- Offer Profile

-

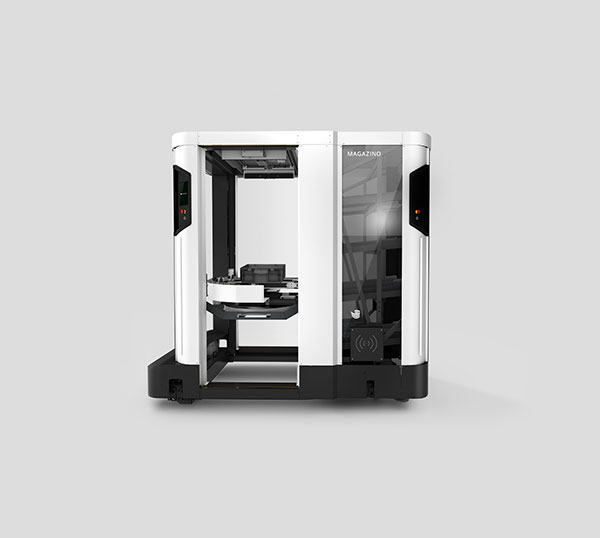

Magazino develops and builds intelligent, mobile robots for intralogistics.

We are Magazino, a robotics company from Munich. We develop and build robots that work together with people – autonomously, safely and at a level of complexity that nobody before us has reached.

This enables us to offer solutions for processes that could not previously be automated and to create intralogistics that are more flexible and efficient than ever before.

Picking the challenge.

TORU

Autonomous picking robot for shoe boxes

TORU can be easily integrated into an existing warehouse and existing warehouse and processes. Once configured, it works autonomously alongside its human colleagues. The connection to a warehouse management system is straightforward via WLAN.

With ARC (Advanced Robot Control), users always have an overview of the entire fleet, the individual robots, order management and relevant KPIs.

The TORU mobile robot is ideal for sorting orders into dedicated compartments and picking up boxes for the storage process. It picks up individual boxes and transports them to a transfer point. Here, TORU can consolidate different items into a single order so that the packaging process can be initiated directly.

Shoe boxes are its specialty: the intelligent picking robot TORU intelligent picking robot picks up individual cartons and takes them directly to the transfer to the transfer station. And for storage or returns? Back again. Up to up to 20 hours a day. This means he can be active outside regular shift times and, for example, smooth out peaks through preparatory work.

Order picking with TORU not only adapts to the environment, but also to increasing demand. New robots can be integrated directly, so your fleet grows with your success.

Applications

Precise order picking

- Targeted cartons gripping and stacking TORU has a precise vacuum gripper arm. arm. This enables it to handle cartons weighing up to 5.8 kg boxes with a maximum size of 390 x 280 x 145 mm 145 mm (L x W x H), with pinpoint accuracy, lifting and depositing. If necessary, even entire stacks.

Autonomous perception

- 2D and 3D cameras TORU localizes objects to be picked objects and free storage locations on the shelf. With intelligent algorithms, TORU searches for the bar codes and can thus identify the correct identify the right object.

High transport capacity

- 16 cartons and a further action area TORU can transport up to 16 objects simultaneously in its backpack rack at the same time. With its range of action from 8 cm to 250 cm above the the floor, it even surpasses the agility agility of a human being - without back pain.

Technology

Drive Base

- The drive base is optimised for maximum manoeuvrability and stability, so that TORU can be easily integrated into existing pick towers.

Tower

- The tower enables the gripper to be positioned quickly and precisely at any desired gripping height, as well as rotating agilely between the storage rack and the backpack.

Gripper

- The gripper moves in the tower and picks objects or stacks from the shelf with its powerful suction unit.

Backpack

- In its integrated backpack, TORU transports already picked objects to the handover station or inbound objects to be stored in the storage area.

Technical data

-

- Base area (LxW): 1375 mm x 685 mm

- Robot height, retracted: 1930 mm

- Robot height, extended: 2912 mm

- Curb weight: 235 kg

- Max. navigation speed: 1.5 m/s

- Battery run time:max. 8 hours

- Operating time: max. 18 hours per day

- Min. object dimensions (LxW): 50 mm x 100 mm

- Max. object dimensions (LxW): 390 mm x 290 mm

- Object height: 80 mm – 145 mm

- Max. object weight: 5.8 kg

Safety

- Our robots can safely interact with humans. For this purpose, we have equipped them with a state-of-the-art safety system from certified manufacturers. In addition, we work closely with our customers' on-site safety professionals to ensure smooth integration. Magazino robots comply with harmonized and non-harmonized standards as well as all relevant provisions of the EC Machinery Directive 2006/42/EC. Accordingly, they have received a risk assessment in accordance with DIN EN ISO 12100:2011-03.

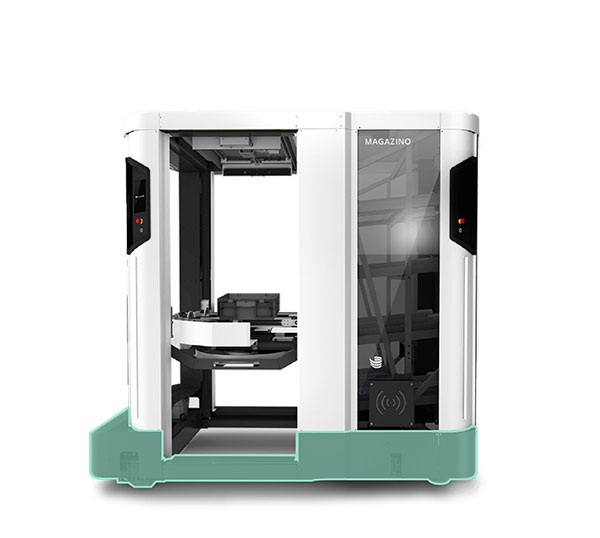

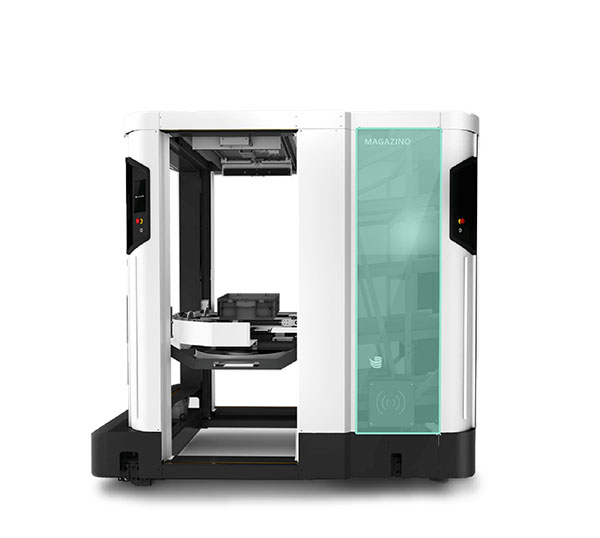

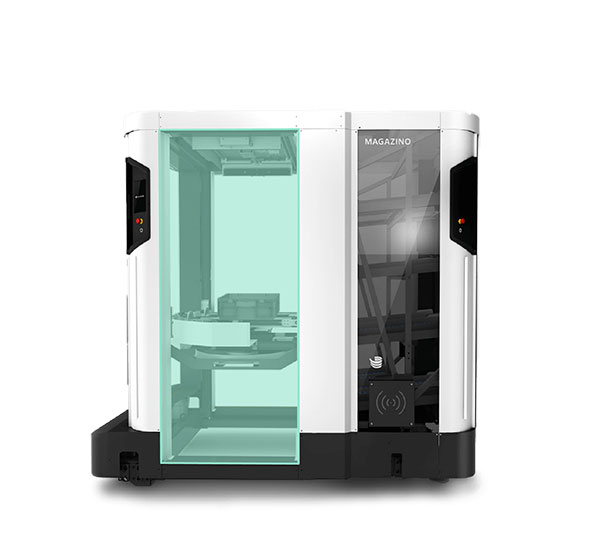

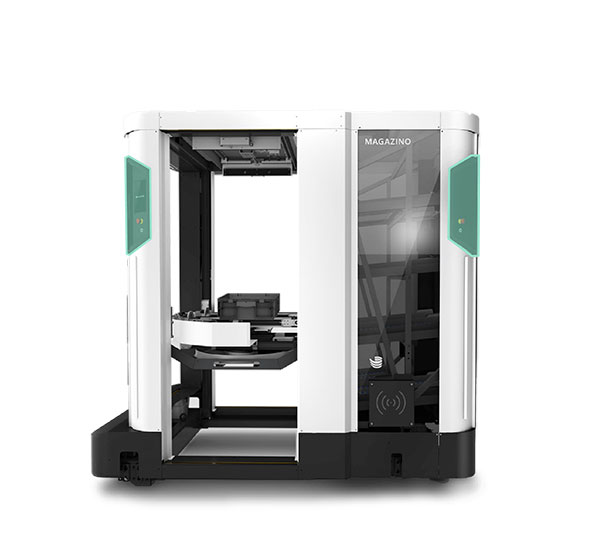

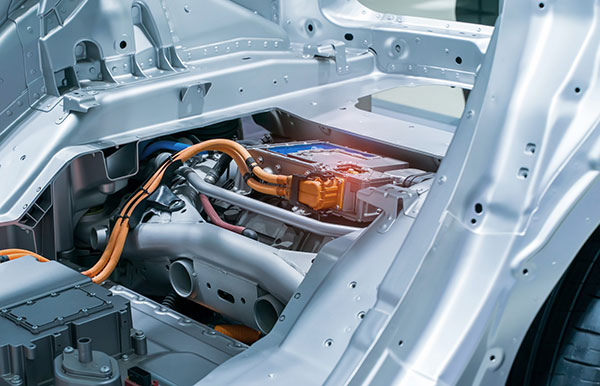

SOTO

A mobile robot that fuels industrial production: SOTO takes over intelligent line feeding, for example in automotive manufacturing.

Until now, supply chain management in production has been has been carried out almost exclusively manually. Driverless trans systems have driven automation forward. SOTO goes one step further and brings materials directly to the to the assembly line, just-in-time and completely autonomously. The initial setup is user-friendly and can be set up largely can be set up largely independently.

SOTO works up to 20 hours a day and enables processes that are processes that are not only more efficient, but also significantly more cost more economical. Its operation is deliberately simple and enables parallel operation with humans. with humans. The hardware is extremely robust and designed for reliability. You can rely on that.

Material flow automation with SOTO not only adapts to the to the environment, but also to increasing demand. New robots can be integrated directly, so your your fleet grows with your success.

The Magazino Fleet Manager offers full transparency in the operation of the robot fleet and process performance at a glance. Adaptations to changing environments are possible at any time. The SOTO fleet closes the gap between automated warehouses and an automated production line. With its high level of intelligence, SOTO is able to perform complex transportation tasks independently, reacting to changes in the environment and changing demand. It can completely replace tugger trains or cooperate with them in a meaningful way.

Features

SOTO Display

- Malfunctions directly on the robot rectify Thanks to its ability to communicate with the with the user via the integrated display communication, even people without without prior knowledge can easily troubleshooting with the robot. Specific instructions from the robot help to quickly get the operation quickly get operations up and running again.

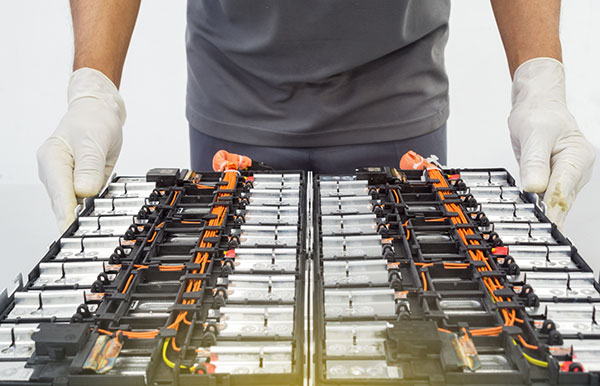

KLTs up to 20kg

- Different sizes and weights The KLT sizes vary from 300 x 200 x 80 mm (L x W x H) up to 600 x 400 x 320 mm. The sizes can be handled the sizes can be handled from the right left or from the front.

KLT Handling

- Flexible gripper mechanism The rotating gripper makes it possible to different sized KLTs by 90° or or 180°. For example This means that KLTs with full loads can be and empties can be picked up again on the short side. The gripper is also The gripper is also flexible in terms of height. transfer takes place at heights between 40 cm and 170 cm above the ground.

Backpack rack

- High transport capacity capacity With the double-occupancy, internal rack, SOTO can transport between 8 and 24 KLTs at the same time - depending depending on the container sizes.

Technology

Drive Base

- The omnidirectional drive enables precise maneuvering even in the tightest of spaces.

Backpack shelf

- SOTO can temporarily store several objects in the vehicle and transport them between source and sink.

transport.

Gripper

- The gripper can move vertically as well as drop and pick up objects in all four directions.

and pick up objects.

Interface

- If interaction with humans is necessary, touch displays show the relevant information and enable intuitive information and enable intuitive operation by employees directly on the robot.

Technical data

-

- Base area (LxW): 1870 mm x 1002 mm

- Robot height, retracted: 1955 mm

- Robot height, extended: 3334 mm

- Curb weight: 370 kg

- Max. navigation speed: 1.5 m/s

- Battery run time:max. 10 hours

- Operating time:max. 18 hours per day

- Min. object dimensions (LxW): 180 mm x 80 mm

- Max. object dimensions (LxW): 600 mm x 400 mm

- Object height: 120 mm – 300 mm

- Max. object weight: 15 kg

Safety

-

Our robots are safe to use with people. To this end, we have equipped them with a state-of-the-art person recognition system from certified manufacturers. We also work closely with the occupational safety specialists at our customers' sites to ensure smooth integration.

A complete overview of all technical details and requirements for the working environment can be found in the data sheet. Further information on the robot is also available in our free webinar.

Sectors

Smart logistics for automotive production

-

Material flow automation with intelligent line feeding for industrial production.

In the automotive industry, production logistics must meet the highest requirements to ensure smooth production.

Optimal logistics processes are an essential success factor in production. Intelligent planning and control of material flows as well as the use of automation solutions through intelligent robots enable high efficiency and flexibility.As the only solution on the market, the autonomous KLT robot SOTO offers the possibility of optimally providing material with different heights and rotations. In doing so, SOTO interacts with existing AGVs and manual vehicles, reduces the error rate in previous manual handling and offers full transparency in terms of inventory and tracking at all times. Even after the conversion of the production line.

Smart logistics for injection molding production

-

Flexible material flow automation with optimized space utilization and container exchange at the same position

High space utilization in injection moulding production requires careful planning and implementation of automation solutions. By using autonomous and mobile logistics robots, you focus on your core business: production — we take care of the transport tasks.

In injection moulding production, optimized use of space is often given by a maximum number of injection moulding machines. A high transport capacity of the KLTs per trip, increases the efficiency of the supply and relieves the traffic of mobile robots.

Another success factor is the container exchange at the machine. Here, automation solutions must be designed to reliably deliver and remove containers at different heights and in different orientations without disrupting the machine’s production flow.

Smart logistics for electronics production

-

Material flow automation with intelligent line feeding for industrial production.

Increasing cost pressure from Asia is pushing intelligent automation solutions further into the foreground for European manufacturers. The use of autonomous and mobile robots increases their own productivity and secures their own competitiveness.

Automation solutions in production are already established. AGV systems take over a large part of the material transport. The last hurdle to the end-to-end solution is material flow automation up to the production line.Especially in electronics production, where high precision and flexibility are required, autonomous KLT robots offer numerous advantages. From easy connection to different types of machines thanks to flexible gripping technology to increased efficiency and throughput times.

Smart logistics for consumer goods production

-

Material flow automation with intelligent line feeding for industrial production.

Industrial automation is a key factor for European manufacturers to remain competitive. Intelligent automation of the material flow increases their own proRegular line conversions are the order of the day. This requires a high degree of flexibility in production. The high variance of parts requires more material and thus more KLT transports.

Regular line conversions are the order of the day. This requires a high degree of flexibility in production. The high variance of parts requires more material and thus more KLT transports.

But often there is no space on the assembly line to provide material in a confined space. SOTO offers the possibility to reduce stocks on the line and to provide material at different heights and orientations ergonomically at the assembly workstation.

Smart fashion and lifestyle logistics

-

Higher, faster, further — the requirements for competitive logistics in e‑commerce are changing massively.

The level of customer expectations has risen significantly in recent years. As have the requirements for companies. Against this background, automation and digitalisation play a decisive role.

Added to this is the growing number of sales channels. In addition to branches and their own online shops, these often include numerous online platforms and social media through which orders are placed directly. The increased order volume requires investments in intelligent logistics processes that secure competitiveness and offer flexibility for the future.

Case Studies

Zalando's smart intralogistics

- Zalando is EuropeÂs leading online platform for fashion and lifestyle. The range includes almost 2,000 world-famous brands as well as various local and self-designed labels. ZalandoÂs logistics network with five central logistics centres enables efficient delivery to all customers throughout Europe. Zalando is convinced that the triad of fashion, technology and logistics offers its customers and brand partners added value. Since 2018 the fleet at Zalando has grown to eight TORU robots. In 2021 the fleet was expanded to a total of 28 robots.

Fiege relies on Advanced Robotics

- The family-owned company Fiege is one of the leading contract logistics service providers in Europe. Fiege has made it possible for Magazino to test theoretical knowledge in practice and to further develop the robots through joint findings. With Magazino, Fiege has found a strong partner with whom it has been able to successfully master the challenges of intralogistics today and tomorrow since 2016. The robot fleet has grown since then to a size of nine TORU robots.

Schuurman Schoenen

- Schuurman Schoenen, a renowned Dutch company specializing in the sale of shoes and accessories, has several stores in the Netherlands and an online store that serves customers throughout Europe. When the company experienced a surge in demand and higher order volumes, it faced the challenge of effectively managing its inventory and streamlining its warehouse operations. Manual searches for specific products were becoming time-consuming and inefficient, so Schuurman Schoenen sought a solution to improve its warehouse management processes.

Vega relies on Advanced Robotics

- VEGA Grieshaber KG is a specialist in level and pressure measurement technology. At the Schiltach site in the Black Forest, the pilot project of SOTO 2 began in spring 2021 after a development partnership lasting several months. The mobile robot from Magazino transports small load carriers (KLT) from the warehouse to the production line. The goal is to completely automate material supply at VEGA with SOTO.

ASICS runs with intelligent robots

- Headquartered in Kobe, Japan, ASICS is a leading designer, manufacturer and retailer of high-performance athletic footwear, apparel and accessories. Founded in 1949 by Kihachiro Onitsuka, the company name is derived from the Latin saying Anima Sana In Corpore Sano (ÂA Sound Mind in a Sound BodyÂ), and this maxim continues to guide the activities of the organization as a whole.

LLOYD Shoes

- Attention to detail, constant striving for further development and the implementation of the latest innovations in the retail trade position the traditional company LLOYD as a pioneer in the identification and fulfillment of current customer requirements.