storemaster

Videos

Loading the player ...

- Offer Profile

- Thanks to an intense evaluation of the problems of the clientele, storemaster® 15 years ago identified a main source for profit loss in metal and plastic processing industries – not caused by the high-duty machine tools themselves, but due to the storing systems in the surroundings. At that period, the corresponding equipment was still based on a rather conventional design. storemaster® started to make use of creative ideas to improve the processes, and meanwhile has developed into one of the most innovative enterprises in this sector.

Product Portfolio

Sheet Metal and Bar Sorage: Pioneers of Storing Technology Present a Bundle of Creative Measures

- It is obvious that an efficient production must be accompanied by an adequate material flow. In view of this target storemaster®, as a medium-sized enterprise and disposing of years of experience in this sector, still goes on developing new handling and storing systems. The daily challenges of manufacturing industry and resellers are thoroughly elaborated and integrated in sophisticated solutions. Sheet types and quantities to be kept in stock, frequency of access necessary, lot sizes, handling of the goods, assignment to machines and process cycles – all these parameters are taken into consideration. In each single case, the structure of the site, transport and handling equipment available, data processing, investment intended and economical perspectives of the client are analyzed and furnish the basis of the draft. The powerful sheet storage system this way configured ranges between simple modern racks and highly automatized solutions for material distribution. The entire sequence of steps in material flow may be comprised, from goods receipt of raw material up to dispatching of the final products. The decision concerning the most convenient design of a particular solution is made after responsible weighing of all criteria for a sheet or bar storage system, with adapting initial data to functions and requirements of the production sector concerned.

Highly Flexible and Cost-Effective: Rack Systems Meeting Current Requirements of Storage Logistics

- Standard racks for sheet stacks, placed on wood pallets and combined with drawer racks, used to be a widespread arrangement in storage technology. The possibility of giving up wood pallets did not yet exist. Together with other innovative solutions for storage of long goods, storemaster® in the year of 1998 introduced sheet storage systems able to do completely without these unpractical wood pallets. Sheet Storage-Drawer Rack Systems are such an innovative approach, with an achievable storage density of 75 mm, allowing insertion of complete sheet stacks after de-palletizing, and to be filled by a loading crosshead. By means of the integrated Sheet Removal Device of a MasterTower, it is possible to take out individual sheets from 20 to 80 available drawers, and to transport them within only one minute to the machine assigned, even by one man handling. In this kind of compact station, the particular storage tower may comprise up to 25 drawers reserved for special sheets and Residual Sheets, intended for Single Sheet Loading. Drawers for sheet stacks of up to 3 t may still be operated manually, whereas items for a carrying capacity of up to 10 t are always coupled to Electric Drives. The latter option may also be part of Automatic Operation.

Efficient Comprehensive Configurations – from Sheet Rack System up to Storage Tower Solutions for Increased Capacities in Material Flow

- Sometimes in a rack system only a restricted number of sheet types frequently needed by the machine, can be stored. In these cases, it is possible to switch to Sheet Storage Tower Systems with Cassette-Flats acting as load carriers. The stack in question is taken out by a fork lift and transported to the machine, so thanks to modern storing technology, the number of sheet types available for sporadic processing is theoretically unlimited. The storage density in a Sheet Storage Cassette Tower can be increased to up to 150 mm per compartment, very close to the density to be achieved in Drawer – Rack systems. A sheet handling unit may be integrated as well. As rational storing with optimal space utilization belongs to basic tasks in metal working industry, cassette towers represent an excellent solution with respect to production economy, particularly because they significantly improve the infrastructure for handling, commissioning and distribution. The entire process speeds up, since a nearly unlimited number of material types in permanent exchange, remains available ready for use at the machine – supply just-in-time.

Two Systems in One: storemaster® Sheet Storage Exchange – Cassettes

- After Drawer Rack Systems and Storage Towers for Sheet Storage Cassette Flats, storemaster® presented the next innovation by combining these two systems. In these units, drawers are replaced by exchange carts to accommodate cassette flats. This configuration provides temporary buffer capacities to the machine in form of a certain number of sheet types, just until an exchange by stacker for following tasks can be performed. The sheet storage exchange cassette system can be used also for autonomous removal of single sheets. Apart from stacker transport, lifting of the cassette flats by crane, supported by a special Load Cross Bar, is possible as well.

Universal Sheet Storage Exchange Pallet as Targeted Complement to a Modern Rack System

- If the procedure of on-site de-palletizing is deemed to be impractical, a universal Sheet Storage Exchange Pallet may be advantageous. Empty and charged euroFlats are mutually exchanged in a permanent run, dispensing with the need for one-way wood pallets. This progressive alternative load carrier, far beyond the standard criteria of a cassette flat, meets the requirements of the sheet cycle, including applicability within any sheet processing machine irrespectively of its trademark. Even though their storage density is slightly reduced, this equipment offers benefits due to its price. The range of applications mentioned above, from exchange system to autonomous sheet removal, is available as well.

Storage of Long Goods for Compartment Filling Organization of Multiple Sizes and Quantities

- When storing long goods like bars, rods or rolls, a configuration with minimum space consumption is not easy to obtain. Besides the sheet rack modules described above, a particular version of the drawer rack systems has been developed, appropriate for any storing period of both raw material and final products. Thanks to an upgradable design and sophisticated structure, highest flexibility of drawer assemblies is ensured, thus offering valuable assistance when storage capacities in spite of restricted space have to be increased. The size of goods to be warehoused is nearly unlimited. Receptacle prisms for rolls are available too, precisely to be adapted to objects to be taken into consideration. In depth, the drawers can be subdivided into compartments by means of separating mandrels, so that also smaller quantities of rods, profiles and tubes can be inserted in a wide variety of types. Many metal processing companies often are in need of storing equipment convenient for semi-finished products in small lot sizes. storemaster® is able to present a corresponding solution for static or dynamical rack storing with optimized constructive form and practice-oriented handling. This enables users to implement infinite storage levels with organization of filled compartments, to be used for long goods in any length and size.

Long Goods Prepared for Crane Transport within 5 Seconds in One Go

- For enterprises handling a large number of rod material types, the long good shelf system TwenTower LG, offered by storemaster already for many years, represents the optimum solution. From now on, the recently developed model ArmStrong Swingout is available on the markets as well. This economically and ergonomically optimized shelf system features cantilevers and has been tailored for clients storing rods or other long goods of medium type variety at any bundle size. It enables products with a weight of several tons quickly to be made available to crane transport in one go, in quadrant under manual control without any effort.

Sheet metal bearing

Drawer Racks: Sheet Storage in Drawers

TwenTower

- Drawer Sheet Storage for all sizes up to 6.000 x 2.000 mm – capacity up to 3 t per drawer, i.e. large size system with pivoted rolling cheeks and pulling out of 2 m for upper drawer: 13 drawers for 3 t each/ 15 drawers for 2.5 t each/ 19 drawers for 1.75 t each; Supply / Unloading at One or Either Side

TwenTower+

-

Drawer Rack System up to Large Size with Filling Height for Drawers of 30 mm

For extended choice of flat goods at lower inventory level

As well as for intermediate storage of Residual Sheets.

Rolling cheeks

Pivoted or fixed at choice,

Supply / Removal from One or Either Side

ShuttleMaster

-

For Exchange of any Number of Sheet Types

Allowing Direct Access at the Machine

with Pivoting Rolling Cheeks

for Pulling Out for Upper Drawer of up to ca. 2 m

e.g. for Large Size Cassette-Flats:

13 Exchange Carts with 2.8 t Load Each / 15 Exchange Carts with 2.0 t Load Each /

19 Exchange Carts with 1.2 t Load Each

Supply / Unloading at One or Either Side,

ExchangePortal

-

Device for Quick Exchange of Sheets + Disposal of Residual Grates + Collection of Parts

By means of this manual exchange portal for system pallets (flats of all kind) with a capacity of up to 3 t, the waiting phase for the sheet type of the following task, may be reduced to zero. This cost-efficient solution is advisable particularly in the case of long cutting cycles and large numbers of identical sheets per task. Further useful options include disposal of residual grates (refer to special flat for residual grates), removal of finished products or entire plates after cutting, resp. integration into other production sequences. Sheet supply or removal may be take place at either transfer point in all of the three directions.

GigaTower

-

For Sheets up to 16.000 x 4.000 mm and 20 t Load per Drawer

Example:

External Store as >Cold Warehouse< for Sheets after Sandblasting.

Pallete systeme

ShuttleTower

-

Compartment height to be adapted by plug-in

Angle-to-Angle Guide

Front-to-Rear Support Construction

Open Forklift Pockets

Highest Storage Density

Hot Galvanized

Insertion Patent

euroTower

-

Universal Sheet Storage-Exchange Pallet

(DBGM)

As Permanent Load Carrier for Sheet Stacks after Removal of Wood Pallets

All storage-, transport- and production-oriented features of a load carrier required for uninterrupted material flow, are combined in one product

ArmStrong® BN

- Preconfigured rack units for all standard sheet sizes, in single or double side versions for different lifting heights of stackers.

ShuttleMaster

-

For Exchange of any Number of Sheet Types

Allowing Direct Access at the Machine

with Pivoting Rolling Cheeks

for Pulling Out for Upper Drawer of up to ca. 2 m

e.g. for Large Size Cassette-Flats:

13 Exchange Carts with 2.8 t Load Each / 15 Exchange Carts with 2.0 t Load Each /

19 Exchange Carts with 1.2 t Load Each

Supply / Unloading at One or Either Side,

Change-Systems

ShuttleMaster

-

For Exchange of any Number of Sheet Types

Allowing Direct Access at the Machine

with Pivoting Rolling Cheeks

for Pulling Out for Upper Drawer of up to ca. 2 m

e.g. for Large Size Cassette-Flats:

13 Exchange Carts with 2.8 t Load Each / 15 Exchange Carts with 2.0 t Load Each /

19 Exchange Carts with 1.2 t Load Each

Supply / Unloading at One or Either Side,

Automatic

- ShiftMaster (DBGM) represents a SheetHandlingStorageSystem particularly designed for fully automatic material supply to sheet processing machines of any type and trademark. At a room height of 3 to 4 m required, it can be configured either as an isolated solution consisting of 1 or 2 exchange towers, or as a sequence of any number of elements disposing of 10 to 15 drawers each. After a corresponding signal from the machine, sheets contained are individually unloaded by means of sheet manipulator (robot) programmed on the basis of an integrated storage management software. The weight of a sheet may amount to up to 750 kg. Each item, supplied on an exchange table to the machine, is then available for the next job. The drawers themselves are charged from the rear side by means of a stacker. In order to establish a continuous supply chain, additional exchange places can be prepared as required, whether above the exchange towers or in a separate multipurpose tower warehouse. Just like the sheet types contained in the towers, the content of the additional places can be used for other sectors of the production as well, so the system offers remarkable flexibility for requirements changing from day to day. Identification and separation of double sheets is included as well. The cycle time for access does not exceed one minute. Even in the case of an interruption or a malfunction, manual access to all sheet types is still possible. After cutting, the products by means of catchers or vacuum grippers can be compiled on load carriers held available – also within the exchange towers.

ShiftMaster SingleTower or TwinTower

-

Fully Automatic

Exchange Tower – Sheet Storage

For Temporary Storing of Pallets

Fully automated sheet supply to processing machines in single or twin tower configurations with 15/30 or optionally 20/40 drawers, for loading by stacker from the rear side, access for machine-controlled sheet manipulator (robot) from the front.

ShiftMaster MultiTower

- Fully automated machine-integrated system for supply of sheets to the machine and removal of finished plates after cutting, for any number of sheet types and connected machines; flexible configuration or extension to Single-, Twin- or Multi-Tower arrangements for drawers or exchange flats. To be filled from the rear side by front-loaders, side-loaders running on rails, or storage and retrieval units for high-bay warehouses. Cycle time ≤ 1 min., room height required: 4 m, de-palletizing and loading station, warehouse management, ProfiNet machine-interface, ERP connection, individual layout-options, unrestricted 24-hour operation, for any number of sheet types in direct or temporary access, return of cut plates, sheet part management, highest efficiency available on the market.

ShiftMaster Job Commissioning Unit

-

Unit for Commissioning of Sheets (Slabs)

Model of a Commissioning Unit for Slabs

Filling of drawers with exchange flats and of the top compartments by stacker from the rear side

Alternative Method for Commissioning:

a) on a plate supplied by the robot / Unloading of the commissioning pallet by stacker

b) in lower drawer level / Unloading of drawer blocks from the rear side by stacker

Top compartments to be used for system or wood pallets (whether complete or partially filled)

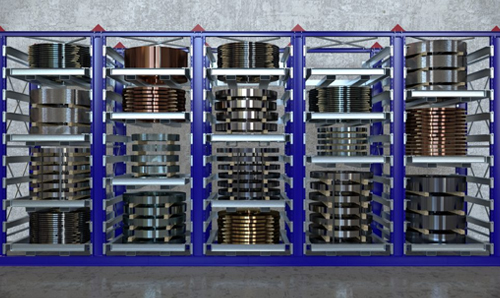

Optimized Coil Storage, developed by storemaster®

Highly flexible, reliable and efficient solutions for intralogistics, particularly for coil storage

-

Heavy Load-HandlingStorageSystem for Coils with an Admissible Load of 10t per Compartment. Operated by stacker or, if required, by storage and retrieval unit for high-bay warehouses, by means of supporting mandrel receptacle. The framework with compartment height adjustable by plug-in, is equipped with patented load belts for coils. Apart from optimized height for the compartments, this feature ensures homogeneous distribution of the load without increased line pressure at the bottom, furthermore an easy adaptability to modified coil diameters. By means of the same load belt patent, corresponding loading aids (ShuttleTower® slide-in flats) can be prepared for transport by fork lift. If coils are intended to remain on wood pallets, the normal horizontal beam Maxirack may be used.

Most efficient coil storage solutions presented by storemaster®:

To be accessed by stackers

Framework with compartment adjustable in height

Patented load belts for coils

Balanced storage, avoiding line pressure at the bottom

Easy adaptation to different coil diameters

SplittingStore

- Heavy Load-Handling Storage for Slit Strip Stacks with an Admissible Load of 10t per Compartment. Operated by stacker or, if required, by storage and retrieval unit for high-bay warehouses. For minimized consumption of space (rack height), the framework is laterally equipped with numerous guide bars adjustable by plug-in, to find the optimum position for the slide-in loading aids (transport and storage flats). This method is useful to adapt the compartment height to current requirements any time. Support may be provided by store management software for dynamical arrangement of items, if required, together with a stacker balance – this enables a permanent inventory to be implemented. If coils are intended to remain on wood pallets, the normal horizontal beam Maxirack may be used.

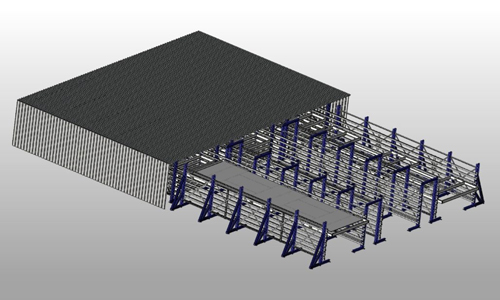

Bar Storage – Static and Dynamic Storage in Racks

-

Reliable, compact, efficient, and clearly arranged: Static and dynamic rack storage for long goods, organized by storemaster®

The importance of efficient use of available storage area in the last years has considerably increased. Dense arrangement of stored objects does not only contribute to economical consumption of space – an efficient storage system is also imperative to speed up the material flow. Optimized handling procedures furthermore can shorten filling and unloading steps in the production sequence. The powerful storemaster® approach for static rack storage of long products takes advantage of infinite storage levels to generate an added up arrangement of filled compartments, for any kind of long and bulky items in different lengths. By a sophisticated combination of structural elements, space can be economized: Accurate insertion of pallet woods into the clearances between crossbeams of the rack reduces the consumption of space in the vertical dimension, thus enabling much lower compartment heights to be achieved, compared to conventional systems. The method of loading without pallets -which is possible as well- may reduce the space consumption further.

A highly efficient, space saving and safe solution: storemaster® configurations for long objects.

Dynamical Bar Storage TwenTower LG

-

Drawer Shelf for a Great Variety of Rod and Tube Material Types

Manual drawer rack for bars, containing up to 500 different types of bar stock with a length of up to 6 m. Operation by crane, Single or double side versions are available, with max. 13 drawers. Individual subdivision of compartments by means of plug-in mandrels and trough shaped shelves, useful for provisioning of short and residual lengths, also for manual removal from the front. Drawer load up to 3 t for manual operation, up to 10 when used with electric drive

Dynamical Bar Storage ArmStrong® swingout

-

Store for Long Goods Appropriate for Crane Handling

Storage levels for bars swiveling out in a matter of seconds, to be accessed by crane with no effort. No additional control equipment required. Appropriate for any kind of long good, up to 8 levels at 2.5 m swiveling out height, with compartments to be subdivided by plug-in, and troughs to be subdivided as well, intended for short items. Compartment load 3 t (manual operation), 10 t with electric drive. For objects disposing of a length of up to 12 m, useful height 125 to 650 mm, individually selectable by plug-in 75:75 mm.

Static Bar Storage ArmStrong® V

-

Rod Material Shelf Store for Crane and Manual Operation

Supply of entire bundles by crane is simplified by plug-in storage aids. Bars can be taken out manually from front and longitudinal side. Plug-in pockets for commissioning enable different bar types to be combined and to be removed afterwards as a bundle by crane belt. For this reason, only narrow passages are required for material handling. Height adjustment of V-arms 75:75 mm is independent of the rest of the levels.

Static Bar Storage ArmStrong® plus

- For more than 30 years, the cantilever/plug-in rack system ArmStrong® has proven its ability all over Europe. Together with universal pallets for long objects, convenient for stacker and crane transport, stackable in a safe manner by patented catch pocket configuration, for material length of up to 12 m, individually to be subdivided by pins in different heights. The sophisticated design prevents squeezing of the belts during supply and removal of goods. For outdoor applications, the system is completely hot-dip galvanized.

Static Bar Storage ArmStrong® S

- Suitable stackers, stacker cranes and storage and retrieval units, without passage supports, with continuous storage levels, in any dimension and for any kind of long product, accessories and details according to customer requirements, for indoor and outdoor applications with roof and wall. Storage levels to be adapted in height by plug-in configuration of 75:75 mm.

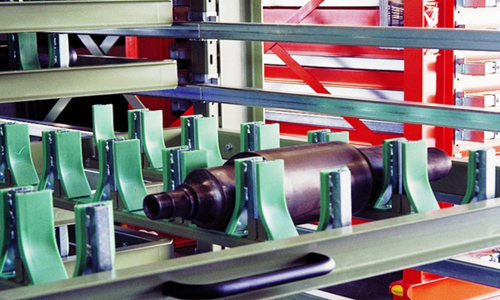

Cylinder Store Professional

TwenTower® for Rolls

-

Cylinder Store Professional

Logistics for rolls with extremely sensitive surfaces, widespread in steel, plastics, paper and printing industry, require particular care. These items with different sizes and weights are accommodated in special receptacles appropriate for crane handling in manually operable heavy load – drawer blocks, available with a maximum load of up to 10 t. Configurations with a weight above 3 t are electrically actuated, so rolling levels are moving in and out in slow and smooth motion (Power Function).

Peripheral

Magazine for Residual Sheets

- System featuring 25 drawers for Residual Sheets, height for pulling out: ca. 2 m, available in compact, medium and large size, height adjustable by plugging of 75:75 mm, pivoting rolling cheeks, drawers individually removable to increase filling height up to 105 mm, access from one or either side.

PalEx

- Multifunctional unit, to be used as de-palletizer, loading or unloading station, DBGM patented, handling station to be moved also without load for de-palletizing of sheets stacks, for filling of drawers and system pallets, or for unloading from the machine to allow manual removal of sheets at working height in any direction. In order to avoid pressure marks in thin sheets, displacing dies on cross incl. protecting cap made of hard rubber, are provided. Hot dip galvanized acc. to EN ISO 1461.

LoadingBeam

-

For Quick Filling of Sheet Storage Drawers with Wood-Free Sheet Stacks by Crane or Stacker

This option proves to be useful for handling of thin sheets. When filling drawers with de-palletized sheet stacks by means of belts (stacker or crane), diagonal pull in longitudinal direction must be prevented, otherwise sag of stacks is possible. Equipped with three adjustable safety – double load hooks, as well as with fork lift entry pockets adjustable with respect to distance of forks, incl. TÜV approval certificate, GS tested load belts and supporting beams preventing stack sagging in depth. To ensure safe transport, edge protection brackets are included.

OverheadTop for MasterTower®

-

Top for Drawer or Exchange Cart Systems with Minimum Space Requirement in Height and Crane Connection for Stacker Operation with Various Accessories

MasterTower®– Element

System-Top-Block to provide positions for stacker forks above the system block for drawers resp. exchange carts for all sizes and loads, for storing of:

One-way wood pallets as well as system pallets.

classic-flat, superflat, euroFLAT

Height of compartment height by adjustment steps 75 / 62.5 mm, pluggable

Overall height determined by lifting height of fork lift and height of the hall

Operation possible from front and rear side

TowerCrane© for MasterTower®

-

Slewing Crane System-integrated for all Drawer and Flat Systems for Removal of Material and Supply by Machine

MasterTower®– Element

Pillar mounted slewing crane, integrated within the system, foundation not necessary. Lightweight construction, installation possible at the four corners of all tower versions (standard method: at one of the long sides at the left and at the right – displaceable). Sheet weight up to 400 kg, admissible hook load 500 kg at a radius of action of 6 m. Crane column and electrical chain block are provided, as well as the electrical installation for manual and completely electrical operation; admissible load may be increased by reduced arm length.

Approval of crane by specialists after installation.

HandlingMaster® for MasterTower®

-

Sheet Manipulator Specially Designed for Sheet Store Drawer-and-Flat-Systems

MasterTower®– Element

Sheet Manipulator in multifunctional ergonomic design featuring comfortable handling functions; particularly developed for use with sheet storage drawer systems. System integrated for 400 kg sheet weight; in external use, even 750 kg are possible. Gravity compensation for horizontal handling is provided. Operation from the stand for gathering of sheets from a height of up to 2,500 mm. Control panel with buttons for all functions ensures safe and easy handling. Control cable protected from rupture by chain guide within the cable spiral. Double sheet separation DBGM (Anti-Adhesion device) + optical/acoustical warning equipment for prevention of accidents.

Cart for Residual Sheets

-

Optimum Overview for Inspection and Safe Access, Ensuring Perfect Management of Residual Sheets

For upright storing of plates in lower quantities, residual sheets and blanks in longitudinal direction for frontal browsing, convenient for stackers and ShuttleTower® – 3300/4300 x 1250 mm, with 48/60 separating shackles with a height of 750 mm, V-shaped for easy browsing (as known form poster stands, rotated by 90°) from longitudinal sides, separating shackle of 50:50 mm pluggable for compartment depth of 40 + n x 50 mm, movable. Guide rolls, fixing brakes as well as sliding grips at either side provided. Hot-dip galvanized, can be lifted by crane, carrying capacity 2 t.

Flexibolo

- Transport cart with central rotating axis (rotates in place at maximum precision) for all types of flats, carrying capacity up to 4,000 kg, sliding shackles at either side, fixed and guide rolls with fixing brakes. Available in single- or multi-size configurations, hot-dip galvanized.

LiftingBeam

-

Overhead Transport of Sheet Stack Flats to any Production Place within the Hall

For transport of flats in all sizes by hall crane, manually guided or not guided in the case of two synchronized chain blocks or cable pulls. This item is particularly useful for exchange of flats in ShuttleMaster–exchange systems, instead of transport by fork lift.

Flat for Residual Grates

- Prevents disarray in the production hall, allowing direct disposal of residual grates from the machine to the scrap container. For all sized and different filling heights, hot-dip galvanized.

CommissioningCart

-

For Commissioning of Finished Parts

for Europallets or euroTablet

800 x 1.200 x 850 mm high, Sliding Shackle

Carrying Capacity 1,500 kg, hot-dip galvanized

with 2 fixed and 2 guide rolls incl. fixing brake

optionally for fork lift and/or crane transport

euroTablet

-

Commissioning Pallet

Uniform exchange pallet euroTablet for compiling, commissioning and shipment of sheet parts / cut plates, special pallet for transport by truck, all sizes up from 800 x 1.200 mm EuroFormat, different filling heights, alternatively with folding frame and closed bottom or securing plate for protection of parts during transport, carrying capacity 3,000 kg, for fork lift or crane transport, stacks of 10 items possible, hot-dip galvanized.