- Offer Profile

-

SYSTEM INTEGRATOR AND SERVICE PROVIDER

With over 50 years of experience in intralogistics, we support you in increasing the efficiency and performance of your systems and in simplifying complex tasks. We implement individual solutions tailored to your needs. With the viadat warehouse management system (WMS) we offer a future-proof standard software for the administration and control of the entire material flow in warehouse and production.

Warehouse and Material Flow Solutions

Stacker Cranes

-

viapal, viaspeed, viaspeed XL - storage and retrieval systems from viastore

The storage and retrieval cranes exclusively from viastore are the perfect solution for your warehousing needs. No matter whether you only need the stacker crane itself, an associated control system via PC or PLC - or a complete logistics system with transfer stations and conveyor technology, viastore can help. You define your needs, we deliver the solution. This includes reliable service, starting with planning, designing, and installation continuing into a lifetime partnership. Our service offers round-the-clock monitoring and support plus continuous maintenance and modernization of your storage and retrieval systems. viastore solutions offers you maximum flexibility in the technical design of stacker cranes. With numerous adaptable options for load handling devices, you can precisely and effectively manage any type of goods. The ASRS cranes can pick up loads that are stored single or multiple deep in the rack, with several load handling devices, as a single-mast or double-mast solution.

viapal is a high-bay stacker crane that can handle aload weighing up to 6,600 lbs. It can be equipped to handle a wide variety of goods- regardless of the height of your warehouse or the storage position of your goods. Using viapal, you always have easy access combined with high performance. The dynamic travel drive with vibration-optimized travel curve enables travel speeds of up to 787 ft/min.The high-quality, durability components of this pallet crane ensure low maintenance costs. The viapal can be used in multiple areas ranging from sorting, production and assembly buffers, manufacturing,shipping/receiving, spare parts and flow storage etc.. In every application, you benefit from the modular design: It makes the storage and retrieval system inexpensive to purchase and has a short lead time to commissioning.

Benefits:- Ideal for Tall Buildings

- High Payloads

- Energy Efficiency

- Energy Balancing

- Energy Recovery

- Automatic Stand-by Mode

- Low Costs

- High Flexibility

Frozen Warehouse

- AUTOMATED FROZEN WAREHOUSE SIMPLIFIES COLD CHAIN COMPLIANCE

- Ensuring the cold chain

- Continuous monitoring of your stored goods

- Lower energy costs due to consistent cooling

- Higher storage volume

- Higher turnover of goods with reduced stocks

Temperature-controlled warehouses can become real energy guzzlers if they are not carefully planned and managed. Temperatures as low as -40° F put a considerable strain on employees and limit working hours in the deep-freeze area to a minimum. In manual warehouses, a lot of cold is lost when the industrial trucks move in and out causing energy costs to rise. In addition, forklift trucks require more space for maneuvering because the racks cannot be built nearly as high.

The most efficient, and in the long term, the most economical solution is an automated cold or frozen warehouse. It enables a higher storage density, smaller storage area, constant temperature and thus significantly lower energy costs. Additional benefits are faster and therefore more frequent turnover of goods, the continuous and transparent monitoring of processes and stored goods, lower personnel and administrative expenses which all increase your profit.

Highest efficiency for your warehouse with a WMSSensitive goods, compliance with an uninterrupted cold chain, and temperatures well below freezing – working in a deep-freeze warehouse presents many challenges. The requirements for such a warehouse are just as demanding: cold-resistant technology, high storage density and energy efficiency, short throughput times with minimal error rates, and seamless tracking of goods.

The automated frozen warehouse is controlled and managed by a warehouse management system. The software maps all processes and enables a high level of transparency and traceability of the stored goods, including the management of batches, best before dates and serial numbers. In addition, the WMS ensures that every product is in the right place at the right time, from goods receipts to storage and picking to shipping. This keeps the cold chain intact, unnecessary goods movements are avoided and energy is saved.

Warehouse systems with SAP EWM

-

Integration of the complete intralogistics in SAP

- Simplification of logistical processes

- Flexible and diverse design of core processes

- Linking people, terminals and information

- Management of batches & serial numbers

- Management of hazardous substances

In 2017, viastore SYSTEMS and prismat GmbH, an expert for SAP solutions in intralogistics, entered into a strategic partnership. The aim: to offer users of automated material flow and logistics systems the advantages of both worlds. SAP EWM (Extended Warehouse Management) supports you in all processes and functions of warehouse logistics - from goods receipt to goods issue, delivery processing, goods receipt and dispatch, and batch management. Whether viadat or SAP EWM: Both products can be used worldwide, meet the highest performance requirements and offer global coverage and support.

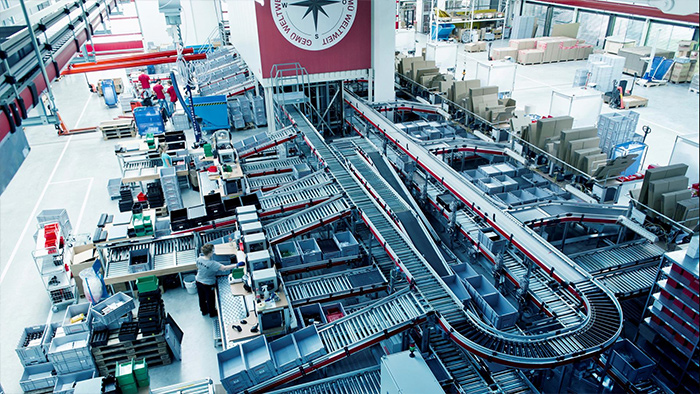

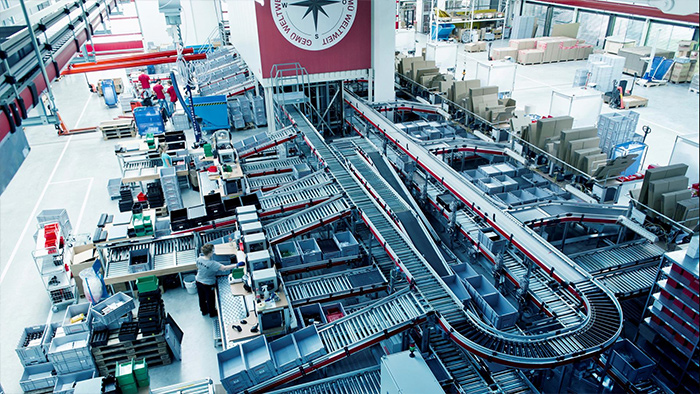

Distribution Center

-

Our Approach: Analysis - Consulting - Appropriate technology

Your dedicated project engineer will work with you from planning phase right through to commissioning. We support you in the construction of your new distribution center. Regardless of the technology, we offer you customer-oriented advice tailored to your specific requirements. Our goal is to help you make the best possible decisions to create an efficient and state-of-the-art distribution center. From planning to the selection of suitable products and commissioning, we are at your side with our expertise and experience. Our holistic approach guarantees you smooth implementation and maximum efficiency in your distribution process.

- Storage solutions

- Sortation solutions

- Order preparation

Warehouse Modernization

-

Improve reliability, uptime and customer satisfaction

- State-of-the-art technology

- Optimized processes

- Reduced downtime, risks, logistics costs, energy costs and human errors

- Increased efficiency, uptime, order processing, throughput and quality

- Spare parts availability

Business models change. To remain competitive, logistics facilities and processes must be adapted to the new demands of the business. With a retrofit, your intralogistics process will remain up to date via hardware and/or software upgrades and services to keep your system running optimally.

If your system has been in use for a long time, maintenance or service measures are often no longer sufficient. Parts on the equipment may be obsolete, software may no longer be supported, and information is not readily available – all of which puts you at risk. The first step for modernizing your system is a comprehensive analysis of the current condition. Based on this, we collaboratively define goals, identify potentials for optimization and create a concept tailored to your individual requirements. The focus is on the optimal interaction of the old with the new. Scheduling of the work required for the upgrade will be planned to have minimal disruption to your business.

Future-proof your automated systemAs systems age, the availability and reliability of the system decreases while maintenance costs increase. In addition, some spare parts are difficult to find or no longer available. The result: unplanned downtime, delivery failures, frustrated customers and uncontrollable costs.

Timely modernization of your intralogistics system will help you remain competitive. You benefit from improved availability, greater throughput, and lower maintenance and energy costs. Unplanned downtimes are avoided and the service life of the system is extended.

viastore does not apply a one-size-fits-all approach. Whether you're a current customer or a future customer with 3rd party equipment, we work with your team to develop a plan that will work for your needs. Some of the offerings available are:

- preventative maintenance

- spare parts audits/obsolete parts cross reference

- controls upgrades/retrofits

- software replacements/upgrades

- modernization of current system to match new business needs

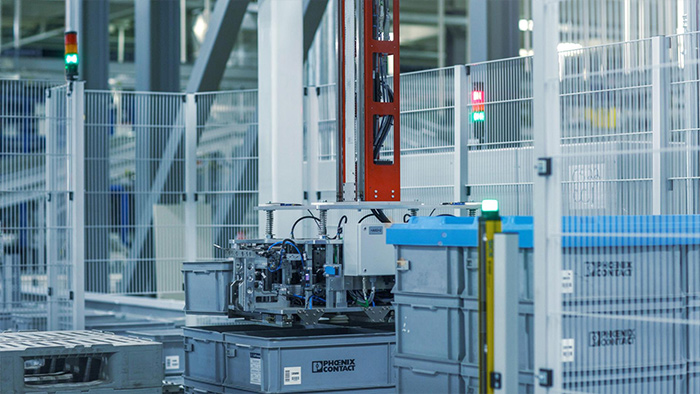

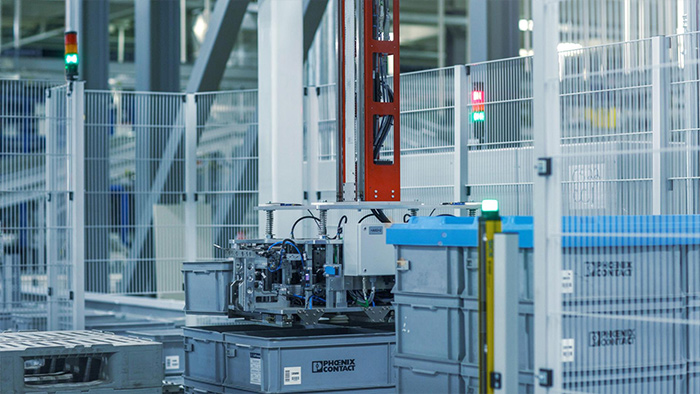

Automated Tray Storage

- AUTOMATED TRAY WAREHOUSE

FOR FLEXIBLE STORAGE OF GOODS OF DIFFERENT SHAPES AND SIZESIn a tray warehouse, stable metal sheets, so-called trays, are used as load carriers. The trays themselves are always the same size, but the storage units can vary in size, weight and packaging - meeting the demands of today's warehouses and distribution centers.

Automated tray warehouses from viastore offer you maximum flexibility and functionality when storing containers, cartons and other products with different weights, geometries and dimensions. They meet all the requirements for your intralogistics and can be individually adapted to your needs.

- Guaranteed flexibility and functionality

- Automated storage and optimal use of space through standardized size

- Storage units are stable and secure

- Very dense storage to maximize space usage

Tray storage systems can be planned with single or multiple aisles and built up to 65 feet high. The system is based on a viaspeed XL storage and retrieval machine (AS/RS), which is equipped with a load handling device that inserts and extracts the trays from the rack structure. They automatically store the products according to their access frequency. This ensures short distances and thus time, cost and energy efficiency.

Our viadat warehouse management software ensures an automatic, trouble-free and fast material flow and supports the order picker in his work with an intuitive user interface.

Production Supply

- EFFICIENT SUPPLY FOR PRODUCTION AND ASSEMBLY

Increasing levels of customization, increasing product individualization, batch size of 1 – what has long been the order of the day in logistics means a real challenge for production. To ensure real-time transparency, reduce inventory levels in the warehouse and in circulation, and react flexibly to different batch sizes and variants, it is advisable to take a holistic view of material flows in logistics and production, to network systems, coordinate workflows and integrate various software tools.

- Reduction of circulating and warehouse stock

- Save storage space

- Faster throughput speed

- Improve economic efficiency

- Increase competitiveness

A modern warehouse management system (WMS) optimizes warehousing, regulates the complete material flow, controls all processes and tasks, recognizes missing and high circulating stocks and adjusts them independently. By connecting the WMS to the Manufacturing Execution Systems (MES) you create the prerequisites for networking your material flows in logistics and production. This enables the demand-oriented supply and disposal of the machines and central storage in your production with the currently required items. Our standard WMS offers an interface to all common MES.Even with targeted measures such as just-in-time, just-in-sequence, a milk run/tugger train or driverless transport system (i.e., AGV), your processes can be made leaner and more flexible while minimizing expenses at the same time. Reduce your circulating and warehouse stock in production and assembly, save valuable storage space, lower costs, increase throughput speed and improve the efficiency and competitiveness of your entire operation – even with small production sizes up to batch size one.

INCREASE EFFECTIVENESS WITH SIMPLE MEANSEffective assembly and production supply is an important part of intralogistics. It encompasses in-house transport to the processing centers and assembly stations, handling, storage and provision as well as order picking. In order to avoid shortages during production and assembly, many companies hoard goods that they need at the installation site. This leads to a high – and costly – inventory, to an increased need for expensive storage and production space and to a lack of transparency, because you no longer know where which goods are ultimately located – circumstances that negatively affect performance, efficiency and profitability of the entire operation. For industrial companies, the right assembly and production supply has great cost and optimization potential. With targeted measures, you can make your internal workflows more efficient, safer and more cost-effective and thus also economically manufacture small lot sizes, improve your ability to deliver and thus increase your competitiveness.

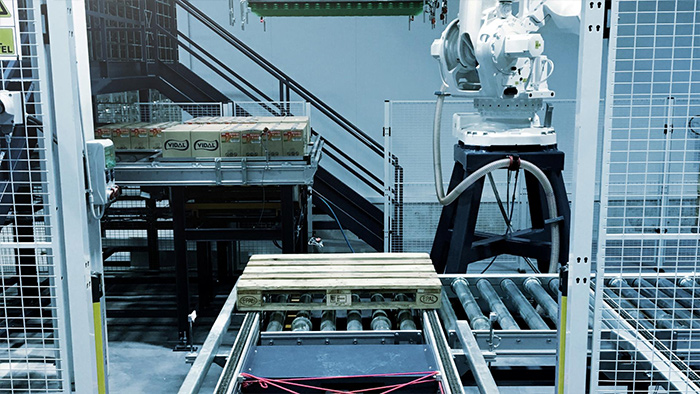

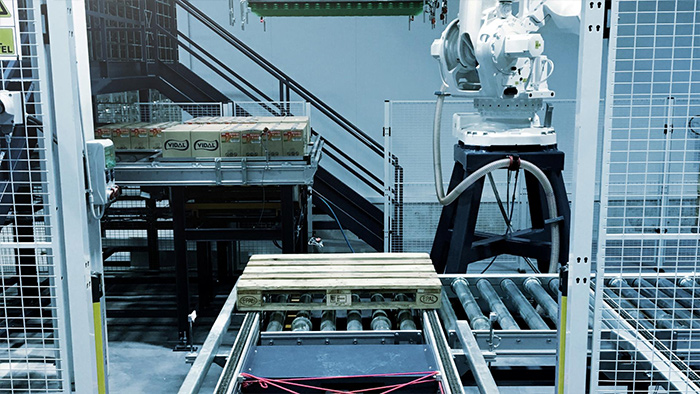

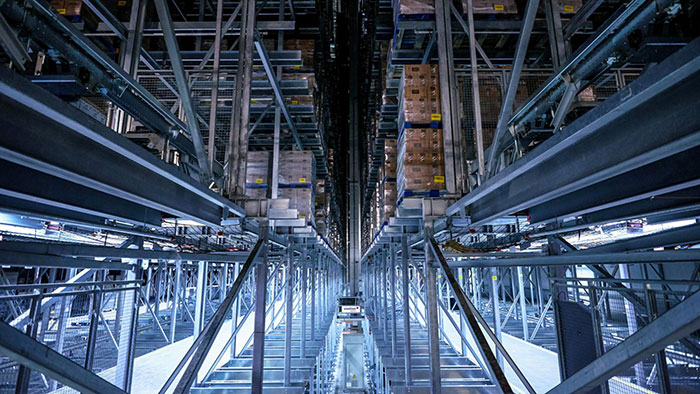

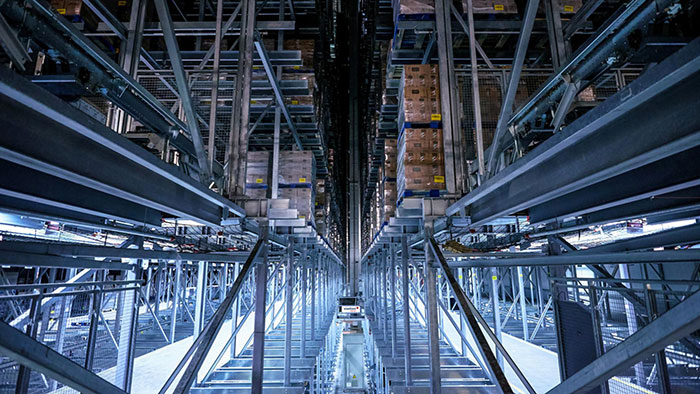

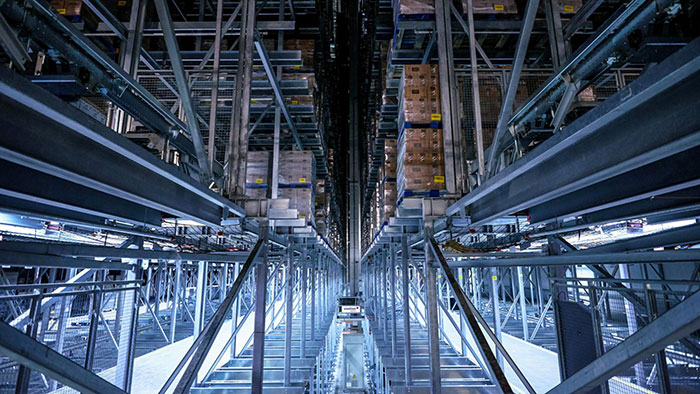

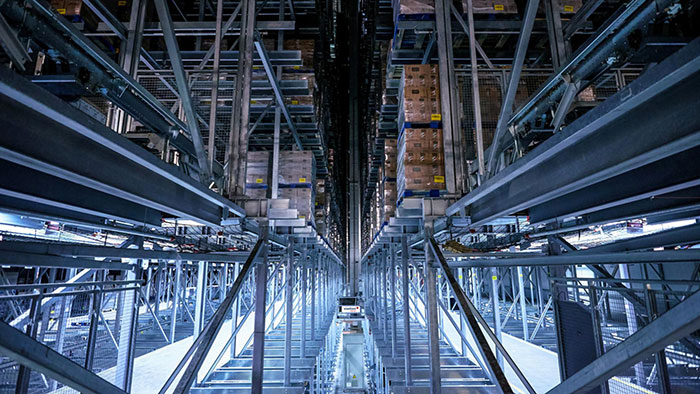

Automated Pallet Storage

- UNIT-LOAD ASRS OPTIMIZE SPACE FOR PALLET STORAGE

With an automatic pallet warehouse, you make optimum use of your existing storage space and obtain dynamic, fast and efficient intralogistics. These systems help you to react appropriately to increased market requirements such as short order cycles, smaller batch sizes or short delivery times. Automatic pallet warehouses are available as a rack supported building or as a free-standing system within a building, and can be built up to 150 feet high. They are suitable for almost all types of goods, and can also be designed as deep-freeze warehouses. ASRS systems show their strength when a large number of articles have to be stored and handled in limited space. A unit-load ASRS such as viapal from viastore, can be utilized with either shuttle forks or other automated systems such as shuttles for deep-lane.

- Optimized storage footprint

- Short throughput times, high availability of goods

- Automated processes that reduce error rates

- Relief of employees from physically strenuous and monotonous activities

Speed and precision are the key factors in the storage and retrieval process. Automated warehouses are efficient, fast, flexible and reliable. They ensure improved inventory management and more efficient order fulfillment as well as short delivery times, require less floor space, have lower energy consumption and enable error-free workflows. Employees are relieved of heavy physical and monotonous work steps and errors are reduced to a minimum. For companies in industry and trade, these factors become a decisive competitive advantage.We support you in the planning, development and implementation of innovative automatic high-bay warehouses (HBWH), as well as all other material handling automation. As a system integrator, we offer a complete system with automated storage and retrieval machines (ASRS), shuttles, picking systems, conveyor technology, control system (PLC), material flow system (MFS) or material flow computer (MFR) and warehouse management software (WMS). The viadat Warehouse Management System (WMS) and our SAP EWM solutions organize, monitor and control all processes. Therefore, you not only optimize warehouse processes but also reduce the error rate to a minimum.

Warehouse System with Viadat

-

The heart of a warehouse system for efficient intralogistics processes

- Connection of logistics and production through MES interface

- Easy integration into existing IT landscapes

- Standard interface to all common ERP systems

- Multi-hosting function

- Multi-client and multi-storage capability

- Web-enabled – also cloud storage

- Upgradable, scalable and powerful

Efficient, intelligent and cross-process software is the basis for lean processes in production and distribution. It helps to reduce inventory and logistics costs while at the same time increasing the ability to delivery. A modern warehouse management system contributes significantly to the success of manufacturing companies and paves the way for them to become smart factories.

The viadat Warehouse Management System (WMS) manages, controls and optimizes your entire intralogistics process in the warehouse and internal transport – from goods receipt through production supply and order fulfillment to shipping of the finished product. The software is scalable in terms of function and performance, making it just as suitable for small warehouses with low throughput as for distribution centers and high-performance plants with several hundred thousand order lines per day. Whether conventional manual warehouse, forklift-operated system or highly automated systems. And best of all: viadat is completely intuitive – anyone who can operate a smartphone can operate viadat.

Automated Mini-Load Storage

- AUTOMATED MINI-LOAD SYSTEM AND SMALL PARTS WAREHOUSE: SHORT ACCESS TIMES AND HIGH THROUGHPUT

An automated small goods warehouse enables you to store goods in containers and cartons quickly, flexibly and reliably. It offers short access times, optimal space utilization, high handling performance and optimal access to small parts. Automatic small parts warehouses are as individual as your requirements. They can be operated under normal temperatures, in a temperature-controlled environment or even as a deep-freeze warehouse and are used in as spare parts operations, order picking of small items, or as buffer storage in a high-speed distribution warehouse.

- Fast access times and high throughput

- Space and cost efficiency through high storage density

- optimal use of space

- reduced error rate

viastore is the right contact for the planning, new construction or modernization of this type of facility. We plan, develop and implement your automatic small parts warehouse for the storage of small-volume units and deliver dynamic and energy-efficient storage systems that are precisely tailored to your requirements. We offer optimal solutions for the single, double or multiple deep storage of different containers and boxes, which can be transported extremely efficiently by shuttle or storage and retrieval machine, such as viaspeed. With various load handling devices, we ensure reliable handling of standard containers as well as individual load carriers. For a fast and efficient material flow as well as high throughput and maximum flexibility. Our WMS software viadat and our SAP logistics solutions manage, monitor and control all processes and thus significantly reduce the error rate.

Industry solutions

Manufacturing Industry

- FAST AND TRANSPARENT AUTOMATED LOGISTICS SOLUTION FOR THE MANUFACTURING INDUSTRY

- Integrated processes in logistics and production

- Optimal use of resources

- Linking logistics and production paves the way to the Smart Factory

- Economic production even with small quantities of batch size 1

- Maximum availability of goods with minimum downtime

- Real-time parts tracking along the entire material flow

- Automation simplifies work steps and relieves employees

In industrial production, reliable and fast logistics, integrated processes and the optimal use of resources are essential. Raw materials and semi-finished products must be available on time and waste must be avoided. This applies to every sector – be it metal or plastic processing, the electrical industry or mechanical and large-scale plant engineering.

Perfectly coordinated and optimized processes such as just-in-time (JIT) or just-in-sequence (JIS) are the basis for being able to remain competitive, achieve the highest production efficiency, avoid downtimes, increase throughput speed and reduce inventories. By integrating your logistics and production processes, you achieve greater transparency, true goods traceability along the entire material flow and thus benefit from optimized production supply.

Our viadat Warehouse Management System (WMS) can be connected to all common Manufacturing Execution Systems (MES) via a standard interface and thus connect your logistics with production. This paves your way to a Smart Factory, reduces your warehouse and work in progress inventory, and enables you to economically manufacture batch size 1, as well as large series. WMS and MES are equal partners, but use and generate different information. The MES knows what and how much each machine produces and which material is required when and where in production. The WMS knows where the required materials are stored and controls the supply and disposal of materials, as well as the transport between the production units. It knows the means of transport, their characteristics and the topology of the plan and can therefore control the optimal routes and times for the transport of goods.

AUTOMATED AND NETWORKED PROCESSES FOR INDUSTRY 4.0As an industrial company, you are faced with unique challenges: high inventory and current stocks, error-prone processes due to frequent manual intervention, expensive batch size 1 production, long production times and, as a result, limited growth opportunities. Equally challenging are the demands of your customers: precision, fast order processing, transparency and flexibility.

In order to overcome these challenges and benefit from Industry 4.0, companies of all sizes rely on automated and networked intralogistics and in-house transport solutions. Driverless transport systems and intelligent software play a crucial role here. It is essential to be networked at all levels. This is the only way to achieve maximum flexibility in manufacturing, ensure continuous supply and disposal of goods to and from machines and keep your inventory transparent – from semiconductors and machine parts to semi-finished products to finished products and spare parts.

Retail

- SOLUTIONS FOR THE RETAIL AND E-COMMERCE INDUSTRIES TO ENSURE PREMIUM DELIVERY QUALITY

In retail and e-commerce industries there are many challenges such as small order quantities with increasing order frequency, short delivery times and large volumes of returns, as well as high speed and flexibility so you can supply your external and central warehouses and customers as required without delivery bottlenecks. Online and omni-channel trade is booming. This will put even more immense pressure on retail companies.

With modern hardware and software you can react flexibly to the increasing demands in the retail sector, secure replenishment and achieve the highest possible throughput.

- Meet your customers demands for flexiblity and shorter delivery times

- Automation to optimize your online and omni-channel presence

- Secure replensihment and maximize throughput

- Solve for seasonal and trend-related order fluctuations

We offer logistics solutions that enable you to meet the needs of your customers at any time, even at short notice. To achieve this, we rely on the right level of automation, a consistenly intelligent control concept, ergonomic picking systems, a modern warehouse management system, and optimal integration of shipping - for trouble-free process in your replenshiment, external or central warehouse.

A modern warehouse management system (WMS) that maps, manages and admisters all processes in your warehouse is indispensable for retail and e-commerce. A WMS like viadat, manages functions such as package determination, determination of shipping routes or the definition of fast, medium and slow movers, and is responsbile for the integration of different subsystems. In addition, with food & beverage retail, viadat manages batch and serial numbers as well as BBE and BBD data of articles, regulates hazardous substance classes, processes for products that respond to consumer intolerances such as gluten, lactose or fructose intolerances as well as the picking of food according to FIFO or FEFO. This enables you to track every article along the entire supply chain and provides you with optimum inventory transparency, even with a large variety of products.

Efficient storage systems keep third-party logistics (3PL) providers competitive

- Intelligent intralogistics as the heart of logistics service providers

- Efficient handling for multiple clients

- Fulfill customer requirements such as short delivery times, adherence to delivery dates and high delivery quality

- Flexible systems to ensure competitiveness

- Optimized processes through automated hardware and software

- Secure processes for satisfied customers

To save costs in warehousing, warehouse operations and vehicle fleet, many companies outsource their logistics. Due to the increasing time pressure for deliveries and increasing expectations from customers, the demand for specialized third-party logistics (3PL) providers continues to grow. But it is precisely these expectations that 3PL's must also meet. Optimal warehouse management, high throughput and fast order processing are key factors for 3PL providers to remain competitive. Flexibility also plays a crucial role, not just because of the changing sales volume and increasingly diverse ranges, but because many contracts only run for two or three years.

Food Industry

- HIGH-PERFORMANCE STORAGE SOLUTIONS FOR THE FOOD AND BEVERAGE INDUSTRY

- Material flow for different temperature zones

- Hygienic and safe handling solutions

- Comply with cold chain requirements

- Reduce energy costs and improve throughput

Since the food and beverage industry works with highly sensitive goods, the material flow system must meet special requirements. Whether food production, warehousing or distribution; high standards of freshness and hygiene, the creation of different temperature zones, consistent adherence to the cold chain and the consideration of best-before dates must be guaranteed.

Safe and thorough cleaning practice are essential, especially in processing plants where food comes into direct contact with equipment.The systems must be designed to the highest hygienic standard to prevent the formation of bacteria. In addition, throughput times between production and storage should be as short as possible. The aspect of perishability or reduction in quality of goods during storage and transport to the end customer poses additional challenges. Efficient processes are therefore indispensable.

viastore's understanding of processes and our expertise support you in responding optimally to the needs of retailers, restaurants and consumers with the right warehouse and material flow systems and in delivering sensitive and perishable goods quickly and reliably in varying quantities.

SENSITIVE GOODS AND DEMANDING CUSTOMERSAn energy-efficient and process-reliable automated cold and deep-freeze warehouse meets your requirements for food production and storage. It enables lower energy costs due to closed cooling, a higher storage volume, high goods turnover with reduced stocks, ensures the cold chain, and helps keep employees out of the cold. All processes are controlled by a storage software such as viadat and executed by automated storage and conveyor technology. The WMS enables you to permanently monitor your goods as well as their BBE and BBD data.

Chemicals & Pharmaceuticals

-

SAFE MATERIAL FLOW SOLUTIONS FOR CHEMICALS & PHARMACEUTICALS

- Strict adherence to legal requirements

- High quality standards

- Proper inventory management

- Avoid errors

- Special handling of sensitive products (cooling & storage of hazardous substances)

In the chemical and pharmaceutical industries, stable and above all transparent processes are required, and the highest safety standards must be met. Especially in the chemical industry you are faced with many specific challenges – even the smallest disturbance can have far-reaching consequences.

Special devices and processes are required to ensure the safety of the stored goods, your employees and the environment during transport, storage and handling. Since many chemical products are highly flammable, intelligent storage according to hazardous substance classes, as well as explosion and fire production play a particularly important role.

Also in the health care industry, error-free storage as well as fast and accurate delivery to your customers are of great importance. All products and processes must be documented, the availability of goods should be 100 percent. Because delays or errors can result in serious health consequences for patients. In order to meet the contracts with health insurance companies, which require that no delivery bottlenecks occur, the stock of raw materials and finished products must be correspondingly large. Therefore, storage capacity is just as necessary for you as perfect inventory management, high picking performance and fast storage and retrieval processes.

With viastore you the right partner - with the right storage and the right technology and software - we optimize your workflows and support you in ensuring proper handling and storage of hazardous and sterile goods. As a general contractor, we supply and install all required components, the entire storage and conveyor technology, as well as software, all from a single source.

STRICT REGULATIONS AND INCREASING REQUIREMENTSThe handling of products from the chemical and pharmaceutical sectors is strictly regulated by law, because safety for people and the environment must be guaranteed at every step. Even more than in other areas of logistics, it is important to avoid mistakes. The more automated and standardized your processes are, the more safety you can guarantee. With an appropriate software solution, you can design your warehouse processes efficiently and dynamically and flexibly adapt them at any time.

Our viadat warehouse management system (WMS) enables complete traceability of goods as well as clear inventory management and error-free batch documentation. The software meets the strictest certifications and validations (e.g. GAMP, FDA), manages the batches, the expiration dates of raw and finished goods, as well as the storage locations so that substances which should be separated are not stored next to each other. The WMS starts the stock removal order for raw materials when a certain product is to be mixed. It also processes orders from the corresponding containers into which the product is filled, as well as for the packaging materials and controls the storage of finished goods and their removal from storage, picking and shipping.

Other Industries

- Individual solutions for your company

Whether automotive, healthcare or consumer goods: our customized intralogistics solutions help you to achieve the greatest possible transparency, efficient processes and optimized delivery capability. With our know-how in systems, software and services, we offer you a broad product portfolio that you can adapt to your individual needs. See for yourself!

Consulting, planning, training: Services for your intralogistics

- With our comprehensive portfolio of services, we ensure you get you the best out of your intralogistics and are able to profit from it in the long term. With our know-how in intralogistics consulting and material flow planning, we support you in making your processes more efficient. In several steps, we examine your facility, systems and workflows and find the solution that is precisely tailored to your industry and your needs – whether you are planning a new facility, an expansion or restructuring. Our education and training programs help you and your employees achieve safe handling of your system.

Intralogistics Consulting

- Our consulting services help you to make your intralogistics processes more efficient – whether you are planning a new installation, an expansion or restructuring.

Material Flow Planning

- We help you to optimize your material flows. For more productivity and stable processes.

Warehouse Modernization

- With a retrofit you remain competitive and your system always up to date.