- Offer Profile

-

Qimarox is a leading manufacturer of components for material handling systems. As a manufacturer of, among other things, palletisers, product lifts, pallet lifts, packaging machines and shielding systems, Qimarox distinguishes itself by its contemporary vision and approach, in which innovation, quality and added value are of paramount importance.

Vertical conveyors for small goods

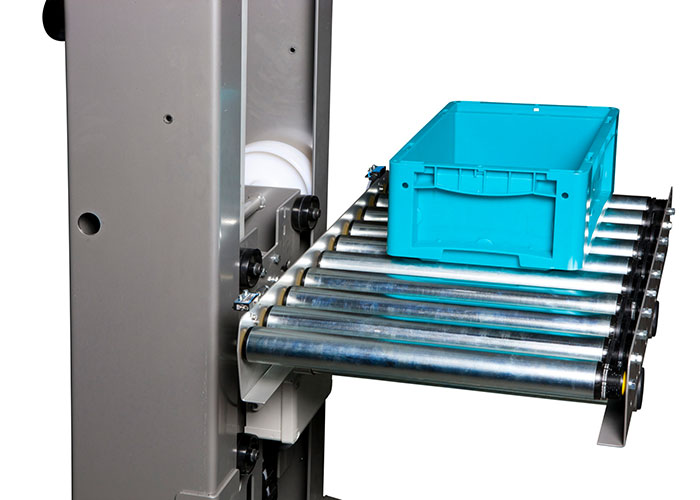

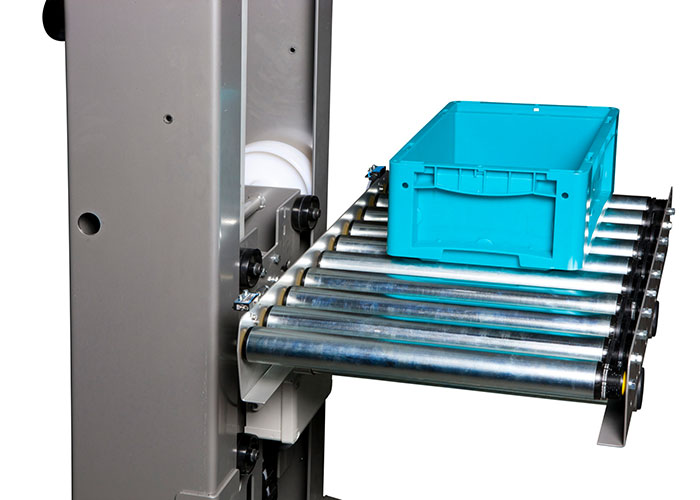

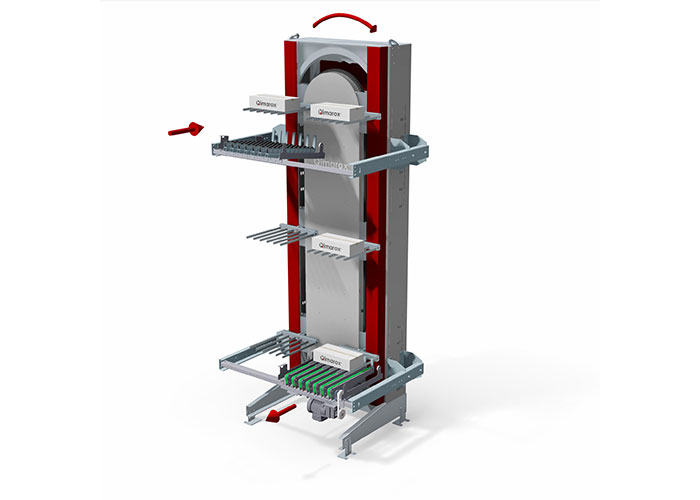

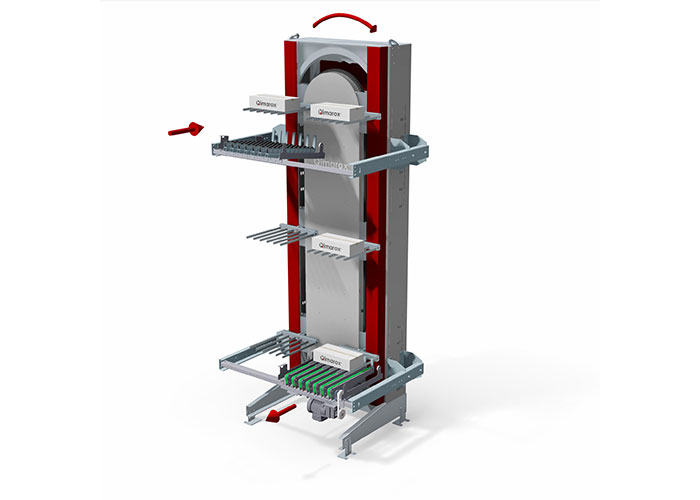

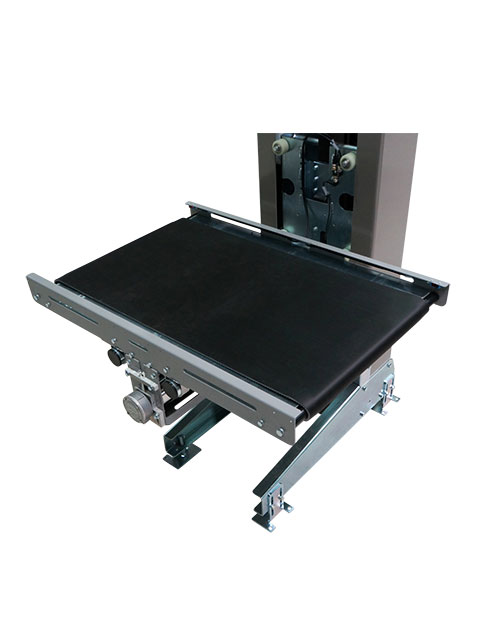

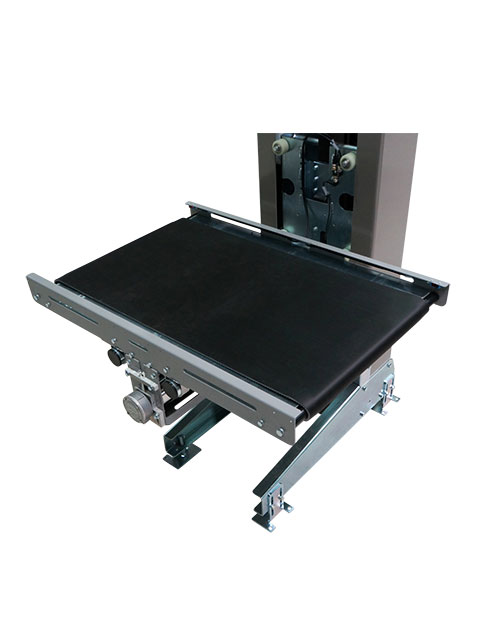

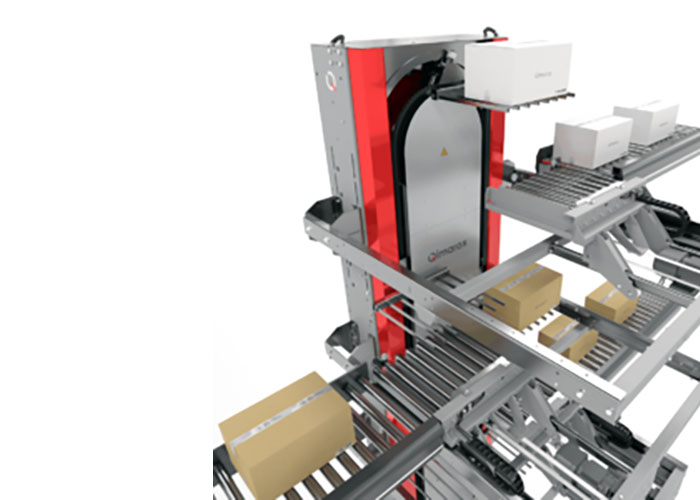

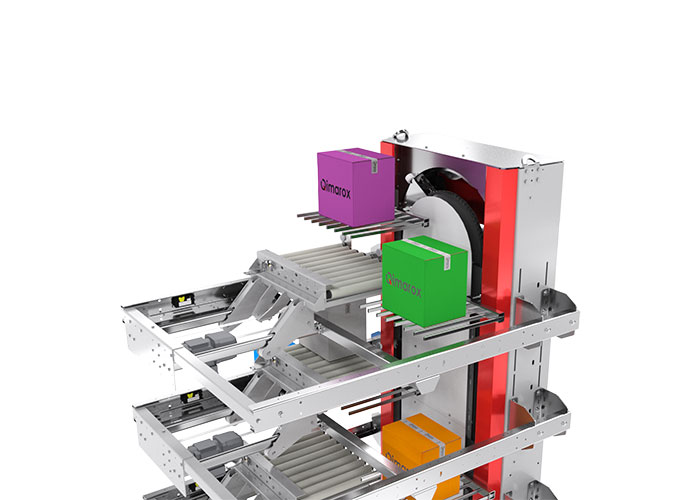

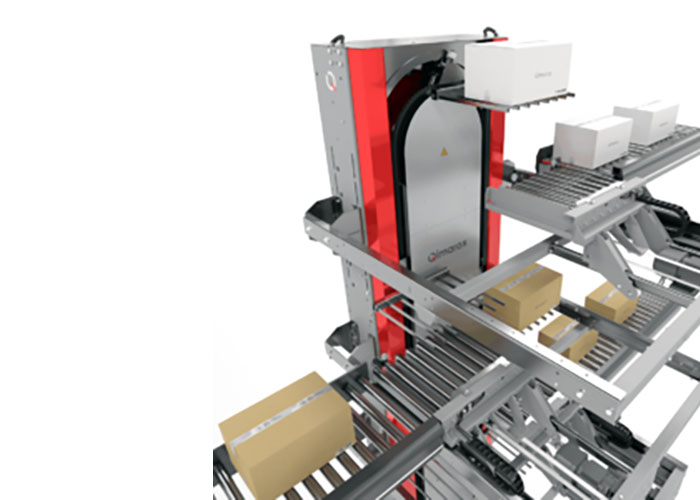

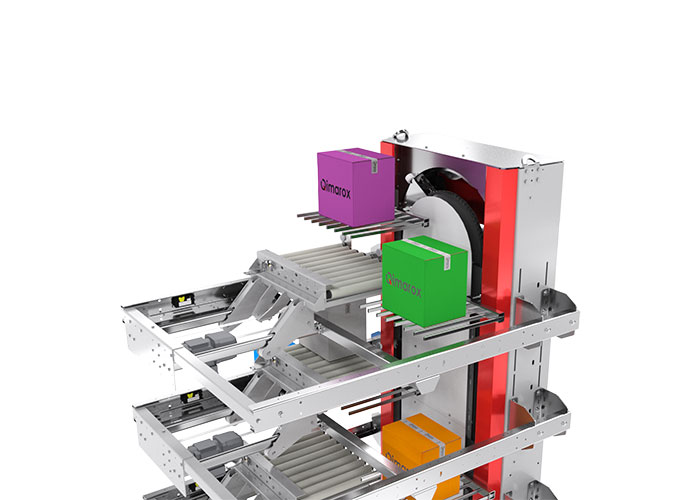

Vertical conveyor Prorunner mk1

-

The Prorunner mk1 is a compact and robust discontinuous product lift that requires minimal maintenance and is attractively priced.

The vertical conveyor Prorunner mk1 has the following specifications:- Lowest infeed/outfeed position of the mk1: 360 mm / 14 inch

- Highest infeed/outfeed position of the mk1: 14,300 mm / 555 inch

- Max. Column height: 14,450 mm / 47 feet

- Drive: SEW 0,55 kW

- Max. Product weight: 100 kg / 220 lbs

- Max. Product size: 910 x 610 mm / 36 x 24 inch

- Max. Throughput: 420 p/hour

- Required surface: 500 x 900 mm / 20 x 35 inch

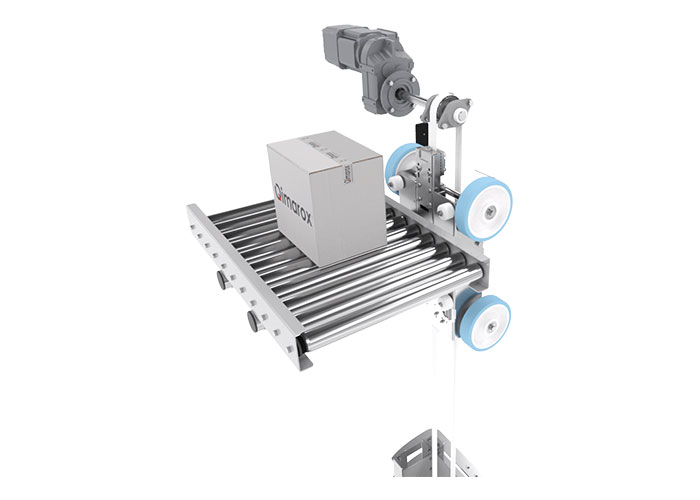

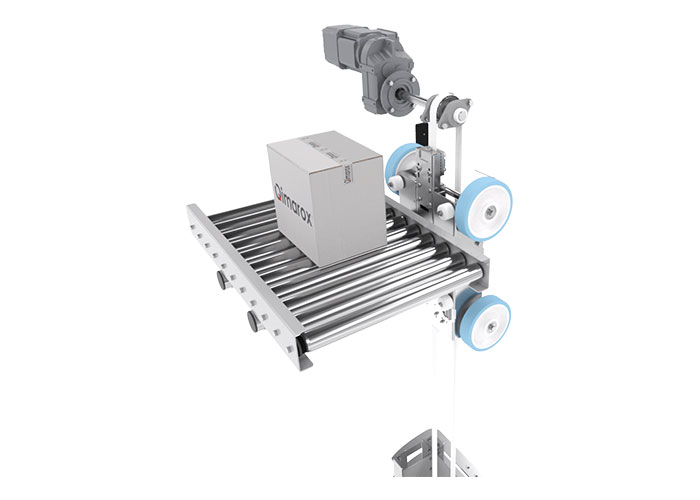

Vertical conveyor Prorunner PR2

-

High-speed VRC (Vertical Reciprocating Conveyor) with a timing belt drive, based on the successful Qimarox Prorunner mk1. This VRC ensures seamless and reliable transport to multiple input and output levels. Compact design: optimizes space utilization in any facility. High capacity: handles loads up to 100 kg with up to 500 movements per hour.

Vertical Conveyor Prorunner PR2 specifications:- Lowest infeed/outfeed position: 350 mm / 14 inch

- Highest infeed/outfeed position: 17,610 mm / 693 inch

- Max. Column height: 17,950 mm / 706 inch

- Drive: SEW DRN 0,55 kW - 3 kW

- Max. Product weight: 100 kg / 220 lbs

- Max. Product size: 1125 x 760 mm / 44 x 30 inch

- Max. Throughput: 500 p/hour

- Required surface: 500 x 900 mm / 20 x 35 inch

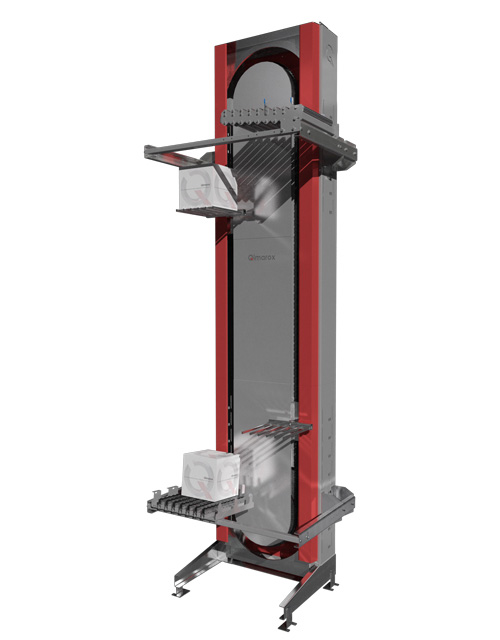

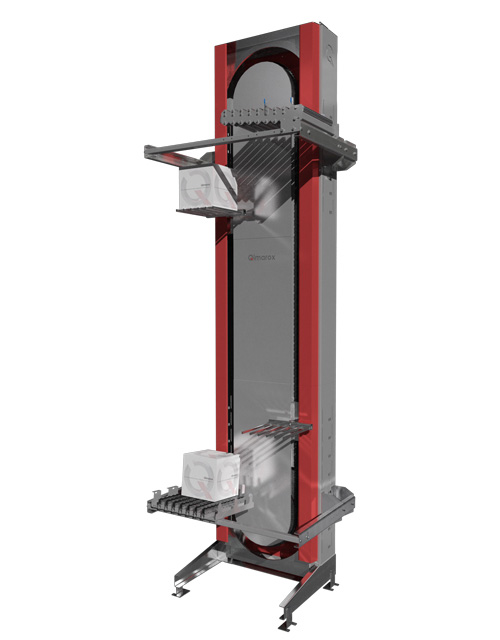

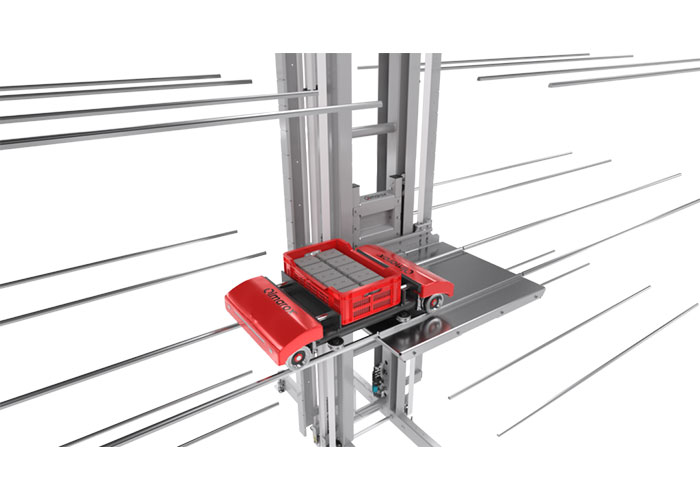

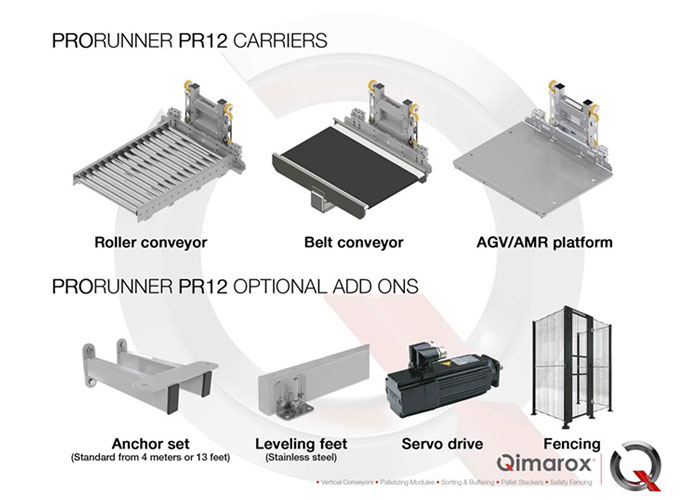

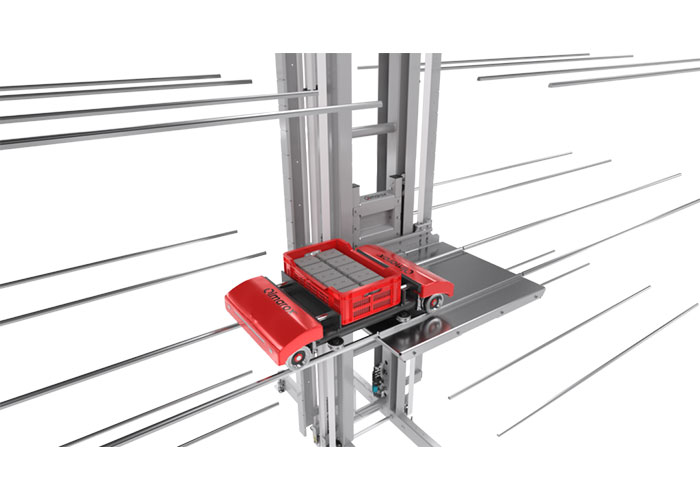

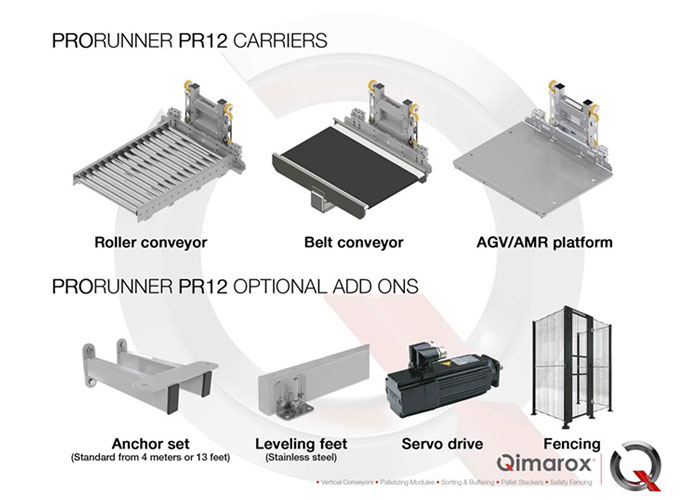

Vertical Conveyor Prorunner PR12

-

The PR12 is a discontinuous vertical conveyor with a small footprint built for AMR and products up to pallet size. The machine has good positioning accuracy, stiffness and a high capacity. The PR12 is the perfect choice to transport Automated Guided Vehicles or products. The machine column can even be fitted with a secondary carrier which is individually driven. This doubles the capacity. Each carrier can be fitted with a roller conveyor or a platform for an AMR.

The specifications for the discontinuous vertical conveyor Prorunner PR12 are:- Lowest infeed/outfeed position of the PR12: 200 mm / 8 inch

- Highest infeed/outfeed position of the PR12: 23.300 mm / 919 inch

- Max. Column height: 24.000 mm / 79 feet

- Drive: Gear motor with encoder (closed loop) / Servo drive without encoder (open loop)

- Max. Product weight: 150 kg / 330 lbs per carrier (can be increased by 75 kg / 165 lbs by choosing for a HD* edition - max. 300 kg / 660 lbs per carrier)

- Max. Product size: 850 x 700 mm / 33 x 28 inch

- Max. speed = 2 meter a second / 6.5 feet p/s

- Required surface single carrier: 966 x 1125 mm / 13 ft²

- Required surface double carrier: 1.125 x 1.932 / 23 ft²

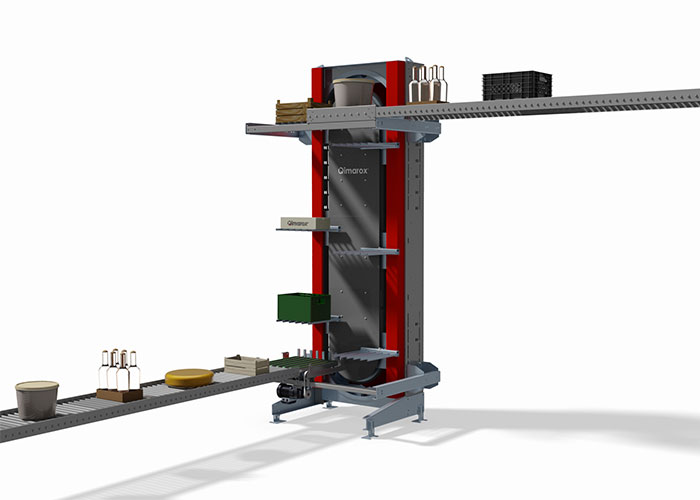

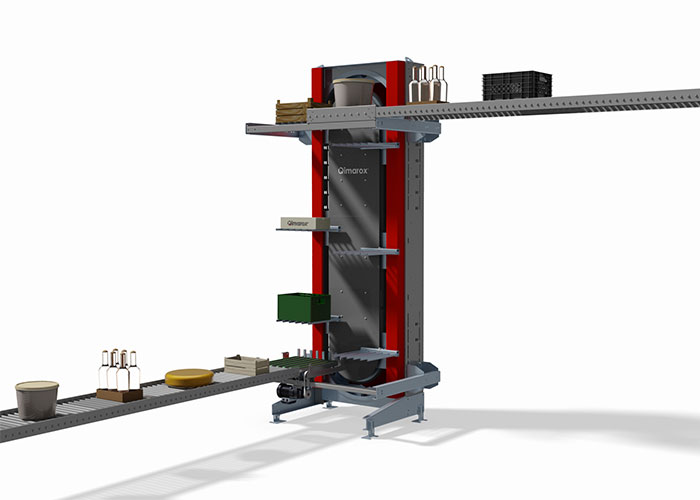

Continuous vertical conveyor Prorunner mk5

-

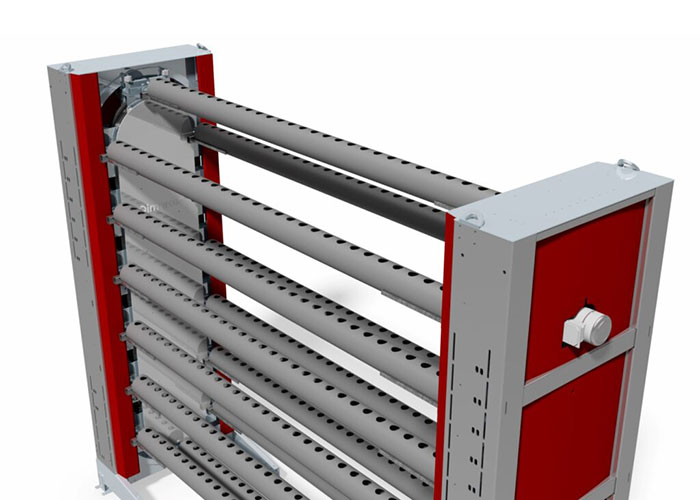

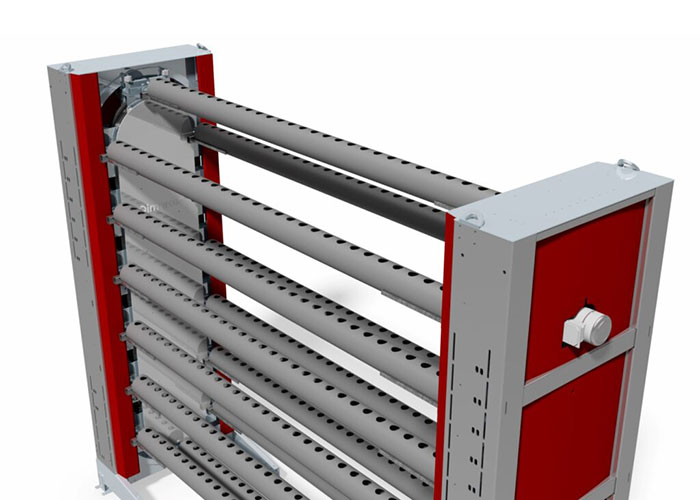

The Prorunner mk5 is a modular continuous vertical conveyor perfect for average to high capacity material handling applications.

The Prorunner mk5 is a fully module based continuous product lift that can be easily assembled in almost any configuration. This system incorporates only highly reliable components that offer an extremely long service life. Maintenance is restricted to an absolute minimum.

The specifications for the continous vertical conveyor Prorunner mk5 are:- Lowest infeed/outfeed position of the mk5: 676 mm / 27 inch

- Highest infeed/outfeed position of the mk5: 19,200 mm / 757 inch

- Max. column Height: 19,700 mm / 65 feet

- Drive System: SEW 0.37 kW

- Max. product weight: 50 kg per carrier / 110 lbs per carrier

- Min. product size: 225 x W x 50 / 9 inch x W x 2 inch

- Max. product size: 600 mm x 610 mm x H / 23.5 inch x 24 inch x H

- Throughput: 1 carrier for 200 products per hour (add further carriers for higher capacities)

- Configuration: B3 or C2 for elevating, 6G or 7F for descending (more options become available with a different type of carrier)

- Securyfence Safety Fencing H=2120 mm (83.47")

- Pitch Product Carrier 75 mm (2.95")

- Infeed Conveyor: gravity roller conveyor / powered roller conveyor optional

- Outfeed Conveyor: gravity roller conveyor / powered roller conveyor optional

Prorunner mk5 Washdown (WD)

-

The Washdown Prorunner mk5 is a continuous vertical conveyor designed in stainless steel for easy cleaning, making it ideal for when clean operations are needed. Suitable for average to high capacity material handling applications.

The Prorunner mk5-WD is a fully module based continuous product lift that can be easily assembled in almost any configuration. This system incorporates only highly reliable components that offer an extremely long service life. Maintenance is restricted to an absolute minimum.

The specifications for the continuous vertical conveyor Prorunner mk5-WD are:- Full stainless steel design

- Lowest infeed/outfeed position of the mk5: 650 mm / 25.5 inch

- Highest infeed/outfeed position of the mk5: 7300 mm / 287 inch

- Max. column Height: 8000 mm / 26 feet

- Drive System: SEW 0.37 kW

- Max. product weight: 50 kg per carrier / 110 lbs per carrier

- Min. product size: 600 x 400 / 23.6 inch x 15.7 inch

- Max. product size: 600 mm x 600 mm x H / 23.6 inch x 23.6 inch x H

- Throughput: 1 carrier for 200 products per hour (add further carriers for higher capacities)

- Configuration: B3 or C2 for elevating, 6G or 7F for descending (more options become available with a different type of carrier)

- Securyfence Safety Fencing H=2120 mm (83.47")

- Pitch Product Carrier 75 mm (2.95")

- Infeed Conveyor: gravity roller conveyor / powered roller conveyor optional

- Outfeed Conveyor: gravity roller conveyor / powered roller conveyor optional

Continuous vertical conveyor Prorunner mk5-XL

-

The Prorunner mk5-XL continuous vertical conveyor is suitable for average to high capacity applications. It is perfect to transport (bigger) products vertically up and down.

The specifications for the Prorunner mk5-XL are:• Lowest infeed/outfeed position of the mk5: 810 mm / 32 inch

• Highest infeed/outfeed position of the mk5: 17,300 mm / 680 inch

• Max column height: min. aprox. 18 mtr / 705 inch

• Drive System: SEW 0,55 - 4,0 kW

• Max. product weight: 50 kg per carrier / 110 lbs per carrier

• Max. product size: - 900 mm x 610 mm x H / 35 inch x 24 inch x H

• Throughput: 1 carrier for 200 products per hour (add further carriers for higher capacities)

• Configuration: B3 or C2 for elevating, 6G or 7F for descending (more options become available with a different type of carrier)

• Securyfence Safety Fencing H=2120 mm (83.47")

• Pitch Product Carrier 75 mm (2" 61/64)

• Infeed Conveyor: gravity roller conveyor / powered roller conveyor / belt conveyor / shuttle roller conveyor

• Outfeed Conveyor: gravity roller conveyor / powered roller conveyor / belt conveyor / shuttle roller conveyor

Vertical Conveyor Prorunner PR12

-

The Prorunner PR12 (Vertical conveyor for Shuttle, AGV & AMR and products up to pallet size)

The PR12 is a discontinuous vertical conveyor with a small footprint that excels in positioning accuracy, stiffness and high capacity. This makes the machine an excellent choice to transport Automated Guided Vehicles.

The machine column can be fitted with a secondary carrier which is individually driven. Each carrier can be fitted with a roller conveyor or a platform for an AGV, AMR or products. The PR12 vertical conveyor transports AGV (automated guided vehicle), AMR (Autonomous Mobile Robots) or products to different levels of your facility. Next to that it's possible to add rails to the carrier to transport shuttles.An AGV or AMR gives more flexibility to your daily operations and can reduce labor costs in your operation in many ways. With the new PR12 vertical conveyor an even higher level of flexibility can be reached as this versatile lifter makes it possible to transport an AGV or AMR vertically and have it operating at multiple different mezzanine levels. The PR12 is designed to use a minimum of floor space and can be equipped with either one or two platforms. As an option it is also possible to replace a platform with a roller conveyor. By using a servo drive the unit can be integrated easily into any demanding, dynamic and challenging system design.

The specifications for the discontinuous vertical conveyor Prorunner PR12 are:- Lowest infeed/outfeed position of the PR12: 200 mm / 8 inch

- Highest infeed/outfeed position of the PR12: 23.300 mm / 919 inch

- Max. Column height: 24.000 mm / 79 feet

- Drive: Gear motor with encoder (closed loop) or Servo motor without encoder (open loop)

- Max. Product weight: 150 kg / 330 lbs per carrier (can be increased by 75 kg / 165 lbs by choosing for a HD* edition - max. 300 kg / 660 lbs per carrier)

- Max. Product size: 850 x 700 mm / 33 x 28 inch

- Max. speed = 2 meter a second / 6.5 feet p/s

- Required surface single carrier: 966 x 1125 mm / 13 ft²

- Required surface double carrier: 1.125 x 1.932 / 23 ft²

*HD means Heavy Duty

Vertical Conveyor PR14

-

Vertical Conveyor PR14 - Discontinuous compact vertical conveyor

PR14 vertical conveyor is a compact, narrow‑column lift engineered to shuttle cartons and totes seamlessly between two stacked conveyor lines. Its fixed lower roller deck and motorized upper rollers intermesh for reliable bi‑directional transfer, all within a minimal footprint.

Unlike bulky lifts that only move in one direction, the PR14 features a fixed roller deck at the lower level and a motorized roller section above. When the upper conveyor lowers, its rollers slide smoothly between the fixed lower rollers, allowing full cartons or totes to be transferred downwards. Reverse the motion, and empty containers picked up from below ride the same intermeshing rollers back up. This bi‑directional transfer uses the proven Prorunner MK1 lift mechanism, ensuring a perfectly synchronized, low‑vibration exchange every time.

Despite its compact footprint, the PR14 handles loads up to 83kg per cycle. Its lightweight column and sturdy rollers combine durability with minimal maintenance. Height of conveyors is easily customized, up to 2.5 m so it can bridge mezzanines, mezzanine‑style packing tables, cold‑storage zones or any two‑tiered conveyor layout in your facility.

Vertical Sorter – Prorunner mk5

Vertical Sorter – Prorunner mk5 Continuous vertical sorter to handle your products

The Prorunner mk5 vertical sorter is a high-performance vertical conveyor equipped with integrated, retractable roller- or multibelt conveyor modules. Unlike traditional multi-level sorters that require separate lifts or fixed chutes on each floor, the mk5-soter uses one moving lift assembly with retractable decks to feed or discharge cartons, totes and bins at any desired level.

Based on the Prorunner mk5 vertical conveyor it’s possible to add retractable conveyors to feed or discharge products from the side or front of the vertical conveyor on multiple levels. It’s also possible to have an upstream and downstream productflow within one system.

ProRunner mk5 Twin

ProRunner mk5 Twin Two Prorunners mk5 connected as a twin set

If you need your larger products to be vertically transported it’s possible to have two standard Prorunner mk5 Twin vertical conveyors connected and have this set equipped with a larger conveyor. This gives you the possibility to handle longer products but still use a minimal amount of floor space. Also it creates the possibility to two vertical conveyors as a buffer solutions.

The Prorunner mk5 Twin is a module based continuous product lift that can be easily assembled in almost any configuration. This system incorporates only highly reliable components that offer an extremely

long service life. Maintenance is restricted to an absolute minimum. In addition, Qimarox is also developing a ProRunner mk5 Twin Sorter as part of an R&D concept. This solution is designed for advanced vertical sorting applications and is currently only upon request for co-development projects.

Vertical conveyors for pallets

-

Qimarox offers various types of vertical conveyors for empty or loaded pallets which can be used in combination with our palletising modules or as stand-alone units in pallet conveyor systems.

A vertical pallet conveyor is a type of conveyor system that is used to transport pallets or other large items between different levels in a warehouse or manufacturing facility. Unlike horizontal conveyor systems, which move items along a single plane, vertical pallet conveyors lift items vertically, allowing them to be transported between different floors or levels of a facility.

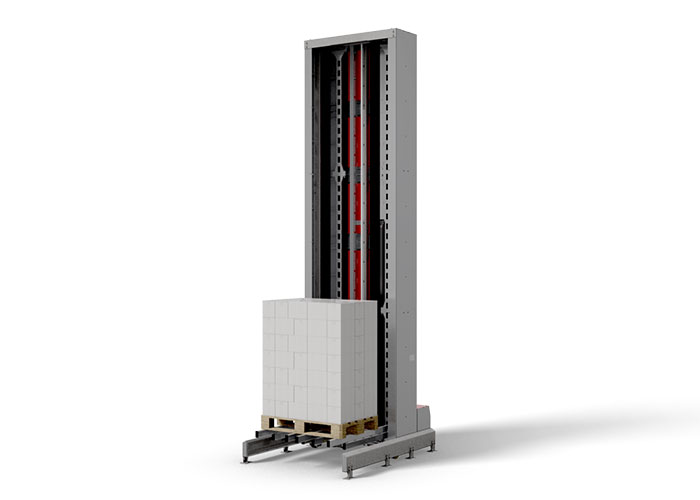

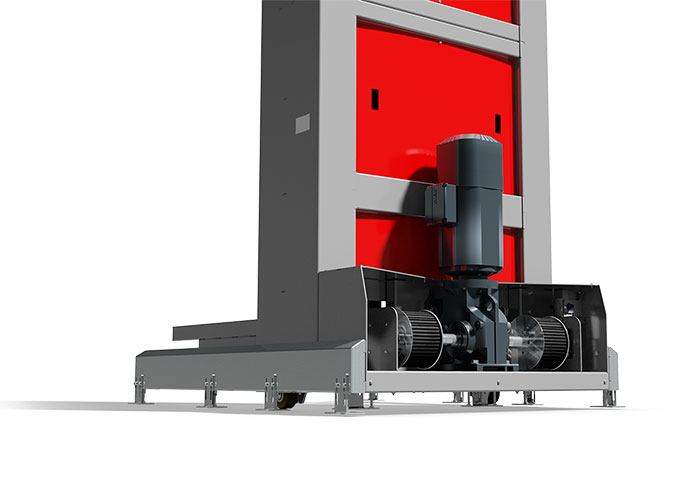

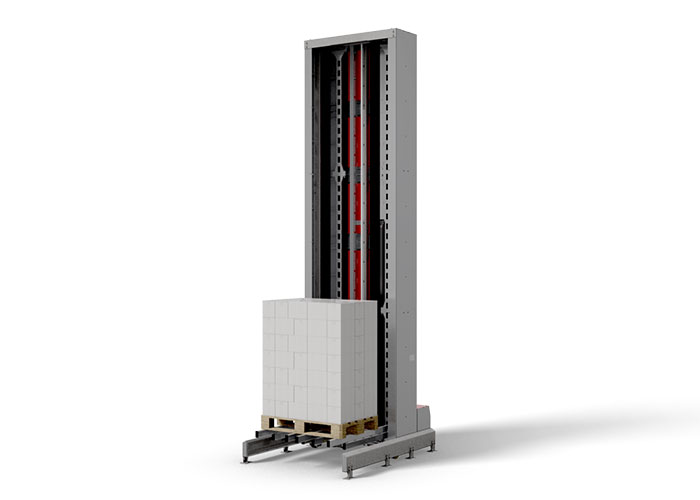

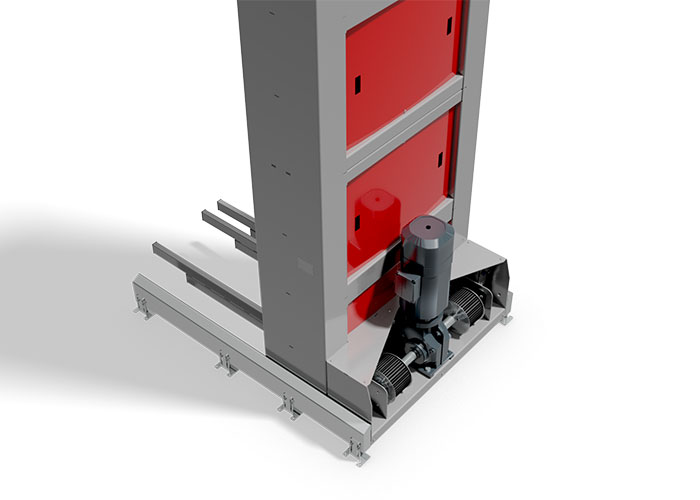

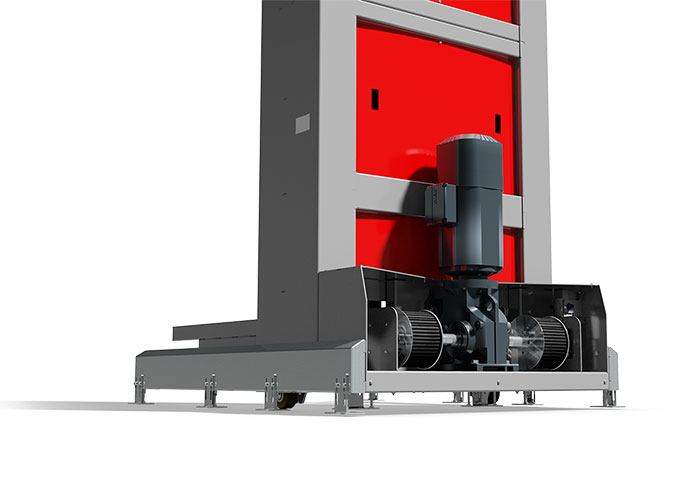

Pallet lift Prorunner mk9

-

The Prorunner mk9 is a vertical pallet conveyor that automates the transport of pallets by lifting and/or lowering the pallets to the desired level of your facility. No manual labor is required anymore when you choose for the Prorunner mk9

Advantages of the vertical pallet conveyor Prorunner mk9 are:- Minimal footprint

- Right-angled setup also possible

- Suitable for vertical sorting (multiple floors)

- Pallets, racks, etc. up to 1,250 kg

- Sturdy, low maintenance machine

- No chains need lubricating or tightening

- It makes minimal operating sound

- Solid steel construction

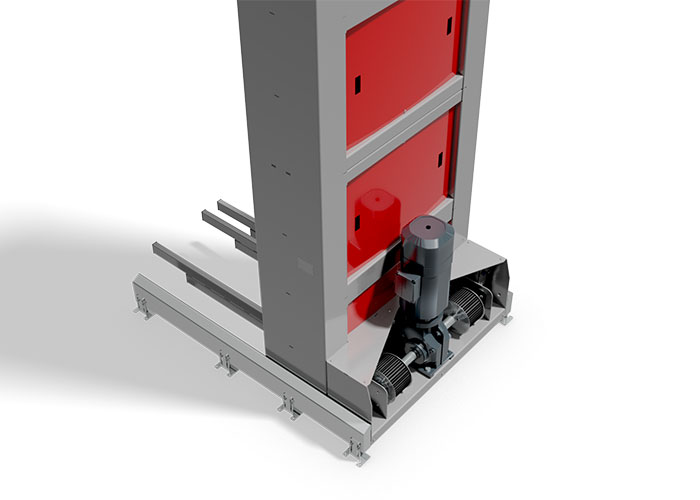

Pallet lift Prorunner mk10

-

The Prorunner mk10 is the perfect pallet lift for heavy pallets and offers a solution for capacities of up to 100 pallets per hour.

Advantages:- Minimal footprint

- Infeed / discharge to all sides

- Suitable for vertical sorting (multiple floors)

- Pallets, racks, etc. up to 2000 kg

- Sturdy, low maintenance machine

- Quiet

- Solid steel construction

- Standard equiped with drop-down safety

Pallet lift Prorunner mk10-XL

-

Extra-Large Vertical Conveyor for Heavy & Oversized Loads

The Prorunner mk10-XL is the perfect pallet lift for larger pallets, multiple pallets per cycle or pallets with overhanging products and offers a solution for capacities of up to 200 pallets per hour.

Designed for manufacturers, warehouses and automated facilities that need to move two pallets - or one long, overhanging load, per cycle, the Prorunner PRmk10‑XL builds on Qimarox’s proven PRmk10 platform with a 50 % larger footprint, double the carrying capacity and all the modular customization options that make vertical conveyors the go‑to solution for high-density, multi-level logistics.

Palletizing solutions

- Palletization or palletizing is a logistic process which consist of placing items/goods stacked together on a pallet. The goal of this process is to make it easier for a manufacturer to transport their loads.

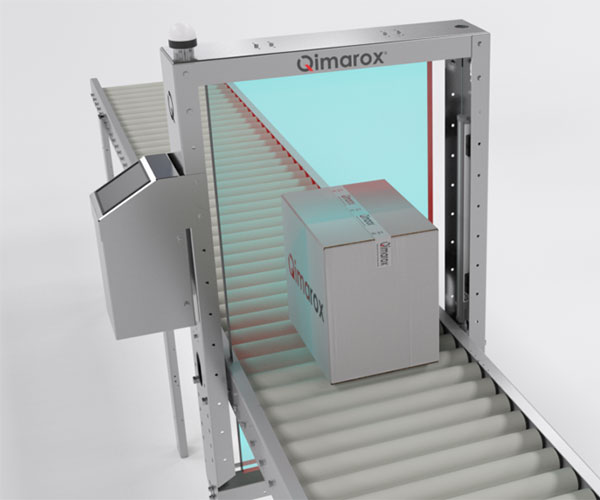

ContourScanner CS1

- Overall Equipment Effectiveness (OEE) Improvement

Most disruptions in a production line are caused by poorly packaged products. Issues such as inconsistent packaging shapes or dimensions can significantly reduce Overall Equipment Effectiveness (OEE). Additionally, defective packaging that reaches the palletizing machine can lead to improperly stacked pallets. The ContourScanner CS1 helps improve OEE by minimizing these disruptions.

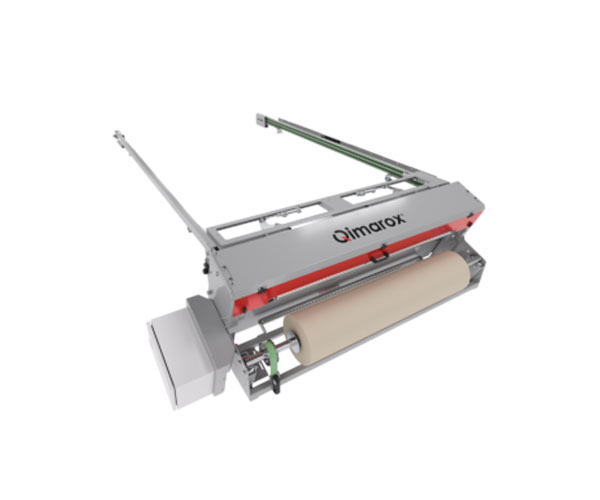

Intermediate sheet placement with Sheetrunner SR2

-

Why automated intermediate sheet placement improves pallet stability

The Sheetrunner SR2 automates placing intermediate sheets between product layers in automated palletizing systems. It improves stability, reduces damage, and also handles slip sheets.

Intermediate sheet placement is a critical step in any automated palletizing process. The Qimarox Sheetrunner SR2 automates this task by placing sheets—also known as layer pads or interlayers—between product layers. Whether stacking boxes, bags, or crates, proper sheet placement helps prevent shifting and ensures secure, transport-ready pallet loads.

Layer pads provide friction and distribute weight evenly, protecting goods from sliding or being damaged. This is especially valuable when palletizing smooth packaging, fragile items, or uneven products. Automating intermediate sheet placement eliminates manual errors and increases throughput.

Intermediate sheet placement with Sheetrunner SR3

-

Why automated intermediate sheet placement improves pallet stability

Placing intermediate sheets is a vital component of any automated palletizing system. The Qimarox Sheetrunner SR3 lines this process by automatically inserting sheets - commonly referred to as interlayers or layer pads -between product tiers. Whether dealing with boxes, crates, or bags, precise sheet placement minimizes movement and keeps pallet loads stable and ready for transport.

Layer pads increase friction and help distribute weight evenly, reducing the risk of damage and shifting - especially important when handling delicate items, slick surfaces, or irregularly shaped goods. Automating this step not only reduces human error but also boosts operational efficiency.

Highrunner HR8 Palletizer for IQF products

-

Flexible palletizer for frozen food, mainly vegetables, fries & fruits

The Highrunner HR8 is designed for palletizing IQF products (cartons containing frozen food, mainly vegetables, fries & fruits) and has handling capacities of 900 – 1,800 products per hour.

Palletizing cartons with IQF products comes with many challenges different from any other industry. With many installations over the past decades Qimarox has proven to offer the best solution to deal with these challenges. With the Palletizer Highrunner HR8 for IQF products we developed a special configuration that is focused on handling cartons that are not completely filled to the top or are so full they are bulged on each side. The HR8 layer palletizer comes with all layer patterns known to the sector already programmed. These patterns can be selected automatically without any manual adjustment needed.

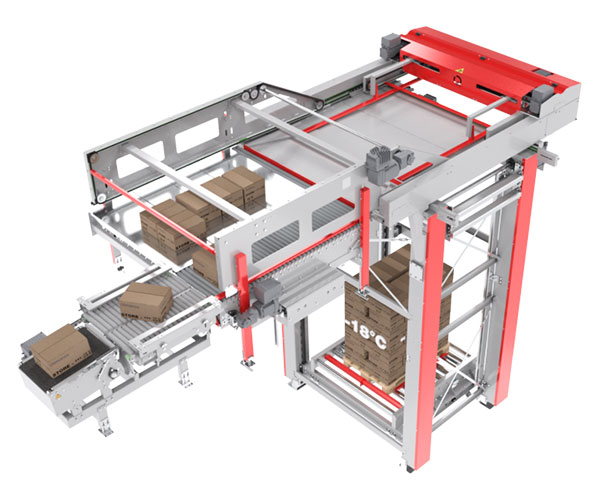

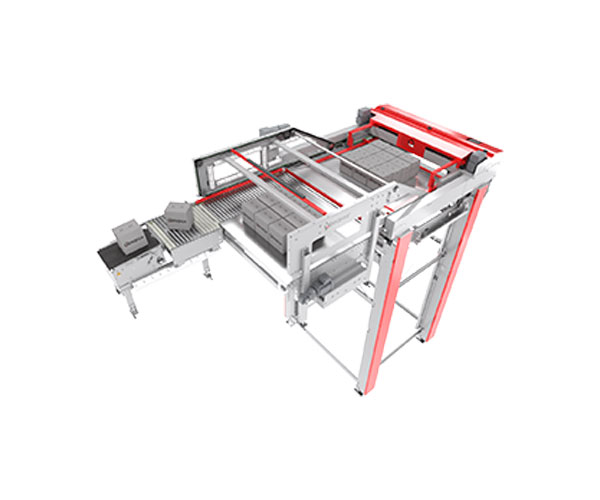

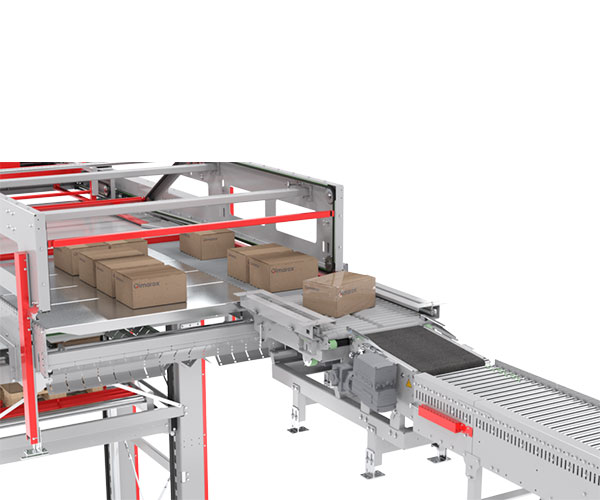

Highrunner HR9 Logistics Palletizer

-

Highrunner HR9 Logistics Palletizer - Flexible palletizer for logistic operations

The Qimarox Highrunner HR9 Logistics palletizer is specially designed for logistic operations. Therefore, this machine is very effective where many different products are handled in short batches. Our unique and patented layer-formation system can generate a large variety of layer patterns. These patterns can be selected automatically or generated by the state-of-the-art pattern generator. A specially designed pattern generator will present to you the most optimal layer pattern according to box size and pallet size. As example, if the installation is equipped with a full 3D product scanner it is even possible to have the system working fully autonomously.

Because the pattern formation system is at high level and the pallet is moving up and down with the pallet lift, (Qimarox Prorunner mk10) higher throughputs can be achieved. The top of the pallet is consequently always located at the same level as the pattern-formation conveyor. As a result higher layer capacity is possible as stacking plates can receive a new layer quickly after a layer is placed onto a pallet.

Highrunner HR10 Palletizer for the Beverage industry

-

Palletizer designed for beverage industry

The Highrunner HR10 is a palletizer designed for the beverage industry and has handling capacities of 900 – 1,500 products per hour. Reinforced layer handling to handle layers weights up to 280 kg. Motorized layer restraints ensure perfect layer positioning.

Within the beverage industry there are several challenges to address if you are looking to automate the palletizing process.

The Qimarox HR10 Palletizer for Beverage industry is designed to deal with the main topic within this industry; which is the overall throughput of a production line. This required throughput exceeds the need from many other industries. By using the advantages of a high-level infeed machine based on the Highrunner HR7 the Qimarox HR10 palletizer can realize a high throughput in combination with high flexibility. Next to that the layer weight can be much higher compared to other industries. The layer handling system of this palletizer can handle layer weights up to 280kg.

Change over time of empty pallets and loaded pallets is minimized by having a buffer position for an empty pallet directly in front of the loading position. As soon as a loaded pallet is transported out of the system an empty pallet is transported into position. While moving up the empty pallet is centered and aligned to receive the first layer. The unique layer formation ensures that a layer is produced at high rate. By adding a buffer position for a complete layer the layer formation will not come to a stop at change of pallets.

Highrunner HR11 Palletizer for Canned Foods

- Palletizer designed for canned foods

The Highrunner HR11 is a palletizer designed for the canned food industry and has handling capacities of 600 – 2,400 products per hour with a single infeed and 1200 – 4380 products per hour with a double infeed.

The Qimarox Highrunner HR11 palletizer is specially designed to automate the palletizing process in the canned foods industry. In this industry, efficiency, consistency, and safety are important. The specialized Highrunner HR11 palletizer is designed to meet these needs and more, providing a range of benefits that enhance your production process. Whether food is packed in cans or glass the HR10 will be able to handle both. In most situations the cans or jars will be grouped in a tray with or without film, also here the HR10 is able to handle both.

Palletizing can help to improve the processes of a canned food producer by increasing the efficiency, protecting the canned products, enhancing storage capabilities, reducing manual labor with risks of injury and improving safety in general for workers.

Highrunner HR12 Palletizer for PET / HDPE bottles

-

Flexible palletizer for PET / HDPE bottles non-food

The Highrunner HR12 is a palletizer designed for PET / HDPE Bottles (Non-Food) and has handling capacities of 720 – 1,500 products per hour.

In industries handling PET and HDPE bottles, efficient palletizing solutions are essential for smooth production processes. The Qimarox HR12 Palletizer for PET / HDPE Bottles is designed to meet these specific needs with precision and reliability. This innovative machine ensures optimal palletizing for non-food PET/HDPE bottles, allowing for customizable rotation options of 0°, +90°, -90°, and 180° (also possible for bigger products), giving it a unique combination in both flexibility and capacity over conventional and robot palletizers.

Highrunner HR13 Palletizer – Tailored for the Snacks Industry

-

The most flexible palletizer for snack cartons

The Highrunner HR13 by Qimarox is the ideal palletizer for the snacks industry, specially designed to palletize cartons of chips, popcorn, pretzels, and other snack products efficiently and reliably. With its high speed, flexible stacking patterns, and compact design, the HR13 meets the demands of modern snack production environments. It handles lightweight, fragile cartons without damage and ensures consistent, stable pallets even at high output levels. The system integrates easily into existing packaging lines and is built to meet the strict hygiene and safety standards of the food industry.

Highrunner HR15 Palletizer for drink cartons

- Palletizer designed for beverage industry

The Highrunner15 Palletizer is specifically engineered for the beverage industry, ideal for drink carton palletizing systems for example for TetraPak and Combibloc. The HR15 Palletizer can handle layers weights up to 180 kg. With high-level infeed capabilities, the HR15 offers both high throughput and flexibility.

Automating the palletizing process presents unique challenges. High throughput, precision, and flexibility are essential to meet the demands of modern production lines. That’s where the Qimarox Highrunner HR15 Palletizer for drink cartons comes in, an advanced solution designed to optimize performance in high-demand environments.

The Qimarox HR15 Palletizer is specifically engineered to address the complexities of palletizing in the beverage industry. With high-level infeed capabilities, based on the successful design of the Highrunner HR7, the HR15 offers both high throughput and flexibility. The HR15 palletizer is ideal for palletizing systems for products with drink cartons like TetraPak and Combibloc. The HR15 layer palletizer comes with all layer patterns known to the sector already programmed. These patterns can be selected automatically without any manual adjustment needed.

Highrunner HR17 Palletizer for Fresh Food

-

High infeed palletizer for Fresh Food such as fruit and vegetables

The Qimarox Highrunner HR17 palletizer is specially designed for the Fresh Food Produce industry. In the Fresh Food produce industry, handling delicate products like fruits and vegetables presents unique challenges. Traditional manual processes can lead to bruising, damage, and inconsistency, ultimately affecting product quality and shelf life. To avoid this, the specialized Highrunner HR17 palletizer comes in, offering benefits tailored to meet your specific needs. The palletizer is engineered in such a way to minimize the risk of product damages and improve the end of line process, reducing costs and optimizing cycles.

Palletizer Highrunner HR7

- Flexible palletizer

The Highrunner HR7 series is used for handling capacities of 500 – 4.500 products per hour.

The Qimarox Palletizer Highrunner HR7 is a machine composed of standard modules, designed for situations where no standardized industry configuration is available. This allows for a certain level of customization.

The standardized Qimarox palletizers are developed based on decades of experience and common challenges within the specific industry.

Palletizer Lowrunner LR1 Qimarox

-

The modular LOWRUNNER LR1 palletizer from Qimarox is a 5-axis palletizer with a capacity of up to 800 packages per hour. It is an entry-level model, suitable for an environment where rapid return on investment is desired or necessary. Optionally, the LOWRUNNER mk1 can also places the pallets and intermediate sheets by itself.

The modular LOWRUNNER LR1 palletizer from Qimarox is a 5-axis palletizer with a capacity of up to 800 packages per hour. It is an entry-level model, suitable for an environment where rapid return on investment is desired or necessary. Optionally, the LOWRUNNER LR1 can also places the pallets and intermediate sheets by itself. *NOTE: Delivery time to be discussed*

Palletizer Lowrunner LR3

-

The modular LOWRUNNER LR3 palletizer from Qimarox is a palletizer with a capacity of up to 1,500 packages per hour. It is suitable for an environment where rapid return on investment is desired or necessary. Optionally, the LOWRUNNER LR3 can also be equipped with the Qimarox Sheetrunner to put intermediate sheets between layers.

The modular palletizer Lowrunner LR3 from Qimarox is a palletizer with a capacity of up to 1,500 packages per hour. It is suitable for an environment where rapid return on investment is desired or necessary. Optionally, the Lowrunner LR3 can also be equipped with the Qimarox Sheetrunner to put intermediate sheets between layers. *NOTE: Delivery time to be discussed*

Palletizer Lowrunner LR8 - for IQF products

-

Flexible palletizer for IQF products suchs as Vegetables, Fruits and Fries

The Lowrunner LR8 Palletizer is designed specifically for palletizing cartons containing frozen foods, such as vegetables, fries, and fruits.

Palletizing cartons with IQF (Individually Quick Frozen) products presents unique challenges distinct from other industries. Over the past decades, we have demonstrated the ability to provide the best solutions for these challenges.

The LR8 palletizer for IQF products features a special configuration specifically designed to handle cartons that are either not completely filled to the top or are overfilled and bulged on each side. This LR8 layer palletizer comes pre-programmed with all the layer patterns known to the sector. These patterns can be selected automatically without any need for manual adjustments, ensuring efficient and reliable palletizing for frozen foods such as vegetables, fries, and fruits.

Pallet handling

- Qimarox can supply various modules for pallet handling. These modules can be used in combination with our pallet lifts or palletising modules but also as stand-alone units. Pallet handling machines are industrial machines that are used to move and manipulate pallets, which are horizontal platforms typically used for storing and transporting goods. These machines come in a variety of types and sizes, and can be used for tasks such as loading and unloading pallets from trucks, stacking and unstacking pallets, and moving pallets within a warehouse or storage facility. Some examples of pallet handling machines include forklifts, pallet jacks, pallet dispensers and pallet conveyor systems. These machines are essential for efficient and safe handling of pallets in industrial and commercial settings.

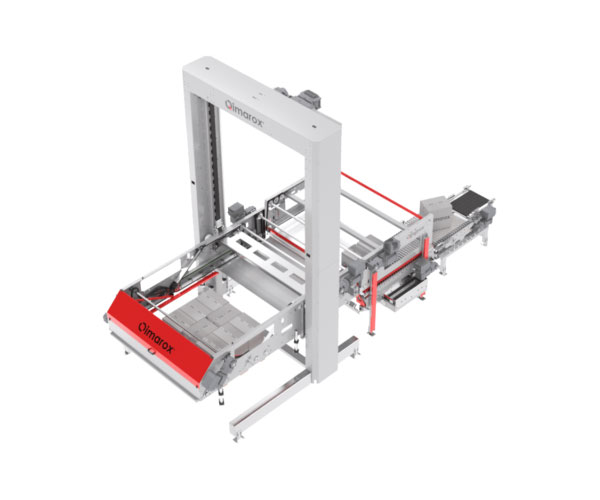

Loaded pallet stacker Prorunner mk10-PS

-

Based on our successful Prorunner mk10 pallet lift the loaded Pallet Stacker is a very versatile unit to stack loaded pallets on top of each other.

The specifications of the pallet stacker Prorunner mk10-PS are:• Lowest infeed/outfeed position of the mk10-PS: 0 mm / 0" inch (Floorlevel)

• Highest infeed/outfeed position of the mk10-PS: 1,000 mm / 40 inch

• Max. lifting weight: 1000 kg / 2200 lbs

• Max. pallet size: 1,750 x 1,550 mm / 67 x 61 inch

• Max. infeed throughput: 120 single pallets p/hour

• Max. outfeed throughput: 60 doubled pallets p/hour

• Also possible to stack more than 2 pallets on top of each other

• Standard stacking height 3.000 mm / 120 inch

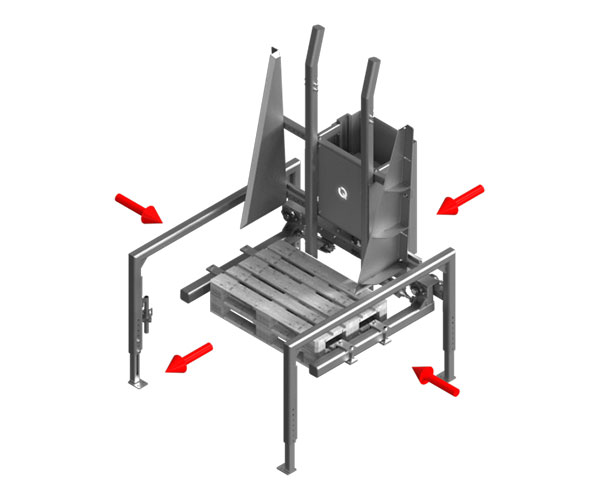

Pallet Dispenser PD1 for empty pallets

-

The Qimarox Pallet Dispenser is suitable for stacking and/or de-stacking of empty pallets.

The specifications of the pallet dispenser PD1 are:Min. pallet size: 800 x 800 mm /32" x 32" inch

Max. pallet size: 1200 x 1200 mm / 48" x 48" inch

Throughput (incl. pallet transport): 225 p/hour

Maximum pallet stack height: 2,500 mm / 98" inch

Lifting power: 300 kg / 660 Lbs.

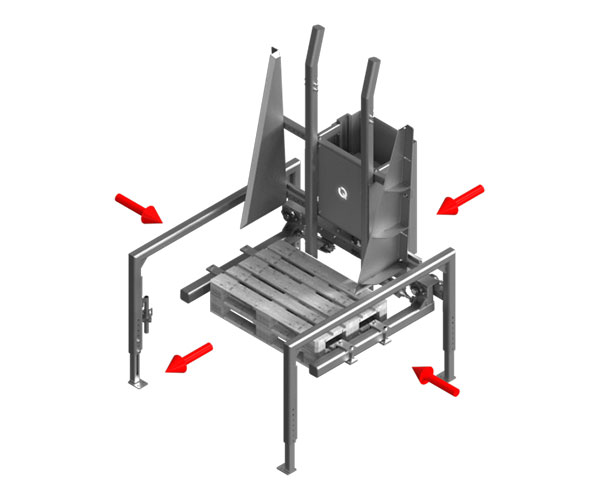

Pallet Dispenser PD2 for empty pallets

-

The Qimarox Pallet Dispenser PD2 is suitable for stacking and/or de-stacking of empty pallets.

The specifications of the pallet dispenser PD2 are:Min. pallet size: 800 x 800 mm /32" x 32" inch

Max. pallet size: 1200 x 1200 mm / 48" x 48" inch

Throughput (incl. pallet transport): 120 p/hour

Maximum pallet stack height: 2,500 mm / 98" inch

Lifting power: 400 kg / 880 Lbs.

Safety fencing

- Industrial safety fencing is a type of fencing used in industrial settings to protect workers and equipment from potential hazards. This fencing is typically made of sturdy materials such as steel or aluminum, and is designed to withstand the rigors of industrial environments. It is often used to enclose machinery or hazardous areas, or to create barriers around areas where workers may be at risk of injury. Safety fencing can help prevent accidents and injuries, and can play an important role in ensuring the overall safety of industrial workplaces.

Safety Fence Mesh Panels – Securyfence

-

Securyfence consists of profiled mesh panels that are screwed to the posts via tubes. The standard sizes don’t fit? You can easily cut and saw the mesh panels and tubes to fit on the spot.

All Securyfence mesh panels have a mesh size of 40 × 39 mm and a wire thickness of 3 mm.

The mesh panels can be attached to sturdy, square columns with simple hand tools. Specifications of the columns:

- Thickness: 50 x 50 mm

- Height: 2256 mm or 1156 mm

- Base plate: 138 × 138 mm and a thickness of 6 mm.

Safety Fencing Hinged Doors – Securyfence

-

Securyfence hinged doors offer easy access to protected machines or shielded areas. The hinged doors are available in two widths.

Securyfence hinged doors are available in three standard widths:

- 730 mm

- 990 mm

- 1240 mm

The dimensions were chosen so that the doors can easily be exchanged with standard mesh panels. This also means you can easily install an additional door afterwards, without having to adjust the complete setup.

Safety Fencing Sliding Doors – Securyfence

-

With Securyfence sliding doors, you can create an opening in your machine guard or area guard in even the most confined of spaces.

Securyfence sliding doors for safety fencing are available in three standard widths:

- 730 mm

- 990 mm

- 1240 mm

The dimensions were chosen so that the doors can easily be exchanged with standard mesh panels. This also means you can easily install an additional door afterwards, without having to adjust the complete setup.

Stainless Steel – Securyfence

-

Stainless steel safety fencing, perfect for environments that needs to be clean such as food processing or for pharma.

Benefits of the Securyfence Stainless Steel fencing at a glance:- Quick to assemble

- Simple to customise

- Extra sturdy thanks to profiling

- Modular system

- Good transparency

- Available in stainless steel

- Dimensions meet all CE and NEN standards