- Offer Profile

- Experience our innovative solutions made of rubber and plastics for mechanical and plant engineering, environmental technology, agricultural technology and energy technology.

Material Combination

- Our products made from the combination of elastomers with plastics or rubber with metal can be found both in our individual components, the products for conveyor technology and in the field of belts and tapes.

Separate Components

- Individual components from the field of material combinations are technical parts made of several materials, which only attain their full functionality when installed. Despite their comparatively simple construction, individual components are sometimes subject to enormous stresses. For this reason, we combine several materials with different properties in order to meet the demanding requirements of the industry.

Rubber-Plastic Elements

- In many areas of application with extensive loads,

components made of a single material quickly reach their limits. For this

reason, we offer elements made of several, directly connected components

that combine the advantages of different materials. Chemical-physical direct

composites between thermoplastics and elastomers as well as TPE

(thermoplastic elastomers) are our core competence.

Since the elastic component is injected directly onto the stable thermoplastic body without prior priming, the associated costs can be effectively saved. In this way, applications in accordance with common food and drinking water requirements (FDA, BfR, etc.) can be guaranteed and demanding specifications of the electrical industry can be fulfilled.

In addition, additional functions are integrated into components through material combinations. Bendable or filigree parts made of rubber become dimensionally stable and can thus be mounted in a functionally reliable manner. This leads to a reduction in the scope of assembly as well as additional reworking and lowers quality assurance costs. A central advantage of rubber-plastic compounds is that, unlike metallic materials, they are not prone to corrosion. Moreover, the total weight is reduced enormously by substituting the metals accordingly.

We offer various material combinations of plastics and elastomers in direct bonding. In addition, an application-related material selection enables function- and cost-optimised solutions.

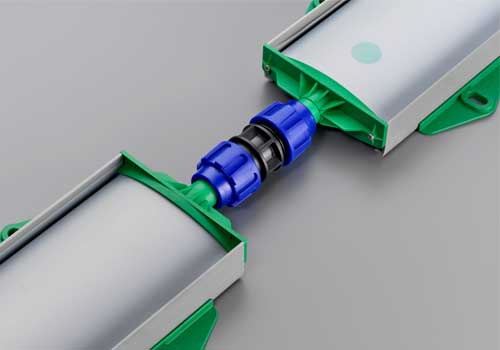

Pipe clamp made of rubber and plastic: Our modular tube connector system was developed for connecting glass tubes in photobioreactors. The requirements for the rubber-plastic pipe clamp are extensive, because on the one hand the component must resist the existing pressure of the plant and on the other hand it must guarantee a reliable tightness.

The simple assembly and disassembly of the pipe clamp using a torque wrench also eliminates the need for heavy power tools. Furthermore, the tight screw connection of conventional metal clamps often leads to glass breakage, which can be significantly reduced by using the Jäger clamp.

The use of the rubber-plastic pipe clamp in other industries or with pipes made of different materials (glass-plastic or metal-plastic connections) is possible without any problems. They are already used in solar water treatment plants or in the plastics industry for granulate conveying.

Pressure roller for seed drills: Components for the agricultural sector are usually exposed to various environmental influences and strong physical stresses. They must be resistant and should remain serviceable for as long a period as possible. Should individual components fail, this can have serious economic consequences, as the periods during which sowing and harvesting can take place are limited.

Above all, material combinations of rubber and plastic allow reliable and consistent use of the machines, as they provide the necessary robustness despite their low weight and without the risk of corrosion.

Seed drills use pressure rollers to regulate the depth of seed placement and for soil compaction after the sowing process. Previously drawn furrows are closed to prevent the seed from lying open in the field. For this purpose the press rollers must work permanently with appropriate pressure and on different types of subsoils.

The JÄGER Group manufactures assemblies made of high-strength rubber and highly resistant plastic for this purpose in order to withstand the extensive influences such as abrasion and specific force-displacement behaviour. The penetration of dirt into the pressure roller bearing is optimally prevented by a well thought-out construction of lip seals and dust caps.

Rubber-Metal Elements

- The combination of the specific properties of rubber and

the known metal properties results in a very wide range of applications for

construction elements made of rubber-metal compounds. We encounter them in

all branches of industry as clutch buffers, friction wheels, bearing

elements, spring and damping elements, bushings, valve balls, piston bodies,

stators, disc springs or also as shaft bearings. In particular, machine feet

and other rubber buffers, which serve to damp oscillations and vibrations,

are used in mechanical and apparatus engineering as well as in measuring

instrument technology and precision mechanics. The JÄGER Group offers an

extensive range of different materials and hardnesses in the field of

rubber-metal elements both for standardized and for components designed

according to customer specifications.

Suspension elements: Suspension elements manufactured as moulded articles with a firmly adhering connection of rubber and metal are used as components for vibration insulation, shock absorption and noise damping. While the actual spring body is made of rubber, the metal is used for stabilization and fastening.

Compared to insulators made of other materials, mounting elements made of rubber-metal offer the advantage of damping, damping and springing. They are maintenance-free as well as easy and quick to install. In addition to an extensive range of standardized bearing elements which are kept in stock, we are your competent partner for the development of special parts.

We supply suspension elements in the following designs:

- Silentium Drive, the quiet innovation in the combine harvester

- rubber-metal buffer and elements

- torsion bushings

- conical bearing elements

- machine feet as rubber-metal connection

- hollow springs

- rubber-metal rails

- axial and radial bushings

For special requirements, however, the use of alternative materials is possible and sensible.

For applications in the upper temperature range, for example, silicone is a suitable material.

Injection molded seal: In many technical systems, the highest demands are placed on the individual components installed with regard to reliable sealing. In addition, the assembly process of individual components is often difficult, as conventional flat gaskets or profile gaskets cannot be installed due to the lack of space. For this reason, we offer the possibility of vulcanising the seals directly onto metal lids or housings using a tool in the injection moulding process. Thus the gasket is directly connected to the metal component and offers the following advantages, especially compared to freely applied gaskets:

- precise seal cross section

- profiled sealing cross sections with lips possible

- constant cross section over the entire seal length

- no butt joint and therefore better sealing

- Connections without adhesive application possible

Coating for rollers: In roll coating, metal cores are coated with a rubber layer, thus enabling a combination of both material properties. During production, the unvulcanised rubber is either wound onto the metal core or applied in a compression or injection mould to vulcanise it afterwards. The range is supplemented by roll cover hoses, which are already vulcanized and then wound under pretension onto the metal core.

We also offer covers made of already vulcanized rubber sheets, which are glued to the metal core with special adhesive. In many cases, roller covers are exposed to several stresses at the same time. This is why special experience is required to determine the cover quality, the design of the core and the surface quality. We have decades of experience in this field.

Balls

- Rubber balls and plastic balls are mainly used as

closures in valves and pumps or for the cleaning of pipelines, heating

systems and screening plants. For our balls we use different types of rubber

and plastic depending on the requirements in order to be able to offer the

right material properties for each application. For this reason, our valve

balls and screen cleaning balls can be found in many areas of the chemical

industry as well as in mechanical and plant engineering.

Valve balls: In valves, rubber balls act as a common shut-off device and thus prevent the unwanted backflow of gases, liquids or granular materials and dust. In the cage of the ball valves is the freely movable rubber ball, which is lifted from the valve seat by the inflowing medium. In the event of backflow, the ball is pressed back into the hard valve seat by force and its own weight, thereby sealing it. The valve seat should be adapted to the material used for the valve ball. Another field of application is the area of float balls. Ball concepts with floating elastomers and core materials are used here. For the various specific operating conditions, we have appropriate materials made of elastomers and plastics available.Screen cleaning balls: Our rubber balls are used for cleaning industrial screening plants. The balls are added to the material to be screened and their bouncing behaviour causes permanently repeated collisions with other balls, the material to be screened as well as the screen itself. These recurring impulses keep the screen passages clear. In order to counteract the resulting abrasion pressure and to ensure the required bounce characteristics, we use materials that are characterised by low abrasion and good rebound elasticity. This ensures the best possible results during the cleaning process. Our expertise in the field of balls enables us to produce a wide range of standard dimensions as well as numerous intermediate sizes in various degrees of hardness to meet your specific sealing application.

Compression Packing

- Stuffing box packings are regarded as reliable and

durable elements of sealing technology. Since they provide reliable leakage

protection with high chemical and temperature resistance, stuffing box

packings are used in various technical systems. They are preferably found in

mechanical engineering such as pump technology or valve technology, but also

in the chemical or metalworking industry as well as in tool and mould

making.

Stuffing box packings are used to seal a rotating or axially moving shaft against the effects of liquid or vapour pressures, as well as against penetrating dirt or escaping lubricant.

A stuffing box consists of the stuffing box packing (the actual seal) and a stuffing box gland (a flange-like sleeve), with which the stuffing box packing is pressed axially by means of screws or springs.

With elastic sealing material, the axial compression also results in radial compression of the stuffing box packing on the shaft. Thus the sealing gap can be adjusted to a minimum adapted to the operating conditions. A small leakage cannot be completely excluded, but is often desired.

Advantages of compression packing: Universally applicable High mechanical strength Minimum cold flow Dimensionally stable Low leakage values and reduction of possible cross-sectional diffusion Fulfils the TA air and blow-out guidelines Suitable for use in the pharmaceutical and food industry (FDA and EU 1935/2004) Can be stored for an unlimited timeAdvantages of compression packing:

- Universally applicable

- High mechanical strength

- Minimum cold flow

- Dimensionally stable

- Low leakage values and reduction of possible cross-sectional diffusion

- Fulfils the TA air and blow-out guidelines

- Suitable for use in the pharmaceutical and food industry (FDA and EU 1935/2004)

- Can be stored for an unlimited time

A special material — expanded PTFE (ePTFE): Our strategic partner TEADIT® uses a thermal expansion process following the sintering of the stuffing box packings to minimize the creep behavior of PTFE typical for the material. This results in sealing elements such as tapes or cords with monoaxial alignment or flat gaskets as well as plates with multidirectional structures. A high chemical resistance as well as a very good compressibility characterize ePTFE and predestine this material for sealing plastic and steel joints as well as for enameled flange connections. Furthermore, they often replace plates with hollow glass bead fillers.

Materials Handling

- The field of conveying technology covers all applications where solid, liquid or gaseous media have to be transported over a certain distance. In order to be able to guarantee an economic transport of these goods in the long term, innovative further developments of the known processes are required. In this context, the best possible adaptation of the conveying systems to the respective operating conditions and processes in industry, mechanical engineering and plant construction is essential.

DELTA Transport System

- The modular transport hose system is flexible and easy to

integrate into existing systems. It consists of a delivery hose, seals and

reusable, metallic flange couplings that are adapted to the application. The

special feature of the suction and pressure hose system: The fittings are

mounted around the hose from the outside so that no unevenness occurs within

the conveying system. In addition, the hose connections do not come into

contact with the medium to be pumped, thus enabling hydraulic transport of

solids even in corrosive liquids.

A pneumatic or hydraulic transport of abrasive solids can be easily mapped. The exact adjustment of the suction and pressure hose to the material to be conveyed results in a significantly extended service life compared to conventional steel pipelines.

In addition, a significantly lower noise level is to be expected. The design of the system allows easy and flexible installation within the industrial plant. Due to the comparatively short installation times, unnecessary downtimes and the associated costs can be effectively avoided.

The areas of application for these industrial hoses are diverse and range from the construction industry, power plants or gravel pits to the chemical industry and feed production. The delivery hose system is available as yard goods or in individual lengths as well as in many different dimensions. The assembly of complete hose line systems is also possible.

Pump Stators

- Stators for eccentric screw pumps

In the field of materials handling, progressive cavity pumps are successfully used for tasks that exceed the technical possibilities of pumps of conventional design. They have decisively expanded the range of available conveying systems and are used for conveying highly viscous, abrasive and corrosive media. The components of the progressive cavity pumps are the fixed stator and the rotating component, the rotor. Rotation and the design of both components create chambers through which the respective media are transported from the suction to the discharge side of the pump.Stators consist of a steel jacket lined with rubber. The composition of the rubber compound in the stator depends on the requirements of the progressive cavity pumps and the medium to be pumped.

In materials handling technology, not only the abrasion behaviour but also the given physical, chemical and thermal medium properties are important factors that affect the composition of the material in the stator. The rubber mixture is therefore composed in such a way that the material wear of the stator is kept as low as possible. This increases the service life of your stators and prevents costly failures.

Pump Rotors

- Rotors for eccentric screw pumps

Eccentric screw pumps belong to the positive displacement pump family and are used where the technical tasks exceed the possibilities of pumps of conventional design. In the field of conveying technology, they are used for pumping abrasive, highly viscous and corrosive media. This has contributed to a significant expansion of the range of available conveying systems. Eccentric screw pumps consist of a rotating component, the rotor, and the stationary stator located around it. The rotor rotates eccentrically, as its axis of rotation does not correspond to the axis of symmetry of the stator. The construction of both components form chambers through which the respective medium is conveyed by rotation in the pump via the suction to the discharge side. Rotors consist mainly of steel and have a special spiral geometry as the rotating centre in the stator. Different materials are used in the JÄGER Group in the manufacturing process of rotors for eccentric screw pumps.

Hose Assemblies

- Hoses made of rubber, plastic and metal connections offer

universal application possibilities in all areas of industry. They are used

for conveying and conveying liquid, granular and gaseous media or for

suction and pressure transmission. In addition, protective hoses are used to

shield cables or other sensitive lines from external influences. The

requirements for hoses and hose lines of the JÄGER Group are correspondingly

extensive. These should be flexible, elastic and abrasion-resistant, but

must also be pressure and vacuum stable as well as mechanically, thermally

and chemically resilient. The fields of application for hose lines extend to

most different industrial areas. They are used in the construction and food

industries and in the chemical industry, as well as in agriculture, pump

technology and pipeline construction.

Assembled hose lines: Hoses and fittings are assembled by us into a functional and application-specific complete line. We procure all the necessary connecting and fitting parts, cut the hoses to the exact length and assemble them into ready-to-use systems. According to customer specifications, we can check and document the operating pressure for each hose line individually.

Our range of hoses and fittings extends from simple water hoses to chemical hoses against aggressive media. Among other things we supply hose lines in the following designs:

- Sandblasting hoses

- Food hoses

- Hoses against abrasive media

- Metal braided ultra high pressure hoses

- Heated hoses for two-component adhesives

- Sterile tubes for the pharmaceutical industry

- Heat protection hoses for electrical and hydraulic lines

- Hose lines for the rotor blade production of wind power plants

- Hose lines with leakage and drip-free couplings

SPIRA® Power Sections

- SPIRA® stators for drill motors

In addition to conventional stators, Artemis also produces stators with uniform rubber wall thickness under the brand name Spira®. These stators used in drilling motors are mainly used in the oil sector, but also for geothermal or mine drilling.Spira® stators offer many advantages over conventional stators. In particular, the higher torque for the same stator length, the uniform swelling in aggressive drilling fluid media and the uniform thermal expansion ensure significantly higher efficiency and longer durability. Spira® stators therefore drill to the required depth even in difficult applications without having to be replaced in between, thus saving a lot of time and money. The availability of different elastomers such as NBR, NBR-HR, HNBR and FKM for our stators offers optimal adaptation possibilities for your applications.

Advantages of SPIRA® Stators

- Higher efficiency due to increased motor differential pressure

- Better heat dissipation

- High performance, high temperature resistant NBR and HNBR rubber compounds

- Increased durability / less stumbling / deep drilling

- Suitable for motors with low speed and high torque

- Higher torque at the same length compared to conventional stators

- Shorter power sections at the same torque compared to conventional power sections

- Reduced swelling and stator profile deformation due to aggressive drilling fluids

- Uniform swelling around the stator contour

- Uniform thermal expansion around the stator contour

- Minimal stator profile distortion due to thermal expansion

- Excellent thermal conductivity through a thin, uniform rubber layer and contouring

- Steel pipe

- Minimum internal heating, no hysteresis

- High-precision, consistently high-quality stators and rotors “Made in Germany

Conveying and Sorting Systems

- Within the JÄGER Group we produce belts and tapes for agricultural technology and mechanical and plant engineering. Through many years of practical experience, we know the requirements and problems of our clients and quickly find the application-specific solution for agriculture, industry, transport and services. Economic considerations, safety requirements, legal regulations and the desire for optimum performance utilisation are taken into account in our product development.

Sprockets and Drive Wheels

- Drive elements are used in agricultural machinery as

positive drive systems. Driving wheels or sprockets transmit the power of

the motor to the screening belt. The JÄGER Group offers various drive

wheels, which are available in diameters from 120 to 800 mm.

Production

Cast iron forms the heart of all drive wheels. Most drive wheels are separable to facilitate assembly and replacement. The wheel halves form matching pairs and must not be mixed. Our drive wheels are supplied drilled and keyed according to your specifications and, depending on requirements, the type and size of the keyways are cut according to German DIN (metric) or customs standards. The friction drive types FR, FRD and KW can be used with any belt type and pitch.

Flights

- Consumers have high expectations of fruit and vegetables,

they want to buy perfect goods. Potatoes whose skin is damaged or apples

with bruises? They rarely make it into the shopping cart. For many buyers,

appearance is synonymous with quality and taste. The harvest must therefore

get from the field to the shops without damage.

Previously used steel carriers are too hard and can cause pressure marks and scrapes on the crop. In order to avoid this, we have developed sieve bar belts with rubberized drivers for the agricultural industry, which enable the gentle transport of the crops. The drivers are used in potato harvesters, for example.

The JÄGER GROUP offers individually adapted elastomer compounds for drivers and conveyor belts, which protect the crop. Furthermore, the light material also reduces the weight of the harvesting machines — the machines need less fuel and are therefore more environmentally friendly.

Our flights can be divided into five categories:- RFL-Flight

- MRF-Flight

- Steel-Flight

- Plastic-Flight

- Snapping Flight

Process Belting

- Profiled rubber fabric belts for loss-free product

transport

Our rubber fabric belts are characterized by precision, durability and efficiency. Efficient transport of a wide variety of goods requires constant new, innovative developments and improvements to the familiar systems. In this context, we focus on the best possible adaptation to the respective operating conditions and processes in industry, mechanical engineering and plant construction. We take belt speeds into account as well as the transport of sensitive goods.Special driver or cam profiles ensure loss-free transport of goods and can be manufactured by us from vulcanisation or plastic injection moulding tools with narrow tolerances.

With individual surface structures and hole patterns, we open up further, diverse process possibilities. We optimize your production processes for the following applications, among others:

- Washing plants for vegetables and fruit

- Screening belts in the harvesting technology for sugar beets and potatoes

- mechanical engineering for conveyor systems, for example for cement bags

We offer among others the following materials in the field of belts:

- Food safe mixture (for direct contact with food)

- Especially ozone resistant mixture

- NR/SBR/EPDM

Silentium Drive

- Silentium Drive — the quiet conveyor system for

combine harvesters

"Silentium Drive", the new innovative conveyor system for combine harvester feeder channels with rubber fabric belts and cam drive eliminates one of the main sources of noise in the combine harvester.

Up to now, a high-speed steel roller chain has been used in the harvester in the feed channel behind the cutterbar, which brings the crop to high speed with steel bars bolted on transversely and feeds it to the threshing units. This causes the chain and conveyor shaft to collide with each other. This creates the typical combine harvester noise, which is a considerable burden on the machine operator and the environment."Silentium Drive"; for more power and comfort during harvesting

Our “Silentium Drive” is based on a rubber fabric belt with parabolic cams, which replaces the conventional steel roller chain. This cam belt is manufactured in two versions: endless wound or with open ends and a special joining method. Bolts are vulcanized into the belt for an optimal connection between steel strips and belt.

A further challenge is the high maintenance requirement of the steel roller chain used up to now. If not re-tensioned regularly, failures can occur and the combine harvester stops. Wear and tear is also problematic, as both the chain and the sprockets must be constantly monitored. If the combine fails during harvesting, the availability of parts and the replacement time are crucial. Every hour that the harvesting machines stand idle causes further costs.The advantages of Silentium Drive

The “Silentium Drive” also helps to noticeably reduce maintenance costs:- The service life of the “Silentium Drive” is significantly longer than that of steel roller chains.

- intake speed and conveying capacity are increased.

- Chain wear reduced to a minimum.

- Drive and deflection wheels are practically wear-free.

- The permanent belt pre-tensioning by rubber fabric makes chain retensioning unnecessary.

- Highest reliability avoids failures and downtime in the field.

- low noise emission to protect the driver and the environment.

- The costs per hectare are reduced.

Over several years the “Silentium Drive” has been professionally developed and extensively tested by Broekema. The hunter company Broekema is a specialist in the development and production of rubber conveyor belts and screen chains with decades of experience in the agricultural machinery industry.

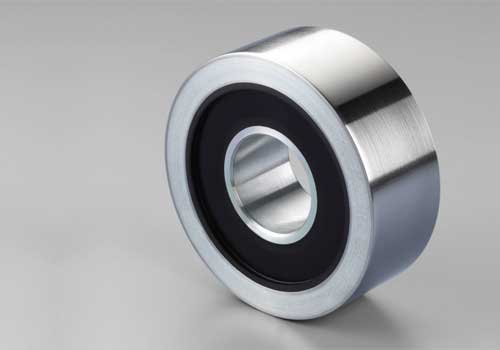

Belt Support Rollers

- We offer you a wide range of idlers, idlers and support

rollers for conveyor belts in harvesters. With them you can transport your

crop safely and smoothly. Our product range includes lightweight rollers as

well as plastic, cast iron and rubber rollers with one or two ball bearings.

We are particularly proud of our specially developed idlers made of glass fiber reinforced plastic in combination with a rubber compound tread. The plastic has a noticeable effect in the lower weight, the elastomer ensures excellent running smoothness and provides the required elasticity for the idler.

We manufacture the lightweight rollers from these special impact-resistant and wear-free plastics:- Polyurethane

- Polyamide

- Nylon

The plastic rollers are rubberized, have a low weight and are equipped with two ball bearings type 6005 2RS. They are available as standard with trunnion or open axle.

The cast iron rollers and rubberized rollers are equipped with two ball bearings type 6005 2RS as standard. Depending on the load, some rollers are offered with bearings of type 6206 2RS.

All plastic, cast iron and rubberized rollers have a three-part seal on both sides as standard to prevent contamination:

- Ball bearing seal

- Oil-soaked felt ring (optionally with Vulkolan or steel filling rings)

- Sealing lip and protective cap

Recycling Belting

- Conveyor belts for recycling and disposal systems

Especially in the waste management industry, forward-looking conveying solutions are increasingly required. We are your development partner with innovative ideas for your screening and conveyor belt — for the transport of the most diverse conveying media in a wide range of applications.

The advantages of our conveyor belts at a glance:- High speeds possible

- Smooth belt run

- Energy efficient compared to steel chains

For example, we equip beach cleaning machines with our conveyor belts. For many years now, these have been used daily in coastal areas to ensure clean beaches. For this purpose the soiled sand is picked up by a sieve belt, the sand is sieved off and falls back to the beach. Waste such as bottles and other larger particles are discharged separately.With our belts and the different pitches of the bar spacing we offer you the best possible influence on the quality of the screened surfaces. Heavy and sharp-edged stones, metals and organic materials can be picked up without any problems.

Fastening Components

- Fastening components for belts

The JÄGER Group supplies optimally coordinated fastening components depending on the installation situation and conditions of use. When connecting belts and rods, we distinguish between detachable and non-detachable connections. Detachable connections for quick installation on site are just as possible as riveted and endlessly vulcanized connections.High-quality products for demanding applications

With our stepped or shafted and then vulcanised endless joints, we achieve release strengths far above the specifications and thus enable high load change stress. Artemis sets standards in the development of endless wound belts in any length as if “from a single mould”.Our innovative technology opens up further diverse applications for rubber fabric belts in a wide range of applications. These long-life belts replace heavy, noisy and wear-prone steel chains in machines for agriculture, waste management, soil remediation and beach cleaning. They make it easy to increase conveying speeds. The existing nominal strength of the belts can be fully utilised. In addition, compared to conventional splicing technology, a lighter fabric construction with lower strength can be made possible when used with smaller deflection diameters. A high pitch accuracy is achieved by a defined fabric pre-stretch. Even with friction drive with hydraulic pre-stretching, a long service life can be achieved with this system.

Within the JÄGER Group, it is possible to continuously develop the different types of connections through laboratory and test bench tests under simulation of real operating conditions.

Feed Belting

- Best Belt feed belts for wide belt sanding machines in

the wood and metal industry

The Artemis feed belts have been developed in close cooperation with users and manufacturers of wide belt and brush sanding machines for the specific needs of the wood and metalworking industry. Artemis offers the right product for your woodworking machine for applications in the trade up to the highest loads in three-shift operation in the furniture industry. Cabinet parts, bed parts, worktops, kitchen parts and more furniture parts can be perfectly sanded thanks to our feed belts. Artemis also has the right feed belt specification for machining metal parts, whether wet or dry grinding or grinding other materials such as glass and plastic. Low manufacturing tolerances in the production of our articles ensure the success of your grinding results. Production widths of up to 2600 mm can be realized without any problems. For wider belts, we will be happy to work with you to develop specific solutions.Sliding layers made of highly abrasion-resistant material, low-stretch tension member fabric combined with high-quality blends guarantee a high, consistent and excellent product quality. Our innovative joining techniques ensure maximum durability at all times. On request, we can supply the conveyor belts ground ready for installation and perforated for vacuum operation with the latest machine technology with exact tolerances according to customer specifications.

Green Products

- We are committed to a clean environment and a sustainable future. Our proven wastewater aerators and textile fixed beds for wastewater treatment plants ensure clean drinking water and our marine technology innovations provide solutions for plastic-free oceans.

Waste Water Aeration

- Jäger Umwelt-Technik has been developing and producing

wastewater aerators for municipal and industrial wastewater treatment plants

since the beginning of the 1980s, because an important element in biological

wastewater treatment plants is the aeration system. With our aeration

technology for waste water treatment we provide clean water worldwide. Our

aerators are characterized by efficiency, reliability and durability. The

JetFlex® tube aerator, for example, has been in continuous operation for

almost 40 years. Saving energy is also important to us in order to protect

the environment and reduce costs for plant operators.

Our JetFlex® product portfolio includes disc diffuser, tube diffuser and strip diffuser, which are suitable for various applications.

We develop the materials of our aerator membranes ourselves: In our in-house laboratory, our chemists test wastewater-resistant materials made of elastomers and polyurethane.

We use the following membrane materials for the aerators:

- Ethylene-propylene-diene rubber (EPDM) for waste water in municipal sewage treatment plants

- Nitrile rubber (NBR) and polyurethane (PUR) for use with oily waste water in industry

- Silicone rubber (SI) for special industrial plants

- Fluoroelastomers (FKM) for special treatment processes

The disc diffuser and tube diffuser are available with membranes made of EPDM, silicone, PUR, NBR and FKM, optionally with PTFE coatings. Both types of diffuser convince by low maintenance and quick installation. The product range is completed by our strip diffuser made of PVC with a micro-perforated membrane made of PUR. They are characterized by easy installation on the pool floor and a long service life.

JetFlex® CBD

- JetFlex® CBD for more efficient mixing with air

For special applications our product portfolio also includes coarse-bubble aerators. These are available either in plate design or as stainless steel tube aerators. Used in the grit chamber of a sewage treatment plant, in sludge stabilization basins or as post-aeration, they offer the possibility of passing large air volumes and thus circulating the medium in the best possible way or ensuring a certain oxygen concentration in the effluent. In addition, the aerators can be used in aeration tanks to induce vertical flows and thus prevent sludge deposits on the tank bottom. This type of aerator, when operated continuously, can be regarded as completely maintenance-free.JetFlex® CBD 105 (Disc Diffuser)

- Diameter of 105 mm

- Air outlet or perforation on the bottom of the support body

- Silicone membrane as well as a supporting body made of glass fiber reinforced plastic for highest chemical and thermal resistance

- Also suitable for intermittent operation

- Check valve (optional

JetFlex® CBD SS (Tube Diffuser)

- Available in two standard lengths of 335 mm and 630 mm

- Made of stainless steel and applicable in highly corrosive waste water

- Reliability even in the highest temperature ranges

JetFlex® Tube Diffuser

- JetFlex® TD Tube Diffuser (TD Series)

The JetFlex® TD series of tube air diffuser is a fine bubble aeration system that uses compressed air. Our tube diffuser combine cost-effective design, low installation and maintenance costs with reliability, durability and efficiency. They are suitable for both intermittent and continuous operation. We also offer replacement membranes to increase efficiency in existing aeration systems.The advantages of our JetFlex® TD tube diffusers at a glance:

- Different perforation types adapted to the operating conditions and requirements

- Precise slits for high oxygen input and low pressure drop

- Low pressure loss due to the grooved polypropylene carrier pipe

- Implementation of high occupancy densities possible

- Active length from 200 — 1200 mm with a standard length of 500 mm, 750 mm and 1000 mm

- The combination of different lengths enables a uniform installation even in unusual pool geometries and round pools

- Standard diameters of 65 mm and 90 mm

- Assembly or connection to round or square steel pipes possible

- Wide range of connection options for steel and plastic pipes — thanks to a comprehensive range of accessories

- Reliability even in the highest temperature ranges

- Production from standard and special materials: EPDM, silicone and PUR Softener-free membrane made of silicone and PUR

- Standard diffuser are available from stock

- Quick and easy installation — even during operation

JetFlex® Strip Diffuser

- JetFlex® SD Strip Diffuser (SD-Series)

The JetFlex® SD strip diffuser completes our product range in the field of fine-bubble water aeration for sewage treatment plants. The high-strength polyurethane membrane with micro-perforation offers maximum service life with maximum efficiency. In addition, the design has been optimized for operational safety, durability, easy installation and handling.- By coupling the standard lengths (1.5 m, 2 m, 3 m and 4 m), different aerator lengths in 500 mm increments up to a total length of 8 m can be realized — in the highly efficient range and with only one air connection

- Implementation of high occupancy densities possible

- Specially developed non-return valve reliably prevents water and sludge from entering the aerator and at the same time allows gentle relief of the membrane

- The combination of different lengths enables a uniform installation even in unusual basin geometries and round basins

- Easy installation on the basin floor due to the corresponding fastening system

- Integrated pipe socket allows easy connection using standard couplings

- Various mounting options: height-adjustable to compensate for unevenness and suitable for lifting on a frame construction

- Low maintenance necessary / Easy maintenance by air

- Softener-free membrane made of PUR

- Quick and easy installation — even during operation

- Standard aerators are available from stock

JetFlex® Disc Diffuser

- JetFlex® HD Disc Diffuser (HD-Series)

An important element in biological treatment plants is the aeration system. The JetFlex® HD disc diffuser series is a fine-bubble aeration system operated by compressed air. It is used worldwide in municipal and industrial wastewater treatment plants. Our disc aerators combine low design, installation and maintenance costs with reliability, durability and efficiency — for intermittent and continuous aeration. The disc aerators can be equipped with an optional check valve that prevents backflow of sludge water into the pipeline even if the diaphragm is defective. To increase the efficiency of existing aeration systems, we also offer retrofit kits and exchange membranes.JetFlex® HD disc diffuser also offer the following advantages:

- Different perforation types according to operating conditions and requirements

- Precise slits for high oxygen input and low pressure drop

- Active diameters from 184 mm, over 218 mm to 295 mm

- Selection of standard and special materials: EPDM, silicone and FKM

- Softener-free membrane made of silicone

- Glass fiber reinforced plastics for highest chemical and thermal resistance

- Check valve (optional)

- Wide range of connection options for plastic and steel pipes thanks to extensive range of accessories

- Standard diffuser are available from stock

- Quick and easy installation — even during operation

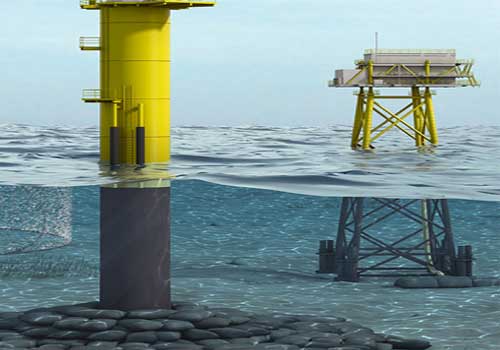

Marine Technology

- As the newest member of the JÄGER Group, Jaeger Mare

Solutions GmbH works on the topics of scour, corrosion and noise protection

for offshore wind energy, the maritime industry and marine technology.

We provide resource-saving and environmentally friendly solutions for the maritime sector. These include both our hose systems such as the bubble curtain for reducing underwater noise during offshore construction work and our innovative products made of sustainable materials such as basalt for offshore structures. In addition to the finished component, we also offer you a complete service — from the initial idea to tests in the water and product use on the high seas.

Scour Protection

- Scour protection: basalt bags

We offer you individual protection from being washed out or undermined in the sea and also in inland waters — with our Jäger Mare Solutions basalt bags. The application possibilities of basalt bags are endless — we think ahead together with you. Developed for offshore applications, the potential behind the idea is becoming increasingly apparent.Offshore wind turbines in particular are faced with the challenge that the ocean currents erode the soil layer around the foundation. This process is usually counteracted with the backfilling of stones.

However, the challenge cannot always be solved in this way. Sometimes the right rock is not available in the region in question to stop the scouring process.

Jäger Mare Solutions basalt bags are a flexible and environmentally friendly solution. The bags are made of a specially developed basalt fabric and are conveniently filled with round gravel or sand on site. Besides the application as scour protection, our Jäger basalt bags can also be used for the weighting of submarine cables or pipelines and as fixation in dike and coastal construction.

Your advantages of our Jäger basalt bags:

- High inertia of the filled bags

- Flexible filling of the bags on site

- Rock independent

- Easy installation Temperature resistant from ‑260°C to 800 °C

- 100 % UV-resistant No rotting of the natural tissue

Corrosion Protection

- Basalt fiber protectors for offshore plants

Jaeger Mare Solutions manufactures durable protectors from a composite of basalt fabric, which protect steel structures in the offshore sector both against corrosion and mechanical stress. At the same time, the increased friction between the steel structure and the rubber fender caused by the protector promotes safe climbing over for technicians. Thanks to the long service life of our protectors you reduce your maintenance costs many times over.Boatlandings of wind turbines are exposed to particularly high loads — maintenance boats damage the surface coating of the boat landing during docking due to the up and down movement caused by waves.

Hunters Mare Solutions protectors provide a remedy: The hard shells made of basalt fabric and vinyl ester resin are attached to the fender tubes with an adhesive specially manufactured for this application — similar to a shin guard. This can be done both on- and offshore.

Since basalt is a natural product, it is also non-toxic and therefore absolutely future-proof. Hunter’s protectors have to be as well, because even in cold salty sea water and under high UV exposure our protectors have a very long life span due to the basalt fabric.

Your advantages thanks to our JÄGER protectors:

- Cost-efficient by reducing maintenance costs

- Abrasion-resistant: long-term protection against mechanical damage

- UV-resistant

- Flexible installation both on- and offshore

- Individually definable length and color possible

- Safe passing of the technicians

- Corrosion protection

- Shock absorbing at mechanical loads

Noise Mitigation

- Noise protection system: Bubble curtain

Jaeger Mare Solutions GmbH will provide you with a noise mitigation system tailored to your requirements. In addition to the proven conventional Big Bubble Curtain (BBC), we offer you two novel systems for reducing underwater noise.

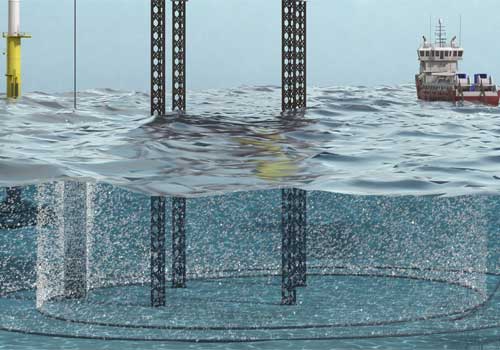

Underwater jobs such as laying foundations or detonations of munition can cause substantial sound emissions. Particularly the construction of offshore wind turbines causes noise which can adversely affect sea dwellers. With its Big Bubble Curtain, Jaeger Mare Solutions contributes to the protection of marine animals during rammings of the heavy offshore foundations. For the benefit of the kind-protected porpoises, differently defined noise level limit values must be adhered to. The goal of Jaeger Mare Solutions is not merely the adherence to these values but a general minimization of sound emissions.The Big Bubble Curtain

The Big Bubble Curtain is comprised of one or two hoses which are laid out in a ring around the source of noise. The perforated hoses are pressurised with compressed air – bubbles emerge from the sea-bed to the surface of the water which create a ring-shaped protective wall around the noisy construc-tion site. With the help of the bubble curtain the sound waves extensively spreading over the seabed are broken multiple times, decreasing the sound intensity and thus protecting the marine animals. After deployment, the hose system is retrieved and brought to the next construction site.The Jaeger CBC

Our Conducted Bubble Curtain ensures less noise in the direct vicinity of the ramming point. Jaeger Mare Solutions is currently developing a flexible Conducted Bubble Curtain which is directly attached to the steel rod rammed into the seabed and which creates a dense net of air bubbles. This reduces the noise of the over 1000 required rams directly at the source while ramming the pile into the seabed.The Jaeger BBC

With our new hose system, which is still under development, we can achieve the same noise mitiga-tion performance with substantially less pressure. For this reason, Jaeger Mare Solutions employs a technology developed for waste water treatment which has been tried and tested for 40 years at Jae-ger Umwelttechnik. With our innovative Big Bubble Curtain, we want to protect the marine animals, encourage the development of renewable energies, and reduce the costs for our customers. This is achieved with an improved bubble performance and the reduction of the required compressors.

Textile Fixed Bed

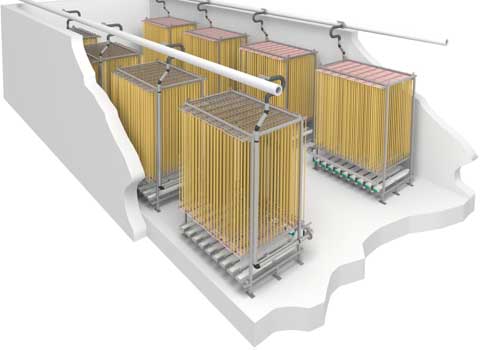

- Cleartec® Textile Fixed Bed

Jäger Group provides with Cleartec IFAS system a high performance and low footprint solution to im-prove treatment capacity of municipal and industrial wastewater treatment plants. The technology combines the best of activated sludge and biofilm process in a single step and is capable of achieving very high COD/BOD and ammonia removal rates. The system can also be easily configured for full Bio-logical Nutrient Removal.How does it work?

CLEARTEC® IFAS system enhances the performance of a conventional biological process by increasing the active biomass concentration to a quantity that is not achievable in a conventional activated sludge system. With its surface roughness and flexibility, Cleartec Fixed Bed provides a very high surface area for active microorganisms to grow without flow restrictions. The biofilm attached to the textile in-creases the microorganisms concentration in the aeration tank leading to improvements on existing wastewater treatment efficiency without additional plant footprint Cleartec media is held in place by rigid support structures, ensuring no risk of media washout into dis-charge streams. Aeration and media scouring is provided by high-efficiency fine bubble diffusers.Advantages at a glance

- Improvements on treatment performance of existing plants

- Modular construction

- Reduction of plant footprint for new projects

- Increased Biological Nutrient Removal (BNR)

- Easy Retrofit – simple to install High operational stability, increased resilience to hydraulic and loading shocks

- Improved sludge settleability (typical SVI’s lower than 80)

- Low maintenance effort, no cleaning necessary

- High energy efficiency, up to 50% less energy than other MBBR/Moving Bed IFAS systems

- No blocking or fouling

- No flushing out of growth media

Cleartec® BioCurlz

- Cleartec®

BioCurlz

Cleartec® offers an attached growth media in the shape of a synthetic textile which is waste water resistant. The material is either Polypropylen (PP) – Biotextile or a combination of PP and Saran (PVdC) — BioCurlz. In order to keep the media in the system, the textile is fixed to e.g. a Stainless Steel module. Nevertheless the media is able to move due to the textile nature. The increased biomass produced by the curl-like textile enables biological wastewater treatment on a small surface area.Material

69% polyvinylidene chloride yarn 31% polypropyleneLength

customer-specific, max. 3.5 mWeight

approx. 11 g/m, plus pair of holding stripsTextile

cord-shapedHolding bars

Injection molded plastic, reinforced with stainless steel Presentation 6 cords per retaining bar unitField of application

Biological stage of a sewage treatment plant, municipal, Industrial, special applicationsService features sludge properties

SSVI = approximately 80–100 ml/gCapacity increase

more than 50 % through additional biomass (no expansion necessary)

Cleartec® Biotextil

- Energy-efficient wastewater treatment with textile

high-performance fixed bed — for municipal and industrial wastewater

Biological wastewater treatment with textile fixed bed

Cleartec® Biotextil is a textile growth carrier for microorganisms and is used for expansion or perfor-mance enhancement in municipal and industrial wastewater treatment plants. It is also used for space-saving biological treatment or pre-treatment of industrial waste water directly in the plant. The high efficiency enables a very compact design when constructing new sewage treatment plants. Cleartec® Biotextil is made of Polypropylen (PP).Its flexibility, highly structured, large active surface and high resistance to chemicals relevant to wastewater technology make it an excellent material for supporting biological activity in wastewater treatment plants.

Biological wastewater treatment in combined process

The Cleartec® Biotextil system is usually operated in a combined process. This means that both the suspended biomass as in the normal activated sludge process and the so-called sessile biomass fixed on the biotextile contribute to the cleaning performance.The advantages of Cleartec® Biotextil at a glance:

- Structured growth surface with large surface area

- Built-in cage

- Stable discharge values with very good BOD and nitrogen elimination

- Particularly energy efficient due to optimal flow

- Fixed bed and aerator can be controlled by liftable support frames

- No blocking due to flexible structure

- Active together: suspended and sessile biomass

- Increased performance for existing plants

- Relief of the secondary clarifier

- Reduction of investment and operating costs

Cleartec® Module

- Cleartec® Biotextil and BioCurlz are used as fully

submerged fixed beds in the biological stage of a wastewater treatment

plant. The media are fixed in a stainless steel module that can be mounted

above an existing aeration system or with integrated diffuser. The module

dimensions are influenced by the required amount of Cleartec® Media and the

aeration tank geometry. The modular design of Cleartec® provides an easy to

install and low maintenance system.

The Cleartec® module consists of:

1. Stainless steel module

The stainless steel module serves as a supporting structure for Cleartec® Media (Biotextile and BioCurlz). The biotextile panels are fixed in the module by support tubes which are built into fixing loops. Each biotextile sheet has up to four loops, depending on the total material length. BioCurlz are fastened in the module by metal-reinforced support rods.

2. Cleartec® growth media

The textile structure of Cleartec® BioTextile and BioCurlz offers a large surface area and high roughness. It supports ideal conditions for the growth of biofilms. The textile flexibility associated with the air flow generated by diffuser regulates the biofilm thickness and prevents media clogging.

3. Diffuser

Fine bubble aeration diffuser are installed underneath Cleartec modules and the textiles. The diffuser have two functions to supply microorganisms with oxygen and to create a vertical flow. This vertical flow helps to control the biofilm thickness and contributes to its constant regeneration. It easily removes parts of the old biofilm and provides space for new active microorganisms to attach themselves to the media.Advantages of the Cleartec® module for wastewater treatment

- Optimal growth conditions of the biomass

- Easy handling of the individual modules — even during operation

- Durability and time saving through maintenance-free operation

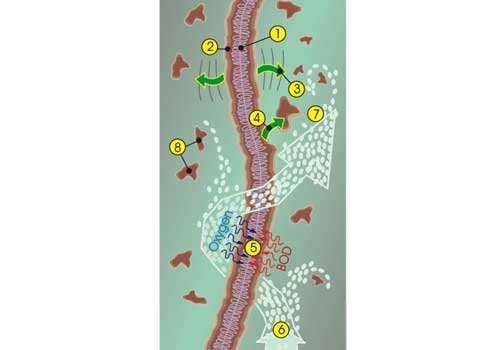

IFAS-Process

- IFAS systems in waste water technology

An IFAS process (Integrated Fixed Film Activated Sludge) combines the advantages of conventional activated sludge with those of biofilm systems by combining the two technologies in a single reactor. In an IFAS system, synthetic media are used in the activated sludge tank as growth area for additional biomass. This combination allows a much higher biomass concentration and sludge age compared to conventional activated sludge processes.

The solid biomass also helps to improve the resistance of the system to organic or hydraulic shock loads. Our IFAS technology has been integrated into municipal and industrial wastewater treatment plants to modernize existing systems (improving treatment capacity and wastewater quality) and reduce the space requirements of new plants (by optimizing the aeration tank volume). With the IFAS process, an increase in treatment capacity of up to 100 percent can be achieved without construction work.The process with Cleartec® Biotextil

1.Cleartec® Biotextile

2.Biofilm

3.flexibility

4.Removal of surplus

or completely mineralised biomass- absorption of oxygen and pollutants

- fine-bubble

- aeration aeration flow / turbulence

- suspended biomass

Rubber

- Started as a »Gummi-Jäger« in 1942, the JÄGER Group has been at your side for over 75 years with its broad specialist knowledge and many years of experience in the rubber sector. Discover our wide range of rubber products!

Rubber Solutions

- The success of our company is based on the material

rubber — benefit from our many years of know-how and our own mixing plant.

Our chemists are very familiar with the material properties of rubber and

the various manufacturing processes such as compression molding, transfer

molding and injection molding.

We produce rubber products for sealing and damping worldwide. In the field of sealing technology we produce rubber profiles, O‑rings, molded rubber parts and foams. The latter two products are also suitable for insulation and damping. Our rubber hoses are also used in a wide variety of industries. The flexible hoses can be used to transport liquids or solids. Our products are not only used in industrial applications, but also in professional sports. For example, we also manufacture billiard boards for tournament tables from high-quality natural rubber.

- The success of our company is based on the material

rubber — benefit from our many years of know-how and our own mixing plant.

Our chemists are very familiar with the material properties of rubber and

the various manufacturing processes such as compression molding, transfer

molding and injection molding.

Power Transmission

- The field of drive technology includes all elements for

the transmission of power and motion between different shafts. This

transmission enables, for example, an effective speed conversion, the

control of motion sequences in industrial production facilities or the

general transport of goods. The JÄGER Group offers a wide range of products,

especially for the area of belts and tapes made of rubber, plastic and

various material combinations. In contrast to chain drives, which have a

high degree of efficiency but do not allow any twisting within the system,

belts and bands offer a significantly lower noise development with low

maintenance. For these reasons, they are used in mechanical and plant

engineering, the packaging industry as well as in the equipment and

agricultural machinery industry, among others.

Non-positive drive elements

If the energy in a technical system is transmitted by the frictional forces generated between belts and driving wheels, this is referred to as non-positive drive elements. These are used wherever no synchronous movement of the elements is required and the drive may or should have slip. For this area we offer, among others, V‑belts, V‑ribbed belts and flat belts.flat belts have a rectangular cross section and, like all non-positive drive elements, transmit energy exclusively via frictional forces. The contact surfaces of the associated drive wheels usually have upwardly curved or raised edges to prevent the belts from slipping off the pulley.

V‑belts are characterized by their easy installation and long service life and allow a high transmission ratio. They are available with sheathed or open-flank design and offer higher transmittable power than flat belts.

V‑ribbed belts have individual ribs which run lengthwise to the belt itself. The larger contact surface on the V‑belt pulley results in greater friction and thus a higher power transmission than with ordinary V‑belts. They are very well suited for the simultaneous drive of auxiliary units.

Billiard Cushions

- Artemis tournament billiard cushions made of rubber

In the billiard sport there are up to 35 different types of games, which take place on tables of different sizes. In pool billiards, the game is usually played on billiard tables measuring 2.54 meters by 1.27 meters. The increasingly popular game of snooker in this country is played on larger tables. In addition to the selection of billiard balls and cloth, the quality of the rubber cushions is crucial for the game.Artemis billiard cushions are in demand from national billiard associations as well as from renowned table manufacturers. Our profiles can easily be glued to the billiard table and guarantee precision in the course of the game at tournaments and thus objectively comparable game results.

Our billiard cushions are — in contrast to many cheaper products — provided with two cotton fabric pads during production and heated in molds. This guarantees a synchronous run over the entire production length.

The materials used, BIBA RED, TBB GREY and KHF GREY, consist mainly of high-quality natural rubber. Additives according to our formula give the rubber mixture its special suitability for the game of billiards and excellent resistance to ageing.

Freehand Products

- Freehand rubber articles are all parts that are handmade

from intermediate products by grinding, sawing, turning, milling and

drilling. Accordingly, no metal molds are used for this manufacturing

process to represent the required dimensions and geometries. We envisage

freehand rubber articles when the costly production of molds is not

profitable or when a special molding is required for test parts or small

quantities. Freehand articles are also produced in series as rubber elbows,

hose rings and turned parts.

The processing of plates, blocks, tubes, hoses and solid rods is done by hand using mechanical aids. Sophisticated production techniques and qualified personnel guarantee high quality and constant dimensional accuracy. Due to their extensive design possibilities, freehand articles can be used in the most diverse areas. These include general mechanical and plant engineering, pump technology or agricultural technology.

Rubber bends

Bends made of rubber are used in systems where the directional flow of gases or liquids is to be diverted. When choosing the right material, rubber offers the advantage over metal manifolds that it can also be used to transport corrosive fluids. In addition, a certain degree of flexibility can be guaranteed with reliable dimensional stability.

Rubber Molded Parts

- For the production of rubber molded parts, plastic rubber

compounds are placed in specially designed metal molds. The desired geometry

is first formed by pressing or injection, and then the mixture is stabilized

by vulcanization. This process gives the material its specific elastic

properties.

Rubber molded parts are particularly suitable for damping, sealing, insulating and protecting and thus offer almost unlimited application possibilities. They can be found as rubber buffers, seals and much more in all areas of mechanical and plant engineering, the electrical and vehicle construction industry, energy technology as well as agricultural and environmental technology. Most molded rubber parts are not standard or norm parts, but are developed for specific functions in close cooperation between our product development team and our customers and then manufactured to order.Multifunctional

Molded rubber parts are elastic, pressure-resistant and abrasion-proof as well as mechanically and chemically resistant. The respective operating conditions and the desired function determine the choice of material and the type of manufacturing process. Each manufacturing process has specific characteristics and must therefore be precisely matched to the order to be produced and the associated purchase quantities. We can map both individual and series production as well as mass production within the JÄGER Group or via our strategic partners.

For the production of rubber molding parts we have, in addition to conventional vulcanization presses in which displacement and transfer molds are used for the compression molding process (CM) and the transfer molding process, injection presses for the injection molding process (IM) of the most modern design. Material, production process and production method are coordinated in such a way that an economic optimum in production and application is achieved. Among other things, the use of cold runner technology contributes to this, which also helps to protect the environment and conserve resources.Customized

Molded rubber parts are subject to the influence of changing media, temperatures and climatic conditions, mechanical stresses or ozone and UV exposure from solar radiation, which limits their useful life and service life. In order to guarantee high quality, we rely on our own material development and production.

For this purpose, we carry out mechanical and dynamic tests, vulcanization and processing tests as well as material and damage analyses in the development laboratories of the JÄGER Group. For further analyses (e.g. electron microscopic examinations) we cooperate closely with the German Institute for Rubber Technology (DIK) in Hanover.

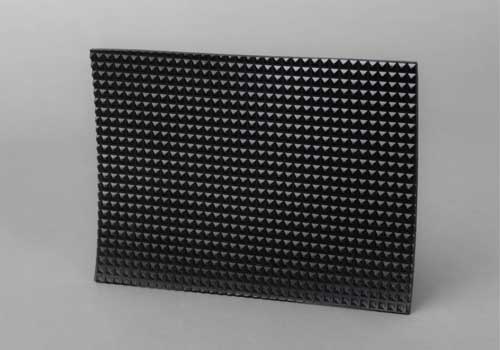

Rubber Mats & Rubber Sheets

- At first glance, elastomer or rubber mats appear to be

comparatively simple semi-finished products, but they reveal enormous

potential for all areas of industry. They are used for protection against

abrasion, for the insulation of vibrations or also for electrical

insulation. For occupational safety, rubber mats and rubber sheets are used

as anti-slip underlays in almost every production area. The materials,

thicknesses or surfaces used are directly adapted to the respective areas of

application. These range from general mechanical and plant engineering to

fittings and apparatus engineering to the chemical and electrical

industries.

Cushioning mats

Cushioning mats and panels are usually made of rubber granulate or cellular materials. These are used to decouple machines and systems and are intended to minimize the vibrations generated during production. The damping of vibrations contributes to the protection of the machine environment as well as to a longer service life of the actual plant. It also reduces the maintenance requirements of susceptible components, which can significantly reduce the associated costs.We supply rubber mats in the following designs:

- Rubber sealing plates

- High pressure sealing materials

- Rubber mats made of cellular materials (cellular and sponge rubber, polyurethane and silicone foams, foams)

Rubber Profiles

- Rubber profiles are produced endlessly by extrusion. For

this purpose, the unvulcanized rubber mixture is plasticized in extruders

and brought into the appropriate cross-sectional geometry by means of

attached extrusion tools (mouthpieces) in the extrusion head of the system.

The mouthpieces can be adapted as required to produce different profile

cross-sections, so that the right geometry can be realized for every

application. The profile is dimensionally stabilized by subsequent

vulcanization. Vulcanization in a steam boiler or salt bath is used here, as

well as hot air vulcanization, UHF production or IR shock vulcanization.

Rubber profiles are used for protection or sealing in vehicle construction,

the construction industry and general mechanical engineering, among others.

Individual

In the case of dynamically stressed profile seals, we calculate the necessary contact pressure forces and then adjust them specifically by means of hollow chambers or foam structures. The necessary overlap or the gasket stroke can be numerically optimized by means of FEM analysis. These special designs are supplemented by a wide range of standard profiles.- full profiles made of one material

- duplex or n‑plex profiles made of several materials or hardnesses

- Foam rubber profiles and soft rubber profiles and their combinations

- Edge protection profiles with and without sealing and covering elements

Finishing techniques

To improve the handling and to facilitate further processing, we offer various finishing options.- Simplified handling of small parts through kiss-cut punching to the liner

- Unique identification of the components through multicoloured liners and printing

- Partial notching and exact cutting to length to achieve tight bending radii of circumferential seals

- Injection of mould corners in elastomer or TPE

- Functional surfaces through flocking and bonded coatings

- connection of cut surfaces

Rubber Hoses

- Rubber hoses are used in various industrial areas. In the

first instance they serve as flexible means of transport for fluids or

solids (as granulate or powder) and thus offer a decisive advantage over

static pipes made of metal or plastic.

The properties of the material rubber open up a wide range of applications for hoses in the most diverse fields of application. Whether elastic and abrasion-resistant or mechanically, thermally or chemically resistant, the specifications of rubber hoses are virtually unlimited.

Where the material reaches its limits, it is also possible to extend the existing properties with textile inserts or metallic reinforcements. Technical hoses are usually standardized industrial products that are standardized according to DIN or ISO.

The JÄGER Group offers a comprehensive range of hoses for all areas of application and supplies hoses for pressure and vacuum stress in practical dimensions, wall thicknesses and lengths with and without fittings. This diversity enables reliable use in agriculture and the food industry (e.g. dairies) but also in gravel plants, mechanical engineering and pipeline construction.Different hose variants

Since both the design and the materials and manufacturing processes used for a hose must always be precisely adapted to the existing conditions of the application, there is no hose that can meet all requirements and loads at the same time. For this reason, we advise you from the very beginning in order to precisely understand the challenges facing the component and to achieve the desired goal together.Mandrel heated molded hoses

Narrow bending radii and limited installation space require the use of pre-bent shaped hoses produced in the mandrel heating process. Hoses manufactured on mandrel are extruded or wound. These usually have only very narrow dimensional deviations in the inner and outer diameter and are therefore suitable for applications which only allow very narrow tolerances. On customer request we develop hoses of any length and diameter. By means of injection molding, form-bound branches and fittings can be vulcanized on.We supply rubber hoses in the following designs:

- Hoses without inlay — for simple applications

- Hoses with textile or metal reinforcements — dimensionally stable and pressure-resistant

- Hoses with spirals or rings and ribbed on the outside — for suction operation and additional flexibility

- Hoses with rings — compressible to a certain degree

- Hoses with braided or spiralled metal reinforcements — for very high pressure loads

O‑Rings

- O‑rings are used in all systems as reliable elements of

sealing technology. These are endless rings with a round cross section which

are manufactured as molded parts from rubber (partly also from plastic). The

possibility of axial or also radial sealing of different fluids (gases and

liquids) distinguishes the simple and robust components.

Here, the JÄGER Group has a wide range of different materials and dimensions at its disposal so that the correct parameters are available for every application. With the correct groove design and material selection, a seal can be used for a long period of time, both stationary and moving, within the temperature limits of the material. The advantage of O‑rings is that they are easy to install and require little installation space.O‑rings made of EPDM and NBR

As with all technical products, there is no universal solution for O‑rings for all applications. The material as well as the dimensions and assembly of the O‑rings must be adapted to the respective overall system and the given influences. If an assembly is exposed to external weather conditions, the material EPDM (ethylene propylene diene rubber) has become established.Since EPDM is highly resistant to ozone and ageing and also has good resistance to cold temperatures, the material is predestined for such areas. However, EPDM has no resistance to mineral oil-based media and swells strongly under their influence. In this case, NBR (acrylonitrile-butadiene rubber) is the ideal choice, as this rubber is highly resistant to greases and oils based on mineral oil.

We supply O‑rings in the following designs:

- Shore hardness from 40 to >90 ± 5 Shore A

- Black or colored

- with or without coating, e.g. siliconizing, PTFE-coating, graphitizing, molycoating, talcumizing, painting

Foams

- Foams are materials with a porous structure and the

associated low density of rubber or plastic. The low specific weight and

good compressibility open up a wide range of applications for foams.

Porous materials such as silicone foam, cellular rubber, sponge rubber as well as foam rubber offer a resistant supplement to solid materials and are excellent for insulating or sealing. For this reason, foams are widely used in vehicle construction, mechanical and plant engineering, medical technology, energy technology, the electrical industry, communications and agricultural technology.Production

Foams are produced with or without pressure, depending on the process. Foaming is achieved by mechanical or physical processing or by a chemical reaction using blowing agents. The selected process and the raw material composition of the materials have a decisive influence on the achievable density of the foams, as they have an open, closed or mixed cell structure after production. The processing can be done by extrusion or injection molding. Prefabricated sheet products are often die-cut.Common to all foams is the low weight, due to the low density. Parameters such as restoring force, compression set (DVR), water absorption capacity, acoustic decoupling, shock absorption, damping and insulation capacity sometimes differ greatly.

Compression behavior

Usually, rubber components are incompressible in a firmly installed state if there is no room for them to escape when force is applied. An exception, however, is in the form of foamed elastomers. Due to the cellular structure of the material, the space required for displacement within the pore structure itself is provided, allowing compression even in fully filled spaces. This property predestines foams for sealing and insulation applications where no other material can offer an alternative.

Punched Parts & Blanks

- tamped parts and blanks made of rubber (also of plastic

or composite materials) are used in all industrial plants and machines.

Among other things, they serve as seals, supports, wipers and dirt traps and

are usually produced by machining semi-finished products. In particular,

rubber flat seals, which are manufactured, for example, on punching

machines, water jet cutting machines or plotters, offer extensive

application possibilities. They are intended to compensate for gaps that

occur on surfaces that come into contact with each other and provide a

secure seal against media from inside and outside.

The starting materials are mainly sheets of various mostly elastic materials with and without inlays or mats with surface design. In addition to the standard designs with grooves or burls, we also offer customer-specific surface patterns. In addition to the solid materials, porous materials such as cellular rubber, sponge rubber, polyurethane and silicone foam can be used excellently for various sealing requirements. Stamped parts and blanks can be found in all areas of industry. They are produced for mechanical and apparatus engineering, the food industry, pipeline construction, the electrical engineering industry, vehicle construction or agricultural engineering, among others.Processing of flat semi-finished products — water jet cutting

In contrast to the usual punching process, the manufacturing process of water jet cutting offers the advantage that it is particularly suitable for soft or multi-layer materials. In addition, materials of varying hardness and fine geometries can be processed. Plates lying flat on a metal grid are cut with a precisely directed thin water jet. The large number of different materials and the large differences in the number of stampings and blanks require specific production facilities. We therefore rely on strategic supply partners who complement our in-house production for projects with small quantities and specific manufacturing processes.Refinement

Various finishing techniques can be used to significantly extend the possible uses of stamped parts and blanks. To facilitate component handling and reduce assembly work, the following techniques, among others, can be used- laminating of foils

- Lamination of adhesive systems

- Punching of multi-layer pull-off flaps

- printing

- Assumption of the scope of assembly

Plastic

- Started as a »Gummi-Jäger« in 1942, the JÄGER Group has been at your side for over 75 years with its broad specialist knowledge and many years of experience in the rubber sector. Discover our wide range of rubber products!

Plastic Solutions

- We are very familiar with thermoplastics — discover

our molded parts, profiles, semi-finished products, plugs and hoses made of

plastic. Our strength lies in the production of molded parts made of

plastic.

Our strength lies in the production of molded plastic parts. Due to their specific properties such as low weight, good formability, high chemical resistance and high design freedom, plastic moldings are increasingly replacing metal components. Glass-fiber reinforced plastic moldings achieve outstanding strength. In the field of plastics technology, we are a leader in plastic profiles — our profiles are used in the construction industry, recreational vehicle construction, mechanical engineering applications, plant construction, the electrical industry, agricultural engineering and the wind energy sector, among others. Our hoses are also used in almost all areas of industry. In addition to our standard range, we develop individual, flexible industrial hoses together with our customers, for example sterile hoses for the pharmaceutical industry and heat protection hoses for electrical and hydraulic lines. Together we will find the right plastic for your requirements, whether mechanical, electrical or thermal.

Flip ‘N Seal®

- Flip ‘N Seal Slide-Out Sealing System®