- Offer Profile

-

Partnering our prestigious national and international clientele, we are able to boost and set the scale for the profitability, performance and innovation of advanced intralogistics.

HÖRMANN Intralogistics stands for decades of automation, IT and industrial services competencies as well as cross-industry experience in the planning and building of fully automated turnkey warehouse solutions with optimised data handling processes. Our patented materials handling and award-winning robotics solutions provide our customers with the most efficient single-source material flow systems.

Like all companies of the renowned HÖRMANN Group, we are guided by our passion for logistics, driving our more than 300 staff members to perform at their very best every day. All for sustaining our customers’ success.

Our intralogistics solutions - individual and future-proof

-

With creative storage and conveyor technology concepts as well as innovative warehouse logistics techniques, in our more than 35 years of activity we have implemented many custom-made intralogistics solutions in a wide range of industrial sectors.

We design high-bay warehouses as well as tray, miniload and shuttle warehouses specifically for your requirements, to ensure maximum productivity and cost-effectivenes. As general contractor, we take overall responsibility for implementing new, complex storage systems and modernising existing systems even during active operations.

The whole system is integrated with our HiLIS warehouse management system. HiLIS manages, controls and monitors all material flow processes on-line, ensuring maximum transparency and system availability in all functional areas.With our modern, innovative AutoStore® small parts warehouse, dynamic robotics applications, goods-to-person picking systems and micro-fulfilment solutions, we offer flexible, highly dynamic systems especially for e-commerce.

Automated high-bay warehouses

-

Where goods and merchandise need to be stored in a limited space, we recommend a custom-made high-bay storage system with fully automated stock storage and removal, from goods receipt to dispatch readiness. For pallets, boxes, rolls, stacks, big trays or cartons in different formats and with different weights, we build SRM-based high-bay warehouses as in-house or silo systems, in addition to high storage density and high throughput pallet shuttle systems.

The advantages at a glance:- High-level item variety

- Space saving

- Storage up to four deep

- Effective stacker crane utilisation through double, triple and quadruple formation

- Storage and transport or a wide range of LU sizes

- Storage and transport with or without sub-pallet

- Connected custom-made conveyor technology

Paper roll storage

-

We specialise in systems for handling and storing delicate paper and foil rolls. Our high-bay storage systems offer maximum flexibility and quick, careful access to each roll for a wide variety of load units and roll weights. Careful storage prevents damage to the delicate front ends.

The advantages at a glance:- Gentle handling

- Storage height up to 40 meters

- High roll weights

- Storage and transport with or without sub- pallet

- Connected custom-made conveyor technology

Corrugated intralogistics

-

With decades of experience in the sector, we specialise in systems for handling and storing delicate corrugated board, using cutting-edge conveying and storage technology specifically for this material.

From the corrugator to automatic format goods storage, processing, palletising to finished goods storage, we develop and realise comprehensive, complete materialflow solutions as a general contractor. We’re especially proud of the reviews we’ve received from our major customers.

The advantages at a glance:- Gentle handling

- Multi-depth storage for high volume

- Effective stacker crane utilisation with double, triple and quadruple formation

- Storage and transportation of LU sizes

- Storage and transport with or without sub- pallet

- Connected custom-made conveyor technology

Small parts/tray storage systems

-

For high-turnover, small-format, delicate and heavy items (over 100 kg), we realise customised automated tray storage systems with connecting conveyor technology, picking stations, shipping buffers, etc.

Based on requirements, we design tray storage systems for steel or plastic trays, which can be equipped with special inlays for storing items gently and damage-free.

The advantages at a glance:- High dynamics

- Multiple load

- Effective use of space variable occupancy, multi-depth

- Fully automatic stacker cranes

Small parts/shuttle storage systems

-

We develop custom automated small parts warehouses or shuttle warehouses especially for low weight, high-turnover loads in bins, boxes or trays, ideal for classic warehouse functions as well as for buffer storage, goods service or use as a picking system.

The advantages at a glance:- More room in existing building structures for excellent space utilisation

- Lower construction costs for new warehouse space

- Enormous flexibility and redundancy

- High storage density

- Rapid access to goods (fully automated storage and retrieval)

- Maximum dynamics

- Remarkably high throughput rates

- Remarkable energy-efficient and sustainable through the use of power caps or buffer storage

- Custom solutions, perfectly adapted to your requirements and products

- Holistic support

- Goods-to-person or person-to-goods order picking

Intralogistics in detail

-

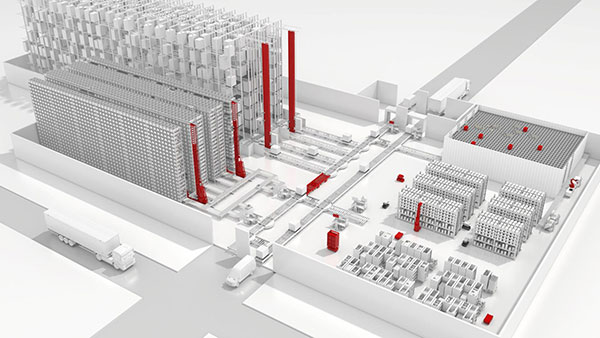

Automatic storage systems - the future of intralogistics with HÖRMANN Intralogistics

Dynamic markets demand efficient warehousing and logistics strategies. Automated warehouse systems ensure highest availability, better use of space, higher productivity and inventory accuracy, lower operating costs, and sequence-accurate goods provision.

Whether automated high-bay warehouses, tray warehouses, innovative small parts warehouses like AutoStore® or picking and conveying systems, HÖRMANN Intralogistics implements high-performance, scalable and space-optimised automated warehouse solutions as general contractor.

Depending on the material flow, space and load requirements, we design and implement storage systems with varying degrees of automation. With its in-house developed HiLIS (HÖRMANN intra Logistics System) warehouse management system, HÖRMANN Intralogistics offers fully integrated WMS solutions for high-availability intralogistics and production systems. Developed in-house for over 30 years, our HiLIS smart software product is flexible, modular and scalable, making it ideal for use in a wide range of industrial sectors. The software can operate with all ERP, production and shipping systems.

This permits flexible control, monitoring and analysis of all functional areas.

This in turn ensures the greatest possible logistics process transparency, in addition to maximum warehouse performance and availability.

Smart integrated warehousing

-

With individual, creative multi-solution intralogistics systems, we realize efficient and future-oriented material flow solutions for diverse industries. Especially for your requirements, we design and combine automated high-bay warehouses, tray, and small parts / light goods storage, AutoStore® plants and picking systems to ensure maximum productivity for our customers.

The advantages of multi-solution intralogistics systems:- Increased storage capacity and throughput with one overall system through automation - even with different product groups

- Digitization and acceleration of processes

- Compensating for the shortage of skilled workers

- Just-in-time and just-in-sequence supply of production and picking

- Amalgamation of different warehousing, goods sizes and handling speeds at a few, space-saving, ergonomic picking workstations

- A warehouse management system for the entire material flow incl. Kanban material replenishment

ROBOTICS

-

High productivity, low operating costs and simple commissioning - along with our efficient partners, we implement innovative robotic solutions that can be commissioned independently or together with other storage and picking systems. Needs-based scalability, easy expansion and maximum dynamics, not to mention seamless integration into our HiLIS WMS make our AGVs and cobots the ideal solution for growing markets.

Based on sector, required volume, product nature and range, existing logistics assets and the required throughput, we can recommend and install the right independent solution for you as both consultant and general contractor. From highly dynamic cube-storage small-parts warehouses like AutoStore, to intelligent pick arms, bring-and-lift robots and mobile racking - we automate and streamline your intralogistics.

Using robotics has numerous advantages:- With high-level automation and high storage density, they need less space and fewer staff

- Reduced staff walking distance and unhealthy strain

- Reduced error: sequence-accurate, just-in-time picking

- Increased volume and efficiency without fatigue

- Problem-free goods throughput peaks

- Interfaces with all major WMS

Micro-fulfilment solutions

-

Micro-fulfilment is an innovative strategy for efficiently fulfilling online retail orders in close proximity to end customers. Especially in cities, fast delivery coupled with low space and staffing requirements offers great opportunities for retailers.

Given the rapid rise in eCommerce, consumer expectations are more demanding than ever, and are based on benchmark delivery speeds, for example. This makes new logistics strategies like automation and distribution warehouses close to cities far more essential. With micro-fulfilment centres, orders are picked the same day and made available to customers immediately for pickup, or delivered directly to their homes.

HÖRMANN Intralogistics specialises in last-mile logistics and handles all project phases, from consulting to requirements planning, technology evaluation and procurement, to automatic solution leasing.

The advantages of Micro-Fulfilment - the effective problem solver:- Micro-Fulfilment features a network of small, flexible warehouses. These can be located directly in the city or on in the suburbs.

- With high-level automation and high storage density, they need less space and fewer staff

- Proximity to customer enables click & collect offers and reduced delivery time and cost.

- Micro-fulfilment centres can operate as stand-alone warehouse and picking centres, or dynamically integrated into existing retail stores

- Potential applications in all sectors, from wholesale and retail sales to industry.

AutoStore®

-

AutoStore® is an innovative, cutting-edge system for automated small parts storage and picking in plastic bins. This compact system optimises volume utilisation, dynamics, energy efficiency, expandability, material usage, and connections to picking stations.

As an official distributor, HÖRMANN Intralogistics offers AutoStore® with the HiLIS AS WMS tailored to it, along with all-round customer service as a general contractor.

The advantages at a glance:- Floor space reduced by up to 75%

- The Red& Black-Line robots tirelessly pick up bins, re-sorting and delivering them to the ports directly couple for receiving and picking goods.

- AutoStore® is a completely modular system, with throughput capacity determined by the number of robots and workstations.

- AutoStore® can be installed as a stand-alone solution or integrated into an overall logistics concept.

Pick-by-Robot

-

Pick-by-Robot is an innovative way of taking the fatiguestress out of picking tasks - reliably, quickly and without fatigue. A flexible, retrofitted pick-by-robot system is the future-looking alternative to manual picking.

With its patented robobrain® solution, our partner Robominds has created a modular process intelligence platform. Based on artificial intelligence, the smart software modules and cutting-edge hardware components form a unique system for customised HÖRMANN Intralogistics pick-by-robot systems - AutoStore® system, Caja Robotics or state-of-the-art conveyor technology for example. We can develop a system customised to your requirements and industrial sector.

The benefits at a glance:- Reliable and fatigue-free

- 24/7 operation

- Low operating costs

- Highest picking reliability

- High productivity

- Error-free picking

- Simple commissioning and flexible integration into existing picking stations

- Self-teaching with AI

- Individual safety concept

Moving Racks solution

-

Moving Racks solution - goods-to-person (logistics) with robots and racks

Constantly increasing item volumes, along with ever increasing demands for fast and efficient order picking, pose new challenges for classic warehouse logistics. Working with SAFELOG, HÖRMANN Intralogistics has developed an innovative moving racks system for picking process automation, even for bulky goods, based on the goods-to-person principle.

Mobile transport robots (AGVs) transport the goods in modular racks, sequentially and just-in-time from the storage areas to the picking stations. HÖRMANN Intralogistics’ smart HILIS Warehouse Management System controls and monitors all picking processes to guarantee maximum performance.

The advantages at a glance:- Reduced staff and walking distances

- Flexible and modular expansion at any time with more AGVs or racks

- Picking areas can be supplemented by support systems, e.g. pick-by-light

- In multi-order picking configuration, the HiLIS WMS offers additional possibilities for increasing picking efficiency with intelligent batch formation.

Caja Cart & Lift Robotics

-

When developing automation solutions for fast-moving business areas, it is essential that the systems perfectly adapt to the intralogistics processes and infrastructures. With our partner, CAJA Robotics, we’ve developed an innovative approach using modern software, specifically developed robots that operate according to the goods-to-person principle, user-friendly workstations and solutions for integrating an existing WMS or the in-house HiLIS WMS.

The advantages at a glance:- More efficient order picking

- Reduced order errors and increased inventory security

- Reduced walking distances and manpower

- Robot and cloud software-assisted, AI-based, fully automated order fulfilment

- Scalable, modular architecture which responds lightning fast to order peaks or drops

- Flexibly adaptable shelf structures as new lines of business emerge

- Use of own bins possible

- Simple commissioning

HiLIS - Our Warehouse Management System is the heart of the intralogistics solution

-

Our HiLIS WMS is the core of the automatic or manual intralogistics process control system in the solutions we develop for customers, in our role as full service provider of custom intralogistics solutions. It's a high-performance software suite capable of mapping any process important to your intralogistics flows. As the central brain of the warehouse, HiLIS manages, controls and optimises both material and data flows.

HiLIS clearly displays all data on the user interface of your choice - whether it be a classic PC workstation or a mobile device. Our Warehouse Management System can even optimise, control and monitor complex customer-specific logistics processes. Moreover, its modular structure allows for custom adaptations to your specific needs, offering maximum flexibility and investment security.

The advantages of HiLIS offers:- Flexible connection to any ERP and production systems

- All WMS functions

- Solution specific to AutoStore® systems: the HiLIS AS

- Imaging on mobile devices

- Clear and ergonomic dashboard

- Material flow control and monitoring

- PLC system integration

- Visualisation

- Maximum plant availability and flexibility

- Transparency and safety

- Scalable and future-proof

- Energy optimisation

CONVEYERS

-

Conveyors - Customised, innovative conveyor technology

HÖRMANN Klatt Conveyors from Neumarkt am Wallersee in Austria has been an important partner for companies worldwide in the field of conveyor systems for many years. Our portfolio includes a wide range of standardised conveyor technologies for a variety of applications, as well as special custom solutions.

We design and implement the best and most economical conveyor solutions:- Consulting and planning

- Manufacturing and pre-assembly

- Project management and execution

- Assembly and commissioning

- Service and maintenance

SERVICES

-

HÖRMANN Intralogistics Services - a strong partner for industry

From the conception to the commissioning, we work around the clock for our renowned customers with our highly qualified, experienced staff, providing full life-cycle support and maintenance, as well as relocation testing services for their automated manufacturing and production facilities.

We ourselves are renowned for our technical competence in the field of electrical and mechanical technology, control systems, robotics, welding, conveyor technology, pneumatic and hydraulic systems, and all the other tools of streamlined industrial engineering. As a consolidated partner, we support our customers with future-proof and efficient automation solutions, innovative machine technology and versatile industrial services, not to mention future-oriented energy management, customised retrofit measures to increase intralogistics system performance and, of course, 24/7 customer service via our intralogistics hotline.

Automation Solutions

-

We develop automation solutions tailored specifically to the needs of our customers: From planning, mechanical and electrical design, manufacturing and assembly to commissioning with PLC and robot programming.

As general contractor, we coordinate all phases of a project, creating maximum transparency and security over the entire course of the works. Our customers can rely on a single contact person, from concept to final acceptance.

Our services at a glance:- Robotic systems programming

- Robot system teaching

- Documentation

- Commissioning

Mechanical Engineering

-

We cover a wide range of services in the area around your machinery and intralogistics equipment and offer our customers a complete services from a single source provider.

We specialise in processing machines for use in the automotive industry and its supply chain, as well as related industries, and have a well-coordinated service team with many years of experience in the field of machine technology under its belt. In addition to inspection services, we can also provide maintenance and repair services of all kinds. Even for complex intralogistics systems, we can provide full service, from construction to maintenance and modernisation.

- Hydraulic assemblies by the professionals

- Pneumatic assemblies

- Gearbox Overhaul

- Spindle repair

- Telescopic cover general overhaul

Industrail service

-

Our single-source provider industrial services include personalised, competent solutions. Our professional teams with vast experience in planning, production-and assembly know exactly what you need.

As a partner to industry, we provide all-round services geared to the life cycle of automated manufacturing and production equipment. From conception, realisation, assembly and commissioning of machines and systems to the relocation or modernisation of existing production facilities, not to mention optimisation and maintenance.

- Operating equipment and systems safety through competent DGUV inspections

- Interruption-free processes and production sequences through continuous maintenance

- Industrial assemblies from single machines to production lines

- System assembly and machine conversion services

- Machine relocation

Energy optimisation

-

Sustainable intralogistics - Eco power management with power caps

Optimising energy consumption is an absolute must for intralogistics solutions, reducing CO₂ emissions from power generation as well as reducing operating costs.

When building a new high-bay warehouse or modernising an existing one, our intelligent HiLIS Eco power management system can reduce the energy consumption of the stacker cranes by approx. 25%.

Using innovative Powercap technology for storage and retrieval machines, power consumption can be reduced by approx. 40% and connected load by approx. 65%.

- Optimal use of generator power generated from one axis for the other

- Reduction of energy demand through optimised weight management

- Storage of generator-generated energy directly on the RBG

- Up to 40% reduction of electricity consumption

- Saving CO₂

Retrofit

-

Retrofit - more efficiency through modernisation

Is the mechanical technology, hardware and software of your logistics system no longer up to date and with high maintenance and downtime costs? Is the installed software nearing obsolescence? Then your system is ready for modernisation.

The advantages at a glance:- Modernisation during ongoing operations

- Increased plant performance

- Increased availability

- Guaranteed maintainability

- State-of-the-art system

Customer Service

-

We are always here for you. Ask our customer service specialists.

Only through regular maintenance, system care and update service can we ensure maximum system availability. In the event of a malfunction, our hotline service provides immediate assistance and, if necessary, immediately sends a team of specialists.

Every hotline message is immediately recorded in our fault database and can be viewed on-line at any time. Through a consistentl analysis of this data we can develop the necessary preventive measures specifically for you.

Our service:- Hotline service 24 hours a day

- Preventive system maintenance and update service

- Individual maintenance concepts

- Spare parts management

- Remote maintenance for software and control

- Disturbance data statistics and analysis

- Highest plant availability

- On-line access to fault database

- Optimised overall cost of ownership

- Lifetime contact person