- Offer Profile

-

With its extensive portfolio of handling systems for lifting, tilting, tipping and emptying, Ventzki offers the right solution for every application. The range of products also includes combination devices which bring together several functions in a single product.

This broad range of products is what makes Ventzki an exclusive, complete supplier of lift and tilt stands - including our own in-house development and production.

VENTZKI – At home in many industries – Ergonomic and efficient in every case

Scissor lift tables

-

Scissor lift tables from VENTZKI: for heavy loads!

The scissor lift tables from VENTZKI Handling Systems are the perfect handling devices for numerous industrial production processes: When it comes to lifting heavy containers or components, every lifting table from our production provides indispensable services: weights of up to six tons are safely and reliably lifted!

All VENTZKI scissor lift tables have a powerful and high-quality hydraulic drive. Our SHT model is able to lift weights up to 6,000 kg in a controlled way. But our flat-form lifting table models UFFT and FFT have a lot of power: Both versions lift weights up to 2,000 kg.

Every lifting table from VENTZKI is designed to compensate for differences in height due to lifting heavy loads. This way, work processes are significantly simplified, and at the same time, they are also significantly more ergonomic: Productivity is increased and your employees' health is effectively protected!

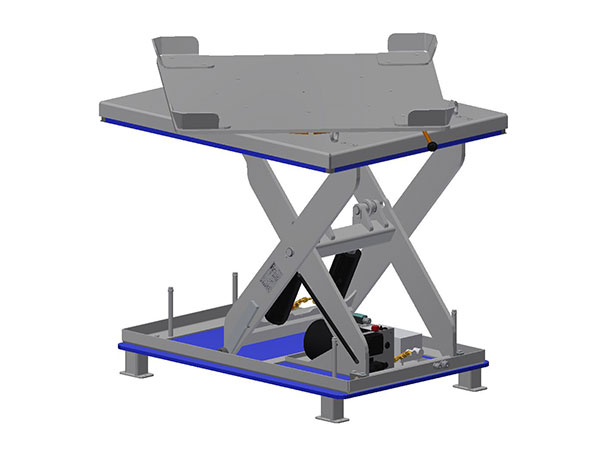

SHT Scissor Lifting Tables

-

Flat-form lifting tables with electrohydraulic drive up to a capacity of 6,000 kg for ergonomic loading and unloading

- Suitable for heavy loads up to 6,000 kg.

- Electrohydraulic drive -- can also be provided with a hydropneumatic drive.

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- The tables meet the latest accident prevention regulations as well as the valid EN standards (DIN EN 1570) and the current EU machinery directives.

- Accessories, such as removable protective railings, cross-over brackets, bellows, roller track attachments, special, turning and tipping platforms, are available.

- Special designs available.

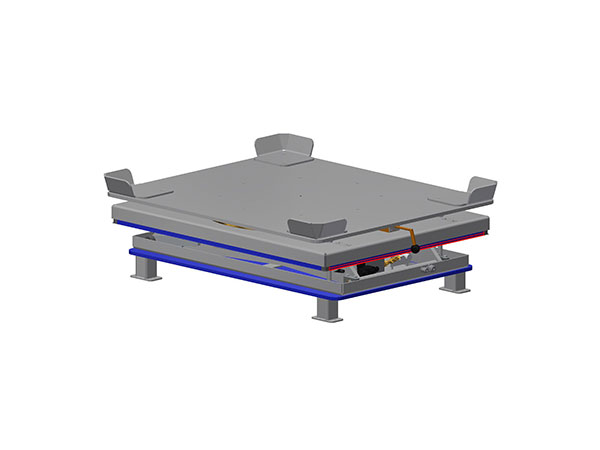

FFT flat form lifting table

-

Flat-form lifting tables with electrohydraulic drive up to a capacity of 2,000 kg for ergonomic loading and unloading

- Practical solution for ergonomic loading and unloading of containers or pallets.

- Suitable for pallets and containers up to 2,000 kg.

- Electrohydraulic drive -- can also be provided with a hydropneumatic drive.

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- Rotating platform available as an accessory. Special designs available.

- Container stops according to customer specifications possible.

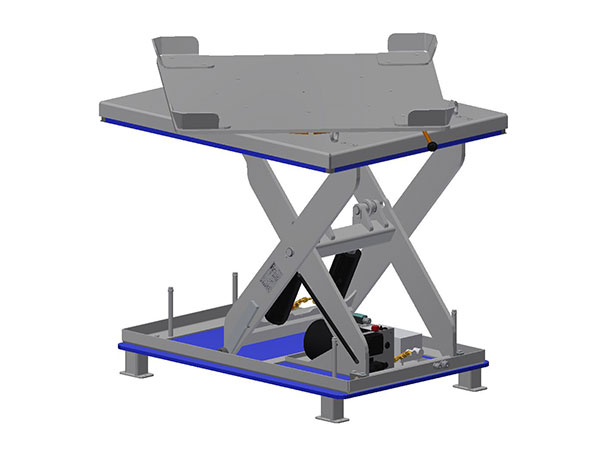

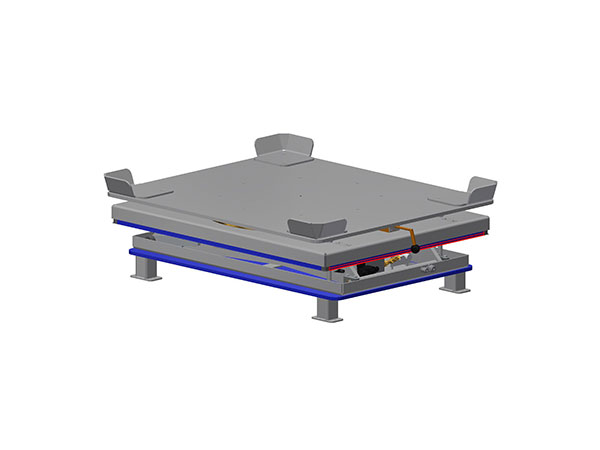

UFFT/EFFT flat form lifting tables

-

Flat-form lifting tables with electrohydraulic drive for ergonomic lifting of containers and pallets up to 2,000 kg

- Practical solution for ergonomic loading and unloading of containers or pallets with manual pallet trucks or electric manual pallet trucks.

- Suitable for pallets and containers up to 2,000 kg.

- Electrohydraulic drive -- can also be provided with a hydropneumatic drive.

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- Rotating platform available as an accessory. Special designs available.

- Container stops according to customer specifications possible.

Container lifting devices

-

Fatigue-free work with a VENTZKI lifting device!

A universally usable lifting device from VENTZKI Handling Systems is an enormous boost to manufacturing processes: The production process in your industrial company will be more efficient, and work flows will be ergonomically healthier for your employees. Learn more about the high-quality lifting devices from VENTZKI!

During assembly or repairs, containers and components must be easily and quickly accessible. Every lifting device from our production can be adjusted to the correct working height in a comfortable and infinitely variable manner. KLT boxes, small containers, trolleys, floor rollers and skeleton baskets can be lifted according to your requirements. Your staff is thus able to work quickly, without fatigue and in a health-protective manner.

Our reliable lifting devices are equipped with different drive systems to be able to provide a constant performance for the widest range of applications. Each of our models can be easily customized to the needs of your business. In addition, the high-quality workmanship of the individual device components ensures a remarkably long, low-maintenance and interference-free operating time.

HM 990

-

Mobile lifting devices without energy supply to be used with containers up to 200 kg

- Suitable for small containers such as KLT boxes and other load carriers.

- Automatic-mechanical drive system: can be set steplessly with a crank - independent of any outside energy source

- Weight-dependent height regulation

- With steering and fixed rollers, steering rollers with brakes.

- Ergonomically shaped handles for convenient transport to the place of use.

- Removable border strips on the platform secure the containers.

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

HE-LP 100

-

Mobile lifting devices with electromotive drive (battery) for energy-independent use with containers up to 100 kg

- Suitable for the transport of small load carriers.

- Load receptacle with an MDF wood panel.

- Four steering rollers, of which two with brakes.

- Operate with a hand lever.

- Useful height: 1,250 and 1,700 mm

- Special load holders possible (prongs, mandrel).

- LED load display

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- 230V charging device included with delivery.

HP 200/250

-

Lifting devices with pneumatic drive for a continuously adjustable ergonomic working height for containers up to 250 kg

- Suitable to carry small containers, carts, floor rollers and grating baskets.

- Load capacity, depending on model, from 200 to 250 kg.

- Sidewalls (in the HP 200).

- Pneumatic drive according to the latest safety requirements.

- Safety valve technology prevents the load carrier from dropping if there is a break in the line.

- Stepless adjustment to the desired ergonomic working height.

- Stationary devices with side loading available.

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

HP 300/500

-

Lifting devices with pneumatic drive in stationary or mobile (with chassis) version for containers up to 500 kg

- Suitable to carry small containers, carts, floor rollers and grating baskets.

- Load capacity, depending on model, from 300 to 500 kg.

- Suspension consists of two steering rollers, including brake and one caster for individual and flexible uses.

- Pneumatic drive according to the latest safety requirements.

- Safety valve technology prevents the load carrier from dropping if there is a break in the line.

- Stepless adjustment to the desired ergonomic working height.

- Stationary devices with side loading available.

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

HE-EP 200-1000

-

Lifting devices with electromotive drive for a more energy-efficient use with containers up to 1,000 kg

- Lifting device with 230 V connection or 24 V exchangeable battery (up to 500 kg load capacity).

- Suitable to carry small containers, carts, floor rollers and grating baskets.

- Load capacity, depending on the model, 200 kg to 1,000 kg.

- Stepless adjustment to the desired ergonomic working height.

- Available in mobile or semi-mobile versions (for lifting capacities up to 500 kg) and stationary version.

- Automatic operation by means of sensory height detection as special equipment possible.

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

HE 1000/2000/3000

-

Lifting devices with electrohydraulic drive for large load carriers and containers up to 3,000 kg

- Particularly suitable for holding pallets and large containers.

- Load capacity, depending on the model, up to 3,000 kg.

- Low-maintenance electrohydraulic drive.

- Stepless adjustment to the desired ergonomic working height.

- Available in a stationary design.

- Optional with rotary or special platforms and light scanners for position sensing (special equipment).

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- Safety contact strip as special equipment available.

Container tilting devices

-

Container tilting devices: Load machines more effectively

The mobile or stationary tilting devices from VENTZKI are suitable for containers and pallets of all kinds and are suitable for more effective and fatigue-free loading of machines. The material is thereby placed in the most advantageous position for the user.

Your most important advantages at a glance:

- Four different, application-oriented designs.

- Mobile and stationary tilting units from VENTZKI are immediately ready for use in a simple and flexible way at many workplaces. With electrohydraulic or hydropneumatic drive, they can be used in most production fields.

- Ergonomic design of all device types according to state-of-the-art technology, for the stress-free and fatigue-free workplace.

- All devices are equipped with safety systems, such as protective screens, bellows or protective straps. Line breakers prevent an uncontrolled drop in the event of damage to the hydraulic system.

- High-quality and robust components guarantee a low maintenance and trouble-free operation.

- Special versions are possible.

NE 330

-

Stationary tilting devices with electrohydraulic drive for large-load carriers with space-saving design and a load capacity of up to 1,200 kg

- Small space requirement due to two-dimensional tilting motion, thus no container overhang in the working area.

- Pick-up of large load carriers such as skeleton boxes.

- Can position containers using a route pulling system.

- Low-maintenance electrohydraulic drive.

- Tilt angle up to 80°.

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- With side protective grid.

NE/NPX 304-328

-

Stationary tilting devices with electrohydraulic or hydropneumatic drive for low maintenance and trouble-free operation with containers up to 2,500 kg

- Electrohydraulic drive: NE; hydropneumatid drive NPX (connection 6 bar, maximum load capacity 2,000 kg).

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- Stepless setting of the tilt angle.

- Ideal for frequent container changes.

- Low clearance 100 mm (loading on three sides possible)

- Mobile option available.

- Operation alternatively with foot or hand control device (hand control device on the standpipe).

NE 018/019

-

Mobile lifting devices with electrohydraulic drive for energy-independent use with containers of any kind up to 1,500 kg

- Electrohydraulic drive.

- Stepless setting of the tip angle

- Ergonomic design according to the latest state of the art.

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- Mobile use in different areas.

- Steering castors with brakes and rollers.

- Hydropneumatic version possible on request.

- Shifting bracket provided as standard equipment.

Container tilting and dumping devices

-

Container tilting and dumping devices: Greatest flexibility

The tilting and dumping devices of the NEE series can be used universally and flexibly for the loading of machines such as presses or punches, and are suitable for integration into all types of plants as well as in separation processes.

Your most important advantages at a glance:

- Containers with bulk materials are always available in the positions required for fatigue-free and effective operation.

- With semi-automatic container locking by means of safety straps.

- Optionally available with electrically lockable wing doors or light barriers.

- Considerable productivity gains in the flow of materials are made by means of a safe and rational process.

- High-quality and robust components of the NEE devices from VENTZKI ensure a low maintenance and trouble-free operation.

- Special versions are possible.

NEE 511-519

-

Compact and functional dumping devices up to 2,000 kg with electrohydraulic drive for safe work processes and increased productivity

- Electrohydraulic drive.

- Maximum tilt angle: 135°.

- Available in stationary or mobile version

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- Pouring width: 400 mm.

- Dumping height: 750 mm with adjustable chute on the base frame, 1,050 mm with load carrier as chute.

- Optional versions are possible, such as electrically lockable wing doors, manual dispensing flap, manual slides at the dumping chute, pouring liner, vibration unit and bonding plates at the dumping chute.

Container tilting and lifting devices

-

Container lifting and tilting devices: Accelerate work processes

A considerable facilitation and acceleration of the work processes during the loading of machines is achieved with the lifting and tilting devices. Ventzki offers various solutions for a number of purposes.

Benefit from our comprehensive service:

- Lifting technology directly from the manufacturer

- Commissioning and testing according to BGR 500

- Special designs on request

Your most important advantages at a glance:

- Four different, application-oriented classes.

- Separate lifting motion of the containers, the tilt angle can be adjusted steplessly and without work interruption.

- Loading direction alternatively from the front or the side.

- All electrohydraulic devices are equipped with safety devices such as line breakers and pressure relief valves.

- Special versions are possible.

- With the Ventzki devices, you get everything from a single source, directly from the manufacturer: Assembly, commissioning and testing according to BGR 500

NHE 304/305

-

Mobile lifting and tilting devices with electrohydraulic drive and a tilt angle of up to 90° for different use locations and containers up to 1,500 kg

- Suitable for holding standard containers and pallets.

- Maximum tilt angle 90°.

- Load capacity, depending on the model, up to 1,500 kg.

- Low-maintenance electrohydraulic drive.

- Stepless setting of the working height and tilt angle.

- Equipped with fork rakes standard.

- Two steering and two fixed rollers. Steering wheels with brakes

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

HNE 750-3000

-

Lifting and tilting devices for pallets and large containers with electrohydraulic drive for space-saving and need-based use

- Suitable for holding pallets and large containers.

- Tilting one-sided 45° (standard) or 2 x 45° as special equipment (HNE 3000 only possible 1 x 45°).

- Load capacity, depending on the model, up to 3,000 kg.

- Low-maintenance electrohydraulic drive.

- Stepless setting of the working height and tilt angle.

- All devices can be loaded either from the front or from the side.

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

NHE 350/360

-

Lifting and tilting devices with electrohydraulic drive for pallets and large containers up to 2,000 kg with optimized freedom of entry

- Low-maintenance electrohydraulic drive.

- Maximum tilt angle 90° (NHE 350: Standard 60°).

- Compact and space-saving design.

- Also can be used in narrow spaces.

- Both side and front loading possible

- Useful height: 300 mm.

- NHE 360 with even smaller access width and separate hydraulic unit (NHE 350 with integrated unit).

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

HKE 750/1500

-

Lifting and tilting devices with electrohydraulic drive for containers up to 1,500 kg and for holding large-volume carriers with floor rollers

- Low-maintenance electrohydraulic drive.

- Maximum tilt angle: 40°.

- Compact and space-saving design.

- Also can be used in narrow spaces.

- Front-loading

- Useful height: 450 mm.

- Container stop in special version available

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- Optional: Undercarriage (underrun clearance 100 mm)

High-capacity lifting-dumping device

-

Highly versatile in filling

Powerful lifting and tilting devices enable a more efficient production and ergonomically healthy work: The practical High-capacity lifting-dumping devices from VENTZKI Handling Systems are especially designed and built according to your requirements: you will receive a custom lifting-tilting device which is specifically made for your business!

The first-class handling devices from VENTZKI are your first choice if small-sized bulk goods have to be raised and filled in large quantities, whether they are screws, granules or punched or forged parts! Our high-capacity lifting-dumping devices can be ideally used as lifting and tilting devices. In particular, the loading of packaging, filling or separating systems becomes much faster and more effective by the use of these apparatuses. Our dumpers can also be used for counting, weighing and mixing processes with excellent results.

We manufacture a lifting and tipping device specifically according to your specifications. Additional components such as light barriers and safety fences are as easy to supply as custom-made products. Just let us know your desired specifications. Our engineers closely monitor your requirements and develop the best possible solution for your specific application.

HEE 100/300/500

-

High-capacity dumping devices with electromotive drive for stepless adjustment of the inclination angle for containers up to 500 kg

- Custom solutions - customized for each user.

- Electric motor drive.

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- Stepless setting of the tilt angle.

- Additional components such as photodetectors, protective grids available as options.

- Special designs available.

Self-Tipping Containers

-

Self-tipping containers: Securely tip tons

The LC self-tipping container can be used in many ways in internal and warehouse transport. Loads of up to 2,500 kg can be safely and efficiently transported in the container, tipped and emptied with the forklift truck.

Your most important advantages at a glance:

- High-quality and robust components guarantee a low maintenance and trouble-free operation.

- All containers are welded oil-proof up to the maximum container height and subject in the raw state to a full inspection for leaks.

- Rolling curve on both sides secured by protective sheet metal.

- Accessories: Lockable fixed and steering wheels, hinged lid, sieve bottom, drain cock.

- Special versions are possible.

LC 803–812

-

Self-tipping containers with load capacities up to 2,500 kg for transporting, tipping and emptying of, for example, chips and scrap parts

- Load capacity up to 2.5 tons Capacity up to 1,200 litres

- Low-maintenance and trouble-free operation thanks to high quality, robust components.

- Accessories: Steering and fixed rollers, hinged lid, sieve bottom, draincock.

- Rolling curve on both sides secured by protective sheet metal.

- All containers are welded oil-proof up to the maximum container height and tested for leaks.

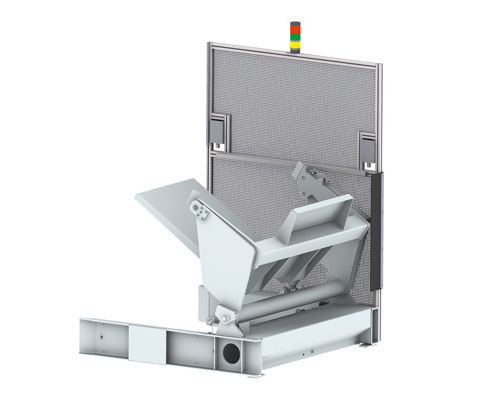

PALOMAT®-Palett maganzine- GREENLINE

-

Fully automatic stacking and destacking

Pallets are moved into or out of the PALOMAT Greenline by means of a pallet truck, electric forklift or fork lift. The PALOMAT recognizes the pallets by photo sensors, after which they are stacked or destacked one by one, fully automatically. Pallet handling takes place at floor level.

When destacking, a stack of maximum 15 or 25 pallets is inserted into the PALOMAT, which are then destacked individually one after the other fully automatically. During stacking, the pallets are inserted one by one, after which the pallets are stacked fully automatically, up to a maximum of 15 or 25 pallets. The entire stack can then be removed.

- PALOMAT Greenline is only operated manually with the touch panel when switching between stacking and destacking, or vice versa.

- The PALOMAT can handle all 4-way pallets made of wood, plastic and metal regardless of length, width or height.

- We can modify the PALOMAT Greenline to fully adapt it to your pallet.

Highlights:

- The PALOMAT stacks and destacks the empty pallets one after the other. All pallets are handled at floor level.

- The PALOMAT automatically raises/lower the whole pallet stack so that you can easily insert a new pallet at floor level, for example, with a hand pallet truck. A touch panel is used to operate the machine.

- A full stack of pallets (15 or 25 pallets) can be inserted into or removed from the PALOMAT - without using a forklift.

Fields of application

Relief of employees and time savings

Greenline is one of PALOMAT's standard models. The pallet magazine can be placed anywhere and is simply connected to 230 V. With Greenline, all pallet handling is done automatically and at floor level. Users simply insert or remove the empty pallets with a forklift or hand pallet truck, and Greenline does the rest, i.e. stacking and destacking. Operation when switching between stacking and destacking is done manually via a touch panel. Rotary tables

-

VENTZKI designs individual rotary tables and handling systems with integrated turning devices for efficient container positioning in industrial intralogistics.

This additional function enables the worker to maintain an optimum and constant working position at the workstation when removing parts and components. The changing fill levels are processed optimally and flexibly from all sides of the container and load carrier.

In addition, further optional movement functions can be integrated into VENTZKI swivel frames. In addition to the horizontal rotation of the work supply, the containers and load carriers can also be lifted or tilted to achieve an ergonomic positioning in the optimum position for the worker.

Rotating platforms for two containers and load carriers allow the worker to work ergonomically on the container from one side, while another worker removes the empty load carrier and places a newly filled container on the opposite side.

This means that the next work process can be activated by manually or optionally motor-driven turning of the containers by 180 degrees without the worker having to change position and reload his parts supply himself. This significantly reduces set-up times, effectively shortens throughput times in the production process and thus realizes noticeable cost savings.

The comprehensive service from VENTZKI Handling Systems:

- Special versions on request

- Integrated concepts from planning to installation

- Testing and repair service by the manufacturer

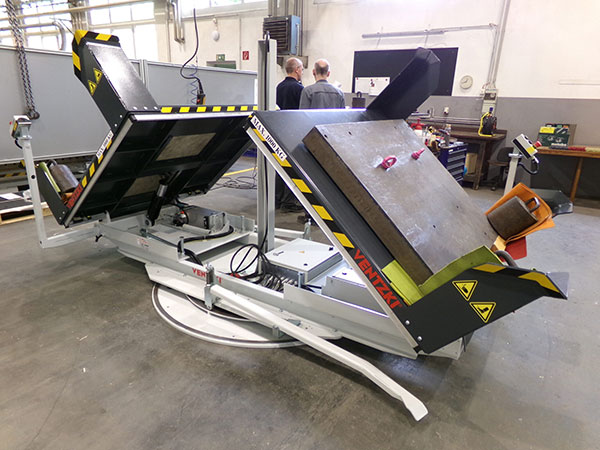

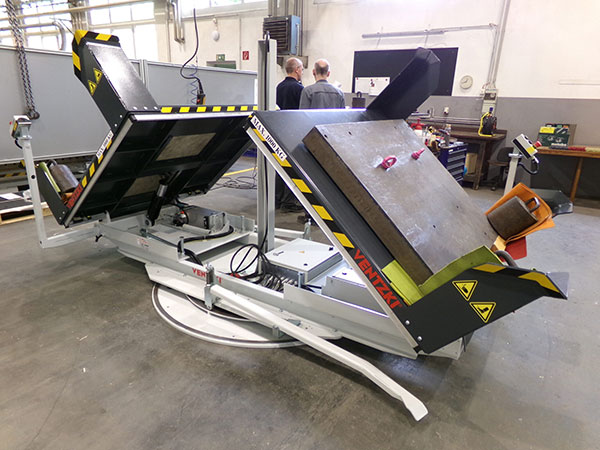

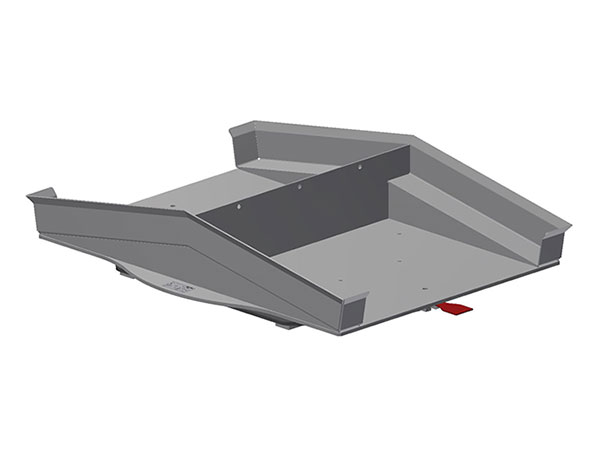

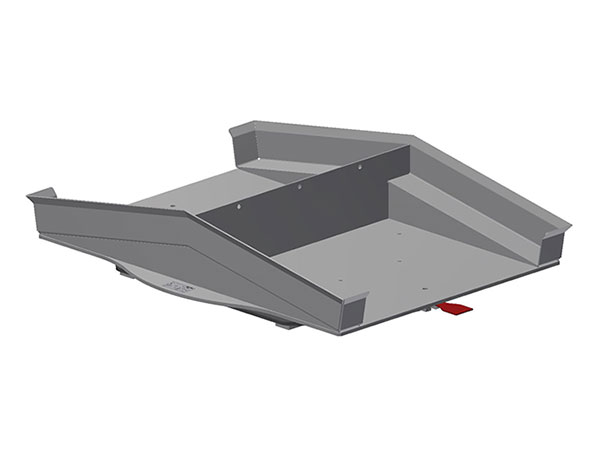

Double tilting devices on rotating platform

-

The most important facts in brief:

- Electro-hydraulic drive for two tilting platforms.

- Two mounted tilting platforms, 45° tilt possible.

- Rotating device locks manually at 0° or 180°.

- Only available in stationary version.

- Low-maintenance and low-failure operation thanks to high-quality, robust components.

- Control by hand switch, permanently mounted on the device, dead man’s control.

- Length of supply cable: 5 m.

- Loading with forklift.

- Platform cover on smooth sheet metal.

- Stops for containers L 1,400 mm x W 1,200 mm x H 758 mm.

- Maximum load per tilting unit 1,000 kg.

- The expected torsional forces are approx. 150 N.

Rotary table for two large load carriers

-

The most important facts in brief:

- Rotating device locks 2 x at 180°.

- Designed for two containers with inclined frame, each inclined by 10°.

- Only available in stationary version. Machine must be anchored to the floor.

- Low-maintenance and low-failure operation thanks to high-quality and robust components.

- Manual operation.

- Container stops 130 mm high.

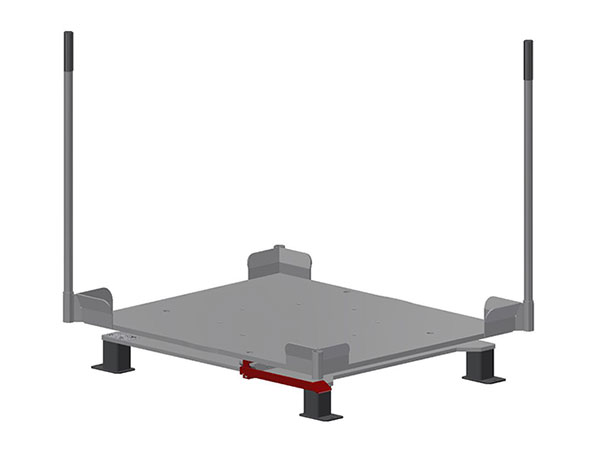

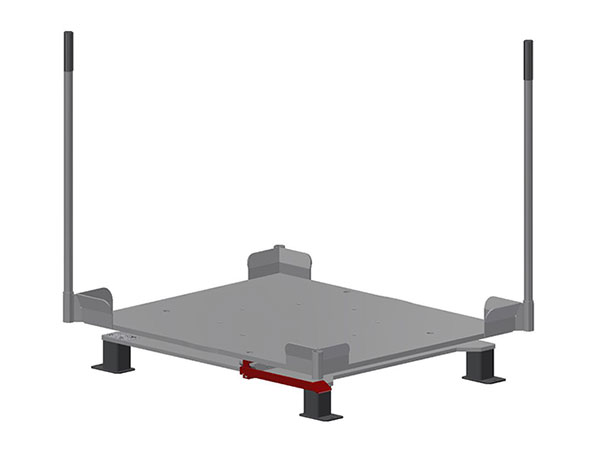

Rotary table for large load carriers

-

The most important facts in brief:

- Turning device locks 4 x at 90°.

- Only available in stationary version.

- Low-maintenance and trouble-free operation thanks to high-quality and robust components.

- Smooth steel platform cover.

- 4 stops for containers 80 mm high.

- 2 plug-in tubes 1,100 mm long for turning the platform.

- 4 welded-on eyelets for inserting the tubes (offset 20 mm outwards)

- Foot pedal for releasing the locking mechanism with lateral actuation.

Lift table with rotating platform

-

The most important facts in brief:

- Electro-hydraulic drive.

- Locking 2 x 180°.

- Available in stationary or mobile version.

- Low-maintenance and low-failure operation thanks to high-quality, robust components.

- Control and operation via hand switch with 3 m cable.

- Platform cover on smooth sheet metal.

- 4 corner stops each 80 mm high (20° incline) screwed on.

Scissor lift table mounted on slewing ring

-

The most important facts in brief:

- Electro-hydraulic drive.

- Slewing ring 1 x 180° under the lift table.

- Only available in stationary version. Machine must be anchored to the floor.

- Low-maintenance and trouble-free operation thanks to high-quality and robust components.

- Platform cover on smooth sheet metal.

- All-round safety contact strip on the lift table platform.

- Container stop 60 mm high on one short side of the platform.

- Dimensions of the unit console approx. 600 x 400 x 260 mm.

ERGONOMICS

-

VENTZKI: Lifting devices for ergonomically healthy working

VENTZKI develops and produces high-quality lifting devices for material logistics in the manufacturing industry. Decades of experience and state-of-the-art drive technology are combined in our handling devices to provide highly effective and safe operating equipment. The health of your employees is spared and the production process is optimized - for the best ergonomics in the workplace!

The 7 VENTZKI advantages:

- Easy work with heavy loads – Height differences are evened for ergonomic loading and unloading

- Fatigue-free working – Lift containers, tools and products comfortably to different heights

- More effectively machine loading – the best position for each user

- Speed up work flows – easier and faster loading of machines without physical stress

- Maximum flexibility – universal and flexible use in lifting and tilting processes, as well as in all kinds of manufacturing plants

- Highly versatile in filling – custom solutions for filling, mixing and weighing processes

- Safe tipping of heavy weights – versatile helpers for material logistics and in-house transport