- Offer Profile

-

Your palletizing specialist

Verbruggen offers the best solutions for palletizing boxes, bags or crates by automatic stacking methods. We have more than 25 years of experience developing the most efficient, long lasting palletizers with unprecedented stacking capacities. We have provided many different palletization solutions worldwide within the agricultural industrial sectors offering customers the best in automated solutions for stacking the most difficult products.

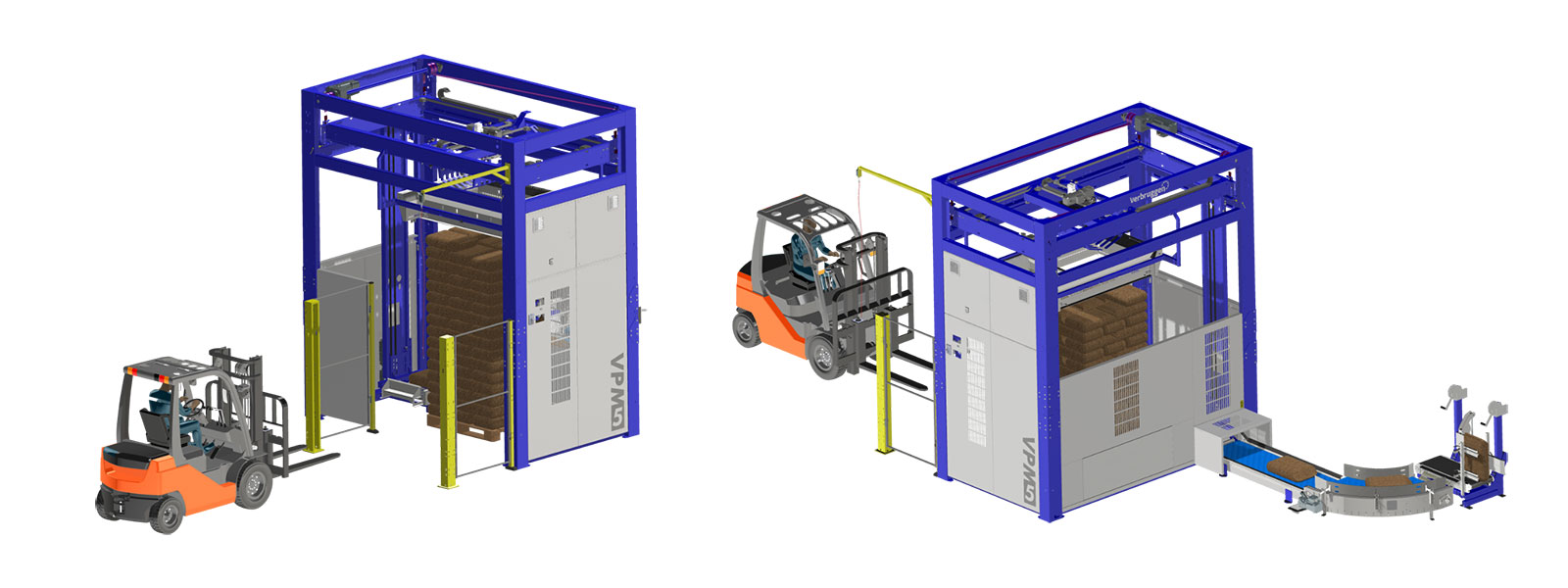

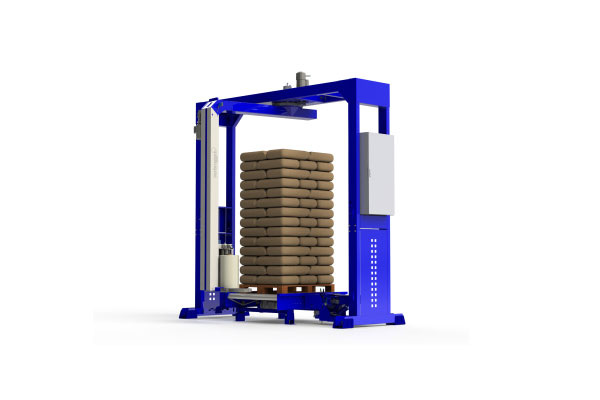

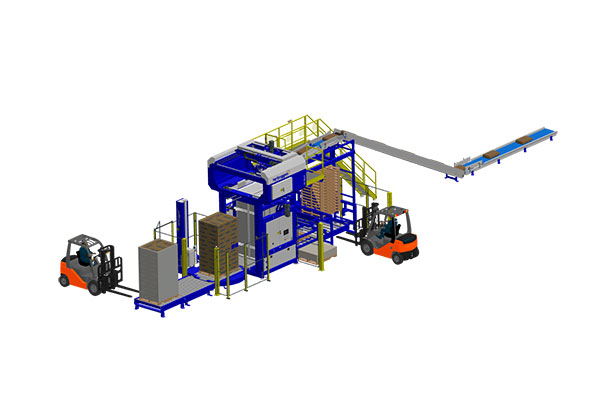

Palletizer VPM-5

-

Looking for an efficient stacking solution while eliminating the need for manual labor? Palletize your products with the innovative technology of the VPM-5. Automated stacking becomes a reality with the accurate and overlapping placement of products by manipulator & formation collar creating consistent and stable pallet loads. This machine is manufactured using the latest in Dutch technical innovation.

Benefits:

- Consistent & stable pallet stacks

- Small equipment footprint

- Low power consumption

- Efficient operation & low maintenance intervals

- High return & short payback period on investment

The VPM-5 has the bags supplied at floor level to the machine. The position of infeed is configurable at 10 different positions. Pallets are placed on the floor allowing full pallets to be easily changed by an empty one with a pallet jack, or forklift.

Our palletizing machines are also equipped with smart machine software and are easily operated by the user-friendly touchscreen. Remote access technology is also included, enabling remote service support from any location. The machine can also be built to suit your specific needs and is available with a wide range of options.

Most Selected Options:

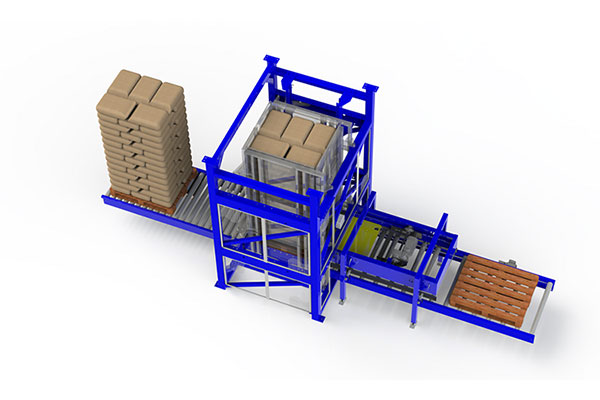

- Pallet transport by roller conveyors with pallet dispenser and wrapper

- Center flaps (for bag width less than 470 mm)

- Standalone wrapper (separate from palletizer)

- External start new pallet

- Extra collar section for less changes between pallet dimensions

- Fork extension guides for easy moving the machine by forklift

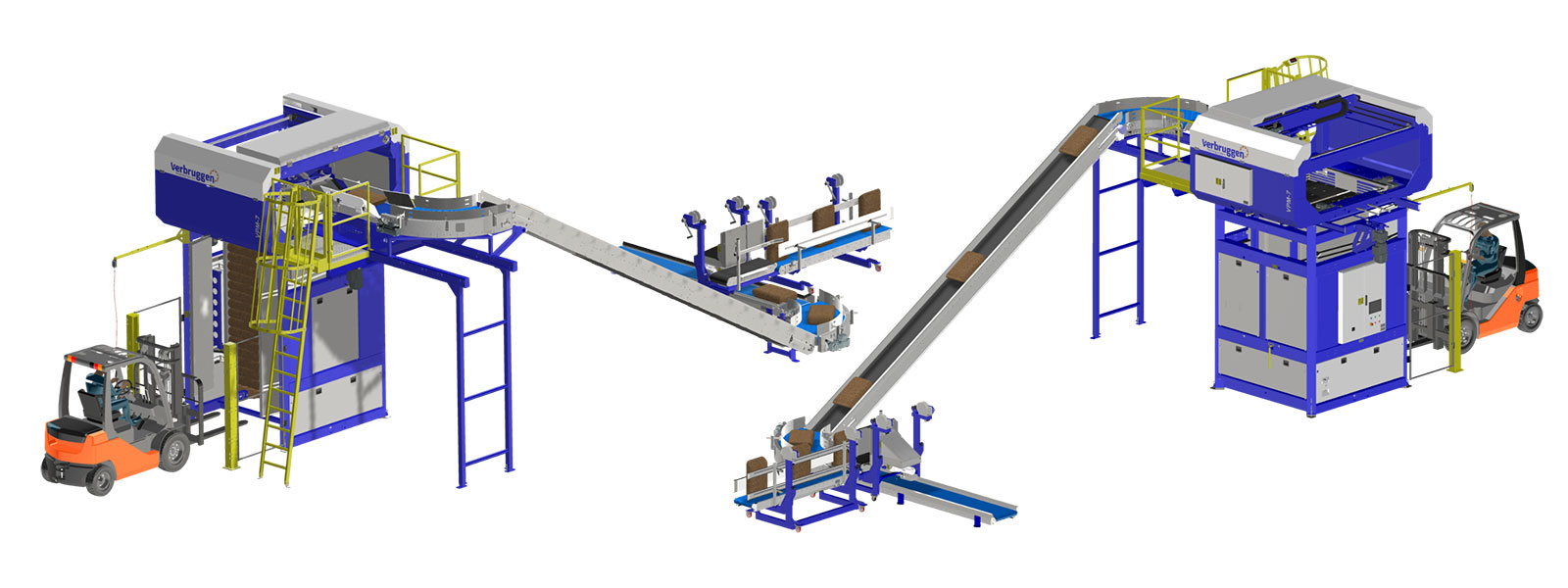

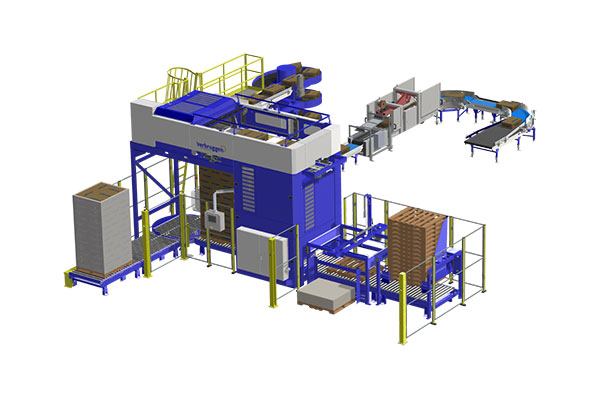

Palletizer VPM-7

-

Looking for an efficient stacking solution while eliminating the need for manual labor? Palletize your products with the innovative technology of the VPM-7. Automated stacking becomes a reality with accurate and overlapping product placement combined with adjustable vertical compression force inside a 4-sided enclosed stacking bin. This machine is manufactured using the latest in Dutch technical innovation.

Benefits:

- Consistent & stable pallet stacks

- Relatively small equipment footprint

- Low power consumption

- Efficient operation & low maintenance intervals

- High return & short payback period on investment

Products are supplied to the manipulator by reliable conveyor belts including automatic product buffering. Products will be handled by the special manipulator equipped with center flaps for an accurate product positioning. Horizontal moving formation doors allow each pallet/product layer to be compressed against the formation doors inside the stacking bin while the machine continues forming the next interlocking product layer resulting with the perfect finished product stack.

Our palletizing machines are also equipped with smart machine software and are easily operated by the user-friendly touchscreen. Remote access technology is also included, enabling remote service support from any location. The machine can also be built to suit your specific needs and is available with a wide range of options.

Most Selected Options:

- Adjustable stacking bin and formation collar for multiple pallet dimensions

- Soft landing on formation doors

- Electrical compressing collar

- Integrated (inter) sheet dispenser (in between layers)

- Combi manipulator for bags, crates and/or cartons

- Larger manipulator for bags up to 50 kg

- Standalone wrapper (separate from palletizer)

- External start new pallet

Palletizer VPM-8

-

Do you need to stack your products consistently & quickly? Palletize with the innovative technology of the VPM-8 for fast product stacking while eliminating manual labor efforts. Fully-automatic stacking at fast speeds becomes a reality with accurate and overlapping product placement combined with adjustable vertical compression force inside a 4-sided enclosed stacking bin. This machine is manufactured using the latest in Dutch technical innovation.

Benefits:

- Consistent & stable pallet stacks

- Fast stacking capability

- Low power consumption

- Efficient operation & low maintenance intervals

- High return & short payback period on investment

Products are supplied to the manipulator by reliable conveyor belts including automatic product buffering. Products will be handled by the special manipulator equipped with center flaps for an accurate product positioning. Horizontal moving formation doors allow each pallet/product layer to be compressed against the formation doors inside the stacking bin while the machine continues forming the next interlocking product layer resulting with the perfect finished product stack. Our palletizing machines are also equipped with smart machine software and are easily operated by the user-friendly touchscreen. Remote access technology is also included, enabling remote service support from any location. The machine can also be built to suit your specific needs and is available with a wide range of options.

Most Selected Options:

- Adjustable stacking bin and formation collar for multiple pallet dimensions

- Soft landing on formation doors

- Electrical compressing collar (electric)

- Integrated (inter) sheet dispenser (in between layers)

- Combi manipulator for bags, crates and/or cartons

- Larger manipulator for bags up to 50 kg

- Empty pallet dispenser

- Slip / push-pull sheet dispenser

- Driven roller conveyors

- Fully integrated automatic wrapping machine

Palletizer VPM-10

-

Looking for an efficient stacking solution while processing your goods consistently & quickly? Palletize with the innovative technology of the VPM-10 and upgrade your bussiness. Fully-automatic stacking at high quality becomes a reality with accurate and overlapping product placement combined with adjustable vertical compression force inside a 4-sided enclosed stacking bin. This machine is manufactured using the latest in Dutch technical innovation.

Benefits:

- Consistent & stable pallet stacks

- Fast stacking capability

- Low power consumption

- Efficient operation & low maintenance intervals

- High return & short payback period on investment

Products are supplied to the manipulator by reliable conveyor belts including automatic product buffering. Products will be handled by the special manipulator equipped with center flaps for an accurate product positioning. Horizontal moving formation doors allow each pallet/product layer to be compressed against the formation doors inside the stacking bin while the machine continues forming the next interlocking product layer resulting with the perfect finished product stack.

Our palletizing machines are also equipped with smart machine software and are easily operated by the user-friendly touchscreen. Remote access technology is also included, enabling remote service support from any location. The machine can also be built to suit your specific needs and is available with a wide range of options.

Most Selected Options:

- Adjustable stacking bin and formation collar for multiple pallet dimensions

- Soft landing on formation doors

- Electrical compressing collar

- Integrated (inter) sheet dispenser (in between layers)

- Combi manipulator for bags, crates and/or cartons

- Larger manipulator for bags up to 50 kg

- Empty pallet dispenser

- Slip / push-pull sheet dispenser

- Driven roller conveyors

- Fully integrated automatic wrapping machine

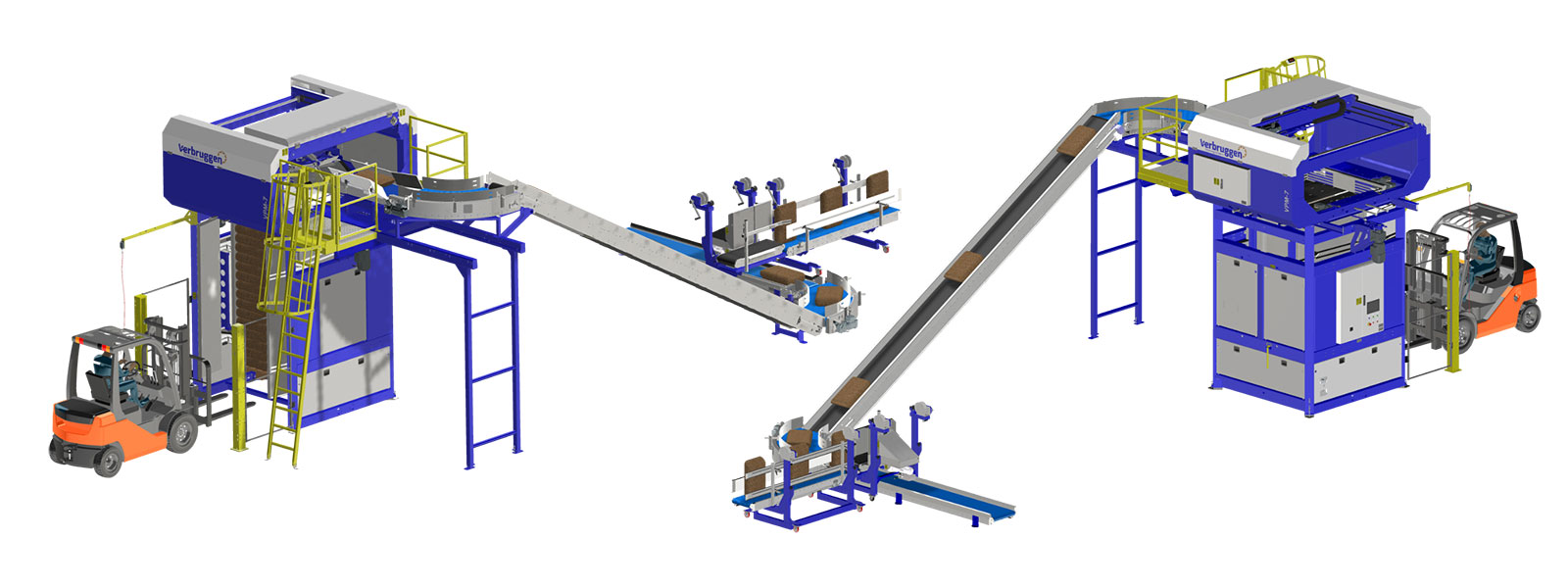

Palletizer VPM-14

-

Looking for an efficient stacking solution while processing your goods on high-speeds? Palletize with the innovative technology of the VPM-14 and upgrade your business. Fully-automatic stacking at high quality becomes a reality with accurate and overlapping product placement combined with adjustable vertical compression force inside a 4-sided enclosed stacking bin. This machine is manufactured using the latest in Dutch technical innovation.

Benefits:

- Consistent & stable pallet stacks

- Fast stacking capability

- Low power consumption

- Efficient operation & low maintenance intervals

- High return & short payback period on investment

Products are supplied to the manipulator by reliable conveyor belts including automatic product buffering. Products will be handled by the special manipulator equipped with center flaps for an accurate product positioning. Horizontal moving formation doors allow each pallet/product layer to be compressed against the formation doors inside the stacking bin while the machine continues forming the next interlocking product layer resulting with the perfect finished product stack.

Our palletizing machines are also equipped with smart machine software and are easily operated by the user-friendly touchscreen. Remote access technology is also included, enabling remote service support from any location. The machine can also be built to suit your specific needs and is available with a wide range of options.

Most selected options:

- Adjustable stacking bin and formation collar for multiple pallet dimensions

- Soft landing on formation doors

- Electrical compressing collar

- Integrated (inter) sheet dispenser (in between layers)

- Combi manipulator for bags, crates and/or cartons

- Larger manipulator for bags up to 50 kg

- Empty pallet dispenser

- Slip / push-pull sheet dispenser

- Driven roller conveyors

- Fully integrated automatic wrapping machine

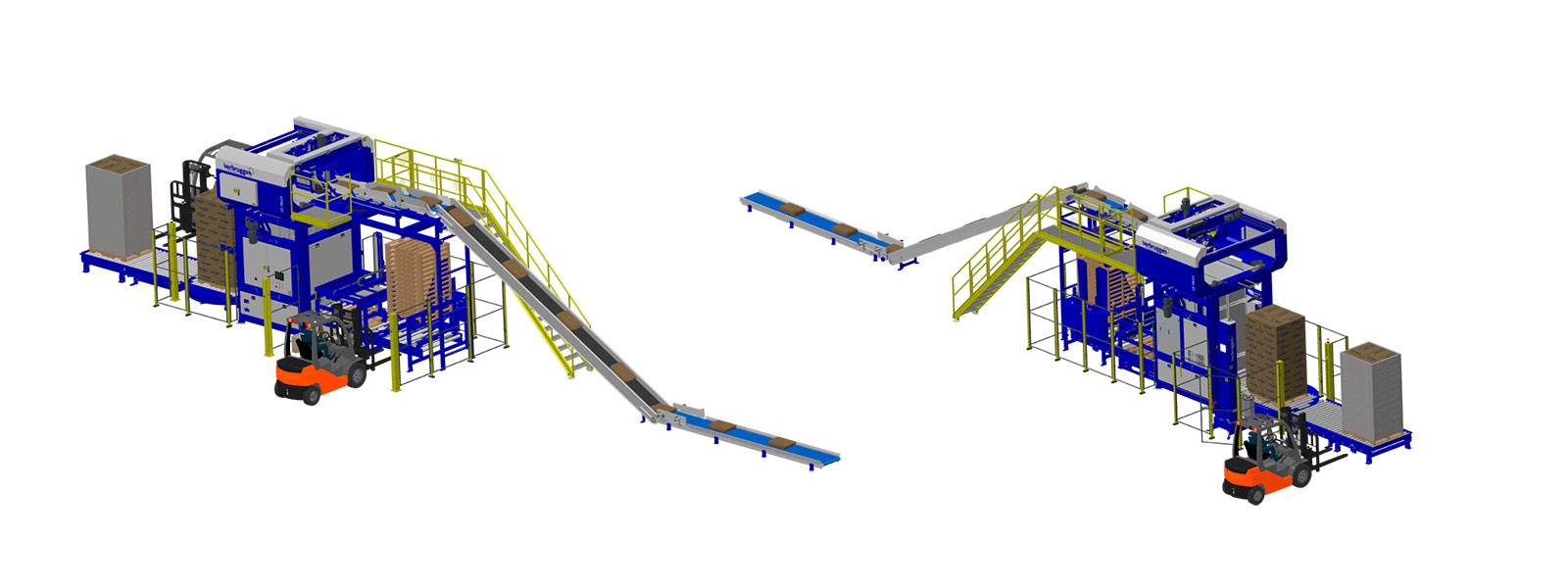

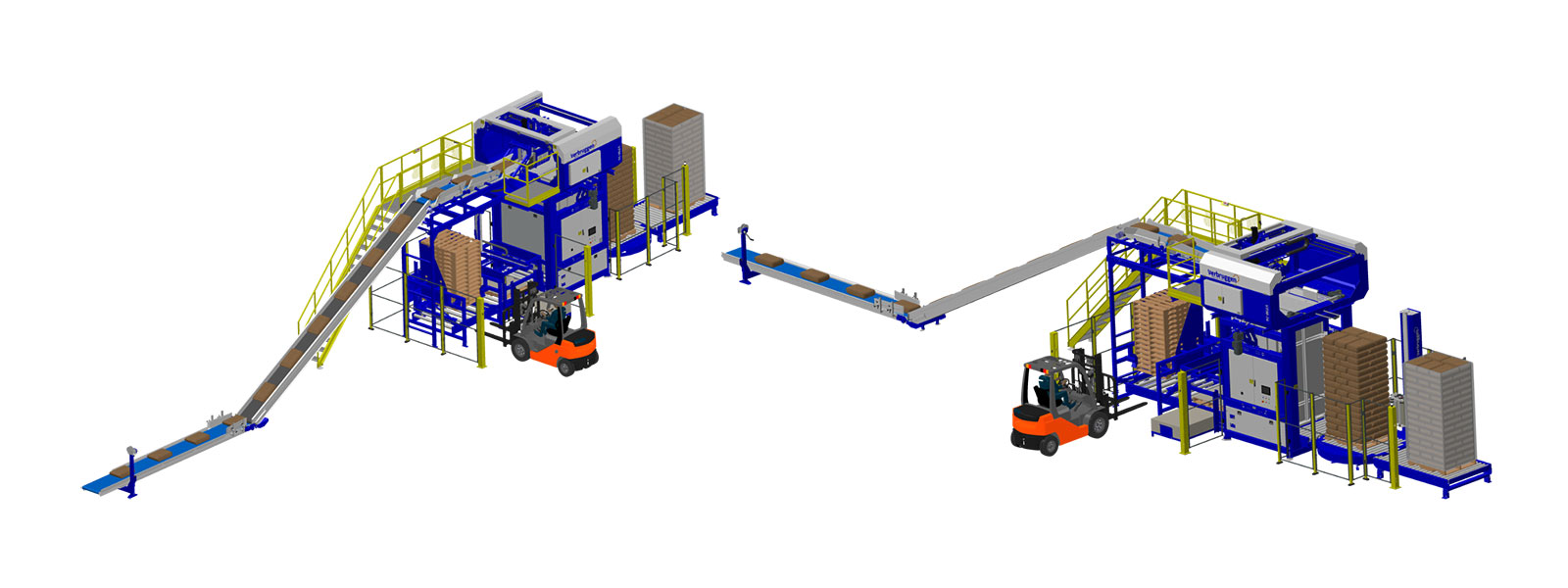

Palletizer VPM-BL

-

Looking for an efficient stacking solution while processing your goods consistently & quickly? Palletize with the innovative technology of the VPM-BL and upgrade your business. With the optionally extention of an automatic pallet transport system, fully-automatic stacking becomes a reality with accurate and overlapping product placement. This machine is manufactured using the latest in Dutch technical innovation.

Benefits:

- Consistent & stable pallet stacks

- Fast stacking capability

- Low power consumption

- Efficient operation & low maintenance intervals

- High return & short payback period on investment

Products are supplied to the machine by reliable conveyor belts including automatic product buffering. Products will be handled by the layer formation equipped with turn unit and sliding arm for an accurate layer formation. The horizontal moving formation door brings each layer to the specified position on the pallet while the machine continues forming the next interlocking product layer. The 4-sided enclosed collar take care about the finishing touch resulting with the perfect finished product stack.

Our palletizing machines are also equipped with smart machine software and are easily operated by the user-friendly touchscreen. Remote access technology is also included, enabling remote service support from any location. The machine can also be built to suit your specific needs and is available with a wide range of options.

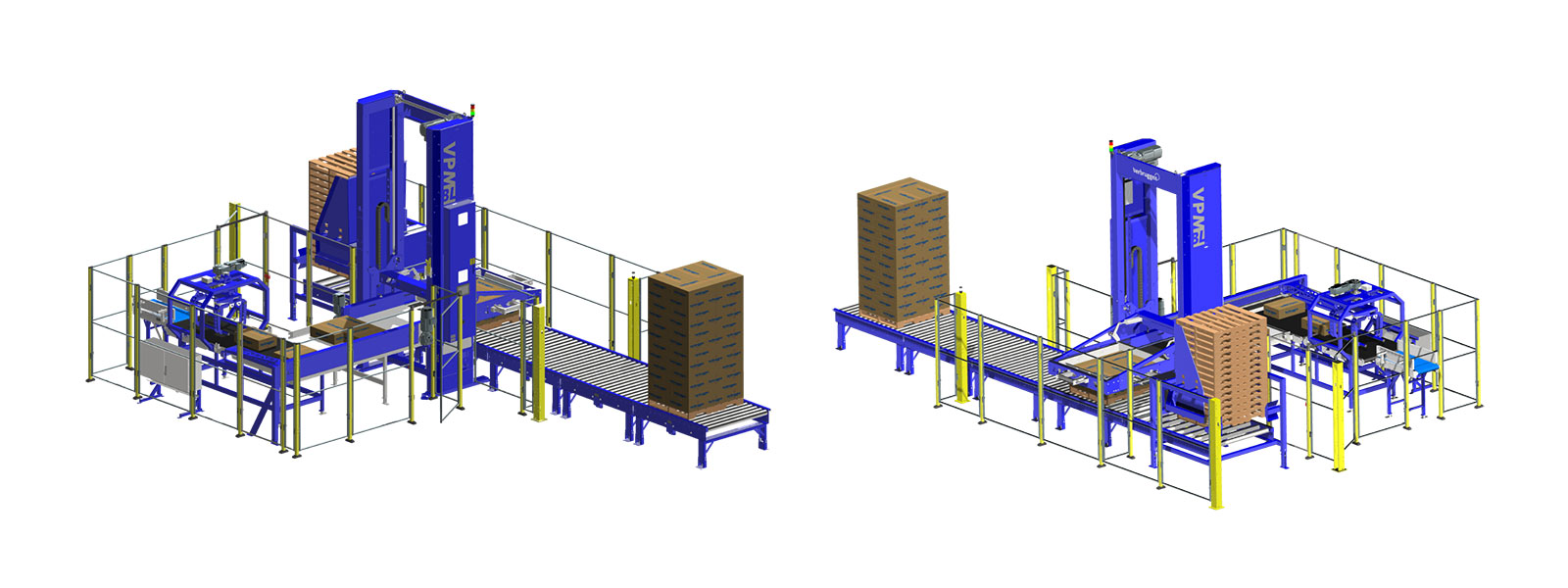

Palletizer VPM-ACP

-

Looking for an efficient stacking solution while processing your goods consistently & quickly? Palletize with the innovative technology of the VPM-ACP and upgrade your business. Fully-automatic stacking at high quality becomes a reality with accurate and overlapping product placement. This machine is manufactured using the latest in Dutch technical innovation.

Benefits:

- Consistent & stable pallet stacks

- Fast stacking capability

- Low power consumption

- Efficient operation & low maintenance intervals

- High return & short payback period on investment

Products are supplied to the machine by reliable conveyor belts including automatic product buffering. Products will be handled by the layer formation equipped with turn unit and flybar for an accurate and fast layer formation. The horizontal moving formation doors bring each layer to the specified position on the pallet while the machine continues forming the next interlocking product layer. The 4-sided enclosed collar take care about the finishing touch resulting with the perfect finished product stack.

Our palletizing machines are also equipped with smart machine software and are easily operated by the user-friendly touchscreen. Remote access technology is also included, enabling remote service support from any location. The machine can also be built to suit your specific needs and is available with a wide range of options.

Most Sold Options:

- Adjustable formation collar for multiple pallet dimensions

- Integrated (inter) sheet dispenser (in between layers)

- Empty pallet dispenser

- Slip / push-pull sheet dispenser

- Driven roller conveyors

- Fully integrated automatic wrapping machine

Palletizer VPM-VHV

-

Looking for an efficient stacking solution while processing your goods consistently & quickly? Palletize with the innovative technology of the VPM-VHV and upgrade your business. Fully-automatic stacking at high quality becomes a reality with accurate and overlapping product placement. This machine is manufactured using the latest in Dutch technical innovation.

Benefits:

- Consistent & stable pallet stacks

- Fast stacking capability

- Low power consumption

- Efficient operation & low maintenance intervals

- High return & short payback period on investment

Products are supplied to the machine by reliable conveyor belts including automatic product buffering. Products will be handled by the layer formation equipped with turn unit and flybar for an accurate and fast layer formation. The horizontal moving formation doors bring each layer to the specified position on the pallet while the machine continues forming the next interlocking product layer. The 4-sided enclosed collar take care about the finishing touch resulting with the perfect finished product stack.

Our palletizing machines are also equipped with smart machine software and are easily operated by the user-friendly touchscreen. Remote access technology is also included, enabling remote service support from any location. The machine can also be built to suit your specific needs and is available with a wide range of options.

Most Sold Options:

- Adjustable formation collar for multiple pallet dimensions

- Integrated (inter) sheet dispenser (in between layers)

- Empty pallet dispenser

- Slip / push-pull sheet dispenser

- Driven roller conveyors

- Fully integrated automatic wrapping machine

- Fully automatic product buffer system

- 100% electrical version

Wrapping machines

-

A pallet wrapper, also known as a stretch wrapper or wrapping machine, is a machine used to wrap stretch film around a pallet. This is done to secure the load on the pallet and protect it during transport or storage. They are commonly used in industries such as manufacturing, logistics, and warehousing to streamline packaging and shipping processes and improve overall efficiency.

Why Choose a Wrapping Machine?

To make your palletized products ready for transport, you can make use of our semi/fully automatic wrapping machines. To prevent your products from possible external damages and to make your products stable and fixed to the pallet during transportation, we provide you with a variety of wrapping materials depending on your products features, for example:

- Foil: Prevent products from environmental influences such as humidity and dust.

- Net: Allow fresh fruit and vegetables to breath during transportation.

- Combination of net and paper: Prevent products’ exposure from UV light.

With more than 30 years of technology innovation experiences, Verbruggen has developed a complete range of wrapping machines, which can be categorized into three main series.

VAW Wrapper - Verbruggen Arm Wrapper

-

The VAW-series wraps pallets with a very high capacity using a robust swing arm.

CAPACITY- 40 to 60 pallets / hour

- Max. 2500 mm

- 3000 mm

- Max. 1200 x 1200 mm

- Max. 1500 kg

- Roller or chain conveyor

- Clipper, Heat Seal or manually

- Foil, net, net and paper

- EMB brake or electro motor

- A4-tag dispenser

An arm wrapper is a type of wrapping machine that uses a rotating arm to wrap products with stretch film. The arm moves around the product on a turntable or conveyor, applying the packaging material and securing it in place. One of the main advantages of an arm wrapper is its ability to wrap large or irregularly shaped products efficiently and effectively. With programmable settings and sensors, arm wrappers can adjust the wrapping parameters based on the size and shape of the product, ensuring a secure and consistent wrap every time. Additionally, arm wrappers offer speed and flexibility, allowing businesses to wrap products quickly and efficiently while maintaining a high level of product quality.

VTW Wrapper - Verbruggen Table Wrapper

-

The VTW-wrapping machine uses a turntable design, and it will usually be integrated within a palletizing line.

CAPACITY- 30 to 40 pallets / hour

- Max. 2500 mm

- 1650 mm

- Max. 1200 x 1200 mm

- Max. 1500 kg

- Roller or chain conveyor

- Clipper, Heat Seal or manually

- Foil, net, net and paper

- EMB brake or electro motor

- Press plates, Top sheet

A table wrapper is a type of wrapping machine that uses a turntable to wrap products. The product is placed on the turntable, and the packaging material is dispensed automatically, wrapping the product securely. One of the main advantages of a table wrapper is its simplicity and ease of use. With minimal training required, operators can quickly and easily wrap products of varying sizes and shapes, improving efficiency and productivity.

VSW Wrapper - Verbruggen Stand-alone Wrapper

-

The VSW wrapping machine equipped with a turntable, and it will be used separately from the palletizer.

CAPACITY- 20 to 30 pallets / hour

- Max. 2500 mm

- 1500 mm

- Max. 1200 x 1200 mm

- Max. 1500 kg

- No

- Manually

- Foil, net

- Mechanical brake

- Remote, Collision protection, Ramp

A stand-alone wrapper is a type of wrapping machine that operates independently of other packaging equipment. Unlike integrated systems, stand-alone wrappers can be used as a standalone unit, allowing businesses to wrap products without the need for additional equipment or complex installation. One of the main advantages of a stand-alone wrapper is its flexibility and portability. They can be easily moved to different locations or integrated into existing production lines, allowing businesses to customize their packaging processes to suit their unique needs.

Additionally, stand-alone wrappers offer speed and efficiency, reducing the need for manual labor and increasing productivity. With their compact size and advanced automation, stand-alone wrappers can help businesses save time and money while maintaining a high level of product quality.

Palletizing solutions & automated palletizing options by Verbruggen

-

Palletizing solutions refer to the various methods and technologies used to automate the process of loading and unloading products onto pallets. These solutions can range from simple manual systems to highly sophisticated robotic systems. The benefits of palletizing solutions include increased efficiency, improved safety, and reduced labor costs. Palletizing solutions can be customized to meet the specific needs of a variety of industries, including manufacturing, logistics, and retail.

Overall, palletizing solutions are an important part of modern supply chain management, helping companies to streamline their operations and stay competitive in a fast-paced global marketplace.

Less product damage through careful handling

-

Using a palletizer can significantly reduce product damage during the handling and transportation process. Palletizers are designed to carefully and efficiently stack products onto pallets in a way that minimizes the risk of damage. By automating the palletizing process, products are carefully loaded and unloaded without being jostled or dropped, reducing the risk of scratches, dents, or other forms of damage.

In addition, palletizers can be programmed to stack products in a way that maximizes stability and minimizes the risk of shifting or toppling during transportation. This helps to prevent damage caused by products rubbing against each other or being crushed under their own weight

Higher and stable stacking

-

When it comes to palletizing products, one of the key benefits of using a palletizer is the ability to achieve higher and more stable stacking of pallets. This is especially important for companies that need to maximize their storage space and transport large quantities of products in a single shipment.

By using a palletizer, products can be stacked in a uniform and stable manner, which allows for higher stacking heights without compromising safety or stability. This means that companies can fit more products onto a single pallet, which can translate into significant cost savings and improved efficiency. By using precise and automated stacking techniques, companies can avoid overloading pallets or stacking them in a way that could lead to shifting or toppling during transit.

Automated palletizing has a strong ROI

-

A palletizer can provide a company with a strong ROI in several ways. By automating the palletizing process, companies can reduce the need for manual labor, which can result in cost savings related to labor costs. In addition, a palletizer can improve productivity by increasing the speed and accuracy of the palletizing process.

In combination with labor cost savings, a palletizer can also help reduce the risk of product damage during palletizing, which can result in additional cost savings related to product waste and rework.

By reducing product damage and waste, companies can also improve their overall product quality and customer satisfaction, which can lead to increased sales and revenue

Reduce stacking labor

-

By using a palletizer, businesses can greatly reduce the amount of manual labor required for stacking products. This is achieved through the high-speed stacking capabilities of the machine, which can stack products quickly and accurately onto a pallet without the need for human intervention.

Reducing stacking labor with a palletizer not only saves time and effort but also minimizes the risk of workplace injuries related to manual stacking. This can lead to a safer work environment and lower insurance costs for businesses.

With more storage space, businesses can store a greater volume of products on-site, reducing the need for off-site storage and increasing their inventory capacity. This can lead to a more streamlined supply chain and reduced transportation costs, as products can be stored and distributed more efficiently.

High speed stacking

- High-speed stacking is a significant advantage of using a palletizer in modern manufacturing operations. By stacking products quickly and accurately onto a pallet, businesses can achieve optimal efficiency and productivity in their material handling processes. The ability to stack products at high speeds using a palletizer allows businesses to improve production throughput and reduce the need for manual labor. As a result, businesses can achieve significant cost savings and increased profitability over time.

Palletizing to more storage space

-

More storage space can allow businesses to take advantage of bulk purchasing opportunities, as they can store larger quantities of products without worrying about space limitations.

This can lead to cost savings and increased profitability over time.

Customized Palletizing Solutions

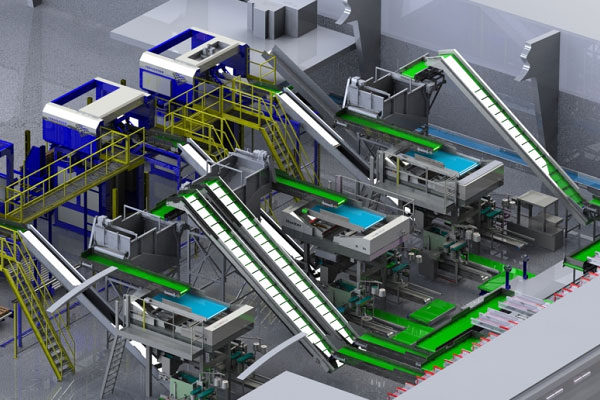

- To offer you an idea about the diversity of our projects, we provide you several examples of our unique machine concepts. Do you have a specific request? Our engineers will develop a customized solution for your situation. Also for very tough-stackable products.

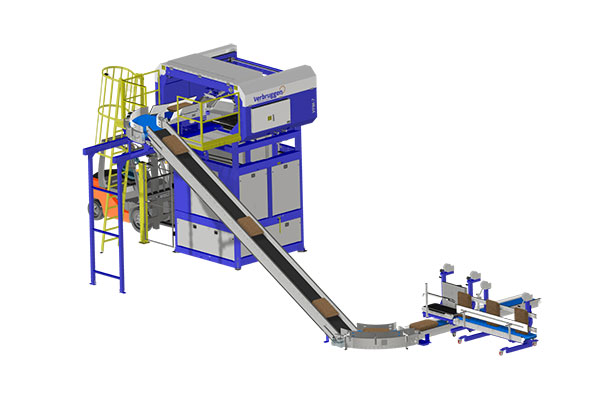

Mobile Palletizing

- To be able to palletize on different locations with one machine, Verbruggen developed the VPM-Mobile. This machine is often used by bulking goods of storage and handling companies. Unique is the easy transport of the machine by truck.

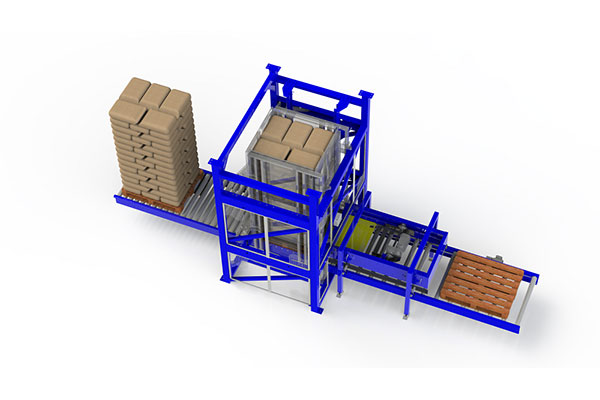

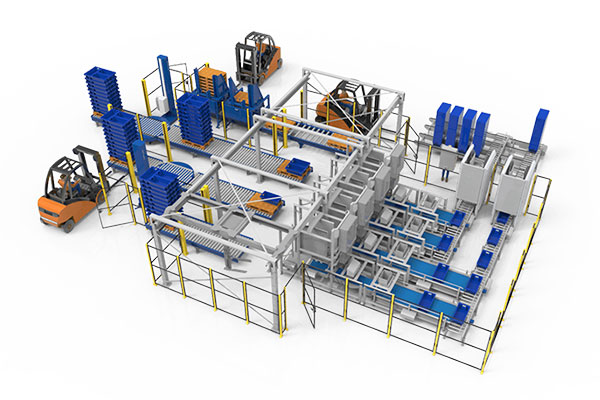

Stacking Nested Crates

- Do you need to stack or unstack nested crates on high-speed? The VPM-CS is especially developed for fully automated processing of products in stackable crates. The crates are supplied automatically and after being filled stacked stably on pallets.

Stacking Different Sizes of Onions at Once

- Stacking different sizes of onions without a storage bunker? With this smart installation three different sizes are processed simultaneously. Three palletizers, three weighing machines and three evenflow bins and product conveyors are completely integrated in the existing production line.

Stacking Inside Pallet Measurements

- Is your product vulnerable for damage during transport? Stack your product with our special indoor palletizing solution providing tight stack tolerances to be achieved prior to placement on a pallet resulting with protection of product from all sides on the pallet.