- Offer Profile

- Honeywell Safety and Productivity Solutions (SPS) provides products, software and connected solutions that improve productivity, workplace safety and asset performance for our customers across the globe. We deliver on this promise through industry-leading mobile devices, software, cloud technology and automation solutions, the broadest range of personal protective equipment and gas detection technology, and custom-engineered sensors, switches and controls. We also manufacture and sell a broad portfolio of footwear for work, play and outdoor activities, including XTRATUF® and Muck Boot® brand footwear.s

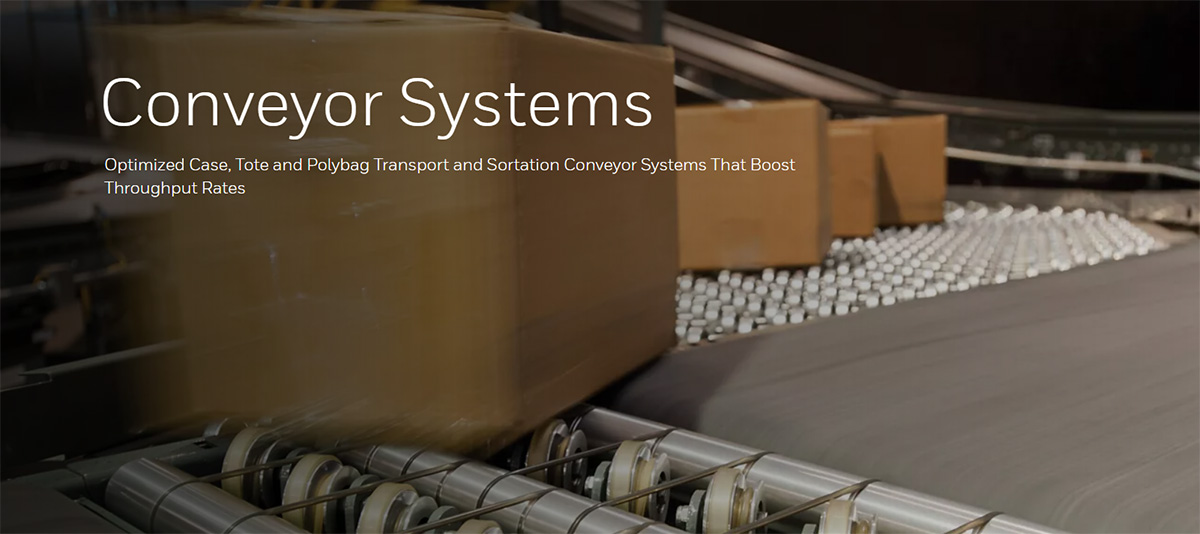

Conveyor Systems

-

Optimized Case, Tote and Polybag Transport and Sortation Conveyor Systems That Boost Throughput Rates

Applying the right level of automation plays a key role in driving maximum productivity for growth. Honeywell offers an extensive variety of conveyor equipment, software and controls to solve the most demanding throughput challenges.

Flexible options for case, tote and polybag handling are provided by a variety of accumulation, transportation, diverting, metering, merging and sorting products. Backed by our powerful and versatile Momentum warehouse execution system, these options can be combined and configured to create an optimal automation solution for your most sophisticated material handling requirements.

Forward-thinking designs and high-quality manufacturing provide high throughput rates, reduce maintenance and maximize reliability, enabling your operation to confidently deliver with predictable results.

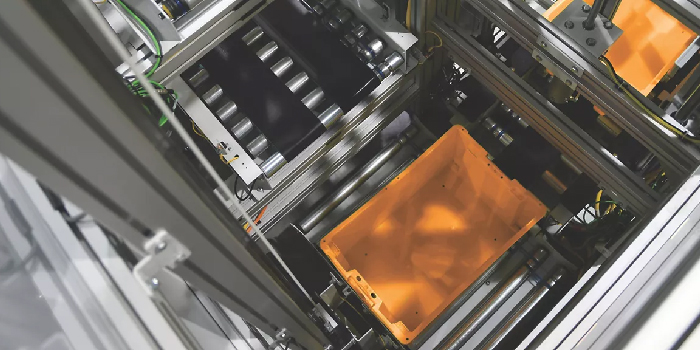

Accumulation Conveyor

- Advanced conveyor systems preserve product integrity in a minimal footprint for high-throughput, high-density, low-pressure and zero-pressure accumulation.

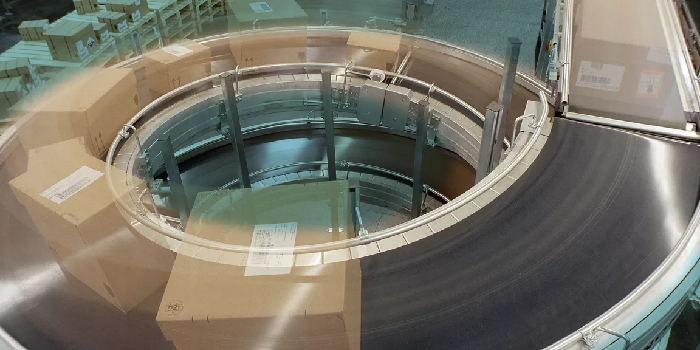

Curve Conveyor

- TransnormÂs flagship Belt Curve range is recognized globally for setting industry standards in performance, reliability and maintenance friendliness.

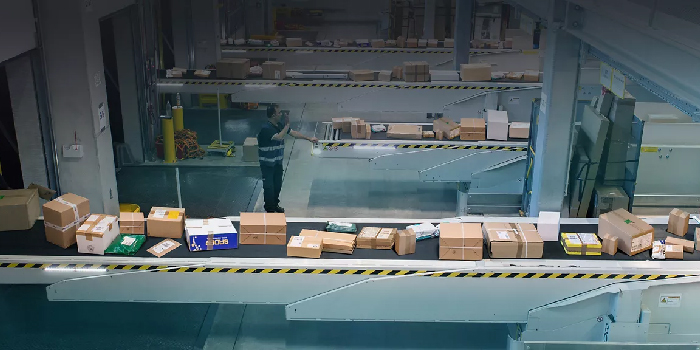

Horizontal Distribution Conveyor

- Precise, configurable and energy-efficient - Transnorm's high performance sorting modules are known to handle the most challenging and non-rigid loads.

Merging & Diverting Conveyor

- Junction conveyors reliably connect multiple lines, either horizontally or vertically enabling consistent onward flow and accurate handling of loads.

Pallet Conveyor

- Flexible and scalable standard and custom-designed accumulation and transportation pallet conveyor systems for manufacturing, warehousing and distribution.

Telescopic Boom Conveyor

- Best-in-class belt and roller telescopic booms boosting productivity and reducing manual handling when loading or unloading trailers, containers and vans.

Transportation Conveyor

- Advanced transportation conveyor solutions enable minimal system footprint and integrate with other material handling components for a fully automated system.

Vertical Conveyor

- Vertical conveyor and sortation equipment grants precise control when transporting items within a compact warehouse where multiple elevation levels are needed.