack systems Made in Kulmbach, some of them for decades, in the DACH countries, in Europe and beyond.

Our experienced sales consultants are at your side throughout the entire process, from consultation and planning to implementation. Take advantage of our know-how and decades of experience.

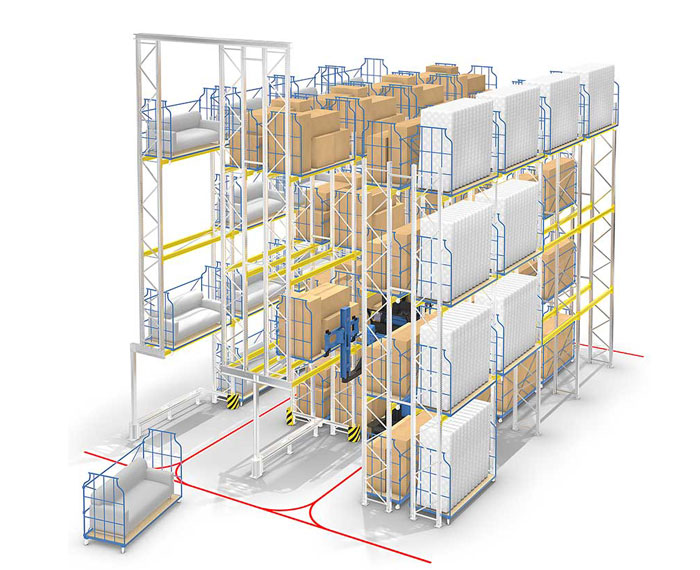

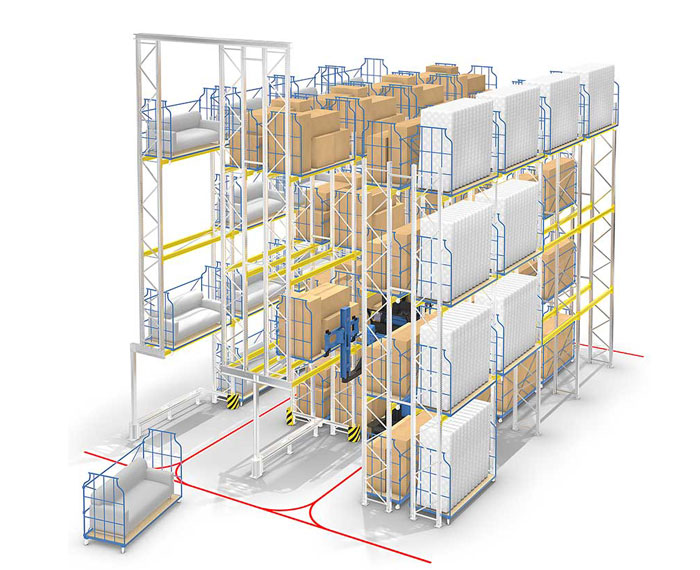

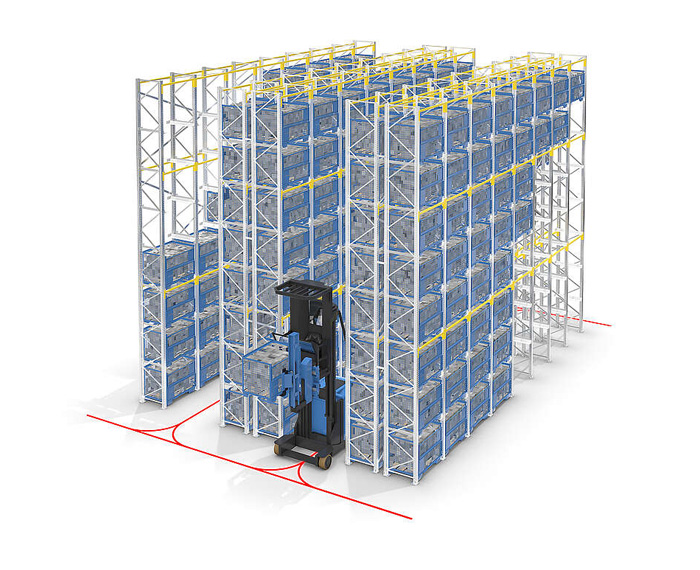

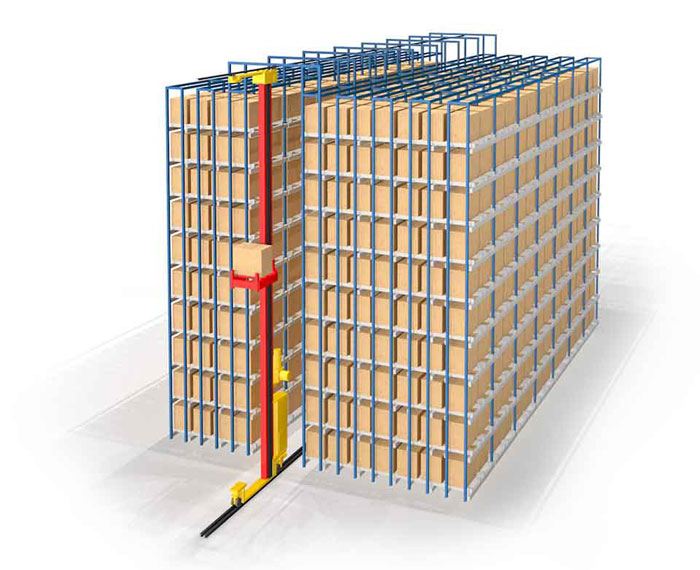

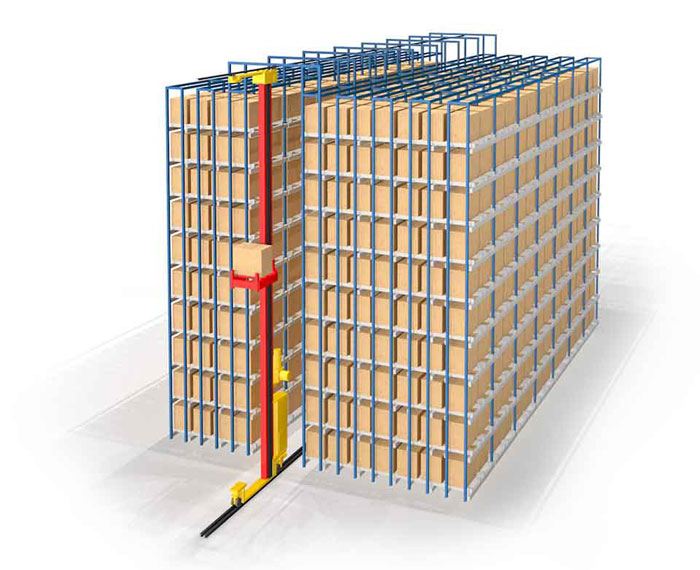

AS / RS (automated storage and retrieval system) / Shuttle

-

GALLER high-bay racking with automatic storage and retrieval systems (AS/RS) and shuttle systems are manufactured from the proven system components of the OMEGA profile. All essential components are profiled, welded and surface-treated in the Kulmbach production facility.

We design the racking system to suit your individual requirements, taking into account the loads from the load units, the loading vehicles and local conditions such as earthquake zones. Perfect alignment and levelling of the system as well as coordinated system components enable the high quality that is indispensable for these rack systems.

Functionality

The automated storage and retrieval system (AS/RS) is guided on a running rail on the floor and on a guide rail in the racking aisle at the racking head. The load handling device, which is adapted to the requirements, picks up the pallets in single-deep or double-deep storage using telescopic forks and transfers them to the conveyor system, which brings the load to the order picking zone. The storage process is analogous. Storage and retrieval are automated in this system.

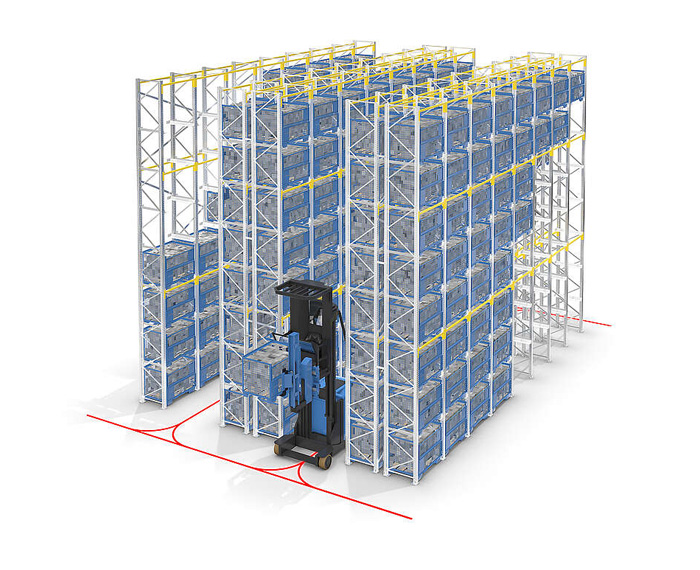

Automated miniload systems

-

With our automated miniload systems (AMS), you can meet even the highest customer requirements regarding delivery times and delivery quality. Thanks to their high-bay design and automation, they allow a very high volume utilisation and highest handling rates.

- A solution from a single source: In addition to rack construction, GALLER also supplies automated storage and retrieval systems, trays and gravity-free conveying and order picking technology.

- We cooperate with competent conveying technology and system integrators for the implementation

- including complete covering of the entire rack installation

Functionality

The automated storage and retrieval system pulls the tray or container from the rack shelf onto the load handling device, brings it to the picking area (or onto a conveyor section to the picking zone) and also picks it up again there (“goods to man”). The automated storage and retrieval systems achieve high accelerations or speeds when moving, lifting and storing, so that very high handling rates can be achieved with an AMS. The load capacity of the automated storage and retrieval systems is usually between 50 and 300 kg.

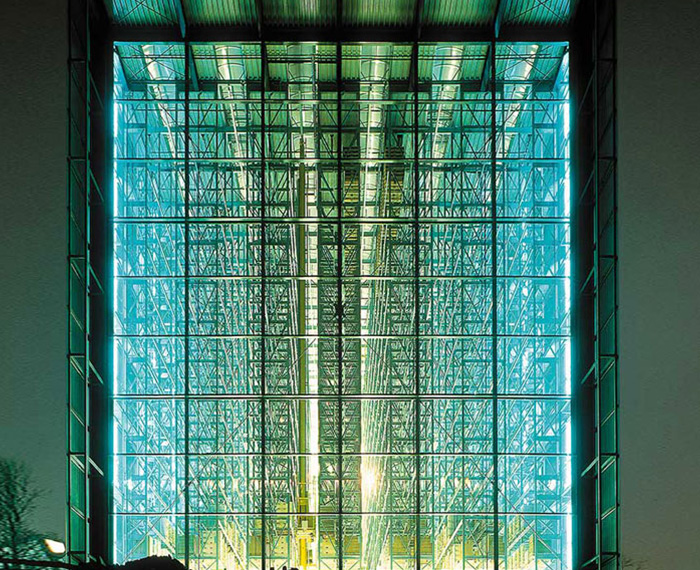

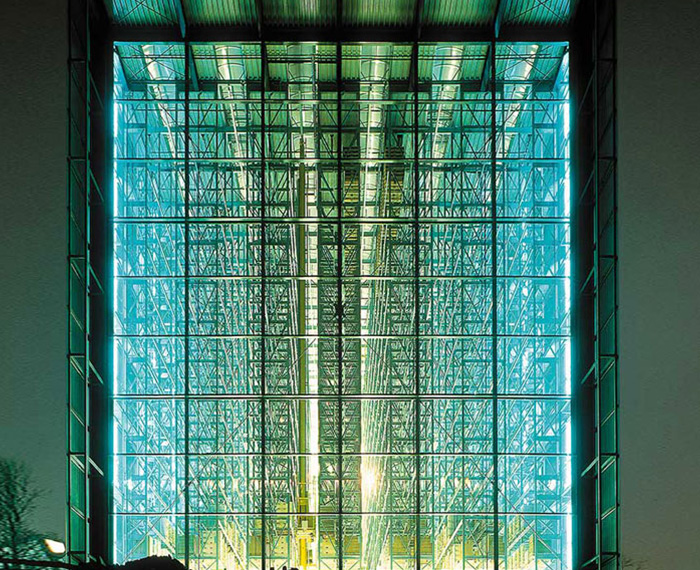

High-bay racking silo

-

High-bay racking silos from GALLER allow you to store large quantities of an item with high handling rate. Thereby, the high-bay pallet racking also takes on the function of a load-bearing building structure. This means that the roof and wall claddings are attached to the rack structure. With this compact design, you make particularly efficient use of the available space. With their dominant dimensions, high-bay silos are striking figureheads of a company. Therefore, architectural criteria should definitely be taken into account during construction.

- The warehouse shell can be claimed as production equipment for tax purposes.

- By eliminating the construction of a separate building, commissioning is much faster and construction times are significantly shorter.

- The silo construction accommodates the load of the stored goods, the own weight of the roof/wall elements as well as wind pressure and snow load.

- From a construction height of 10 m, the silo construction becomes economically interesting.

- Modern high-bay silos combine utility with innovative industrial architecture.

Functionality

The rack aisles in the high-bay silo are usually operated by automated storage and retrieval systems. Usually one automated storage and retrieval system is used per aisle. In storage warehouses with a high number of storage locations and a low access frequency, the control units can also be moved between the racking aisles via a transfer bridge and thus serve several aisles.

Supplementary Storage Systems

-

The extremely load-bearing cantilever racks are the right choice for the storage of long and bulky goods. Pipes, steel profiles, sheet metal or even wooden boards and sheet metal can be stored ideally in this manner. Even old vehicles, sailing ships and all kinds of heavy loads can be stored here. Without a front support, the stored goods can be accessed directly.

Shelf racks are an important component for the flexible storage of goods without special containers or storage aids. They are primarily used for the storage and order picking on non-palletised units of goods, small parts, containers, outer packaging or stored goods in loose form.

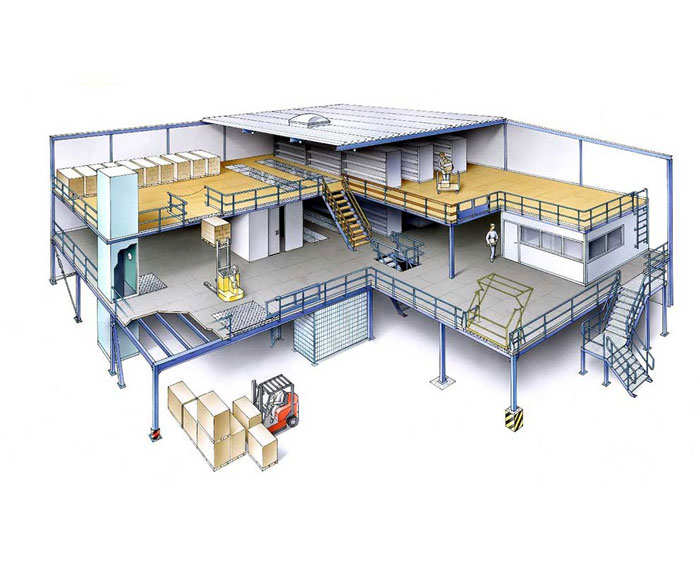

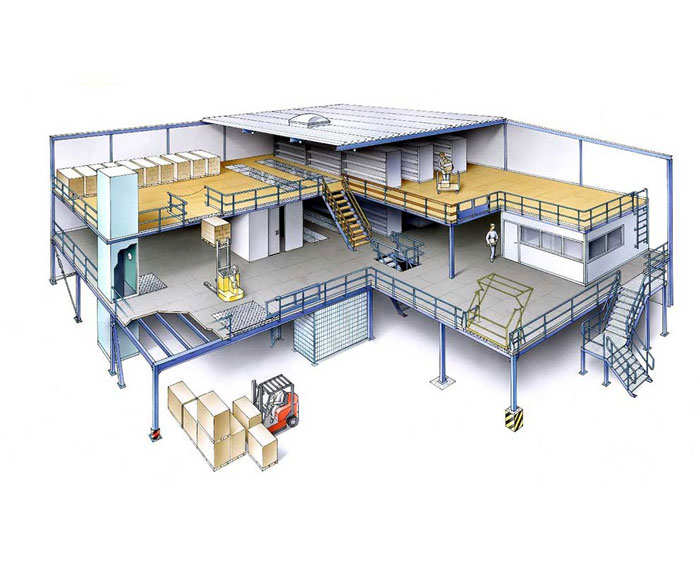

Mezzanine floors in single-level or multi-level construction increase the available area or workspace without the need to add or to convert the building. Mezzanine floors are self-supporting, can be accessed on foot and, in some cases, can also be driven over.

Logistics steel construction from GALLER is the perfect supplement to our rack systems. From stair towers, aisle bridges, fences and railings to complete substructures for conveyor technology, we offer you all of the components to complete your intralogistics projects.

Cantilever rack

-

Cantilever racks from GALLER have no limits: Not only can you store long goods in them;it is also possible to store pallets or other packaging units with the appropriate accessories. There is no racking system more versatile than a cantilever rack.

- All load carriers and all lengths can be stored side by side in a diverse mix..

- Ideal for long, heavy or bulky goods such as profiles, wooden plates, steel, plastic or even vehicles and ships

- Pallets with differing dimensions or overhangs and containers can be stored with no loss of space.

- Arm bridges and shelves make the cantilever rack free of support, providing you with a long and continuous storage level.

- The stored goods can always be accessed directly.

- Optimised storage solutions for numerous sectors and products

- The storage levels are freely adjustable in 100 mm height increments.

- With a roof and wall, the cantilever rack expands outdoor storage.

Shelf racks

-

Flexible in their application and combinable in any way, GALLER shelf racks are particularly suitable for non-palletised goods in small and very small containers. As a manual storage system, they are always used when many goods and small quantities have to be stored As goods are placed directly on the shelf, the small parts can be stored in containers and outer packaging as well as in loose form. The GALLER system allows the construction of multi-level rack systems.

Benefits

- Rack heights between 1,800 mm and 7,500 mm, single or double-sided use

- The shelves are simply inserted into the load-bearing frames in 25 mm increments

- A highly comprehensive range of accessories enables a wide variety of uses

- Trouble-free, quick assembly and conversion if necessary

- The 25 mm insert grid enables optimisation of shelf heights

Variety of Shelves

- GALLER provides you with shelves in four widths and in various depths – individually tailored to your needs

- Two installation heights (25 mm and 40 mm) and four load capacities (85 kg, 150 kg, 250 kg, 330 kg)

Mezzanine Floor, Standard

-

Standard mezzanine floors from GALLER allow you to quickly and easily enlarge your existing working space – with no need for building extensions or conversions. Subsequent installation in your logistics property or production hall is possible without any problems. The entire structure of our mezzanine floors is self-supporting, and foundations are unnecessary.

- It can be fitted precisely to walls and corners thanks to centimetre grids

- Standard mezzanine floor with 300 – 500 kg/sqm load capacity and 3 – 5 m span lengths

- Supports are made of round tubes; beams and rafters are made of narrowSigma steel sections

- Stairs, railings, transfer stations included – depending on requirements

- Flooring of mezzanine floor made of chipboard plates, both sides untreated, 38 mm

- Bolted system – the mezzanine floor can be extended, dismantled and moved at any time

- Depreciable as with machines

In addition to standard mezzanine floors, we also offer you steel mezzanine floors designed and manufactured individually. This enables you to quickly create additional space for further racks, workplaces, production offices or order picking zones. The entire system is independent of the building design and is integrated precisely into your hall construction.

Mezzanine Floor, Individual

- Less expensive and more flexible than concrete false ceilings in new buildings

- Up to 12 m span lengths

- Up to 5 levels and more can be realised

- Up to 2 t/sqm

- With rack systems on the steel platform (highly concentrated loads)

- Can be driven over with electric lift truck (dynamic loads)

- It can be realised with watertight design and with the highest level of corrosion protection

- All shapes and layouts are possible

- Stairs, railings and transfer stations, depending on requirements

- Everything from a single source: Stair towers, fire protection, lifts, load chutes…

- Supports, beams and purlins made of thick-walled steel sections

- Superstructures of production facilities, driveways, storage/working areas

- Obstacles such as passageways, doors, gates, windows, pipes and channels are built around

- Bolted construction: expandable and easy to relocate

- Mezzanine floors and steel mezzanines are depreciable as with machines

Logistics steel construction

-

Steel construction for intralogistics

GALLER provides you with complete intralogistics solutions from a single source. This also includes an experienced steel construction team. We design and assemble all the steel construction elements that your warehouse needs – from the substructure for conveyor technology, stairways and catwalks to fences and railings.- Large project team: own structural analysis, approval technicians, designers, assembly planning, project managers, documentation

- All permits and certificates for planning, production and assembly are available

- Even complex projects up to object sizes of 1,000 metric tons

- Realisation of projects in existing buildings during ongoing operations