- Offer Profile

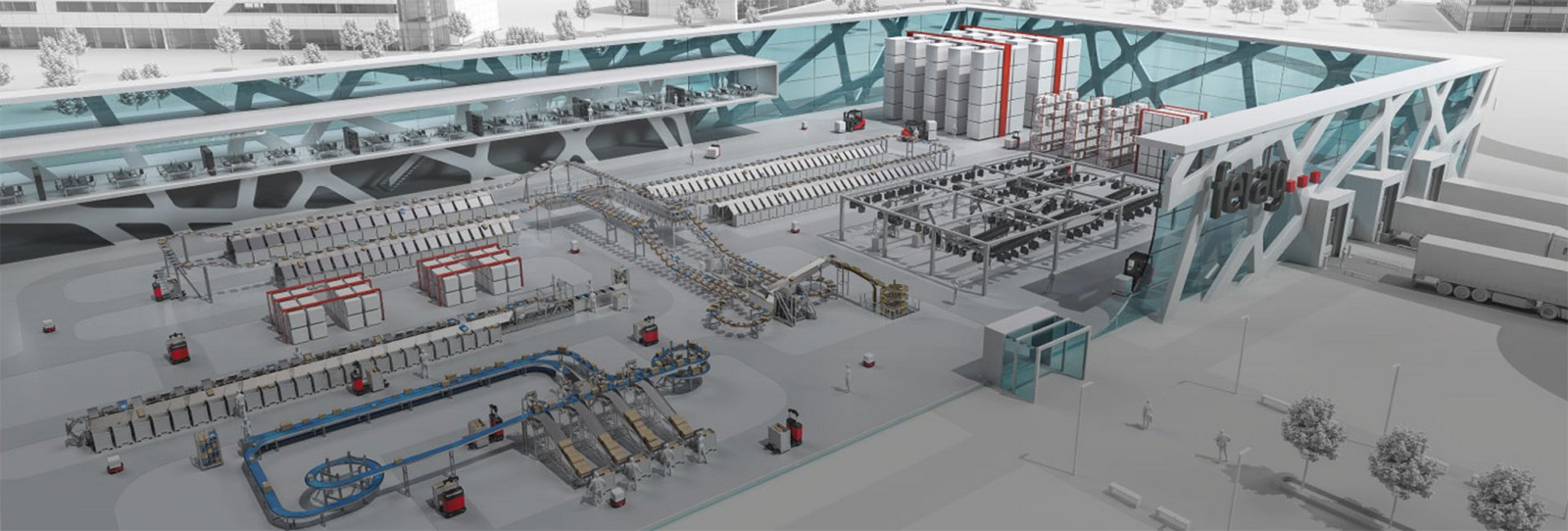

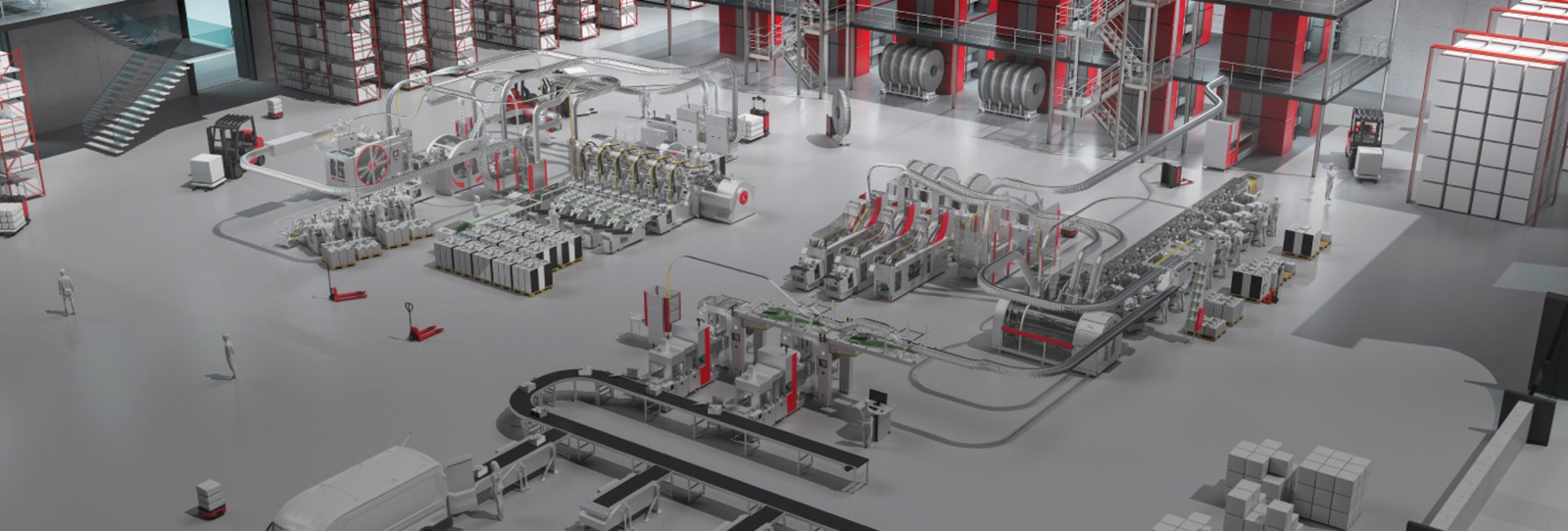

- Ferag AG is a family-owned Swiss company specialized in the development and manufacture of conveying and processing systems in the graphical industry and direct mailing, as well as total material handling solutions across all industries.

Material Handling Solutions

-

Conveying, sorting and buffering

The transport and sorting solutions for intralogistics are a derivative of Ferag's conveyor technology, originally developed for the production of print media. They are ideally suited to distribution logistics outside the graphical industry. Any number of applications are possible. The material flow systems can be used in processing industries, in fashion, automotive and food logistics, and also for e-commerce applications.

Denisort

-

Conveying, sorting and order picking in one system

Conveying, sorting and order picking: the very flexible denisort tilting tray sorter kills no less than three birds with one stone. Thanks to its robust and proven design, the system can be used seamlessly for all three processes, even in the third dimension. This means that denisort not only allows a continuous flow of materials across several levels, but also fully meets intralogistics requirements in the e-commerce sector. Different tray sizes, which can be strung together any which way, for maximum flexibility: in this way, variously sized products can be processed at high throughput rates. The tilting trays are able to open to either side as needed, while ensuring gentle and careful treatment of conveyed goods. Even fragile products such as medicine vials and electronic modules can be handled. In addition, denisort is an ideal solution for handling residual post in postal facilities.The denisort tilting tray sorter:

- Also ideal for bulky, light, round or sensitive products

- 3D capability, also across several levels

- Multilevel for maximum capacity in the tightest of spaces

- Modular and extensible design

- Energy-efficient technology thanks to rolling friction

- Proven and robust engineering

- Cost-effective in operation, service and maintenance

- Low-noise

Denisort Compact

-

Compact and modular vertical sorter

Denisort compact is a modular vertical sorter designed for the sortation of items with a weight of up to 12 kilograms. Total freedom in configuration and fast installation result in a powerful, compact and flexible system for maximum output on smallest footprint, perfectly tailored for a variety of applications, such as CEP services, e-commerce, retail, B2B and 3PL. The intended purpose of denisort compact includes the sortation for dispatch, goods in, returns, cross-docking and restmail.The vertical sorter denisort compact:

- High sorting performance on smallest footprint

- Easy to expand

- Also ideal for bulky, light, round or sensitive products

- Flexible configuration and utilisation

- Short installation and commissioning time

- Simple connection to a higher-level system

- Ergonomic work places and simple operation

- Proven and low-maintenance denisort technology

Deniway

-

Making complex tasks simple

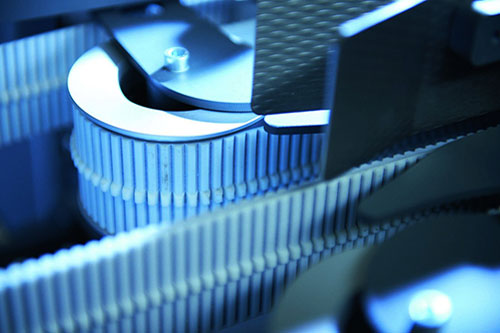

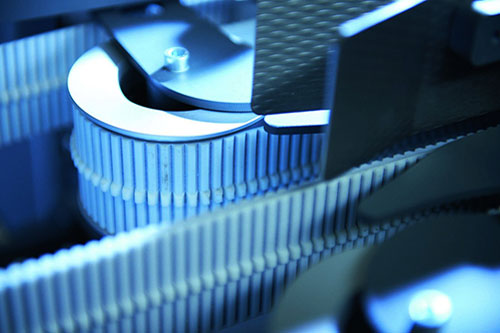

The deniway plate chain conveyor is based on a chain supported by low-friction rollers. Thanks to low rolling resistance, very long conveying distances can be achieved without troublesome transfers and using only a few drives. The 3D layout capability allows continuous material flow over several levels. The system is designed as a modular kit, so it scales easily. A line can thus be modified and extended with very little effort. In this way, all processes taking place in a conveyor can be linked together. The virtually maintenance-free design guarantees a long service life with low running costs and high efficiency.The deniway plate chain conveyor:

- Conveying, sorting and distributing in one system

- 3D-capable for optimum space utilisation

- Material flow over long distances with no transfer points

- Modular and extensible design

- Energy-efficient technology thanks to rolling friction

- Proven and reliable technology

- Cost-effective in operation, service and maintenance

- Low-noise

Easychain

-

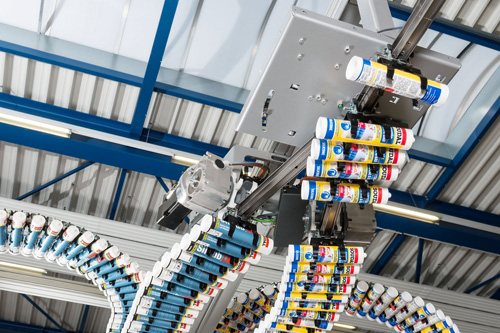

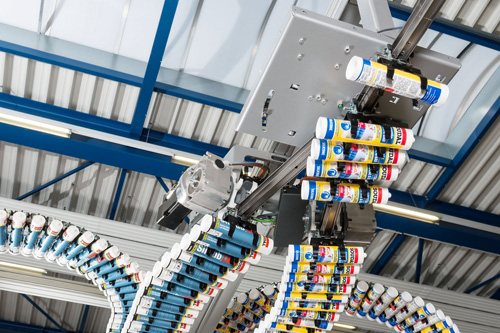

Fast and flexible in all directions

With the continuous and seamless conveying system easychain, even narrower curve radii can be realized than with the „bigger brother“ deniway. This is particularly noticeable when complex, three-dimensional layouts are required. In addition, the highly modular system can be quickly installed and converted. The system is based on rollers that reduce friction and thus both energy consumption and wear. That is why easychain is robust, reliable and largely maintenance-free.

The conveying system Easychain:

- Conveying, sorting and distributing in one system

- 3D-capable for optimum space utilisation

- Material flow over long distances with no transfer points

- Modular and extensible design

- Energy-efficient technology thanks to rolling friction

- Proven and reliable technology

- Cost-effective in operation, service and maintenance

- Low-noise

Skyfall

-

Unique gravity conveyor system

Skyfall is the unique conveyor system that makes use of gravity and the third dimension. A simple rail profile with roller bodies allows the most diverse articles up to 10 kilograms in weight to be conveyed from A to B. Two types of shuttles are available. Type M for items up to 5kg. Type L can carry up to 10kg. And when that weight exceeds 10 kilogrammes, trolley systems are used. For this reason, the load-carrying adapters on the hangers can be adapted to almost any customer-specific requirement.

Performance figures of up to 12‘000 items per hour (throughput per line) position Skyfall alongside the most potent systems available. With Skyfall, Ferag develops made-to-measure and turnkey solutions for all intralogistics processes. From the development and production of intelligent conveyor technology through to system integration and complex material flow solutions.

Processing while conveying is the core competency at Ferag. Automatic loading and unloading of pouches, pick-up, transfer, weighing, ejection, labelling, etc. are functions that are carried out by Skyfall at high speed in a single plane or in the third dimension. The buffering of items between two processes of different throughput rates and buffering in general is one of the big strengths of Skyfall. The decoupling of integrated processes enables troubleshooting interventions as well as the compensation of throughput rate variations. The buffer saves space and energy and can be adjusted to fit the exact production requirements.

The unique gravity conveyor system Skyfall:

- Conveying, buffering, sorting, order picking and consignment in one system

- Keeping usable floor area free by use of the third dimension

- Application-specific load carriers with the possibility of multiple loading

- Fully automatic loading and unloading possibilities

- Reduction of manual tasks along the process chain

- Increased productivity and efficiency thanks to automation

- Traceability throughout the system

- Modular and extensible design

- High-quality and maintenance-friendly engineering

- Energy-efficient technology thanks to rolling friction and use of gravity

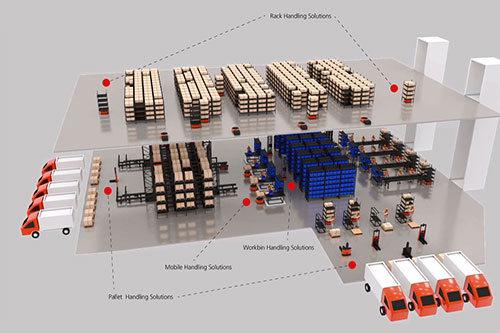

Ferag Intelligent Vehicles

-

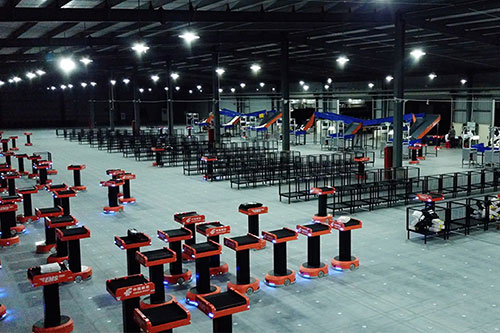

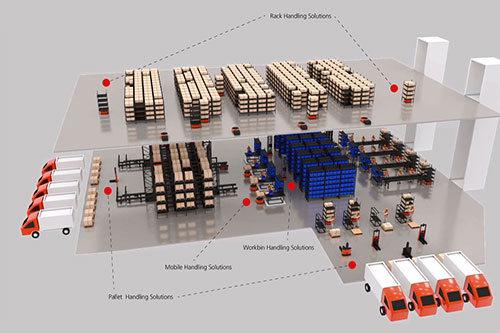

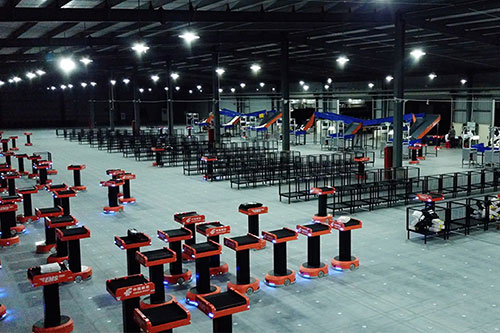

Free humans from manual handling

The state-of-the-art AGV and AMR vehicles with a complete range of products for intelligent intralogistics solutions are based on proven Quicktron technology. These mobile robots include automated solutions for the handling of shelves, mobile devices, pallets and basket of work without an operator. In suitable projects, this new product range will be combined with Ferag products (Denisort, Deniway, Easychain and Skyfall) into fully integrated solutions.

The Ferag Intelligent Vehicles:

- Safer environment for the operators compared with forklift and tugged trains

- Increased productivity and efficiency thanks to automation leads to rapid ROI

- Flexible solution for different seasons (for example Black Friday and regular season)

- Fully automatic loading and unloading possibilities

- Best use of warehouse space thanks to the high precision of the robots (improves storage rate by 60%)

- Excellent path planning ability, various combination of equipment

- Modular and extensible design

Control System

-

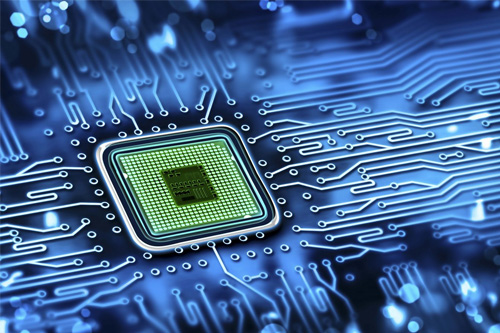

Versatile control and monitoring system for high system availability

Growing digitalization in production and logistics means that software is becoming ever more paramount in the design and manufacture of machines and systems, thus constantly driving up their efficiency. Control and monitoring of such systems therefore becomes increasingly complex. That requires experts. And so we have developed in-house a proprietary management and process control system for our innovative conveyor and sorting systems. It includes modules covering every tier of the automation pyramid, from the singular field level to plant management. Furthermore, those modules are easily customizable and expandable. Thus, the application meets every functionality required to integrate a Ferag conveyor system perfectly into upstream and downstream processes and to operate it safely and reliably.

The Ferag control system:

- Safety and high system availability

- Easy integration with an existing ERP system

- Control and software architecture optimally matched to the system

- Control system and conveyor technology from a single source

- Customized user interfaces

Graphical Industry

-

Unique mailroom systems

Ferag is the global market leader for conveying and processing systems in the graphical industry. Mailroom systems for small and large circulations are our core competency. From advice through conception to realization, Ferag offers complete solutions from a single source. High-speed systems for the industrial processing of magazines and commercial products are as much a part of the Ferag portfolio as systems for the enhancement of print products.

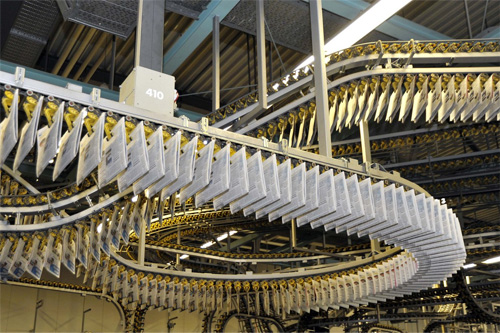

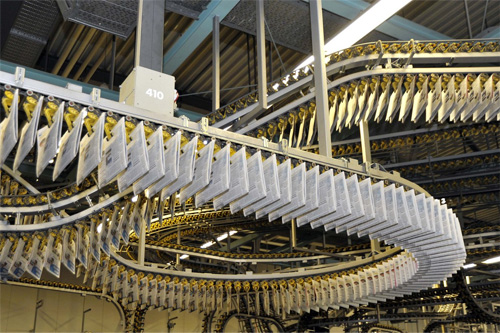

Conveying

-

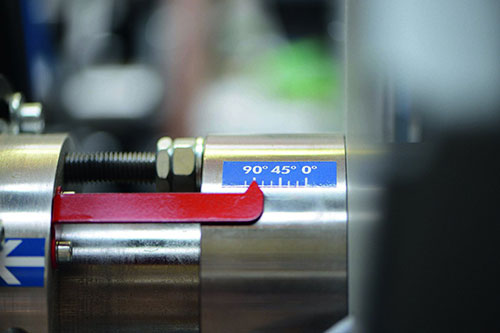

High-speed transport of newspaper products

The UTR Universal Conveyor is the robust backbone of postpress processing. The high-quality, single-copy gripping systems are the most widely sold in the world and guarantee the dependable transfer of print products from the press and from postpress processing in the mailroom at up to 100,000 copies an hour.Conveying system for postpress processing:

- Universal Conveyor UTR

Stacking

-

Powerful compensating stackers for all bundling requirements

With the MultiStack and PostStack compensating stackers, Ferag covers bundling requirements in all performance brackets. Both models are distinguished by their robust construction, their functional and compact design, and their high-efficiency servo drive technology without pneumatics. As an option, the compensating stackers can be equipped with an inline topsheet printing and the automatic format adjustment system.Compensating stackers for postpress processing:

- MultiStack MTS

- PostStack PSK

Inserting

-

Reliable inserting for every speed

Only the rotary inserting concept from Ferag is able to dependably meet today's demands for performance, stability and inserting volume without compromise. Next to the compact EasySert and Rollsert models for the lower and middle circulation ranges, several versions of the MultiSertDrum inserting drum cover the whole spectrum of modern newspaper production, up to the very top. The two RollStream and Flystream precollecting systems enable a phased upgrade to a maximum of 40 hopper stations for commercial brochures and magazines.Inserting systems for postpress processing:

- EasySert ESR

- RollSertDrum RSD

- MultiSertDrum MSD

Storage

-

Space-saving storage system for postpress processing

MultiDisc is a high-performance, space-saving storage system for newspaper and magazine processing that is gentle on products. The system is format-independent, and all adjustments to changing product lengths are rendered unnecessary. In addition to intralogistic applications, the mobile disc carrier is also suitable for interconnection with external users.Storage system for postpress processing:

- MultiDisc

Added Value

-

Generate added value with Ferag systems

When it comes to the efficiency of a modern mailroom, added value like stitching, trimming, folding, gluing, foil wrapping and addressing are now factors that spell success. They offer both publisher and advertiser new ways to promote the publisher's own products and produce them in a magazine-like quality. Innovative special advertising formats also generate interactivity between the reader and advertiser and turn the newspaper into an attractive advertising platform. The return on Investment of a mailroom thus becomes equally attractive. All components in the area of added value can also be integrated into an installation as a modular retrofit.Added Value for postpress processing:

- Stitching

- Trimming

- Foil wrapping

- Folding

- Addressing

- Gluing

- Infix

- Tapefix

- MemoStick

Gathering / Stitching

-

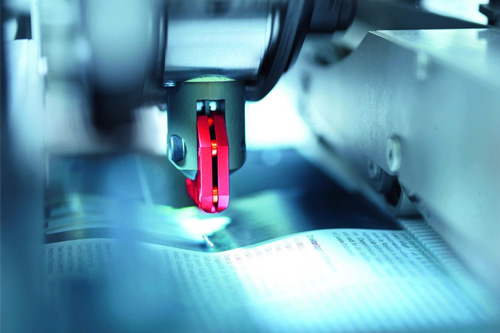

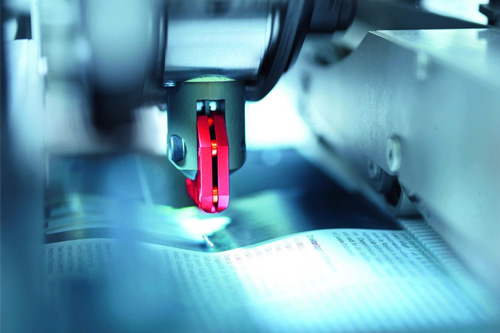

High performance in gathering/stitching for postpress processing

For the industrial postpress processing of magazines and periodicals in the high-speed sector, the UniDrum system is unsurpassed in terms of speed and flexibility. With production speeds of up to 40,000 copies an hour for A4 products and 32,000 for A3 products, the UniDrum achieves maximum efficiency while lowering costs per copy to a minimum. What's more, PreTronics for fully automatic format presetting makes for extremely short set-up times, while QualityEye detects skewed copies or incomplete sections, which in turn ensures very low levels of waste. In combination with the high performance SNT-50 trimming drum and the tried-and-tested inserting drum, trimming and inserting can be accomplished without a loss of performance. So net output comes very close to gross output. Single-copy addressing and foil-wrapping of products can also be integrated as and when required.Gathering / Stitching for postpress processing:

- UniDrum UDR

- TriServer TSR

Advertising inserts

-

New standards for the processing of advertising inserts

When processing advertising inserts for freesheets and weekly newspapers, in terms of efficiency Ferag is setting new standards. Whether it's with a cover, TapeFix, foil or folded insert – EasySert, RollSert in combination with FlyStream and one2out are the perfect solutions. The feeder processes all kinds of advertising brochures and magazines ergonomically and with high precision. And the repair system is a huge advantage. It returns incomplete collections to the loop and thus guarantees 100% quality. In addition, gap-free zoned production increases efficiency and boosts net output by a multiple factor. Time and money can also be saved at the planning stage thanks to the Optimizer, a Navigator control application. At the press of a button, numerous algorithms run in the background to calculate the perfect production strategy in a matter of seconds.Systems for processing advertising inserts:

- EasySert ESR

- RollSert RSD

- One2out

Software

-

Tailor-made control technology

Thanks to the Navigator, the control and visualization of production and processes become child's play. Data input, assignment of production mode and quality control can be monitored by fingertip thanks to the Navigator's intuitive operating sequences, while generic plug-ins enable interfaces to any third-party component. And with the Optimizer, complex production plans are generated in seconds at the press of a key. The Navigator thus guarantees maximum efficiency and profitability. Process and control technology as well as series construction and sound technical support round off our electronics competencies. All software, automation and engineering solutions are programmed and implemented by Ferag subsidiary Sofel AG.

Software for postpress processing:

- Navigator

- Optimizer

- Summarizer