- Offer Profile

- Robotunits is a global manufacturer of a Modular Automation System for production equipment. This includes Conveyor and Linear Motion Technology, Material Handling and Safety Fence systems as well as Machine Framing and Guarding and a unique Aluminum Extrusion & Fastening Technology.The product design strictly follows the Lean Manufacturing concept, which stands for multifunctional and smart component design to reduce time and cost in all areas of your organization.Robotunits has manufacturing operations in the USA and Austria and has additional locations in Germany, Italy and Australia.

Just-In-Time Conveyor Technology

- Our Conveyor Technology stands for high quality, a wide variety of standard and custom conveyors and fast lead times. Benefit from the seamless integration of the Conveyor Technology in our Modular Automation System that saves you design and assembly time.

Belt Conveyors

-

Highest quality and fastest delivery times

Configure your belt conveyors according to your requirements: your choice of belt types, customized drive position, and speed. Each Belt Conveyor can be delivered with a conveyor stand, flexible side guides and many other elements from the Modular Automation System.

Belt Conveyor 40

- Conveyor frame 40x40 mm

- Frame widths from 40 to 400 mm

- Total weight of product to be conveyed up to 240 kg

Belt Conveyor 50

- Conveyor frame 50x50 mm

- Frame widths from 50 to 600 mm

- Total weight of product to be conveyed up to 340 kg

Belt Conveyor 80

- Conveyor frame 40x80 mm

- Frame widths from 80 to 1200 mm

- Total weight of product to be conveyed up to 800 kg

Facts

- Select frame width, length and drive option

- Standard delivery in 10 days

- Freely accessible 14 mm T-slot on both sides

Benefits

- Customized and efficient solutions

- Fast delivery and setup

- Easy integration

Special features

The belt conveyor can be customized to meet your specific requirements. Multiple belt options, e.g. low friction, cut resistant, FDA approved, are available.

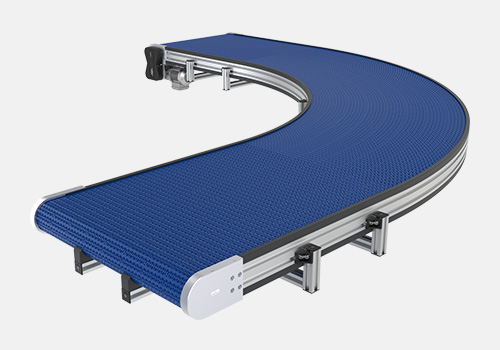

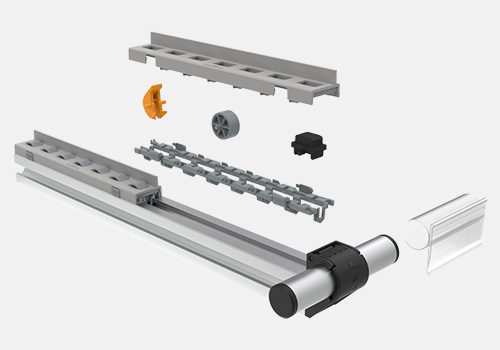

Modular Belt Conveyors

-

Straight sections, curves and inclines with a single drive

The Modular Belt Conveyors are durable and allow transportation of high loads. Straight, curved and inclined sections can be combined requiring only a single drive. The chassis design allows for easy transfer and push off laterally. A wide range of belt options combined with different belt accessories are available.

Facts

- Flexible layout

- No hazardous areas

- Freely accessible 14 mm standard t-slot

Benefits

- Combinations of multiple straight, curved and inclined sections are possible

- Modular belt runs on guide rails, area of catenary sag is covered with clear polycarbonate

- Large savings due to easy integration of the conveyor or for additions or extensions

Application

- Accumulation

- Inclined

- High loads

- Transport of sharp or abrasive parts

Belt design

- Wide range of belt properties

- GripTop

- Flights

- Side guides

Standard

- Standard widths

- Timing belt or direct end drive

- Speeds from 6 to 50 m/min (straight sections)

Timing Belt Conveyors

-

Precise and durable in every situation

The Timing Belt Conveyors are used for precise placement and positioning as well as for the transportation of bulky or heavy parts. A v-guided timing belt guarantees perfect tracking. The belt surface is available with different covers or toolings. High-quality connection shafts allow you to connect single-lane conveyors to multi-lane setups.

Facts

- V-guide for perfect tracking

- Single, dual or multiple lanes

- Positive drive

Benefits

- V-guide for lateral forces

- Subsequently adjustable and expandable

- Positive drive for accurate positioning and indexing

Application

- Indexing

- Positioning

Standard belts

- Accumulation (non-adhesive)

- Medium adhesive

- Adhesive

Special belts

- Flights

- Threaded brass inserts

- Low friction or adhesive covers

Roller Conveyors

-

Customized and ready to use

The Roller Conveyors are 24V conveyors for precise and efficient transportation of containers, totes or boxes. Ideal for zero-pressure accumulation, each zone can be controlled separately. The control units are pre-installed, covered and ready for plug-and-play use.

Facts

- Fully integrated controls (plug and play)

- Fully compatible with the Robotunits Modular Automation System, accessible 14 mm T-slot for additions

- Round belt power transmission

Benefits

- Easy and quick setup

- Maximum flexibility

- No protective guard necessary

Application

- Indexing

- Zero-pressure accumulation

- Positioning

Drive roller

- 24 V DC motor

- Speeds from 10 to 30 m/min

- Temperature range from +2°C to +40°C

Standard dimensions

- Roller spacing 80 mm, 105 mm, 160 mm

- Frame width 490 mm, 690 mm

- Width of product to be conveyed 400 mm, 600 mm

- Standard length ≤ 6,000 mm

Conveyor Technology Accessories

-

Accessories are multifunctional and compatible with the entire Modular Automation System

All accessories are multifunctional and fit not only to an exactly defined component but to all other components in the entire Modular Automation System. This is a basic requirement for a World-Class product range and saves you time in procurement, engineering and assembly.

Linear Motion System

- The requirements for the Robotunits Linear Motion System are top quality and precision. It meets the highest standards in regard to versatility, stability and efficiency.

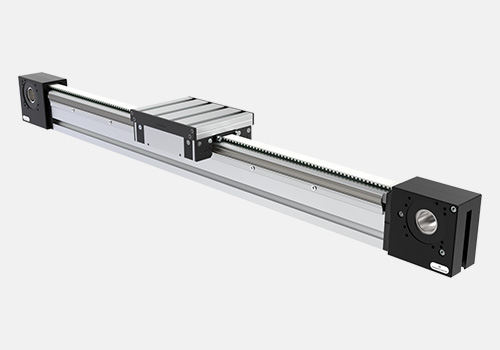

Linear Motion Units

-

The standard Linear Motion Units for individual needs

The Robotunits Linear Motion System is based on our proven Extrusion and Fastening Technology. Its robust and modular construction saves time in design and assembly. Single or double carriages are available and the system allows for the direct attachment of energy chains.

Linear Motion Unit 50 mm

Base extrusion 50x100 mm (PIL5010)

Standard carriage plate 200x150 mm

Net weight of carriage is 2.66 kgLinear Motion Unit 100 mm

Base extrusion 100x100 mm (PIL1010)

Standard carriage plate 200x200 mm

Net weight of carriage is 3.04 kgFacts

- Modular design

- Compatible with the entire Modular Automation System

- Retrofitting of guide rail possible

Benefits

- Cost-effective individually customized Linear Motion System

- Minimal design and assembly time

- Easy installation and integration into existing systems

Standard Data

- Length: up to 6 m

- Available in 50 mm series extrusions

- Maximum drive torque: 60 Nm

- Positioning accuracy: +/-0.2 mm (not including drive backlash)

Special Features

- Play-free, datum edge positioning of the guide rail in the extrusion T-slot

- Expanding coupling

- Integrated Limit Stop

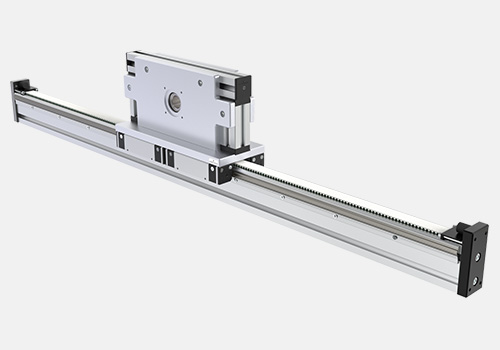

Omega Linear Motion Units

-

Precise technology for advanced applications

Used as individual unit or x-y-z gantry for the transport and exact positioning of parts.

Omega Linear Motion Unit 50 mm

- Base extrusion 50x100 mm (PIL5010)

- Standard carriage plate 400x150 mm

- Net weight of drive unit without motor 15 kg

Facts

- Modular design

- Compatible with the entire Modular Automation System

- Retrofitting of guide rail possible

Benefits

- Cost-effective individually customized Linear Motion System

- Minimal design and assembly time

- Easy installation and integration into existing systems

Standard values

- Length: up to 6 m

- Available in 50 mm series extrusions

- Maximum drive torque: 60 Nm

- Positioning accuracy: +/-0.2 mm (not including drive backlash)

Special features

- Play-free, datum edge positioning of the guide rail in the extrusion T-slot

- Expanding coupling

- Integrated Limit Stop

Linear Motion System

-

Multifunctional

All accessories are multifunctional and fit not only to an exactly defined component but to all other components in the entire Modular Automation System. This is a basic requirement for a World-Class product range and saves you time in procurement, engineering and assembly.

The versatile MBS PickStar

- Maximum flexibility in material flow and supply. Modern factories are more and more geared towards high-speed production. The MBS PickStar scores with its small number of multifunctional components for a wide range of applications. The system runs particularly quiet and the durable construction makes it an ideal solution for workplace material handling.

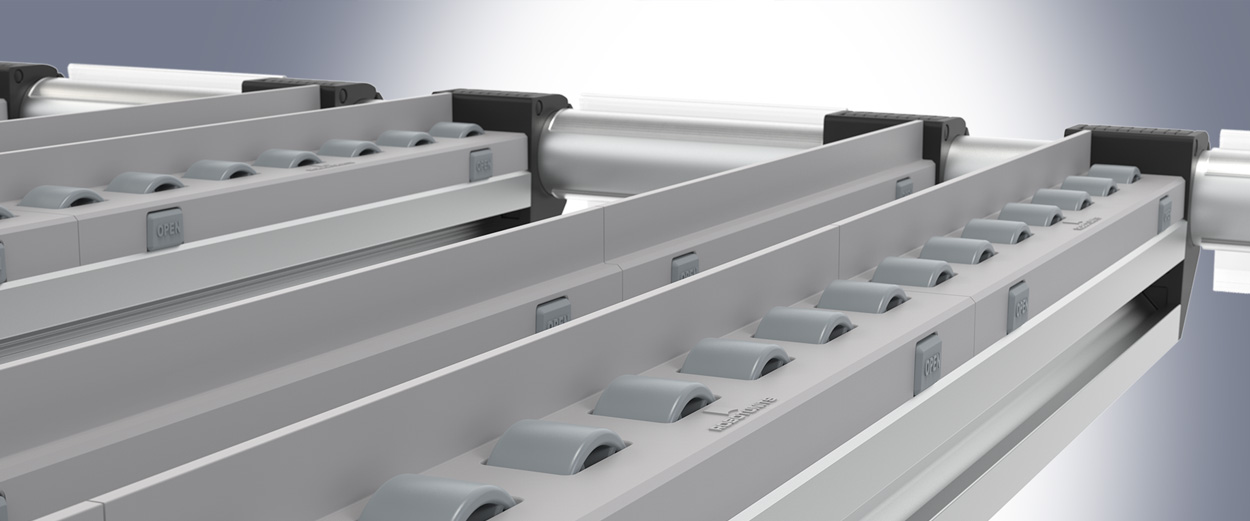

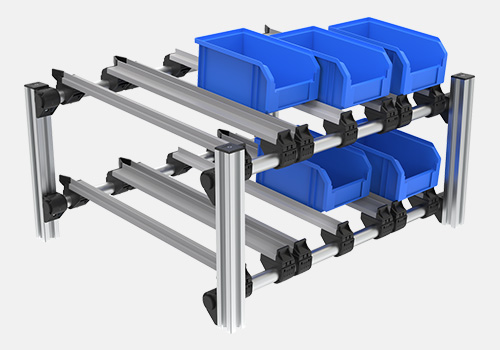

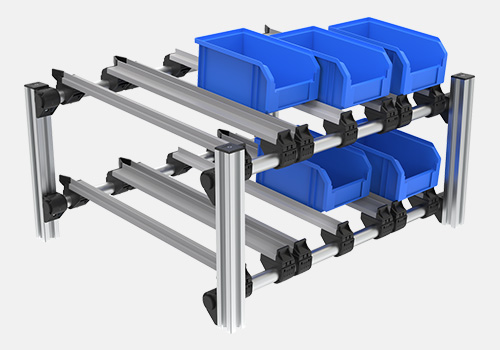

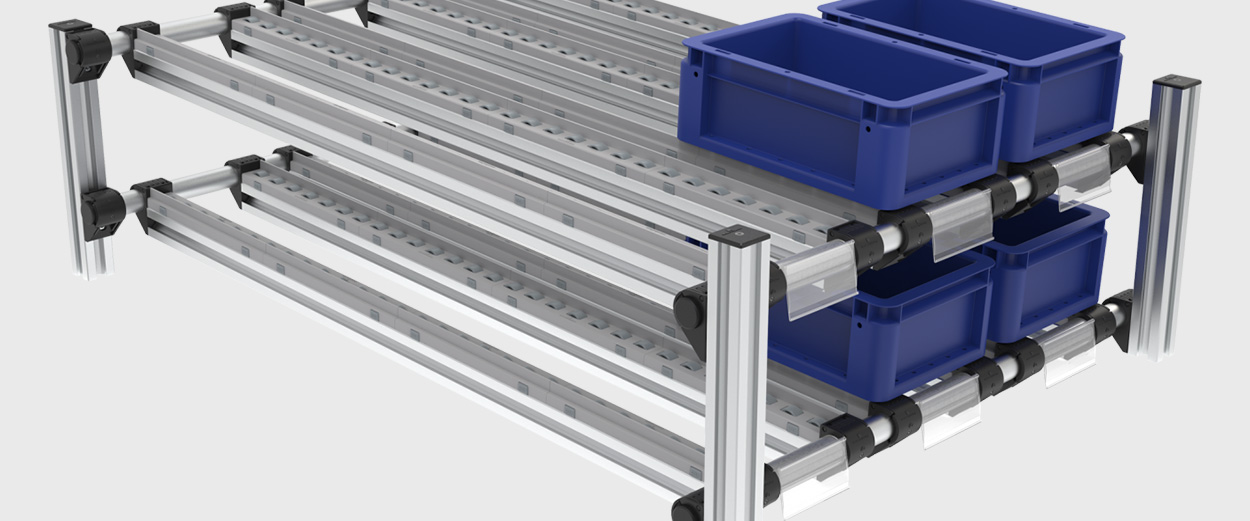

MBS PickStar RL

-

Accomplish a wide range of solutions with a small number of multifunctional components

The Robotunits Material Handling System MBS PickStar RL combines our unique Extrusion and Fastening Technology with individually configurable roller tracks. The system is designed to transport boxes, totes or cartons up to 30 kg. Track widths and lengths are freely adjustable.

Facts

- Modular and flexible system

- Safe and rigid design

- Roller tracks can be fitted with rollers, brakes and anti-reverse

Benefits

- Fast assembly

- Durable and dependable

- Unlimited application options

Standard values

- Length: 250 mm

- Angle of incline: 4° - 6° depending on the product to be transported

- Area load capacity per rail: 15 kg

- ESD tracks available

- Available as parts or kit

Possible applications

- Roller conveyor

- Material handling

- Workstations

- Infeed and outfeed

- Kanban racks and carts

- Transport trolleys

- Rolling side guides

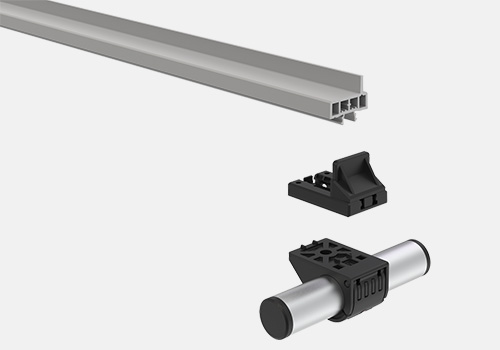

MBS PickStar SL

-

For short sliding track solutions and manual workstations

The versatile Robotunits Material Handling System PickStar SL can be used in combination with the aluminum Round Tube or the Extrusion Technology. This makes the system particularly flexible and easy to design.

Facts

- Modular and flexible system

- Safe and rigid design

- Sliding rails can be used with or without aluminum extrusions

Benefits

- Fast assembly

- Durable and dependable

- Unlimited application options

Standard Values

- Standard lengths up to 1,200 mm

- Surface resistance Rs < 100 GΩ

- Load per rail 1.5 kg (L = 800 mm, without guide)

- Load per rail 2.5 kg (L = 800 mm, with guide)

- Rail material: PVC-U (anti-static)

- Adapter material: PA6 (ESD conductive)

Possible Applications

- Sliding section

- Workstations

- Storage sections

- Braking track

- Kanban racks and carts

- Transport carts

MBS PickStar RL Accessories

-

Individual components and sets for MBS PickStar RL

All accessories are multifunctional and fit not only to an exactly defined component but to all other components in the entire Modular Automation System. This is a basic requirement for a World-Class product range and saves you time in procurement, engineering and assembly.

MBS PickStar SL Accessories

-

Multifunctional elements designed to fit MBS PickStar SL applications

All accessories are multifunctional and fit not only to an exactly defined component but to all other components in the entire Modular Automation System. This is a basic requirement for a World-Class product range and saves you time in procurement, engineering and assembly.

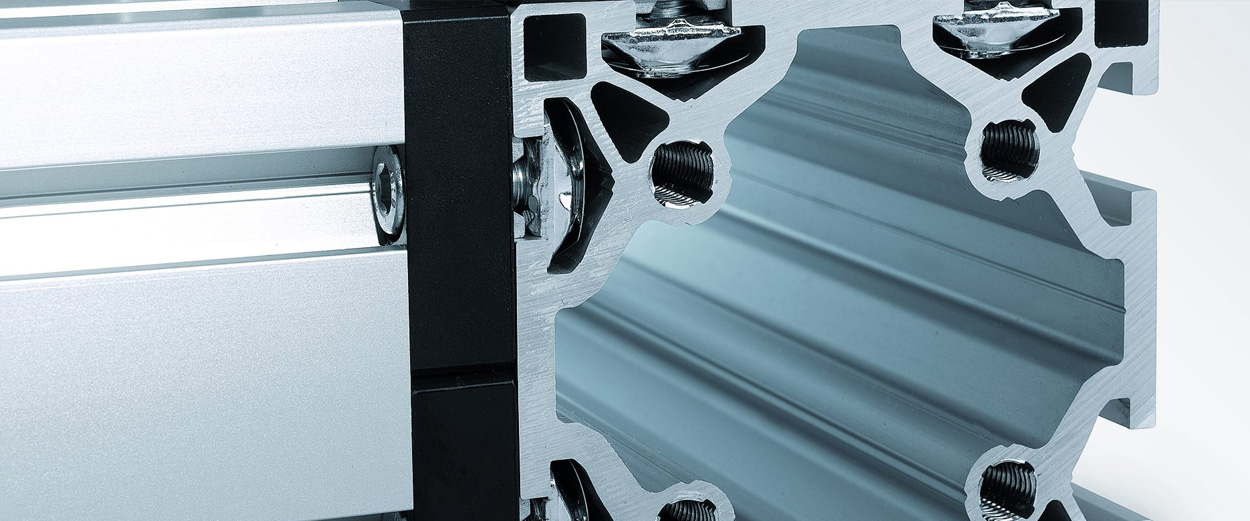

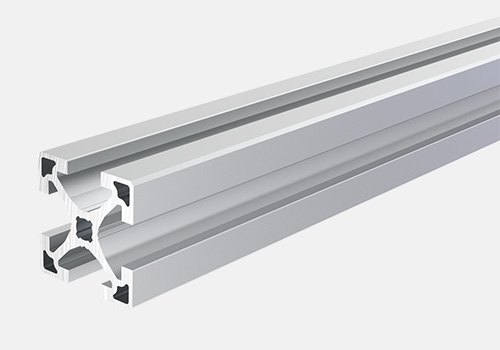

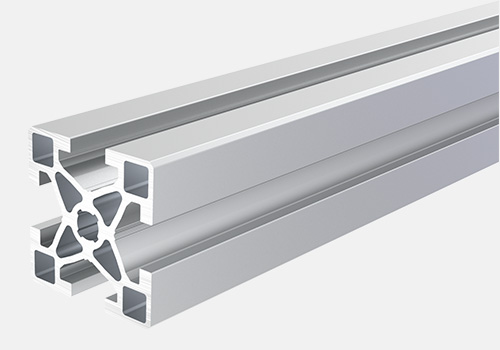

Extrusion & Fastening Technology

- The key elements of the Modular Automation System are the unique Extrusion and Fastening Technologies. Extrusions, available in 40 mm and 50 mm size systems, are fully compatible due to a common 14 mm slot size. In combination with a strong Fastening Technology, the system is unique in its stability and rigidity as well as in its enormous potential for time savings - from design to assembly.

Extrusion Technology 40 mm Series

-

A uniform 14 mm slot size in all Extrusions

The key element of the Modular Automation System is the unique Extrusion Technology. The 40 mm Extrusion Series is ideal for machine guarding, lightweight machine frames and other similar applications. Due to a common 14 mm T-slot and the Robotunits Fastening Technology all Extrusions are fully compatible.

Extrusion Technology 50 mm Series

-

A uniform 14 mm T-slot size in all Extrusions

The 50 mm Extrusion Series with its higher load capacity and strong connectors is used primarily in machine building, protective equipment, assembly cells and manual workstations. Due to a common 14 mm T-slot and the Robotunits Fastening Technology all Extrusions are fully compatible.

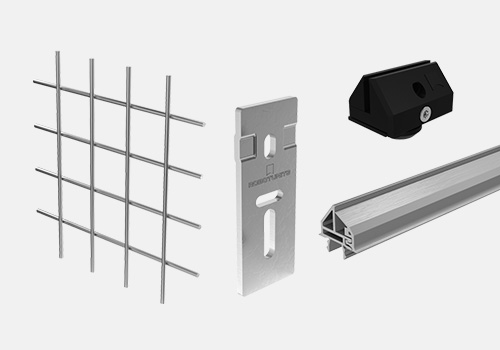

Fastening Technology 40 mm Series

-

Maximum stability with every connection

Robotunits allows you to connect extrusions without drilling or milling using standard screws and space saving fasteners, which provide equal strength on both sides of the connection. Each connection is play-free, form-fit and centered for fast and accurate assembly.

Fastening Technology 50 mm Series

-

Maximum stability with every connection

Robotunits allows you to connect extrusions without drilling or milling using standard screws and space saving fasteners, which provide equal strength on both sides of the connection. Each connection is play-free, form-fit and centered for fast and accurate assembly.

Fastening Technology 40 mm and 50 mm Series

-

More with less - Multifunctional Fastening Technology

The Fastening Technology for the 40 mm and 50 mm series extrusions can be used for the entire Robotunits Modular Automation System.

General Multifunctional Accessories

-

Accessories are multifunctional and are compatible with the entire Modular Automation System.

All accessories are multifunctional and fit not only to an exactly defined component but to all other components in the entire Modular Automation System. This is a basic requirement for a World-Class product range and saves you time in procurement, engineering and assembly.

Safety Fence System

- The Robotunits Safety Fence System is flexible and designed to save time in design and assembly. Easy ordering of pre-assembled panels and quick installation make this system highly efficient and time-saving. At the same time, it offers high impact stability and meets national and international safety standards.

Safety Fence Basic System

-

Flexible and quick installation

The Robotunits Basic Safety Fence System is ideal for standard applications in machine building and production automation and can easily be installed by one person.

Safety Fence Allround System

-

The Allround System convinces with its high flexibility

Each panel can easily be installed between pre-installed fence posts by one person. For large area accessibility, e.g. equipment replacement or modifications, panels can be quickly removed and re-installed.

Safety Fence Accessories

-

Multifunctional Accessories

All accessories are multifunctional and fit not only to an exactly defined component but to all other components in the entire Modular Automation System. This is a basic requirement for a World-Class product range and saves you time in procurement, engineering and assembly.

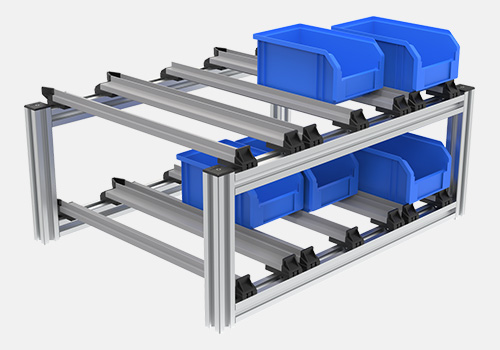

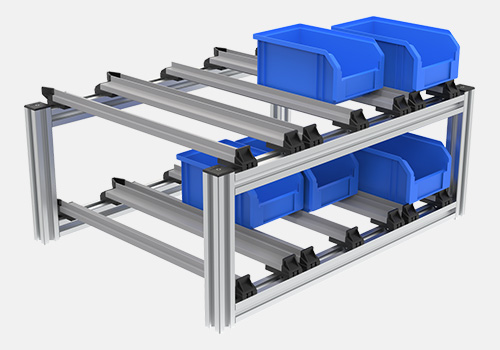

MBS PickStar RL

-

Accomplish a wide range of solutions with a small number of multifunctional components

The Robotunits Material Handling System MBS PickStar RL combines our unique Extrusion and Fastening Technology with individually configurable roller tracks. The system is designed to transport boxes, totes or cartons up to 30 kg. Track widths and lengths are freely adjustable.

MBS PickStar RL Compact

-

Facts

- Modular and flexible system

- Safe and rigid design

- Roller tracks can be fitted with rollers, brakes and anti-reverse

Standard values

- Length: 250 mm

- Angle of incline: 4° - 6° depending on the product to be transported

- Area load capacity per rail: 15 kgESD tracks available

- Available as parts or kit

MBS PickStar RL Ergonomic

-

Benefits

- Fast assembly

- Durable and dependable

- Unlimited application options

Possible applications

- Roller conveyor

- Material handling

- Workstations

- Infeed and outfeed

- Kanban racks and carts

- Transport trolleys

- Rolling side guides

Solutions

MBS PickStar

- Material handling, reliable and silent

Chain circle conveyor

- For use in a robotic cell

Linear Motion Unit

- Designed as a 4.3 m high lift

Work and assembly table

- Freely selectable arrangement of different tool holders

Work and assembly table

- Height-adjustable workstation with optional rear connection of the MBS PickStar

Work and assembly tables

- Multicoloured design for different work areas

Modular Belt Conveyor

- with integrated carriers for conveying bulk material etc.

4-Lane Belt Conveyor

- Coupled, synchronously running Belt Conveyors for different materials to be conveyed

Linear Motion Portal With Omega Drive Unit

- For fast and precise lifting and positioning of all types of loads

Linear Motion Portal with X-, Y-, Z-Axis Units

- For horizontal and vertical operation

Linear Motion Portal with self-supporting unit

- Linear motion solution with powered standard linear unit

Linear Motion Unit supported measuring station with height-adjustable table

- Manually adjustable, ergonomic table with Linear Motion Units

Robotunits Belt Conveyor With A Hollow Belt

- Hollow shaped, centrally aligned Belt Conveyor for small parts transportation

Robotunits Belt Conveyor with dual track

- Coupled, synchronous Belt Conveyors with protective device for larger scaled products

Robotunits Belt Conveyor with Linear Motion Unit

- Combination of standard modular elements for conveying and the lateral displacement of containers and boxes of any kind

Robotunits Belt Conveyor with Nose Bar and Conveyor Stand

- Nose Bar Conveyor on custom Conveyor Stand for transferring small objects

Robotunits Belt Conveyor with special drive

- Belt Conveyor with double translated drive for high-precision speed control

Belt Conveyors 90° aligned

- Belt Conveyors 90° aligned with customized gearbox

Hollow Frame Belt Conveyor Enclosed In A Casing

- Hollow frame Belt Conveyor with custom casing and roller shutter and covered T-slots

Robotunits Belt Conveyor with structured side guide

- With direct drive, structured sliding plate and side guide, for conveying components containing oil

Robotunits Belt Conveyor with base unit

- Fully wired incl. switch cabinet and racks integrated in the base unit, start/stop button