- Offer Profile

- Gilgen Logistics, an

international company, is a leading provider of integrated logistic systems

for in-house logistics. As a general contractor with more than 20 years of

experience, we offer tailor-made complete solutions with our own products –

from the idea up to the realization of the turn-key logistic system.

Our key areas of expertise encompass conveying systems, storage systems, automation, IT so-lutions, loading systems and special equipment.

AUTOMATED STORAGE SYSTEMS: ONE OF SEVERAL PRODUCTS

- As a general contractor for intralogistics, we offer a broad spectrum of products and services. Our key areas of expertise encompass conveying systems, storage systems, automation, IT solutions, loading systems, special equipment and customer service.

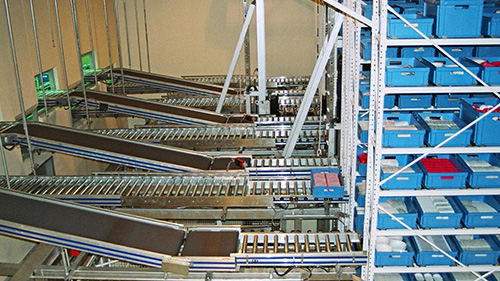

CONVEYING SYSTEMS FOR TRAYS & UNIT LOADS

-

FAST AND SAFE TRANSPORT OF TRAYS AND UNIT LOADS

High customer requirements for readiness to deliver and availability call for new logistics concepts. The conveying systems mecom® effectively implements logistics solutions for both simple and complex material flows.

Modularly structured elements transport, sort, distribute, stack, store and pick the goods to be conveyed, in each case guaranteeing process-oriented execution.

Our optimally designed standard system elements, such as belt transfers, diverters, turntable transfers, etc. are suited for horizontal transport.

Vertical connections often form the nodes of a system. For high capacity requirements, our elevators, lifts or paternosters provide a perfect solution. Floors can be connected to one another up to a height of 70 m.

Together with you, we analyse the process steps at your facility, so that the conveying and picking systems used are tailored to your needs.

ADVANTAGES OF THE SYSTEM

- The high-performance conveyor system is suitable for trays, packages and unit loads up to 50 kg

- Faster, more reliable and extremely gentle transport

- Field-proven, modularly structured standard elements transport, sort, distribute, stack, store and pick the goods to be conveyed

- Systems that are optimally geared to one another for the performance required

- Vertical connections with high-performance elements, such as lifts, elevators and paternoster lifts

- High availability and readiness to deliver

- Ergonomically planned workplaces provide maximum comfort

- Systems for administrative areas (very quiet running, design)

- Conveying elements and conveyor systems that meet international safety regulations

- We ensure good value for money, low life-cycle costs and our comprehensive services

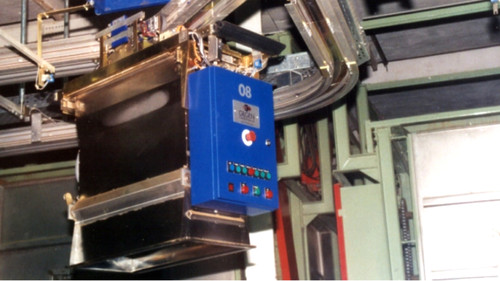

CONVEYING SYSTEMS FOR PALLETS

-

GENTLE AND RELIABLE TRANSPORT FOR PALLETS

Our pallet conveying system provides logistics solutions for simple and complex material flows. Whether horizontal or vertical, these systems transport pallets up to 1,500 kg.

With this system technology, high-performance shuttle cars are used with one or multiple-place conveyors. With conveying speeds up to 3 m/s and intelligent electronics, high capacity requirements are met in an optimal fashion.

Two lift concepts are available for vertical transport of pallets over multiple floors:

- electromechanical / - hydraulic.ADVANTAGES OF THE SYSTEM

- Robust, simple and low-maintenance elements for gentle transport of pallets and lattice boxes (roller and chain conveyors) up to 1,500 kg

- Modular system elements join together to form complete systems

- High-performance shuttle cars for increased requirements

- Powerful vertical connections such as lifts and elevators

- Reliable elements with very high availability

- Conveying elements and conveyor systems that meet international safety regulation

CONVEYING SYSTEMS FOR ROLL CONTAINERS

-

SIMPLE AND FLEXIBLE TRANSPORT FOR ROLL CONTAINERS & COMBINED SYSTEMS

Roll containers are often used today when various items such as loose goods, packages, bags and containers are to be picked and delivered to respective branch locations. Intermediate storage for empty roll containers uses a lot of space, which can be better used for other purposes.

Here we offer a specially developed technology with toothed belts. The roll containers are deposited onto the conveyor equipment either manually or by forklift and sent to an automatic interim storage unit. Such storage unit systems can also be installed on platforms. As a result, no valuable handling space is occupied.

COMBINED TRANSPORT FOR ROLL CONTAINERS AND PALLETS

-

With our combination conveyor system we can transport roll containers and pallets on the same system (roll containers up to 500 kg, pallets up to 1,000 kg)

-

All the functional elements for the roll container technology are also available in the combination technology.

ADVANTAGES OF THE SYSTEM

- Robust and low-maintenance elements for gentle transport of roll containers (toothed belt conveyors) up to 500 kg

- Buffers for empty roll containers can be installed on platforms so that no valuable handling space is occupied

- The roll containers are delivered just-in-time to the picking and delivery process

- Overview of the empty roll containers available

- Controlled transport of full roll containers increases efficiency and readiness to deliver

- The technical design of these conveyor systems is also very well suited for use in the food-stuffs sector

-

AUTOMATED DEVICE AND RETRIEVAL SYSTEMS / HIGH-BAY WAREHOUSE

-

INDUSTRY-SPECIFIC SOLUTIONS FOR AUTOMATED WAREHOUSES & DISTRIBUTION CENTRES

Our broad product range of storage and stacker cranes allows industry-specific overall solutions for automated warehouses and distribution centres. These standardised storage and stacker cranes, connected with an automated picking zone, are functional and economically efficient.

Whether single- or double-masted, aisle-bound or aisle switchable version; the ideal device is available for any application. Special designs for large weights and loads can be realised for all series.

We offer one-stop overall material flow solutions adapted to your processes, from the idea to a realised turnkey logistics system.

ADVANTAGES OF THE SYSTEM

- Mobility, functionality and economic efficiency for pallet transport and storage

- Storage and retrieval stacker crane in the versions: - aisle-bound / - aisle switchable

- Single- and double-masted stacker crane, depending on the application needs

- Single- , double- or multiple-deep storage for increasing picking and inventory turnover performance

- Speed when travelling: up to 3 m/s, and when lifting 1-2 m/s acceleration / deceleration to 1 m/s2

- Short approach dimensions

- Newest energy and security concept after EN ISO13849-1

- Sturdy construction, no subsequent swaying, durable

- All elements to be serviced are at the bottom of the device

COLD STORAGE WAREHOUSES AND CONVEYING SYSTEMS

-

GENTLE AND RELIABLE CONVEYOR AND STORAGE SYSTEM

The new-generation of the standardized pallet conveyor elements, developed and manufactured by Gilgen, offer efficient, safe and economical transport of goods and materials.The modular design of the components and the energy-saving, frequency-controlled drive technology enable flexible, in-house transport of EURO pallets, half pallets and plastic pallets with a payload of up to 1,500 kg.

The identification and testing of the pallets contributes to a high degree to the reliability of the systems. The pallets are checked for weight, foot clearance control, hanging down running boards, pallet deflection control, as well as displaced or oversized loads. Thus, disturbances in the automatic conveyor and storage facilities can be avoided.

The robust and low-maintenance conveyor technology offers high delivery quality and reliability of the supply chain in the overall system and guarantees the gentle transport with high availability.

With this system technology, high-performance shuttle cars are used with one or multiple-place conveyors. With conveying speeds up to 3 m/s and intelligent electronics, high capacity requirements are met in an optimal fashion.

Two lift concepts are available for vertical transport of pallets over multiple floors: electromechanical or hydraulic.

ADVANTAGES OF THE SYSTEM

- Robust, simple and low-maintenance elements for gentle transport

- Modular system elements join together to form complete systems

- High-performance shuttle cars for increased requirements

- Powerful vertical connections such as lifts and elevators

- Reliable elements with very high availability

- Conveying elements and conveyor systems that meet international safety regulation

AUTOMATED SMALL PARTS STORAGE WAREHOUSE

-

FAST, FLEXIBLE AND EFFICIENT SMALL-SPARTS WAREHOUSE

Our automatic small-parts devices for storing various sizes of containers and trays are available to you fordifferent performance requirements.

These stacker cranes are automatically operated rail-mounted devices for automatic warehouses. These systems are designed for containers and trays weighing up to 50 kg.

The running gear and hoisting mechanism being constructed primarily of aluminium section, the storage and retrieval device only weighs about 2,000 kg.We offer one-stop overall material flow solutions adapted to your processes, from the idea to a realised turnkey logistics System.

ADVANTAGES OF THE SYSTEM

- Mobility, functionality and economic efficiency for transporting packaging and for storage

- Fast and precise access to inventory, improvement of the overview of inventory and invento-ry security

- Speed when travelling: up to 6 m/s, and when lifting up to 2 m/s acceleration / deceleration to 2 m/s2

- Short approach dimensions

- Single- , double- or multiple-deep storage for increasing picking and inventory turnover performance

- Flexible load-carrying, carousel with up to 10 loading aids simultaneously

- Low overall weight

- Vulkollan track wheels make for less flexing work, lower energy requirement

- Frictional drive system, optimum efficiency, high energy efficiency

- All elements to be serviced are at the bottom of the device

WAREHOUSE MANAGEMENT & CONTROL SYSTEM

-

FOR AN EFFICIENT WAREHOUSE MANAGEMENT

Short delivery times, high delivery quality, delivery flexibility and preparedness to provide information are central to logistics requirements. Efficient warehousing is not only a matter of organisation; having the right tools also plays an important role.

Coordinated facility control systems and software developments optimise material flow in warehouse and production areas, allowing independent, customer-oriented and project-specific solutions.

The warehouse management System wocom is based on basic functions that are extendable by modules. Fast and perfect data conversion is ensured for system interfaces such as SAP, Infor, proALPHA, etc.

ADVANTAGES OF THE SYSTEM

- State-of-the-art, modular architecture

- Flexible removal strategies, configurable

- Process-oriented restocking, configurable

- 100% release-capable

- Easy to operate

- 100% documented

- Browser-based, no Web interface required

- Multiple-client-capable

SPECIAL-PURPOSE SYSTEMS

-

AFTER YOUR NEEDS AND REQUESTS

We plan special-purpose systems on a case-to-case basis according to the customer’s needs and requests, designing and installing them in compliance with regulations.

SPECIAL AUTOMATIC LUGGAGE LOCKER SYSTEM

Passenger stations around the world harbour substantial potential for modernisation. All current redesigns are giving to understand a contemporary development away from purely a transportation hub towards “a world of experiences at the station”. Customer-friendly design is, of course, an important feature of the shopping arcades. Customary locker systems require important retail floor space in such shopping arcades. When all the lower lockers are taken, heavy pieces of luggage have to be put in above one’s head.

The solution to this is the automatic luggage locker systems, underground luggage storage sites with attractive luggage terminals in railway station shopping arcades. These compact luggage terminals can be placed directly in the flow of visitors to such shopping arcades.

MEDIA, BOOK & FILE CONVEYING AND SORTING SYSTEMS

-

FAST AND LOW NOISE TRANSPORT AND PRESORTING OF MEDIAS

Specially developed low-noise conveying elements (roller and belt conveyors) with a modular design are used. Our logistics systems are essentially characterised by their ease of use, low noise and reliability. The requirements for the operating personnel of our conveying systems are thus kept to a minimum from a technical perspective.

- Container conveying System - The media and files are transported in plastic containers on the conveyor system. Powerful standard elements as well as various vertical systems transport the containers to the individual destination areas. The containers always remain horizontal. This is the basic prerequisite for gentle transport.

- Individual Transport - The media and files are transported directly on the conveyor system. A wide variety of functional elements are available (belt conveyors, curve roller conveyors, inward/outward transfers & elevating transfers), making it possible to configure even complex layouts.

- 24-hr media return - Automatic 24-hr media-return machines enable simple and fast return of media even outside opening hours. Media to be returned are placed on the transport belt individually at a terminal and identified with the help of RFID Labels. Automatic checking back into the Library Management System (LMS) is carried out via a communication interface to a higher-level user Interface.

- Vertical transport

The connections between different floors are realised with fully automatic paternoster lifts, linear lifts and lifters. Ascents/inclines can be overcome with specially designed belts. Our systems are characterised by gentle transport of the media and minimal noise pollution for employees and users. - Intermediate buffer / External book towers / Fully automatic storage unit

The so-called “fast movers” are stored in intermediate buffers. These are characterised by fast access times in conjunction with automatic issue and return Systems. External book towers and storage stacks are technically sophisticated buildings geared especially to long-term storage of media. This storage unit is characterised by a low-cost design and optimum climatic storage conditions. The media are stored and retrieved fully automatically. Access times with these systems are under 30 minutes. Inventory runs can be made during off-peak hours at any time using RFID Technology.

CONVEYING SYSTEMS FOR PARCELS

-

ERGONOMIC AND RELIABLE TRANSPORT FOR PARCELS

Conveyor systems and storage systems solve internal transport, distribution and storage tasks. The emphasis here is on fast processing and gentle transport at modern postal distribution centres (parcel centres and letter centres). Consisting of modular elements, the various systems can be combined however desired, employing amodular design approach. They are extremely economical, robust, low in noise and are therefore particularly suitable for rough use in everyday postal operations.

- Conveying systems for parcels - The high-performance conveyor system is used to supply parcels onto a parcel sorting machines. Conveyor belts transport the parcels at a speed of over 2 m/s. Cross switch units are used to distribute goods from one conveyor belt to two transport routes, which alternately distribute over 4,500 parcels per hour. In a further step, a merging point merges parcels from two conveyor lines onto one, doing so at a capacity of 7,000 parcels per hour.

- Horizontal and vertical transport - Horizontal transport is carried on conveyor belts, roller conveyors and accumulation roller conveyors. For changes of direction, a wide variety of elements are available, depending on the requirement. Differences in elevation are realised with S/C conveyors, paternosters and lifts.

- Connection to the parcel sorting machines - The high-performance conveyor system is used to supply parcels onto a parcel sorting machines. Conveyor belts transport the parcels at a speed of over 2 m/s. Cross switch units are used to distribute goods from one conveyor belt to two transport routes, which alternately distribute over 4,500 parcels per hour. In a further step, a merging point merges parcels from two conveyor lines onto one, doing so at a capacity of 7,000 parcels per hour.

- Tray Unloading Device (TUD): automatic container-emptying device - The mail is automatically sorted by standard and large letter sorting machines in containers. By the TUD the delivered containers are automatically tilted and the letters are ergonomically supplied to the sorting machine. The letters are handled gently, and handling of heavy containers is omitted.

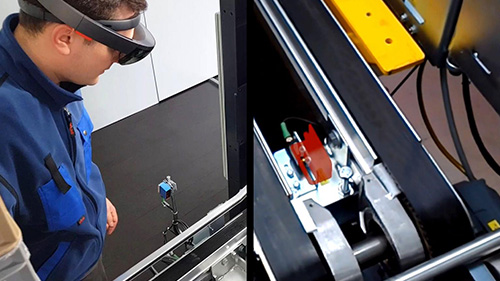

AUGMENTED REALITY

-

FASTER RESPONSE TIMES WITH AUGMENTED REALITY

Ongoing developments in digitisation open up new opportunities in the logistics sector too. Fast response times, and consequently short system downtimes, are an important success factor in intralogistics. Gilgen Logistics has taken a further successful step in this direction with its “Augmented Reality” pilot project. Customers, service technicians and fitters can be given visual instructions and support in any location with the help of cutting-edge aids.

Digitisation in the working world has become a matter of course for many companies. It is already well advanced in the planning and engineering of logistics systems. The demands on cycle and response times as well as the use of sophisticated technologies have intensified in recent years. Augmented reality is primarily used in warehouses for inventories and picking. It is as yet less commonly used for the efficient set-up and operational maintenance of logistics systems. If, for example, the installation progress is delayed, this can have serious consequences for the project lead time; a system standstill and idle times lead to lost turnover and extra costs. The manufacturer has to intervene as quickly as possible. Specialist know-how is needed in many cases. Unfortunately, the specialists are often far away, so that valuable time is lost. This is a significant cost factor with globally installed systems and may tie up valuable resources for several days. If we also bear in mind the fact that the problem can often be solved by a specialist in next to no time, we quickly realise just how big the influence of travelling time is on the downtime or cycle time.

RETROFIT & SYSTEM MODERNISATION

-

RETROFITTING YOUR FUTURE

The dynamic nature of technology is a common driving force behind change. However, it usually takes foreseeable process changes or even known bottlenecks to actually update a logistics system. This includes:

- Technical obsolescence

- Usage-related wear and tear

- Outdated functionality

Even well-designed systems and warehouses cannot keep pace with new requirements. While the mechanical parts of older systems are often still in good working order, the control hardware as well as the drive mechanisms and sensors may no longer be state of the art. This is why modernisation steps are frequently considered solely for the control and drive Areas.

The desire to avoid interrupting production or bringing down the whole system tends to cause excessive procrastination prior to refurbishment. The susceptibility to failure increases while efficiency declines. The potential for optimising the workflow goes unexploited over long periods of time.

DIGITALIZATION

-

DIGITALIZATION MEETS AUTOMATION

As part of Industry 4.0, Gilgen Logistics AG is increasingly relying on digitization along with augmented reality for the intralogistics systems it has developed in-house. Our first projects have already been successfully implemented. Further digitization steps are to follow.

Gilgen Logistics AG has been at the cutting edge of intralogistics systems for 60 years. Now we are moving into the next big step of development. Because digitization does not stop at our high-bay storage facilities and the logistics systems connected to them. ÂIn an Industry 4.0 approach, the goal is for our systems to become an important part of our customers value chain. In this manner, all of our conveyor systems will be digitally supported in the future, further advancing automation, said Daniel Gilgen, division head of Systems and deputy CEO.

Business Solutions: Logistics and Storage Systems

-

As a general contractor for fully integrated logistics solutions, we have been working for many years in certain sectors on behalf of our customers on national and international projects. We have established competent engineers and developer teams in these sectors. Our experts can fall back on established know-how gained through many years of experience.

High customer requirements for readiness to deliver and availability call for new logistics concepts, which include the right logistic solutions for your business.

TRADING

-

Intense competition, internationalization, increasing delivery requirements, new sales channels and growing customer demands impact the life of retail and wholesale companies. High customer requirements for readiness to deliver and availability call for new logistics concepts. The conveyor and storage systems from Gilgen Logistics effectively implement logistics solutions for both simple and complex material flows

In any case, a solution adapted to the processes. Our broad product range allows industry-specific overall solutions for automated warehouses and distribution centres. So that retailers and wholesalers can choose the challenges of offering the best service, delivering within the shortest possible time, while keeping inventory levels as low as possible for cost reasons.

FOOD INDUSTRY (PACKED, INCL. COLD CHAIN AND DEEP FREEZE LOGISTIC)

-

FOOD / GOODS (ALREADY PACKED)

Merging materials or articles to fulfil orders is a key and labour-intensive process in production and distribution systems. Our broad product range allows industry-specific overall solutions for automated warehouses and distribution centres.

High customer requirements for readiness to deliver and availability call for new logistics concepts. Our conveyor and storage systems effectively implement logistics solutions for both simple and complex material flows. It is important to deliver the sensitive and perishable goods (already packaged) quickly and reliably. A high level of efficiency and process understanding is required here.

Modularly structured elements transport, sort, distribute, stack, store and pick the goods to be conveyed (trays, containers, unit loads, cardboard boxes, roll containers and pallets), in each case guaranteeing a solution adapted to the processes. A central and labor-intensive process in production and distribution systems is the merging of materials or articles for the execution of an order. Our wide range of products enables total solutions for automated warehouses and distribution centers in the food industry.

LIBRARIES & ARCHIVES

-

The beverage industry places high demands on the material flow and new logistics concepts. Large turnover figures and seasonal peaks, heavy and sensitive loads, sometimes with strict regulations regarding hygiene and temperature.

Our conveyor and storage systems effectively implement logistics solutions for both simple and complex material flows. Modularly structured elements transport, sort, distribute, stack, store and pick the goods to be conveyed (trays, containers, unit loads, cardboard boxes, roll containers and pallets), in each case guaranteeing a solution adapted to the processes.

Merging materials or articles to fulfil orders is a key and labour-intensive process in production and distribution systems. Our broad product range allows industry-specific overall solutions for automated warehouses and distribution centres.

INDUSTRY

-

High customer requirements for readiness to deliver and availability call for new logistics concepts. Our conveyor and storage systems effectively implement logistics solutions for both simple and complex material flows.

Modularly structured elements transport, sort, distribute, stack, store and pick the goods to be conveyed (trays, containers, unit loads, cardboard boxes, roll containers and pallets), in each case guaranteeing a solution adapted to the processes.

Merging materials or articles to fulfil orders is a key and labour-intensive process in production and distribution systems. Our broad product range allows industry-specific overall solutions for automated warehouses and distribution centres.

HOSPITALS & LABORATORIES

-

HOSPITAL LOGISTICS

For patients well-being and recovery, not only is qualified medical care of great importance, but also up-to-date surroundings with modern infrastructure. Excellence is demanded from individuals working in hospitals, which it is necessary to support with their external setting, including intralogistics.

LABORATORY LOGISTICS

Appropriate infrastructure is needed for structured working in a modern laboratory. Work in processes and procedures is supported by automatic goods conveying systems, which efficiently link up the various individual work and laboratory areas. New solutions are demanded of laboratory logistics by the centralisation of subareas, such as central autoclaving, cleaning and sterilisation areas and centralised sample distribution.

POST LOGISTICS

-

Conveyor systems and storage systems solve internal transport, distribution and storage tasks. The emphasis here is on fast processing and gentle transport at modern postal distribution centres (parcel centres and letter centres). Their economic efficiency and superior technology mean our systems can offer customised solutions on a case-to-case basis.

Consisting of modular elements, the various systems can be combined however desired, employing a modular design approach. They are extremely economical, robust, low in noise and are therefore particularly suitable for rough use in everyday postal operations.

LIBRARIES & ARCHIVES

-

The libraries and archives are adapted to the current requirements of the scientific work of the 21st century and be designed for a 24-hour operation over 365-days.

To relieve the staff of manual transport tasks and to accelerate the transport operations of the media inside the building, to reduce the waiting times and to make the media quickly available for users, modern RFID controlled conveyor and storage systems are installed. With this support, the libraries and archives can respond flexibly to different performance peaks.

The conveying system for media are essentially characterised by their ease of use, the ergonomics, the low noise and the reliability.

FURTHER SERVICE PROVIDERS

-

AFTER YOUR NEEDS AND REQUESTS

For other service providers, such as rail, banks, administrations, etc., our conveyor and storage systems, as well as special systems - We plan special-purpose systems on a case-to-case basis according to the customer’s needs and requests, designing and installing them in compliance with regulations.

SPECIAL AUTOMATIC LUGGAGE LOCKER SYSTEM

Passenger stations around the world harbour substantial potential for modernisation. All current redesigns are giving to understand a contemporary development away from purely a transportation hub towards “a world of experiences at the station”. Customer-friendly design is, of course, an important feature of the shopping arcades. Customary locker systems require important retail floor space in such shopping arcades. When all the lower lockers are taken, heavy pieces of luggage have to be put in above one’s head.

The solution to this is the automatic luggage locker systems, underground luggage storage sites with attractive luggage terminals in railway station shopping arcades. These compact luggage terminals can be placed directly in the flow of visitors to such shopping arcades.

RETROFIT & SYSTEM MODERNISATION

-

RETROFITTING YOUR FUTURE

The dynamic nature of technology is a common driving force behind change. However, it usually takes foreseeable process changes or even known bottlenecks to actually update a logistics system. This includes:

- Technical obsolescence

- Usage-related wear and tear

- Outdated functionality

Even well-designed systems and warehouses cannot keep pace with new requirements. While the mechanical parts of older systems are often still in good working order, the control hardware as well as the drive mechanisms and sensors may no longer be state of the art. This is why modernisation steps are frequently considered solely for the control and drive Areas.