- Offer Profile

-

IdentPro was founded in 2007 with the goal of eliminating the manual scanning of barcodes for identification and localisation of products in intralogistics. Why?

In our opinion, barcode scanning is such a banal activity that it cannot be justified by the use of human labour. Rather, we believe that employees should take on better, more appropriate and demanding tasks. That is what we strive for and we are constantly improving ourselves and our products.

We believe in thinking differently and therefore question the status quo in order to achieve optimal solutions. We redefine the status quo by making our products digital, autonomous and highly available.

Based on these beliefs, we have worked long and hard for our groundbreaking solutions in vehicle localisation, digital twins in intralogistics and autonomous mobile robots.

Today, our solutions are in productive use at leading automotive companies, the world’s largest brewery and the world’s leading steel group in more than 10 countries.

Warehouse Execution System

-

IdentPro’s Warehouse Execution System revolutionizes intralogistics and creates the missing link between ERP / Warehouse Management Systems and the real warehouse world. Designed for superior efficiency, the Warehouse Execution System offers complete visibility and error-free deliveries in warehouse and production with a unique technology. Our Warehouse Execution System locates and identifies pallets and similar load units by tracking the movement of forklift trucks. This creates a real-time digital twin (RTLS). This enables us to return existing transport orders, including navigation, to the industrial trucks. Here it does not matter whether manned or unmanned.

IdentPro’s Warehouse Execution System eliminates the basic problems in the warehouse: misplaced pallets and incorrect barcode scans. Intelligent programming also shortens empty runs, makes better use of warehouse capacity, and reduces fleet sizes. The inventory data in the ERP system always matches the real warehouse situation 100%. Whether indoor or outdoor, our system finds the stored goods even if they have been placed in an unassigned location.

Real-time localization with manned forklifts

-

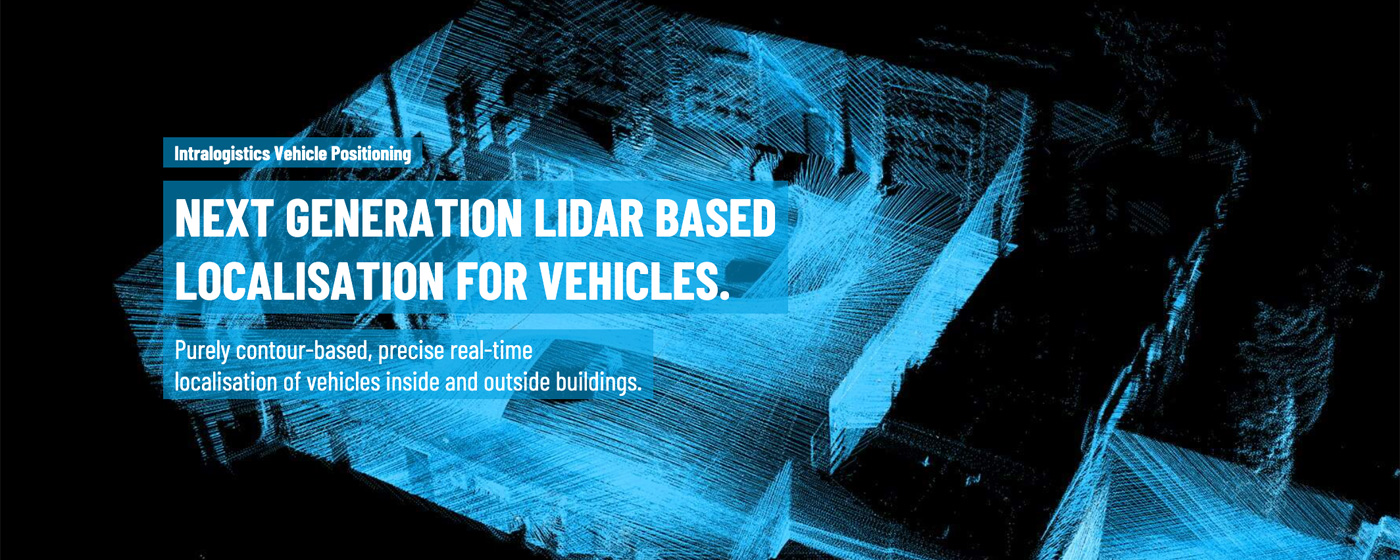

For the 100% digital twin, tracking of all stock movements is essential. This includes not only the automated movements, but also in particular the movements of manned industrial trucks. Various technologies such as GPS, radiolocation and state-of-the-art camera systems can be used for this purpose. Analogous to the development of automated driving in the automotive industry, a laser-based localization system has also proven its worth here. The advantage of this system is that it does not require any additional infrastructure. It is also characterized by its high precision (cm-accurate) and robustness for indoor and outdoor use. Due to its extensive use in the automotive industry, its introduction in intralogistics is now also competitive in terms of price compared to the systems mentioned above.

After we mount the sensors on the any vehicles, it captures the environment every second and creates the digital image of the warehouse. This is updated with each movement after a brief initial capture. The forklift terminal transmits its position simultaneously via 5G or Wifi. The system works exclusively with the contours of the environment and does not require any other sensors, reflectors or other aids.

Automated vehicles (AMR)

-

IdentPro’s AMRs are revolutionizing intralogistics. The fully autonomous transport robots (Autonomous Mobile Robot, AMR) were developed to meet the requirements of collaborative use with manual forklifts. The AMRs serve any source/sink and – optionally through an integration in the Warehouse Execution System – enable scan-free, end-to-end pallet tracking. These can be used stand-alone or integrated into the overall warehouse optimization via the Warehouse Execution System.

- True autonomous navigation including obstacle avoidance

- Picks up pallets from ground even in slanting position

- 24/7 operation possible due to Li-Ion battery technology

- Safety technology for the detection of persons and obstacles (CE approved)

… selected references

Automotive industry BMW

-

BMW: Paperless internal material transport and error-free deliveries

- Application: Container tracking and loading control

- Solution: Warehouse Execution System, AMR

- Integration: with SAP® WM

- Special feature: Integration of freely navigating transport robots in resource control system

For its intralogistics lighthouse project Supply Center VZ2 at the Landshut location, the BMW Group required a paperless material flow with automatically triggered postings in the ERP system SAP® WM. The aim is to permanently ensure correct deliveries to internal and external customers. In addition, the transport capacities (forklifts and AMRs) are to be optimally utilized via an intelligent control system.

It quickly became clear that the defined goal could only be achieved by foregoing the error-prone scanning of barcodes by forklift drivers. For this reason, the BMW Group opted for IdentPro’s Warehouse Execution System at an early stage. The solution was set when selecting the logistics partner and since July 2017 the system navigates and supports the forklift drivers in the scanning-free execution of internal transports. All transport orders are monitored in the background by the Forklift Management System for correct execution (source, HU, sink).

Beverage industry Refresco

-

Refresco: more transports by eliminating scanning and reducing empty runs

- Application: Tracking of pallets without scanning

- Solution: Warehouse Execution System

- Integration: with SAP® EWM (partner: prismat GmbH)

- Specialty: Transport of up to 6 load units simultaneously, integration with conveyor technology

Refresco Germany is part of the international Refresco Group, and, with over 6 billion liters, one of the leading producers of fruit juices and soft drinks in Europe today. Task: The consolidation of two locations required a significant improvement in warehouse efficiency. The goal was the complete elimination of any unproductive processes, such as manual barcode scanning, searching for pallets, storage locations and batches. Implementation: The previous warehouse management based on a classic SAP® WM solution with hand scanners was converted to SAP® EWM and automatic feedback through the automatic localization and identification of forklifts and pallets using IdentPro’s Warehouse Execution System.

Plastics industry A+C Plastic

-

A+C Plastic: Customer deliveries and removal from storage with loading lists and automatic checks for accuracy and completeness

- Application: Stock transparency, paperless loading and simplified traceability

- Solution: Warehouse Execution System

- Integration: with DS-SOFTWARE

- Specialty: Integration of scales; grown, labyrinthine topography

A+C Plastic produces 25,000 tonnes of high-quality industrial packaging made of LDPE film on ultra-modern extrusion lines every year. As one of the most modern production facilities in Europe, A+C Plastic offers individual and tailor-made solutions for all important industrial sectors. In addition, very individual application areas are also served.

In multi-stage production processes, a large number of products and product variants are produced. Semi-finished and finished goods and residual quantities are weighed before storage. The aim of A+C Plastik was to ensure accurate pallet tracking within the warehouse and during dispatch. For loading, the forklift drivers receive loading lists on the forklift terminal and are navigated to the goods required. Completeness and correctness of the loading are checked automatically.

IdentPro’s Warehouse Execution System is based solely on natural environmental features, this has made system implementation much easier in the winding terrain.

Warsteiner brewery

-

Warsteiner: Avoidance of the obligation to scan with SAP EWM, optimization of empties collection and resource utilization

- Application: Tracking of pallets without scanning, handling of empties, scan-free factory transport

- Solution: Warehouse Execution System

- Integration: with SAP® EWM (partner: prismat GmbH)

- Specialty: Transport of up to 12 load units simultaneously, integration with conveyor technology, dialogues at the forklift terminal for empties collection. Loading image for scan-free transports between two plants Loading pattern for scan-free transports between two plants

The Warsteiner Group is a successful family business exporting beer to over 60 countries, the leading position among German private breweries. Task: After conversion to SAP® EWM, the company will continue to work without barcode scanning. The goal was to achieve complete transparency of full and empty stocks as well as all shipments. At the same time, empty runs are to be reduced and the handling of empties simplified for the forklift drivers. Implementation: Warehouse Execution System from IdentPro complements SAP® EWM and takes over the control of the forklift fleet. Confirmations to EWM take place automatically. By means of an application developed by IdentPro at the forklift terminal, four clicks are sufficient for the collection of empties. Also newly introduced is a “loading image” which enables the scan-free exchange of goods between the locations Warstein and Paderborn.

Warehouse Execution System - Creating visibility. From shop floor to board room.

Warehouse Execution System

-

The Warehouse Execution System from IdentPro is able not only to record the movement of goods, but also to control and optimize it through the virtual mapping of the entire warehouse with accuracy to the second and centimeter. Using WiFi or 4G, the system is in constant exchange with all material moving equipment used – regardless of whether it is a manned or automated vehicle. The vehicles equipped with IoT sensors simultaneously provide up-to-date 3D information about the movement of the currently transported and stored goods as well as the image of the surrounding room geometry. The usual, extremely error-prone process of scanning during storage, transfer or removal is no longer necessary.

The Warehouse Execution System is also used to route transport orders to the driver terminals or to automated vehicles. A transport that is not recorded by the system is no longer possible. Empty runs are reduced, routes are optimised.

- Autonomous identification and 3D localization of cargo and warehouse by means of internal transports

- Control and optimization of transport orders and routes

- Error-free transports and stocks without scanning

Implementation in existing buildings

-

We mainly implement our Warehouse Execution System in existing properties and with existing material moving equipment. The type, dimensioning and installation of the warehouse is actually unimportant. The existing transport vehicles will be retrofitted with LIDAR and IoT sensors. This can be implemented with any vehicle for indoor and outdoor use. All moving equipment in the warehouse is now connected to the server of the Warehouse Execution System via WiFi or 4G and provide a virtual image of the current warehouse situation. Conversely, transport orders and warehouse locations are transmitted to the IdentPro driver terminals.

A connection to an existing or later planned WM (Warehouse Management)/WMS (Warehouse Management System) is possible, but not necessary.

Through cloud technology, all software is offered as SaaS (Software as a Service).

- Retrofitted forklifts navigate drivers and create a virtual image of the warehouse

- Bidirectional connection to WM/WMS possible directly or later

- SAAS reduces investment costs and allows stand-alone operation

Automation

-

Due to the challenges on the job market, the automation of forklift fleets is an urgent issue in many of our customers’ production logistics. Simple, continuously repetitive transports can already be easily mapped by unmanned vehicles. IdentPro has upgraded various Linde forklift trucks for this purpose. These can search their way independently and without further aids – and can also be used collaboratively. They can be used completely self-sufficient or integrated into IdentPro’s Warehouse Execution System. In the rare event of a malfunction manual operation is possible without losing cargo tracking. An AMR (Autonomous Mobile Robot) is available here under the generic term AGV (Automatic Guided Vehicle)). This means that it can find its own way without a guide lane or fixed routes, avoid obstacles and, of course, electical loading by induction.

It may be useful to start initial pilots with an AMR as an isolated solution. However, the later integration capability into the entire intralogistics up to the ERP should always be taken into account.

- IdentPro forklifts can drive completely autonomously and collaboratively

- Integration into the Warehouse Execution System ensures digital transparency

- The Warehouse Execution System can be used to map manned and automated transports in parallel