- Offer Profile

-

Our solutions do more than automate fulfillment operations. We fundamentally transform supply chains to enable more flexibility, scalability and efficiency. In turn, our customers find they can offer new propositions and fuel growth, turning the supply chain from an operating cost center to a revenue driver and strategic differentiator.

Make the move to modern fulfillment

At GreyOrange, our approach is applied innovation that delivers measurable results for value and advantage. Our scientists, designers and engineers never stop solving in the dynamic quest for continuously higher performance, greater efficiencies and more satisfied customers for your business.

Fulfillment Orchestration Platform

-

Advanced fulfillment science

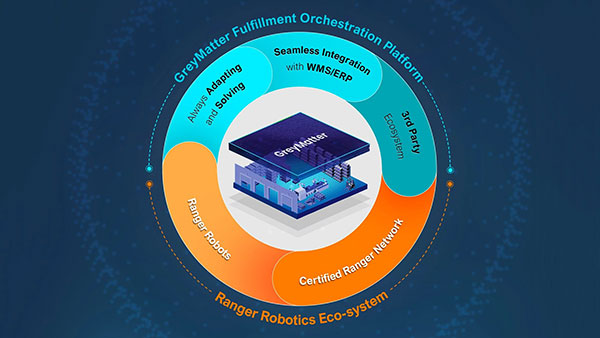

GreyMatter AI is the brain of the GreyOrange fulfillment platform. The platform integrates with smart Ranger robots – and other best-in-class robots – to orchestrate GreyOrange fulfillment software, robots and people across the robotic warehouse automation system. To enhance performance across every fulfillment node, including omnichannel, micro fulfillment, ecommerce and in-store fulfillment.

Stronger than the sum of its (bot) parts: How GreyMatter works

Most autonomous mobile robots (AMRs) – and the fulfillment software they run on – solve problems using individual bots or agents, leading to siloed solutions for individual workflows and areas. In contrast, the GreyMatter fulfillment Orchestration Platform integrates multiple agents – including different bots and the human beings who interact with machines in the fulfillment process – to drive seamless fulfillment across the whole warehouse.

The GreyMatter orchestration engine assigns multiple agents to drive work across various areas and material flows to solve myriad intricacies impacting warehouse efficiency. Drawing on data from across the full spectrum of operations, GreyMatter drives optimal decision making through its entire software, robot and human ecosystem.

The result is that GreyMatter produces real-time solutions that are more powerful than the sum of individual bots – and robots and solutions that are all interconnectable, autonomous and resilient.

Multiple bot orchestration. One powerful fulfillment solution.

- Go robot agnostic

- Integrate seamlessly

- Accelerate performance

- Scale and grow

- Gain resilience and stability

- Boost flexibility. Minimize risk.

- Execute an end-to-end robot orchestration.

- Access real-time insights and control.

Unleash the power of AI. Achieve next-level fulfillment.

-

From dock-to-stock processing of high-volume inventory, to handling multi-variant SKUs, palletizing and inventory, through to rapid picking and pickup. Successful last-mile fulfillment requires an omniscient operating system capable of negotiating complex interconnected variables, in real time. It’s only possible through intelligent software that’s always solving – GreyMatter.

GreyMatter Fullfillment Orchestration Platform

-

The GreyMatter Fulfilment Orchestration Platform continuously solves to drive optimal decisions, efficient orchestration and rapid execution across the entire fulfillment operation. So you’re ready in real time, for whatever the market has in store.

Powered by AI that seamlessly integrates fulfillment software, smart robots and people, GreyMatter instantaneously models the best decisions to drive optimal workflows and execution using machine learning and adaptive learning.

Every new scenario’s unique complexities are instantaneously assessed in real-time. Each outcome’s formula histories are called up, tested, applied or rejected and fluidly calibrated for best fit and highest probable accuracy, efficiency and speed. The result is a dynamic knowledge base of data-driven information and best-case workflows – all to accelerate every future scenario process.

Always solving for whatever the market brings

-

GreyMatter evaluates and drives real-time decisions to orchestrate people, processes and robots to enhance order fulfillment – making it faster, more efficient, cost-effective, more productive and accurate.

Choose the level of GreyMatter functionality and performance that supports your goals for expansion and growth. GreyMatter is engineered to meet you where you are – and elevate your level as you expand your vision.

Person-to-Goods Cobots for Assisted Picking

-

Ranger™ Assist, powered by GreyMatter™, is a highly configurable mobile cobot system that works alongside the human workforce. It delivers assisted picking for multiple operators across the warehouse.

The GreyMatter multi-agent orchestration platform directs bots to travel along an optimized path to multiple locations and floors, enabling the right picks and transfers, at the right time. Working with humans, systems and robots from multiple vendors, GreyMatter maximizes productivity.

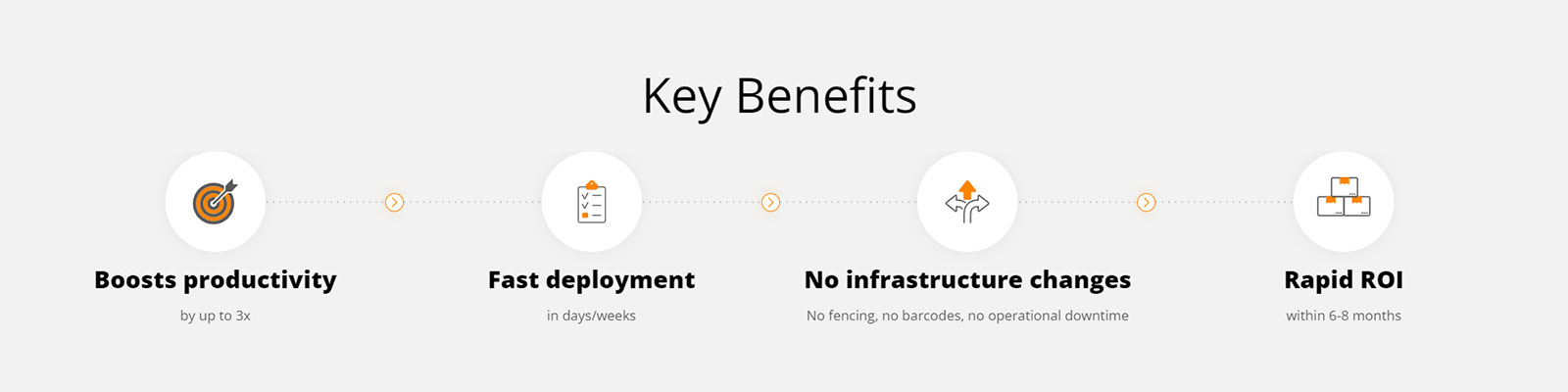

Ranger Assist can be easily deployed without warehouse infrastructure changes, requires minimal operator training and delivers increased productivity from day one.

Ranger Assist

-

A leading 3PL was looking for a quick-to-implement warehouse automation solution to ensure on-time ecommerce fulfillment for their premium performance sportswear client. They selected Ranger Assist powered by GreyMatter, which would significantly boost productivity by dynamically orchestrating order allocation across multiple floors. With hybrid picking, the allocation and distribution of orders to workers across dynamic zones, and the combination of multiple orders for maximum bot and worker, the 3PL was able to achieve 2.2x greater picking throughput and fulfill orders with 99.9% accuracy.

- Payload: Up to 220 lbs

- Maximum Operating Speed: 1,5 M/s (3.4mph) up to 1.75 m/S (3.9 mph)

- Navigation Method: SLAM via LiDAR

- CE Certified: Meets all safety, health and environmental protection requirements

GreyOrange Ranger Assist Automation Solution

- Flexible configurations

- Peak management

- More accurate picking with less walking

- Reduced training time

- Worker safety

- Workforce retention

Autonomous Picking Arm

-

Ranger PICK - Ranger PAL – Autonomous robotic picking arm

This category focuses on automating repetitive grasping and placing tasks across a wide variety of object form factors and fulfillment applications. AI powered perception, manipulation and grasping are the foundational technologies behind the robotic arm, robot arm or autonomous picking arm – as they are called, in this category which unlocks several applications such as unloading cartons/totes at inbound docks, pallet creation, vertical and horizontal each picking. These warehouse picking equipment or picking systems are basically an order picking system which help a warehouse picker with an improved efficiency and speed.

Autonomous Picking Arm - Ranger Pick™

-

Ranger PICK key specifications

- Industry’s first vertical arm picking

- No Pre scan of inventory required

- Safety certified

- Pick up to 15kg with dimensions of 10×10 to 40x40cm

- Handle a variety of inventory

- GreyMatter enabled auto order processing

Ranger PAL™

-

- High speed operations – handle up to 600 cases/hr

- Easy integration with case picking stations, sortation stations, loading/unloading docks, packing machines etc.

- Pick heavy payload up to 50 kg/unit

- Handle a variety of inventory in form of cartons, cases, totes etc.

- End effector: Pneumatic/Suction actuators

- Robotic ARM with cell: Both options (Cobots & Industrial Range)

Both options available (PneumaticElectric)

Payloads up to 50kg/case (carton) - Conveyor: Rollover conveyors (Zero pressure accumulation type)

- Docking pallet: Supports all types of pallet sizes (Euro, Standard American sizes etc.)

- Undocking pallet: Robot Control Panel (Teach pendants)-Microcontroller or PLC based systems

Dock to Stock

-

Unload. Stock. Ship.

Optimize Efficiency – All Across the Fulfillment Continuum.

Smooth inventory replenishment is a prerequisite to efficient fulfillment. Navigating complexity, the effective modern warehouse restocks efficiently – so it can complete orders on-time and cost-effectively.

Optimizing palletization, ensuring accurate rainbow pallet formation, enabling efficient cube formation, and maximizing truck fill rates. Ranger Dock-to-Stock (DTS) delivers the one-stop solution for optimizing dock-to-stock, truck-to-stock and stock-to-truck transfers and shipments.

Ranger DTS automates the palletization and transfer of inventory to various warehouse locations. And choreographs people and robots – including palletizers, automatic robot arms and intralogistics system – to execute complex stock movements that power your fulfillment operation to:

- Receive and organize more stock faster

- Fulfill more customer orders accurately

- Free up humans for value-added work

Ranger™

-

Achieve broad, measurable results

Ranger DTS enables the warehouse to achieve the following:

- Accelerate truck loading and unloading by 3-4x – and reduce dock turnaround time 2.5-3x

- Drive high throughput – ranging from 8 to 25 cases per minute – for loading and unloading

- Achieve 99.9% palletization efficiency and accuracy in rainbow pallet formation

- Reduce user fatigue, cut operational overtime spend, and achieve ROI in just 1.5 years

Ranger™ Dock to Stock. Powered by GreyMatter™

Powering it with 360° operational warehouse awareness to orchestrate dock-to-stock processes in sync with the flow of the floor – and keep pace with demand. The activities of Ranger DTS are integrated into GreyMatter’s machine learning capabilities to constantly enhance its bots’ operational performance.

Goods to Person

-

Maximize goods-to-person (GTP). Accelerate throughput. Drive omnichannel.

Choice and speed are the watchwords of today’s omnichannel retail model – presenting the fulfillment operations of leading retailers with big challenges. But fast fulfillment can’t be met with fixed infrastructure and rigid automation built for a previous era. From putaway all the way to picking, efficient fulfillment must be automated.

Introducing Ranger Rack-to-Person (RTP) – the goods-to-person autonomous mobile robot (AMR) – for automated putaway, inventory storage, replenishment and order picking in fulfillment and distribution centers.

Powered by the GreyMatter fulfillment operating system, Ranger RTP is configured to operate with mobile storage units (MSUs) and the static pick-put and roll-cage pick-put station accessories available for Ranger products. All designed to allow the warehouse’s robots and human workforce to collaborate efficiently.

Ranger Rack-to-Person (RTP)

- Ranger RTP capabilities

- The Ranger RTP automation system adapts seamlessly to changing inventory profiles, demand patterns, and peaks

- Modular system architecture ensures bi-directional scalability to increase storage volume or fulfillment throughput independently by adding more storage racks or robots as needed.

- From reducing travel time by 5x that of human workers to reconfiguring mobile stock units (MSUs) – and working in tandem with other GTPs and Ranger Pick – the result is fluid, dynamic optimization.

Intralogistics (IL) AMR

- Move More Inventory. Quickly. Efficiently. Safely.

Conventional warehouses pose numerous hazards. Human-operated machines like forklifts can damage inventory and cause serious injury. Indeed, manual fulfillment processes are costly, inefficient and inherently risky. Not to mention that in today’s tight labor market, hiring and retaining workers presents a major challenge.

Introducing the Ranger IL-L platform robot – one half of the powerful Ranger IL intralogistics autonomous mobile robot (AMR) duo that also includes the Ranger IL-H forklift robot. Orchestrated by GreyMatter, the robots navigate through the warehouse environment autonomously through the use of 2-D LiDAR based SLAM technology.

Automate 5 powerful applications

Ranger IL-L transforms how material flows throughout your facility by automating the warehouse material handling fleet. Control control dock to stock, cross docking, integration with goods to person picking, case replenishment, pallet pick and outbound flows – to deliver fast, efficient and safe throughput.

- Dock to Stock

- Replenishment

- Post-pick conveyance

- Cross docking

- Trash / empty pallet movement

Ranger IL-LÂ

-

Accelerate fulfillment with real-time inventory and order orchestration

Ranger IL-L automates the movement of robots and materials across the distribution center – including heavy payloads up to 2,205 lbs – flexibly and autonomously by:

- Dynamically adapting to business rule parameters, while protecting SLAs and the safety of people and materials

- Automating horizontal material transport to focus warehouse activity on value-added activities like scheduling deliveries effectively to optimize throughput

Pallet Mover/Forklift

-

Move More Inventory. Quickly. Efficiently. Safely.

Conventional warehouses pose numerous hazards. Human-operated machines like forklifts can damage inventory and cause serious injury. Indeed, manual fulfillment processes are costly, inefficient and inherently risky. Not to mention that in today’s tight labor market, hiring and retaining workers presents a major challenge.

Introducing the Ranger IL-H forklift robot – one half of the powerful Ranger IL intralogistics autonomous mobile robot (AMR) duo that also includes the Ranger IL-L platform robot.

Orchestrated by GreyMatter, the robots navigate through the environment autonomously through the use of 2-D LiDAR based SLAM technology.

Automate 5 powerful applications

Ranger IL-H transforms how material flows throughout your facility by automating the warehouse material handling fleet. Control control dock to stock, cross docking, integration with goods to person picking, case replenishment, pallet pick and outbound flows – to deliver fast, efficient and safe throughput.

- Dock to stock

- Replenishment

- Post-pick conveyance

- Cross docking

- Trash / empty pallet movement

- Seamlessly move inventory. Move various payloads across the distribution center – from pickup to drop off points – including pallets, trolleys, roll-cages, gaylords and more.

- Adapt to changing workloads. Fine-tune workflows in real time through dynamic integration to respond to changing order volume and environmental and system conditions.

- Realize ROI quickly. Take advantage of ready-to-run implementation to create immediate value in time, cost and accuracy.

- Seamlessly integrate with systems and people. Operate in collaboration with other robots, people, automated infrastructure and inventory with mobile spatial navigation.

Ranger IL-H

-

Accelerate fulfillment with real-time inventory and order orchestration

Ranger IL-H automates the movement of robots and materials across the distribution center – including heavy payloads up to 2,205 lbs – flexibly and autonomously by:

- Dynamically adapting to business rule parameters, while protecting SLAs and the safety of people and materials

- Automating horizontal material transport to focus warehouse activity on value-added activities like scheduling deliveries effectively to optimize throughput

Sortation & Smart Conveying Robots

-

Flexible, scalable fleets convey & sort packages or inventory from receiving through dispatch without bottlenecks or rigidity.

Scale and locate conveying and sorting robots as demand requires

Our fleet are flexible, scalable fleets used for conveying & sorting packages or inventory from receiving through dispatch without bottlenecks or rigidity.

In today’s fast and fluctuating commerce landscape, businesses can’t afford the restrictions of rigid conveying and sorting systems. Once locked-in, these systems can’t flexibly adapt and scale with demand patterns and business changes.

Ranger™ MoveSmart can augment or even replace rigid systems to deliver scalable and portable conveying and sorting systems as you need it, where you need it, especially when handling peaks. Capable of operating in footprints where rigid systems won’t fit, Ranger MoveSmart helps you optimize current facilities, plus can easily relocate to other facilities as you grow

Ranger MoveSmart  sorting robots

-

Ranger MoveSmart specifications:

- Different Induction Modules  Manual Induction  Semi Automatic Induct Station  Automatic Induct Station  Conveyor Induction

- Parcel dimensions: RMS-XL Â 800Ã600 mm RMS-M Â 600Ã450 mm

- Parcel weight: Up to 35 KGs

- Compliance: CE & UL

- DWS: Automatic Dimensioning, Weighing and Scanning

- Rejection provision: Automatic Rejection in the case of Automatic Induct whereas Manual Rejection in the case of Semi-Automatic Induct

Tote to Person Autonomous Robot

-

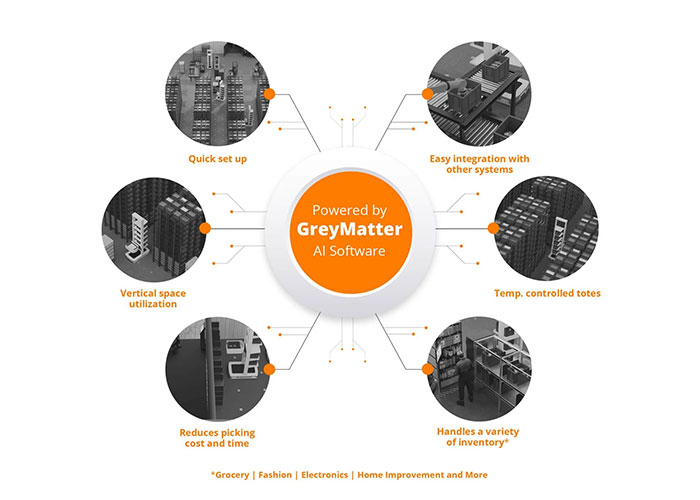

Vertical space utilization

This category focuses on maximizing per square foot utilization by leveraging vertical storage space as well as maximizing throughput from the forward picking zone. The foundational principle is to ensure flexibility in robotics in order to create truly omnichannel and agile fulfillment centers. Ranger Tote-to-person is a vertical autonomous mobile robot which helps in vertical space utilization or tote/carton handling applications with real time adaptability to dynamic channel and SKU popularities. It can work with other Ranger GTP agents to accommodate oversized inventory in a hybrid storage system, helpful in a Micro Fulfillment Solution.

Ranger TTP for micro fulfillment solution

- Space utility: Vertical buffer and lifts for height utilization

- High throughput: Up to 35 totes in + 35 totes out per hour per bot

- Flexible infrastructure: Fast setup and go live with minimal fixed infrastructure

- Storage efficiency: Multilayer Tote & Carton Picking of different sizes

- World class safety: UL & CE Certified , obstacle detection, safety contact edges, sound alarm, emergency stop button, anti collision lifting fall protection

Ranger TTP™

-

Key specifications:

- Maximum weight per tote/carton: 50 kg with customisations for overweight inventory

- Tote/carton dimensions: 30x30cm to 60x40cm with customisations for oversized inventory

- Picking height range: 400mm to 10 meters

- Storage configurations: Single or double deep

- High operator efficiency: Zero Walk automated takeaway workstations

Powered by GreyMatter™ intelligence