Saar Lagertechnik

Videos

Loading the player ...

- Offer Profile

-

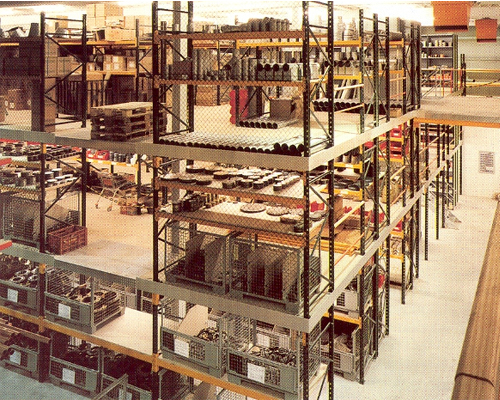

Saar Lagertechnik, a leading European coordinator of logistic systems offers your company turnkey solutions for space planning, automatization of your warehouses and order-picking systems.

Shelving, pallet rack, pallet live-storage, carton live storage and carton-flow installations, pallet and carton push-back systems, cantilever racking for long and cumbersome loads, storage platforms with one or more mezzanine floors, automatic small part storage systems and rack-clad warehouses

Product Portfolio

Turnkey solutions for space planning, automatization of your warehouses and order-picking systems

PALLET LIVE STORAGE

-

With the pallet flow system, Saar Lagertechnik is covering a large range of applications to improve the overall performance of warehousing and distribution centers. From FIFO (First In First Out) to LIFO (Last In First Out) applications, from Buffer to Picking and dispatch lanes, Saar Lagertechnik always has the right solution to cover your needs.

Brake roller

Brake rollers ensure controlled movement of pallets. They are placed in such a way that every pallet is constantly in contact with a brake roller. Brake rollers work on the centrifugal principle: the rotation of the load-bearing roller is transferred at a ratio of 1:12 by a two-tiered planetary gear. Revolving brake shoes are mounted at the exit side of the gear unit and are pressed on to the braking surface by the centrifugal force caused by the rotation.

The brake power is regulated by the downhill-slope force and is thus dependent on the weight of the pallet. Heavy pallets try to accelerate the brake rollers more than lighter ones thereby increasing the pressure on the brake-roller and consequently the brake power. Pallets with differing weights therefore move at the same speed, namely 0.25m/s.- Brake rollers are in direct contact with the pallet thus providing very high efficiency

- Friction-free contact with the pallets

- The top of the brake roller is 1mm higher than the top of the adjacent weight-bearing rollers

- The configuration of the brake rollers allows them to be easily installed and dismounted so that they can also be used in the retrieval units.

The Separator

The Separatorseparates those pallets that are ready to be retrieved from the pallets behind thus making picking easier. Our mechanical Separators work in a similar manner:

- The pallet at the front accelerates briefly and forms a gap between the pallets behind.

- The pallet passes over a switch (lever plate) and presses it down.

- This movement is transferred to a stopper via a lever-arm camrod.

- The stopper moves from it initial position under the level of the rollers into a holding position approx. 15mm above the level of the rollers. The pallet behind stops at this stopper.

- Saar Lagertechnik´s separators are built in such a way that that the pressure from the waiting pallets does not affect the lever plate. A very light pallet at the picking position cannot be unheaved by the pressure of the pallets behind.

- The first pallet can be raised by up to 80mm without releasing the stopper.

- The camrod is either free from pressure (Separator with knee-lever model) or can be subjected to tension (separator with direct operation model) so that no distortion can result from the back pressure caused by the pallets behind.

CARTON LIVE STORAGE

-

Order preparation for small unit loads on the FIFO principle

Live storage units are increasingly being used for order-picking small items on the principle of „man to goods“. The investment for such systems are soon written off by the rationalisation achieved.

Long, straight walkways reduce absenteeism, resulting in greatly increased productivity amongst employees. Not only the drastically reduced travel times – between 40% and 70% compared to conventional racking – but also the up to 30% space saved, guarantee the rational use of SAAR Live Storage for Small Units Systems in practically all environments.

PUSH-BACK RACKING

-

Push-back racks can be built either on the basis of roller conveyors or on Saar Lagertechnik´s Carrier-Push-Back system.

Push-back racking works on the LiFo principle: the first pallet is loaded onto a wheeled carrier at the entry end and pushed back along inclined steel guide channels by the next pallet. The last pallet placed in the rack is the first to be removed. Saar Lagertechnik offer standard roller conveyor lengths up to 8 pallet deep; in addition longer tracks can be built as a special project.

Push-back roller conveyors are also built using standard modules. Only intermediate modules are used since separation units at the entry end are dispensed with.- 2 to 8 pallets deep

- robust

- compact- low construction height

- compact-dense storing

- safe-pallets cannot get stuck

- safe- pallets move automatically by gravity

- low slope – only 2.5% necesary

- pallets can be stored cross wise

- independent from pallet quality

- rails galvanised – no abrasive wear

- drive-in racks can easily be modified for cpb

Stable welded construction. Flanged wheels with ISO-bearings. One pair of rails for each carrier garantees a compact design.

The first pallet is positioned on the heighest carrier. It is pushed back by the second pallet, which then is positioned on the second heighest carrier. The last pallet is positioned directly on the rails.

SHELVING SYSTEMS

-

The system is similar to a pallet rack in as much as it consists of ready-made frames (open or closed using glossy, stove-enamelled steel panels at the sides).

The frames are joined together by longitudinal bracing at given intervals to ensure stability.

The shelves are set on unique support clips giving firm support for even the heaviest loads and are available in lengths from 1000mm up to 1250mm and in depths from 300mm to 800mm.

Loads of up to 250kg per shelf can be stored. Shelves with non-standard dimensions are also possible in larger quantities!

Pierced shelves for fitting steel dividers are also available.

Further accessories include rear cladding, bin fronts, floor trims, etc.

The system is similar to a pallet rack in as much as it consists of ready-made frames in which a selection of beams – depending on the load – are fastened

The interlocking of frame and beam produces a racking system that is stable and does not require bracing.

Shelving materials such as steel panels, steel profile panels and chipboard can be dropped into the beams.

The frames are perforated at a pitch of 50mm allowing the beams to adjusted at this pitch.

The width of the bay depends on the length of the beam and can go up to 3000mm.

Accessories include wire mesh side panels and louvred panels for fitting plastic containers.

CANTILEVER RACKING

-

Storage for lengthy and cumbersome goods

Cantilever racks are perfectly suited to store unusually long materials and other cumbersome goods. Such materials range from light plastic tubes, steel pipes, profiles and wooden panels right up to massive coils.

All cantilever uprights from Saar Lagertechnik can be delivered single or double-sided and in any number of lengths. The cantilever arms are flexible and can be adapted to accommodate goods with different heights and weights. Alignment and adjustment can be carried out retrospectively without tooling. Should you need to store special materials or allow for particular space conditions, our consultant engineers will willingly prepare an individual scheme.

MATERIALS HANDLING

- At the customer´s wish Saar Lagertechnik can supply project-related materials handling schemes for transporting cartons or pallets.

AUTOMATIC SMALL PARTS STORAGE

- The Automatic Small Parts Storage System (AKL) is ideal for storing small parts in, for example, containers. Entire storage units containing small parts are automatically order-picked by unmanned storage and retrieval machines (RBG) guided by computer. The parts are then brought to the commissioning area by a conveyor line connection. Because AKL has to be designed within very close tolerances, this type of racking demands precision in manufacture and installation.

PALLET RACK

- The Saar Lagertechnik palett racking system is a boldless system. The special shape of the upright slots guarantees an absolutely positive interface with the beam connectors so that longitudinal and diagonal bracing are not required. The pitch for beam adjustment is on a 75 mm increment. The face of the frame upright measures 90-120 mm. The pallet racking itself is often basis of several kinds of important racking systems.

PALLET RACKING

-

Adjustable Pallet racking is a flexible system for storing pallets (DIN, Euro, etc.). This type of racking is especially suitable for large quantities and for bulky goods and can be adapted to every load whatever the weight or volume. The racking consists of beams, frames and various accessories: uprights, struts, diagonals, foot plates, supports.

The design of the connector ensures that the beams lock positively into the frame eliminating the use of cross-bracing along the length or width. The pitch allows the height of the beams to be adjusted every 50mm. The beams are manufactured in box sections. Locking pins prevent the beams from being accidentally dislodged. The pallet racking range includes a large number of accessories, such as:

- Cladding supports

- Pallet stoppers to prevent slipping

- Roller supports

- Pallet foot supports

- Stepped beams

- Shelf Panels, etc.

NARROW AISLE RACKING

- Narrow aisle racking is characterised by the use of the special narrow aisle forklift trucks used for loading and unloading. These trucks can be guided by guide rails at the side or inductively. Hereby there are so-callled man-up and man-down trucks. For these racks special tolerances must be observed during production and installation. Perfect alignment and levelling are decisive for such constructions.

PALLET LIVE STORAGE

-

Dedicated channels of inclined gravity rollers guarantee the First-in, First-out principle: the first pallet is loaded at the upper, entry side and rolls to the end of the lane where it becomes the first pallet to be unloaded. Saar Lagertechnik offers standard lanes of up to 25 pallets. Longer installations can be built as special projects.

Advantages of Pallet Live Storage- Increased storage capacity by reducing the number of aisles

- Easier order-picking by storing buffer stock in every lane

- Reduced travel time between two storage points

- Automatic stock turnover due to the First-in, First-out principle

- Storage of large quantities of single commodities

- Lower energy costs due to reduced lighting at the loading and picking ends

- Less cubic space to be cooled in cold storage areas

SATELLITE RACKING

-

Channel storage systems are especially suitable for large stocks of single items together with a limited number of product groups. With channel storage several loading units are positioned behind each other in so-called channels that are mounted on rails and loaded and unloaded by special materials handling equipment.

The advantage of channel storage compared to conventional sky racking is that it saves an enormous amount of space and this can be particularly cost-saving in deep freeze stores.

AUTOMATIC HIGH-BAY

-

For automatically operated pallet racking special tolerances must be observed during production and installation. Perfect alignment and levelling are decisive for such constructions.

The materials handing equipment moves along rails set in the floor and is stabilised at the top by an upper guide rail. Pallets can be stored “one deep” or “two deep”.

- Clear aisle height: distance from highest point of the floor to the underside of the superstructure of the aisle

- Upper and lower approach dimension

- Clear aisle width between the charges (AST)

- Overhang for front and rear approach dimension

- Horizontal forces on the upper guide rail in Z- and X- direction

DRIVE-IN RACKING

-

Drive-In racking is another way of improving space utilisation compared to conventional pallet racking. This is achieved by largely dispensing with aisles. Drive-in racking is particularly effective for storing large quantities of the same article since access to individual pallets is difficult. Drive-in racking provides much the same storage density as bulk storage but provides more stability for the goods.

standard components of our pallet racking system form an ideal basis for drive-in racking and with strut widths up to 140mm drive-in racking can also be used in high warehouses

Important characteristics::

The connectors are simply engaged into the frames and can be adjusted in height every 50mm.

Every channel can be set at a specific height.

The connectors support the runners which guarantee that the pallets are placed in precisely the correct position.

Drive-in racking can be divided basically into three different types depending on the application: racks served from one side, racks served from both sides as well as Drive-through racks. While racks that are served from one or two sides operate on the LIFO (last-in, first -out) principle, Drive-through racks operate on the FIFI (first-in, first-out) basis. Guide rails installed in the floor for forklift trucks protect the racking.

MOBILE STORAGE

-

Compact and dynamic

Mobile storage Mobile storage is made up of traditional pallet racking mounted on mobile bases making it possible to open and close the aisles and offers the ideal solution to save space while still permitting access to individual pallets. Mobile racking is an ideal solution in cold storage areas, avoiding the cooling of unused cubic

DESCRIPTION

Mobile racks are operated manually (by touch pad controls on the base) or by remote control. The software for the controls can be adapted to individual requirements and can be linked up with existing warehouse management systems if desired. Light sensors fitted along the long sides of the carriages and at the end of every rack ensure safe operation. The light sensors naturally fulfil the requirements for personal safety within mobile storage installations.

Mobile storage is often combined with other types of racking e.g. for dispatch management.Mobile racks are guided by rails set in the floor. The rail system usually consists of two outer guide rails and several runner rails.

MEZZANINE FLOORS

- With the Saar Lagertechnik storage platforms, Saar is on a successful way to become one of the market leader. Used as intermediate floor or multilevel installation, the Saar platforms provides a valuable additional floor, e.g. as storage floor or commissioning floor. The Saar Lagertechnik platforms are so successful because even with high load-bearings the construction remains light and variable and therefore is very economical. Each single system component has been developed customer-orientated in practice and corresponds to the latest state of the art of international platform technology.

PALLET RACKING

-

Multi-tier platforms can be constructed over steel structures.

The steel structure serves as the supporting steel work on which the floor of the platform is laid out.

This floor area is decked out with galvanised or painted profile steel panels.

These panels are in turn covered with tongued-and-grooved chipboard forming a completely closed floor.

Die Spanverlegeplatten sind in der Güte V 100, d.h. wasserfest verleimt. Diese Art der Bühne kann sowohl ein- als auch zweigeschossig ausgeführt werden.

Top quality ( V 100), water-resistant, pasted chipboard is used.

This type of platform can be built as a single or two tier structure. Access is provided by stud plate staircases. All open sides on the platform are protected by powder coated rectangular steel walkways.

The edges of the platform are clad with steel decking which also acts as the obligatory kick-plate.

MEZZANINE FLOOR SYSTEM PROPLUS

-

The Pro System or the racking or steel structure serve as the supporting element on which a platform is located. This can consist of a variety of materials such as wood or metal according to the customer´s requirements.

For access galvanised stud plate or industrial metal grating staircases can be used. All open sides of the platform are protected by handrails made of powder-coated rectangular tubing. Every side of the platform is clad with skirting that at the same time prevents items from rolling off the platform.

STEEL PLATFORMS

-

Multi-tier platforms can be constructed over steel structures.

The steel structure serves as the supporting steel work on which the floor of the platform is laid out.

This floor area is decked out with galvanised or painted profile steel panels.

These panels are in turn covered with tongued-and-grooved chipboard forming a completely closed floor.

Top quality ( V 100), water-resistant, pasted chipboard is used.

This type of platform can be built as a single or two tier structure. Access is provided by stud plate staircases. All open sides on the platform are protected by powder coated rectangular steel walkways.

The edges of the platform are clad with steel decking which also acts as the obligatory kick-plate.