- Offer Profile

-

Products from SWF Krantechnik are simply flexible

SWF Krantechnik is a global leader for components for crane and hoisting equipment. The product portfolio ranges from chain hoists and electric wire rope hoists to crane components, electronic monitoring and control systems, and light crane systems. The entire portfolio is also available in explosion-proof (EX) versions.

Products from SWF Krantechnik help independent crane builders and retailers to master tough challenges in the lifting business, set standards in the market and implement flexible, tailored solutions for a wide range of complex requirements.

SWF KRANTECHNIK makes it easy.

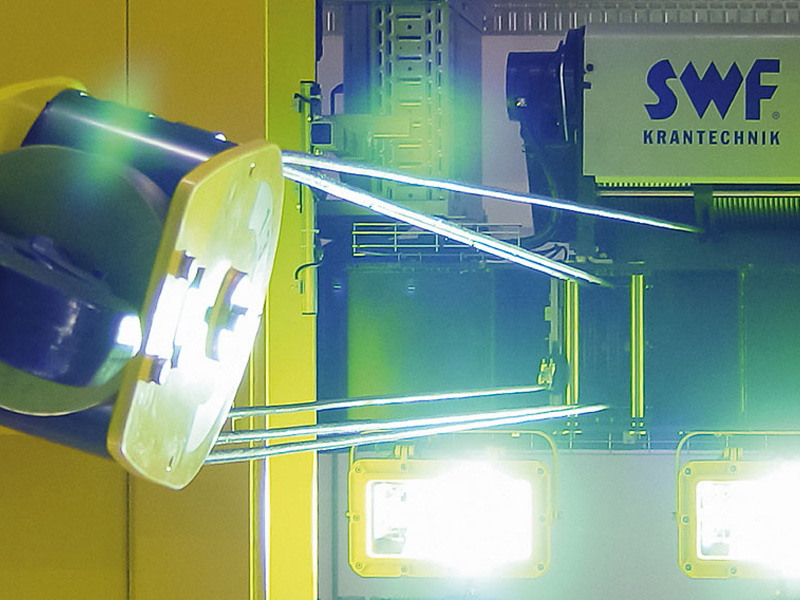

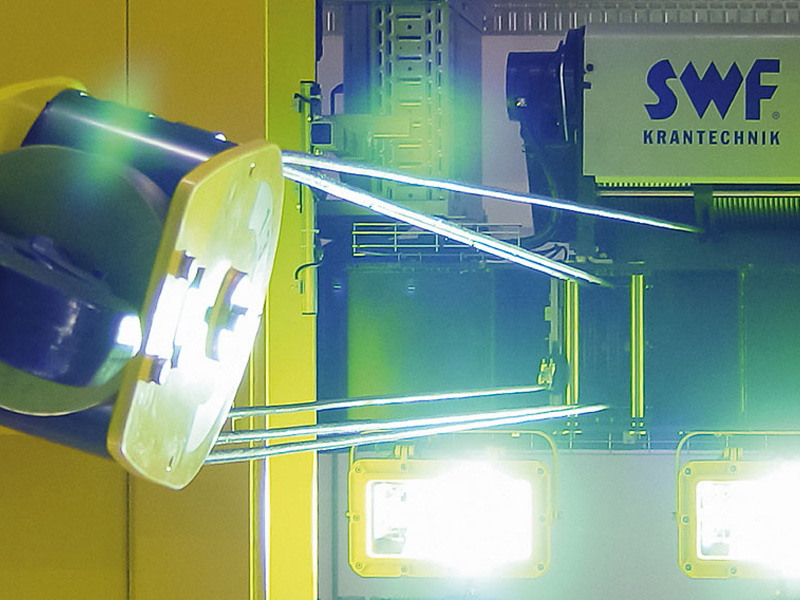

Wire Rope Hoist - NOVA2 rope

We are expanding the product portfolio of our new wire rope hoist NOVA2 rope to include fixed hoists and double girder trolleys for loads of up to 20 tonnes. This expansion makes it possible to use the new wire rope hoist in even more areas of application.

In the summer of 2024, we have already launched the wire rope hoist NOVA2 rope on the market as low headroom hoist for loads of up to 10 tonnes and as machinery hoist. These models are ideal for confined work areas and ensure high performance despite their compact design. Further models are already being planned and will be added over time.

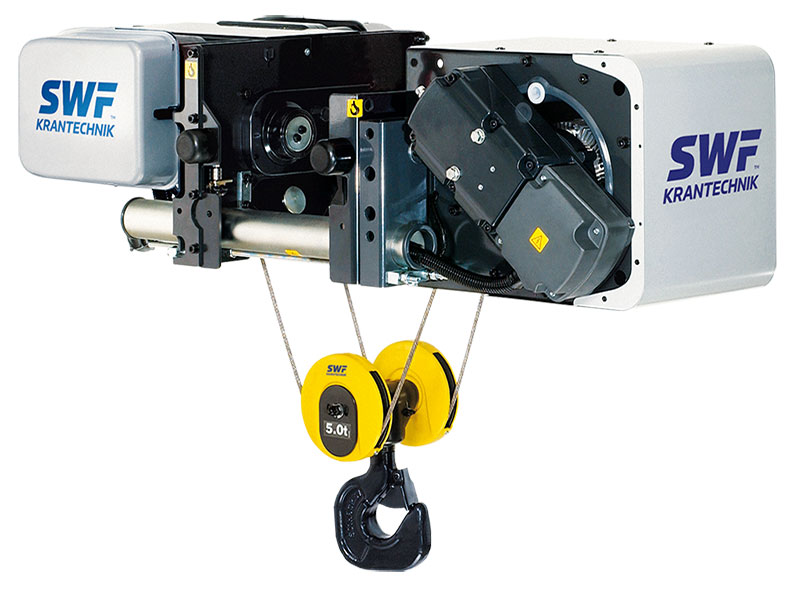

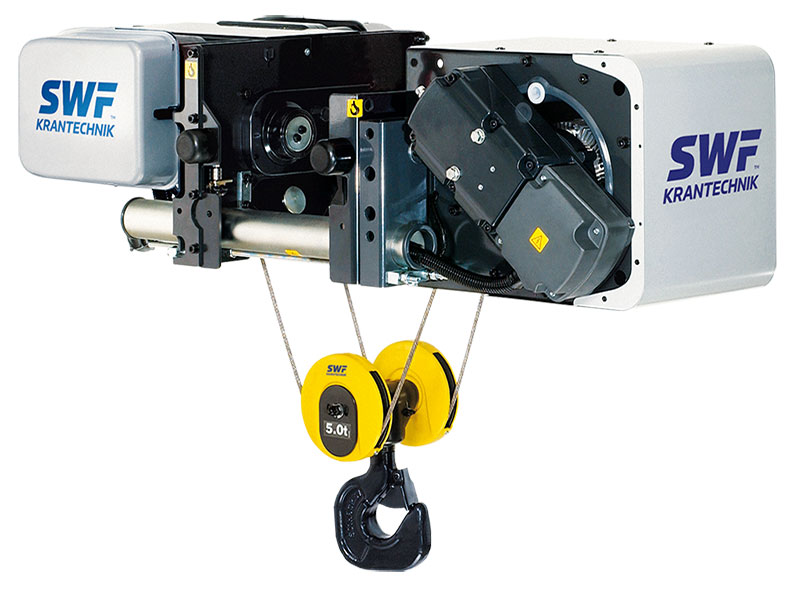

ELECTRIC WIRE ROPE HOIST NOVA2 rope

-

With NOVA2 rope, we are continuing the success story of the NOVA wire rope hoist and at the same time introducing the next generation of electric wire rope hoists.

Comprehensive redesign of the classic wire rope hoist

NOVA2 rope is based on innovative materials, advanced construction and functionally optimized components. Other key topics that have been incorporated into product development deal with user-friendliness, sustainability, digitization and control, as well as service and maintenance.

At the start of the new series, we offer models for load capacities of up to 20 tonnes. Further sizes, load capacities and designs are in preparation and will follow.

ELECTRIC WIRE ROPE HOIST NOVA1 rope

-

NOVA1 rope is one of our flagship products and designed for loads up to 80 t. The wire rope hoists feature optimal space utilization and maximum efficiency. NOVA1 rope is extremely flexible and easy to adapt to the individual requirements of your customers. Conveniently expand NOVA1 rope with electronic monitoring and control features (Crane Intelligence) to optimize monitoring processes.

Advantages:

- Optimal use of space

- Low maintenance costs

- Safe, precise operation

WINCH CRABster

-

Our winches from the CRABster series deliver big-time performance in the smallest of spaces and support up to 250 t loads. These compact, solid hoists ease the burden of working with heavy loads and fulfill today’s high demands on classification and hoisting speed.

- Safe, precise operation

Overload protection through strain gauge load measurement, hoisting frequency inverter with a closed loop, encoder on the hoisting motor, frequency inverter controller for traveling machinery - Optimal use of space

Compact design and optimal approach dimensions - Flexible modules

Construction using standard components, custom configurations with the calculation software CraneMaster - Comes standard with selected Crane Intelligence features

- Low maintenance costs & minimal downtime

- Safe, precise operation

Chain & Belt Hoists

ELECTRIC CHAIN HOISTS ATHLO chain & ATHLO chain SL

-

The ATHLO chain series, our latest generation of chain hoists, is designed for loads up to 5 t. At the launch of the new series, we are offering this model for loads up to 2.500 kg with further options to follow in the coming months.

ATHLO chain combines high security, performance and usability with easy maintenance and a long service life. The modern design features a newly constructed interior and all-new mechanical components. ATHLO chain is easy to use and delivers top performance in different conditions.

In addition to the standard version, ATHLO chain SL is equipped with frequency inverter for sensitive movement. ATHLO chain SL is designed for loads from 125 kg to 2,500 kg.

- Higher durability

The hoist motor with its new 4:1 ratio and redesigned cooling fins provides a better cooling in order to extend the service life of the hoist. ATHLO chain offers a new design for activating the limit switch which works flawlessly both in everyday usage and different conditions. - Easiest maintenance

ATHLO chain is low maintenance because both the hoist gear and bearings are designed to last a lifetime. All components are easily accessible, and no special tools are necessary to exchange components and install spare parts. - Higher performance, better handling

The new chain bag helps the chain run quietly and smoothly thus preventing an accumulation of the chain. To ensure top quality, we build the gears with an extended speed range ourselves in house. The compact design and new upper-eye suspension produce an increased lifting height at the same suspension height. - Improved safety

The new break is designed to handle 1 million cycles or up to a lifetime with the proper handling. It responds instantly when the power is turned off. The slipping clutch has a larger diameter and additional grooves to improve the cooling effect of the gear oil and increase its overall service life. Thanks to the new suspension bracket, a push or motor trolley can be installed using a special safety pin – with no further tools required. - Gentle operation

Low noise emissions, sensitive handling of the load with frequency inverter.

- Higher durability

ELECTRIC BELT HOIST ATHLO belt

-

ATHLO belt presents its advantages wherever cleanliness and safety are important. The numerous series features enable reliable and always safe operation. It can also be optimally adapted to individual requirements. In addition to the already available models with stainless steel components, further components in stainless steel will follow in the course of 2022.

ATHLO belt is designed for the food sector, the chemical/pharmaceutical industry and for all comparable industries.

- Optimal use of space

Minimal C-dimensions enable the optimal building design and the maximum use of the available working space. - Safety & Cleanliness

The high-tenacity and durable hoisting belt is ideal for applications in clean environments. The overload protection installed as standard prevents hoisting in the event of overload. Another protective device is the overheat protection, which is also installed as standard. - Extended offer

Numerous options such as frequency inverter, hot-dip galvanized trolley plates, construction elements with stainless steel components, Dynema belt and models for further loads will follow in the course of 2022.

- Optimal use of space

HAND CHAIN BLOCK CRAFTster

-

Our hand chain blocks from the CRAFTster series handle loads up to 20,000 kg. They are robust and powerful. We offer many different design options, fixings and trolleys to support a wide range of uses.

CRAFTster is a mobile, flexible all-rounder which easily handles a wide range of tasks.- Ideal use of space

Compact design, minimal hook dimensions, optionally with an integrated low-headroom trolley, push or chain driven trolleys available - Flexible in use & gentle operation

Independent of the power supply, easy to operate, convenient transport to the site of operation. Low own weight, easier handling with optional overload protection - High operational safety

Robust, tried-and-tested construction, high-quality interior

- Ideal use of space

ELECTRIC CHAIN HOIST CHAINster

-

Our electric chain hoists from the CHAINster series are designed for loads up to 5 t. They offer high durability and flexibility to handle various types of loads. We have designed the CHAINster series to help you ensure fast, efficient and smooth operations. In addition to the standard model, CHAINsterGT is also equipped with a cross travel frequency inverter drive, overload protection and non-contact limit switches for precise movement.

- Optimum use of space

Compact design, minimal hook dimensions, space-saving trolleys - High operational safety

Emergency stop button, 48 volts contactor control, drop-stop, robust aluminum casing - Gentle operation

Low noise emissions, low load swing and smooth load movements controlled by trolley and inverter - Low installation & maintenance costs

Standardized electrical modules, comfortable access thanks to modular construction, time saving adjustment of trolley flange width - RoHS compliant (EU)

Strengthens the confidence into the product - Safe, rapid load handling, optimal service life

- Optimum use of space

Light Crane Systems

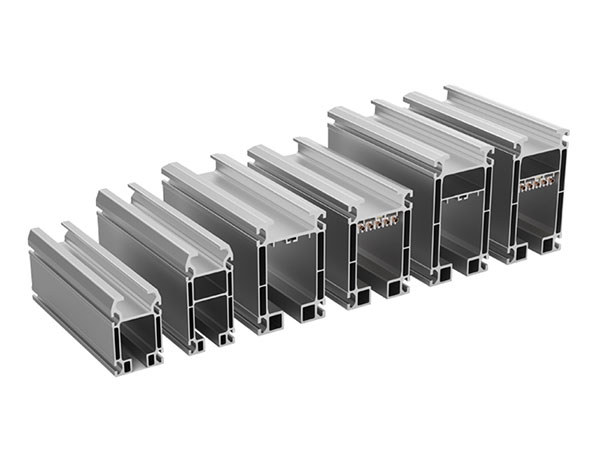

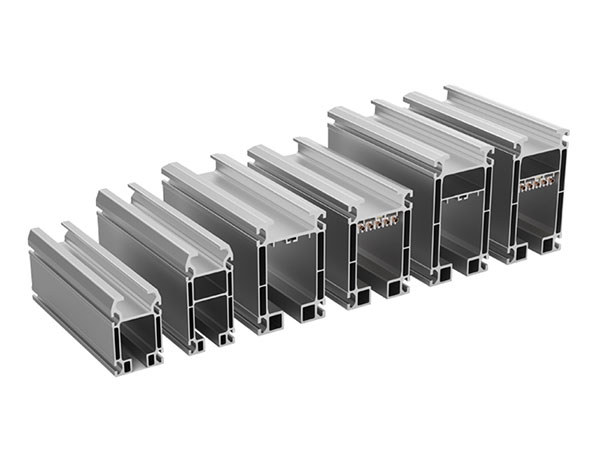

LIGHT CRANE SYSTEM PROFILEMASTER PLUS AL

- ProfileMaster PLUS AL is our modular light crane system made of aluminum for

loads up to 2,000 kg. Its innovative connection system handles heavy loads

so you can create optimal suspension distances and spans. Since all

components are presorted on delivery, you get a fast overview and can match

the individual parts easily. This saves valuable time in assembly.

Choose from six different aluminum profile types in four sizes. Two of these profiles are additionally equipped with an internal conductor line. Connection plates ensure that bolting the joints is fast and simple.- High quality made in Germany

Highly durable material, low own weight, reduced operating noise - Gentle load handling

Smooth movements, easy travelling, specially designed, high-performance running wheels - Tailor-made system

Suitable for use in building structures with low static load capacities, simple, time-saving assembly, optimized number of suspensions

- High quality made in Germany

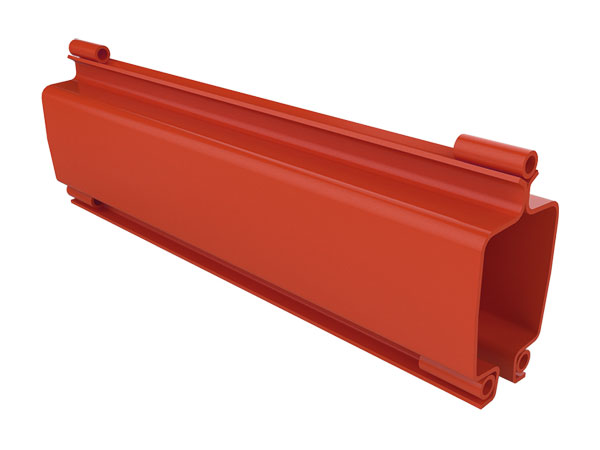

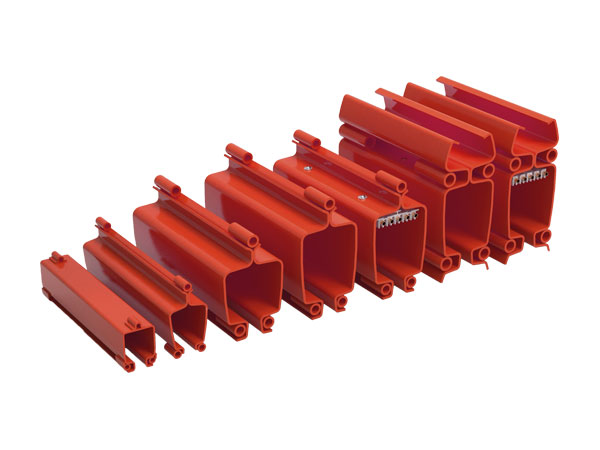

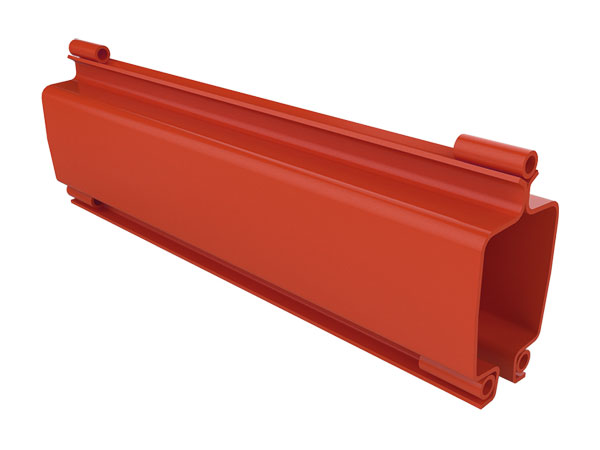

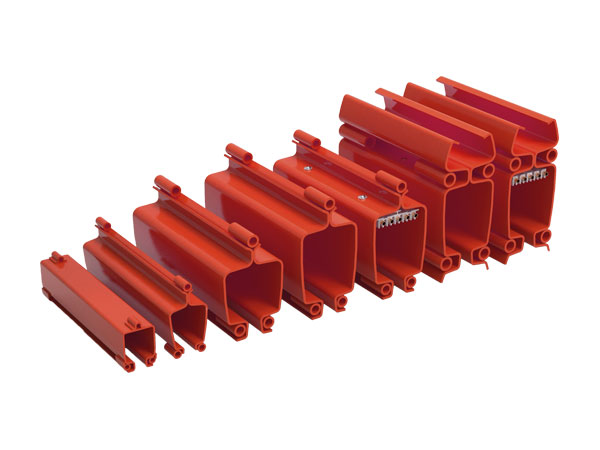

LIGHT CRANE SYSTEM PROFILEMASTER PLUS ST

-

ProfileMaster PLUS ST offers highly flexible planning options and is designed for loads up to 2,000 kg. Compatible components and optimized suspensions ensure a first-time assembly in record speed. You can later extend or modify the system as you need in minimal time.

Choose from seven different steel profile types in five sizes for various loads and suspension distances. Two of these profiles are additionally equipped with an internal conductor line. All profiles are cold-formed and powder-coated, which makes them very rigid.

- Flexible design options

Wide range of profiles, Chain@Master – online configuration tool for standard systems, easy modification and extension options - Low maintenance costs

Long service life, premium, robust profiles, set of highly compatible components - Fast assembly

Reduced profile weight, optimized suspensions and connections, profiles that can be bolted together quickly and easily

- Flexible design options

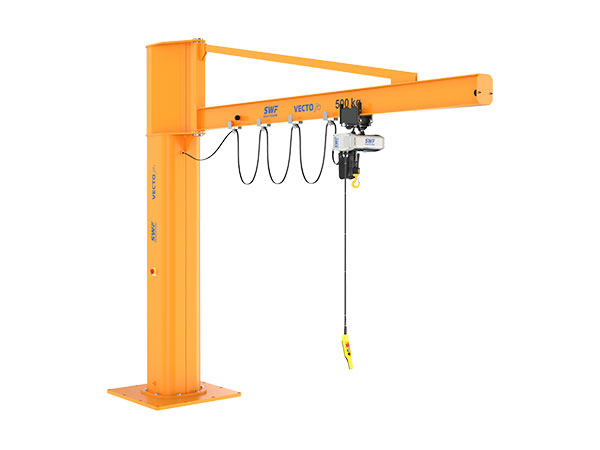

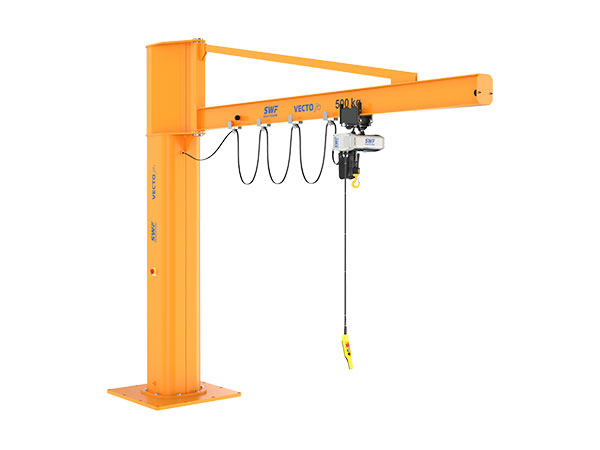

SLEWING JIB CRANE VECTO jib

-

Our slewing jib cranes from the VECTO jib series are designed for loads from 125 up to 2.000 kg. At the launch of the new series, we are offering VECTO jib as wall and pillar mounted slewing jib cranes in three different designs.

We offer VECTO jib wall and pillar mounted slewing jib cranes with:

- over braced ProfileMaster PLUS light crane profile made of steel

- under braced I profile

- over braced I profile

VECTO jib is quick and easy to assemble. The series can be equipped with all ATHLO chain electric chain hoists and CRAFTster manual chain hoists. VECTO jib can be used in numerous industries and work environments.

Further variants with ProfileMaster PLUS light crane profiles made of aluminium will follow in the near future.

Controlling/Monitoring

CRANE INTELLIGENCE

-

Crane Intelligence provides optional features for smart electronic monitoring and control to make operating a crane safer and more user-friendly.

- EXTENDED SPEED RANGE

- MICRO SPEED

- SLACK ROPE PREVENTION

- INCHING

- RESTRICTED LOAD

- SWAY CONTROL

- LOAD FLOATING

- SHOCK LOAD PREVENTION

- TANDEM

- SYNCHRONIZATION

- CRANES IN TANDEM

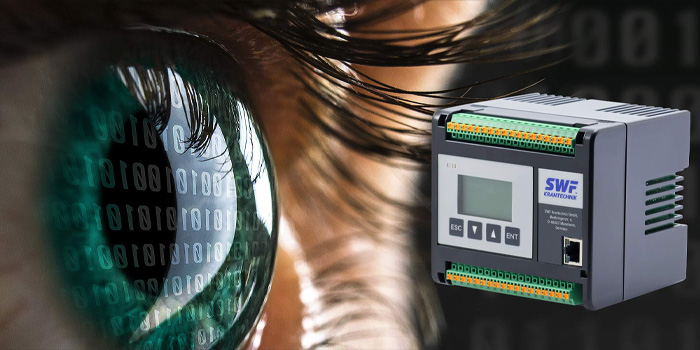

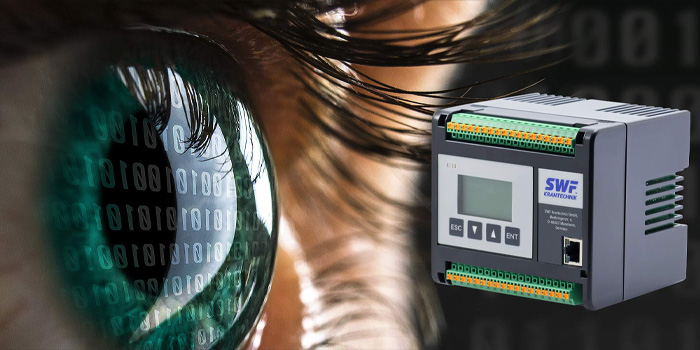

HOIST MONITORING OMNI control / NovaMaster

-

The hoist monitoring systems NovaMaster and the digitally networked successor OMNI control collect and process all parameters of hoist operation. All information can be read out via display or by using a mobile app. This includes, but it is not limited to:

- faults and warnings

- data about hoist condition (SWP hoist, brake and contactors)

- information about hoist usage (load, runtime, overload incidents, temperature, number of emergency stops, overtemperature, etc.)

In other words, the days of worrying about inaccurate or time-consuming calculations for the annual inspection of your crane systems are history.

SWF X-Link complements the NovaMaster hoist monitoring. The app clearly visualizes all NovaMaster parameters on the user’s mobile phone on factory floor level. To work with the app, NovaMaster simply needs to be equipped with a hardware module with antenna for wireless transmission and an adapter cable.

- Continuous monitoring

Hoist monitoring, permanent SWP calculations, overload protection - Minimal downtime

Relevant crane data can be read quickly from the display - Safe working conditions

Monitoring of safetyrelevant hoist components and operation parameters such as brakes, contactors, etc

FREQUENCY INVERTER VARIO control / TravelMaster

-

VARIO control and TravelMaster enable stepless speed adjustments for long and cross travel drives.

The frequency inverter controller ensures gentle operation. Simply put, that means less wear and tear, lower maintenance costs and shorter service periods.

- Precision work under load

Low-sway moving, stepless speed adjustment - Gentle operation

Smooth start and stop is gentle on gears and wheels and reduces wear on wheels and rails - Lower maintenance costs & less scheduled downtime

Longer-lasting wheels and rails and minimal wear on breaks means less maintenance as well as a significant drop in maintenance costs and used materials

- Precision work under load

RADIO REMOTE CONTROL RadioMaster

-

With the remote controls from our RadioMaster series, crane operators flexibly control and monitor long and cross travel along with various other features. Crane operators profit from a greater range of movement. This facilitates everyday steps in the job and makes operating the crane as a whole so much simpler.

- Room to move

Flexibly crane operators control the crane from a safe location – without cumbersome cables in the way - Robust design

Highly durable housing and controls, vibration protection for the receiver, long-life rechargeable batteries, fast charger with back-up rechargeable battery - Versatile usage

Load data in display, push-button and joystick controls, multiple crane or hoist operation (e.g. in tandem or as master/slave), suitable for monitoring other features as well

- Room to move

Crane Components

CRANE COMPONENTS CraneKits

-

Our CraneKits for NOVA electric wire rope hoists support loads up to 80 t. Thanks to their highly modular design, you can flexibly create optimal crane solutions for the specific application and building structure of each client. Innovative, high-quality monitoring and control units, such as frequency inverter technologies, and various other options can be added easily at any time.

- Effective planning and calculation with our crane configuration software, CraneMaster

- Economical and efficient; one-stop shop for all components

- Highly compatible, pre-assembled, pre-wired electric components

- Fast, simple assembly

CRANE COMPONENTS End carriages

-

Our robust, long-life overhead crane end carriages are available as top running and underrunning versions and designed for single and double girder cranes.

- Modular construction

Flexible use of components - Individual colors

Primed or coated in your client’s preferred color – directly from the factor - Various possibilities to connect the end carriages to the crane bridge

- Vast options available, including crash or storm protection, guide rollers, bogie design options, and more

- Modular construction

CRANE COMPONENTS Traveling machinery

-

All of our traveling machinery come standard with powerful frequency inverter motors for extremely sensitive, gentle traveling.

- Standard frequency inverter motors with overheat protection

- Plug connection on the motor (except in large motor series)

- Gentle, precisely positioned long and cross travel

Explosion Proof

ELECTRIC WIRE ROPE HOIST NOVAex

-

The NOVAex series for loads up to 80 t fulfills the highest European and international safety standards. Our products can be used in zones 1 and 2 for gas protection as well in zones 21 and 22 for dust protection.

NOVAex features a compact design, minimal hook dimensions and the best approach dimensions available on the market. Its extra-large diameter of the rope drum is gentle on the load-bearing rope. Plus, the breaks and the lubrication of the hoist gear are designed to last a lifetime.

- ATEX and IECEx certification

- Control panels with robust housings for use in various zones and different types of ignition protection, for example, increased safety “e” and pressure-resistant encapsulation “d”

- Potential equalization of all conductive components

- Grounding cables are factory-mounted and ready for operation

- Robust, enclosed housing for hoist gear and hoist gear limit switch

- Control pendant with robust housing and two-stage rocker switches

- Specially designed hoist motors for different classes of protection

- Load hooks (optionally with bronze coating) and running wheels (optionally available in solid brass) for optimal spark protection

ELECTRIC CHAIN HOIST ATHLO chain EX Zone 22

-

The ATHLO chain EX Zone 22 series combines the advantages of our proven chain hoist with the operational capability for potentially explosive atmospheres. The new generation of explosion-proof electric chain hoists is designed for loads from 160 to 1,000 kg (further loads will follow).

The chain hoists comply with the applicable national and international norms and safety standards (ATEX, IECEx, NEC) and can be used flexibly. The aspects of safety, product service life, ease of maintenance, performance and easy usage were the focus of the development.

ELECTRIC CHAIN HOIST SKex

-

The SKex series for loads up to 5,000 kg meet the highest European and international safety standards. Our products can be used in zones 1 and 2 for gas protection as well in zones 21 and 22 for dust protection.

SKex is reliable and built to last with low maintenance, wear and tear. With SKex, implementing explosion-proof crane systems with very specific requirements is no problem.

- Robust housing and components

- Custom configurations

- Compact design and optimal approach dimensions

- Explosion-proof control panel

- Contactor control with main contactor and transformer

- Motor and break with pressure-resistant encapsulation (Ex d) and temperature control through a PTC thermistor

- Slipping clutch as overload protection

HAND CHAIN BLOCK CRAFTsterEX

-

CRAFTsterEX hand chain blocks are safe, reliable and long lasting. They carry loads up to 20,000 kg in atmospheres with highly flammable mixtures of gas and air or in dusty air in zones 1 and 2 as well as 21 and 22.

CRAFTsterEX is a mobile, flexible all-rounder which easily handles a wide range of tasks in challenging environments and conditions.

- Ideal use of space thanks to the compact design and minimal hook dimensions

- Easy operation

- Flexible usage, independent of the power supply

- Easy transport to the site of operation

- High-safety operation

- Robust, tried-and-tested construction

- High-quality interior

CraneKitEX

-

Our CraneKitEX offers all components – with the exception of the crane bridge – that you need to build a custom crane for use in zones 1 and 2 (gas protection) and zones 21 and 22 (dust protection). The components are highly modular, pre-assembled and easy to install.

- Safe, reliable compatibility among all components

- Fast assembly

- Flexible customization options

ELECTRIC CHAIN HOIST ATHLO chain EX (Zone 2)

-

ATHLO chain EX has been designed for use in explosive environments and complies with the latest safety regulations and is certified both ATEX and IECEx for Zone 2. With a lifting capacity of up to 2,500 kg and an extensive range of configurations, the chain hoist can be perfectly tailored to specific requirements.

Even in the standard version, the load can be moved steplessly and smoothly thanks to the frequency inverter. The wide operating temperature range enables the safe use of ATHLO chain EX in various industries for numerous applications.

Additional models for further load ranges, equipment options, and EX zones will follow.