- Offer Profile

- We are the number one

manufacturer of spiral conveyors in the USA.

Our products include Spiral Conveyors, Spiral curves, Mass Flow Spirals, Continuous Lifts, Vertical Accumulation Buffers, Bucket Elevators, Incline and Decline slat Conveyors. All products can be delivered in powder coated carbon steel, stainless steel, wash down or freezer versions.

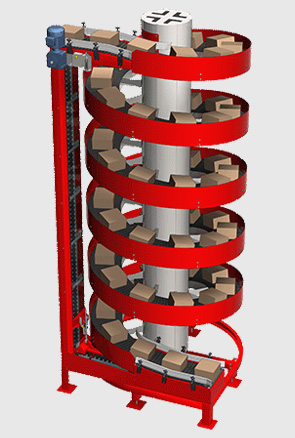

Spiral Conveyors

- Ryson is the number one manufacturer of spiral

conveyors in the USA.

Our spirals are based on a new and innovative technology, offering many features and benefits. Ryson Spirals need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Small Footprint:

A proprietary low friction chain slat arrangement allows Ryson Spirals to operate within a small footprint, saving valuable floor space.

High Throughput:

The spirals convey loads up or down in a continuous flow, facilitating high throughput. The spirals can operate at speeds up to 200FPM and are optionally reversible.

One Drive:

Only one drive motor is required, resulting in substantial savings in energy, controls and systems integration.

Easy to Install:

Most spirals are shipped in one piece, pre-assembled and pre-tested, drastically reducing time and cost of installation.

Low Maintenance:

Ryson Spirals are designed for low maintenance and long life. Only high quality components are used throughout. All bearings are sealed for life and need no further lubrication. The chain is of heavy duty nickel plated construction and needs only infrequent lubrication. The slats need no maintenance and can easily be replaced as single components without the use of special tools.

Proprietary Chain Slat Arrangement

This innovative design enables a low friction operation. The slats are supported by precision steel roller bearings which ride on a polyurethane wear surface. This arrangement effectively takes up the side forces created by a tight radius and at the same time increases the load carrying capacity of the chain up to 75 lbs. per foot. This furthermore facilitates high speed, low noise and long life. Unit Load Spirals

- Save space and increase throughput.

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Modular Design

An innovative modular design allows Ryson to customize with ease and modify in the field to accommodate emerging needs. All spirals are made to order and are available in 4 basic configurations ( A, B, C and D), accommodating most requirements relating to the location of the in and out feed tangents. All configurations can operate up or down in a clockwise or counterclockwise rotation.

Small Footprint

The spiral diameter is determined by the size of the loads (length, width and height) to be handled. A broad range of sizes allows the Ryson Spiral Conveyors to be viable in the manufacturing, packaging, bottling, order picking, distribution, and warehousing operations of most industries.

Proprietary Chain Slat Arrangement:

This innovative arrangement enables a low friction operation. The slats are supported by precision steel roller bearings which ride on a polyurethane wear surface. This arrangement effectively takes up the side forces created by a tight radius and at the same time increases the load carrying capacity of the chain up to 75 lbs. per linear foot. This facilitates high speed, low noise and long life.

Overlapping Slats

The overlapping slats provide a smooth efficient conveying surface suitable for a wide variety of load types and sizes for speeds up to 200 fpm. The slats are made of a fiberglass reinforced nylon and are available in widths of 8″, 12″, 16″, 20″, 24 and 26″. The slats can also be furnished with friction inserts to accommodate slick products such as plastic totes or frozen items.

Custom Solutions

- The position and length of the in-feed tangent on up spirals and out-feed tangent on down spirals can be customized to meet specific layout requirements. Samples are shown below (A-EX, B-MA and C-EX). A horizontal section is provided at in and out feed to assure smooth transition between conveyors. All Ryson Spirals are available in powder coated carbon steel, stainless steel, washdown, and freezer versions.

Built In Protection

- All Ryson Spirals are equipped with an automatic chain tensioning device and built in overload protection. The chain tensioning device is spring operated and a proximity sensor is sensing the correct operating position of the device. The overload protection device has an adjustable torque arm arrangement which is connected to the drive motor. A proximity sensor will sense when the device pivots during an overload condition and cause the motor to stop.

Controls

- Most of our spirals are shipped without controls because

they are normally integrated into an overall conveyor control system. The

spirals always include an inverter duty gear motor and two proximity

sensors, one for the automatic chain tensioner and the other for the

overload protection device.

A Variable Frequency Drive (VFD) is required for the proper operation of the spiral. Ryson offers several controls options including :- Stand alone control panel with interface capabilities

- Prewired motor disconnect

- Proximity sensors prewired to a central junction box

- Prewired missing slat detection sensors.

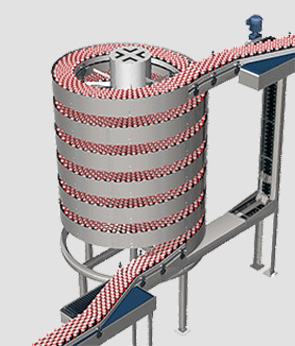

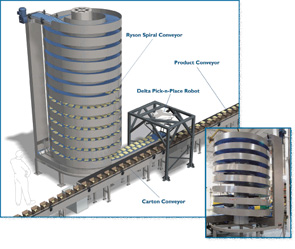

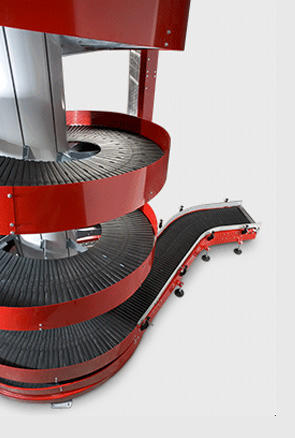

Mass Flow Spirals

- The Ryson Mass Flow Spirals are designed to handle

full and empty bottles, cans, jars and other similar containers.

The Ryson Mass Flow Spiral Conveyors are ideal for canning and bottling operations where units need to be conveyed vertically in mass. Products are conveyed up or down in a continuous mass flow. Ryson Spirals have a small footprint and provide considerable space savings compared to conventional methods.

The Mass Flow Spirals are based on the already proven and reliable Ryson Spiral technology. Only one drive motor is needed, equating to substantial savings in controls and systems integration. All Ryson Spirals are designed for low maintenance and long life. Many spirals operate 24 hours a day, 7 days a week.

The Mass Flow Spirals are equipped with extended in and outfeed tangents to facilitate smooth side transfer to and from external conveyors. They can be delivered with 10”, 12”, 16” or 20” wide slats with capacities of up to 2,000 units per minute. They are also available in powdered coated carbon steel, stainless steel and washdown versions.

Controls

Most of our spirals are shipped without controls because they are normally integrated into an overall conveyor control system. The spirals always include an inverter duty gear motor and two proximity sensors, one for the automatic chain tensioner and the other for the overload protection device.

A Variable Frequency Drive (VFD) is required for the proper operation of the spiral. Ryson offers several controls options including :- Stand alone control panel with interface capabilities

- SPrewired motor disconnect

- SProximity sensors prewired to a central junction box

- SPrewired missing slat detection sensors.

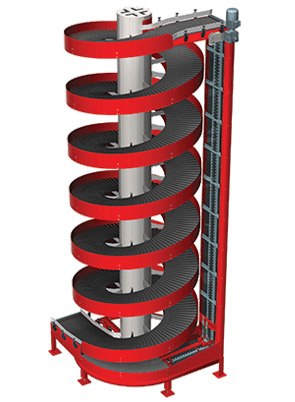

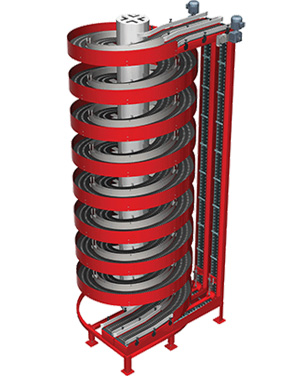

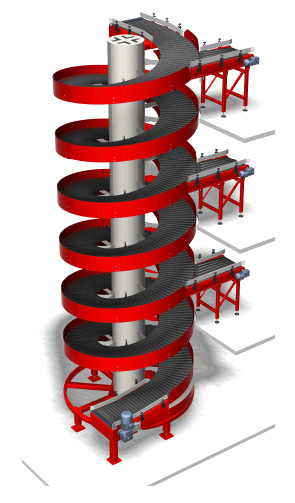

High Capacity

- A Spiral for the Tough Jobs

The new Ryson High Capacity Spirals are in response to our customers need to go higher and handle more weight.

The new spirals handle double the capacity of our regular spirals and ship in one piece which drastically reduce the time and cost of installation.

The load capacity is 75 lbs. per linear foot of conveyor for speeds up to 200 FPM. The total weight capacity in the spiral at any one time is 3200 lbs. Only one drive motor is required, resulting in substantial savings in energy, controls and system integration.

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Ryson Spirals are designed for low maintenance and long life. An innovative modular design allows Ryson to customize with ease and modify in the field to accommodate emerging needs.

Modular Design:

An innovative modular design allows Ryson to customize with ease and modify in the field to accommodate emerging needs. All spirals are made to order and are available in 4 basic configurations ( A, B, C and D), accommodating most requirements relating to the location of the in and out feed tangents. All configurations can operate up or down in a clockwise or counterclockwise rotation.

The position of the in-feed tangent on up spirals and out-feed tangent on down spirals can be customized to meet specific layout requirements. Samples are shown below (A-EX, B-MA and C-EX). A horizontal section is provided at in and out-feed to assure smooth transition between conveyors. All Ryson Spirals are available in powder coated carbon steel, stainless steel, washdown, and freezer versions.Controls

Most of our spirals are shipped without controls because they are normally integrated into an overall conveyor control system. The spirals always include an inverter duty gear motor and two proximity sensors, one for the automatic chain tensioner and the other for the overload protection device.

A Variable Frequency Drive (VFD) is required for the proper operation of the spiral. Ryson offers several controls options including :- Stand alone control panel with interface capabilities

- Prewired motor disconnect

- Proximity sensors prewired to a central junction box

- Prewired missing slat detection sensors.

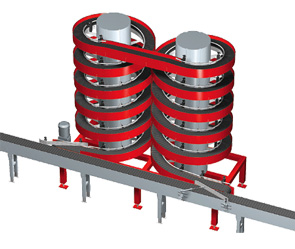

Dual Track Spirals

- The new Ryson Dual Track Spiral Conveyors are the

ultimate in space savings.

Two tracks operate independently within one spiral structure. Both tracks can go up or down, and can optionally be reversible.

Only one drive motor is required for each track, resulting in substantial savings in energy, controls and systems integration. The dual spiral conveyors build on the already proven Ryson Spiral Technology and are designed for low maintenance and long life. Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Models with dual 8”, 12”, 16” or 20” wide slats are available. Some site assembly is required for models with 16” and 20” wide slats.

Standard Configurations

The dual spirals are available in 4 basic standard configurations (A, B, C and D) and will accommodate most requirements relating to the location of the in and out feed tangents. All configurations can operate up or down in a clockwise or counterclockwise rotation.

Custom configurations

The position and length of the infeed-tangent on up spirals and the outfeed-tangent on down spirals can be customized to meet specific layout requirements. This is possible for all standard configurations. The following depict samples of common customizations:- C-EX configuration matches the centerline of the top and bottom conveyor centerlines. Centerline offsets can also be accommodated.

- B-MA is an example of modified in or outfeed angle. The modified angle is normally 45 or 30 degrees, but other angles can be provided.

- A-EX show extended in or outfeed tangents which can be straight or curved and can accommodate centerline off-sets.

The two tracks of the Dual Track Spiral Conveyors do not have to feed in and out of the spiral at the same elevations, and can be applied very effectively to multi-level order picking modules or similar applications. The outside track serves the first level and the inner track the second level. In the examples to the right, the space savings is considerable if you consider that you get two spirals in one compact footprint. Vertical Accumulation Buffers

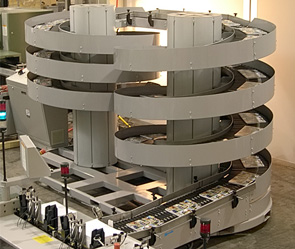

- The Ryson

Vertical Accumulation Buffer is an efficient use of overhead space.

Overhead space is efficiently used for overhead dynamic storage or buffering while preserving valuable floor space.

The Ryson Vertical Accumulation Buffers utilize one reversible spiral or combine two or more spirals for up and down movement. Most conveyable products can be handled, including bottles, cans, pails, bags, bundles, totes, containers and wrapped or unwrapped items.

The accumulation buffers build on the already proven Ryson Spiral technology featuring low maintenance and long life. The buffers are available with 8”, 12” 16”, 20” or 24” wide slats and can be delivered in powder coated, stainless steel or washdown versions.

Dynamic Buffering

The Ryson Accumulation Buffers can be used to provide dynamic storage where products need time for cooling, drying or curing. Additional dynamic buffer storage capacity can be obtained by adding pairs of spirals.

The Ryson Accumulation Buffers can also be used to take up surges between manufacturing processes and can provide dynamic buffering during shorter production or packaging line interruptions. This will reduce downtime and increase productivity. Some products can be merged back into the production or packaging lines directly from the accumulation buffer while others will need additional merging devices – depending on type of product and speed of operation.

Modular Design

An innovative modular design allows Ryson to customize with ease and modify in the field to accommodate emerging needs. All spirals are made to order and are available in 4 basic configurations ( A, B, C and D), accommodating most requirements relating to the location of the in and out feed tangents. All configurations can operate up or down in a clockwise or counterclockwise rotation and custom configurations are available. Call us with your specific needs. Narrow Trak Spiral Conveyor

Narrow Trak Spiral Conveyor

- This new super compact Narrow Trak Spiral is designed to

handle small loads and has an outside diameter of only 3′-9”. It is a great

space saver in addition to enabling high throughput – with speeds up to 200

fpm.

This new NT 1000-120 model builds on Ryson’s already proven spiral technology. Our modular design concept makes it easy to custom configure the spirals and accomodate the customers’ specific layouts. It offers a significantly larger elevation change capacity than what is currently available in the small package marketplace today.

A new 5″ wide nesting slat design provides a smooth conveying surface and can facilitate end-transfer of small cartons and packages or side-transfer small bottles or containers in mass or in a single file. This is a good alternative to side gripper elevators, because the spirals do not need to be adjusted for varying product sizes and requires much less maintenance.

This new spiral incorporates Ryson’s proprietary chain slat arrangement providing low friction operation. The conveyor slats are attached to a heavy-duty steel chain and are supported by precision steel roller bearings. This arrangement efficiently takes up the side forces caused by the tight radius and at the same time increases the load capacity of the chain. It also facilitates smooth operation, low noise, high speed, low maintenance and long life.

This new model will be especially beneficial for the pharmaceutical, nutraceutical, personal care and food products companies.

Multiple Entry Spiral Conveyors

Multiple Entry Spiral Conveyors

- A Solution for Multi-Tiered Product Flow

The Multiple Entry Spirals allow loads to enter the spirals from several different elevations and work best when loads are fairly uniform in size and weight. These spirals are ideal for using a single spiral for multiple production lines or in a multi-tiered order picking operation.

A new high speed induction conveyor provides controlled spiral entry. The conveyor belts are individually adjustable to match the spiral pitch. Traffic controls are required to prevent loads entering from different levels colliding in the spiral.

Multiple inlet spiral from Ryson.

Click on the video below to see an example of how the Ryson Multiple Inlet Spiral can save you considerable floorspace.

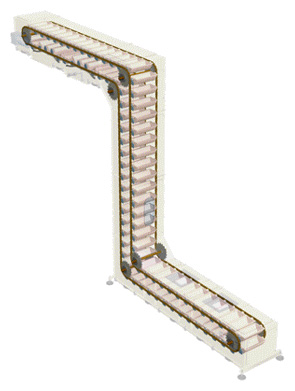

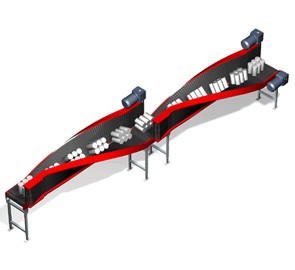

Slat Conveyors

- The Ryson Slat Conveyors and Curves are ideal for

inclines or declines in tight quarters and can handle multiple curves with

one drive

The Ryson proprietary chain slat arrangement becomes a versatile and flexible conveyor when used outside a spiral conveyor. Only one drive is required for each 250 feet of conveyor, which minimizes the number of transition points required. This also significantly reduces the cost of controls and system integration. Available in slat widths of 8″,12″, 16″, 20″ and 24″. The Ryson Chain Slat conveyors can also be configured as an oval shaped spiral, becoming a space efficient dynamic buffer storage device. More details on the Ryson Chain Slat arrangement are available under the spiral conveyors page.

The Ryson proprietary chain slat arrangement becomes a versatile and flexible conveyor when used outside a spiral conveyor. Only one drive is required for each 250 feet of conveyor, which minimizes the number of transition points required. This also significantly reduces the cost of controls and system integration. Available in slat widths of 8″,12″, 16″, 20″ and 24″. The Ryson Chain Slat conveyors can also be configured as an oval shaped spiral, becoming a space efficient dynamic buffer storage device. More details on the Ryson Chain Slat arrangement are available under the spiral conveyors page.

High Speed Rotator

- The Ryson High Speed Rotator is a new innovative conveyor

for in-line rotating of cases and other unitized loads.

The loads can be rotated 180º or 90º in a continuous motion. This new conveyor is used in packing lines where products need to be rotated upside down or to one side without delay or product damage, The Ryson High Speed Rotator can accommodate a wide range of load sizes without adjustment.

Bucket Elevators

- Bucket Elevators, Bucket Conveyors and More

A new generation of bucket elevators from conveyor manufacturers Ryson International

Ryson International has developed a new generation of bucket elevators and bucket conveyors. These enclosed pivoting bucket systems can have multiple in and outlets. The bucket elevators combine vertical and horizontal transportation of bulk material in one integral unit. Their modular design and rugged construction make them suitable for a wide variety of applications. Choose from painted carbon steel, stainless steel or washdown versions. You can download a Bucket Elevator RFQ Form here. Just fill it in and e-mail it to sales@ryson.com to find out specifics and pricing.

The Ryson bucket elevators are designed for gentle handling and quiet operation to facilitate transportation of measured quantities. Available in several sizes, the buckets overlap at the infeed and remain in an upward position until emptied to prevent spills. Ryson Bucket Elevators are well-suited for a broad range of bulk products in the food, agriculture, pharmaceutical, cosmetic, chemical, ceramic, glass, recycling, building and metallurgical industries.Bucket Elevators with Rugged Construction

The Ryson Bucket Elevators are designed to withstand many years of heavy duty operations. Elevators with multiple outlets have selective bucket tipping capabilities created by an air actuated tipping ramp. The last tipping ramp stays in a fixed position to assure that all buckets are emptied.

The chain is a 2″ roller chain with hollow pin shaft and 1 1/8″ diameter rollers. The conveying surface is made of polyurethane for smooth and quiet operation. The buckets are made of a food grade reinforced polycarbonate molded in one piece that can handle temperatures from -5 to 215 degrees Fahrenheit.

Anti-static and stainless steel buckets are optional. The bucket elevators allow for controlled feeds at one or more locations and can easily interface with various types of feeding devices.

Bucket Elevator Models

Three standard models are available, sized to handle capacities of up to 350, 830 and 2,000 cubic feet per hour. Ryson also provides custom solutions to help those with needs that fall outside of our standard models.

Optional Bucket Elevator Features

Several optional features are available to accommodate specific needs:- Dust proof enclosures

- Weather tight construction

- Anti-static buckets

- Stainless steel buckets

- Built-in forced ventilation

- Automatic bucket cleaning

- Variable speed

- Explosion proof

Low Maintenance

Ryson bucket elevators use only high quality, low maintenance components. All models have easy to remove inspection covers and a conveniently located inspection window. Drawers underneath all horizontal sections facilitate easy cleaning, while smooth inside walls prevent dust buildup. All bearings are mounted outside for easy access. The buckets have a quick release mechanism to facilitate fast installation or removal of buckets. All elevators are equipped with an automatic chain tensioning device and built-in overload protection.