- Offer Profile

-

Stow Group develops and manufactures advanced logistic solutions for storing pallets, small goods, long items, and mezzanine structures. Its portfolio includes pallet racking, shelving, cantilever systems, shuttles, and automated high-bay warehouses.

Leadership in storage & racking solutions

-

Storage solutions like pallet racking systems are used in a wide range of industries to store products ready for delivery to customers and consumers around the world, or to supply production lines with materials needed for manufacturing. Warehouses need optimised storage space designed for maximum productivity and efficiency.

Storage and racking solutions from stow not only meet these criteria, but often set new standards in quality, speed of installation and ROI. From pallets to small goods, cantilever systems to mezzanines, stow’s portfolio of solutions for companies looking to maximise their warehouse space and storage capacity meets all challenges.

Pallet racking solutions

-

An effective pallet racking solution should address several key points to improve your warehouse operations and meet your specific needs. With stow, you’ll always get a pallet racking solution that optimises your warehouse space and ensures the safety, productivity and efficiency of your operations.

Our pallet racking solutions are the ideal way to optimise your warehouse. They are technologically sophisticated, economical and durable. With solutions from stow, you can:

- Maximise storage capacity: Our pallet racking systems take advantage of your warehouse height by offering multi-tier shelving, high-bay racking, or other solutions that store items vertically. Features like adjustable shelving or mobile racking systems can help eliminate wasted aisle space and maximise storage density.

- Enhance picking efficiency: Features like automated retrieval systems (shuttles) expedite picking processes.

- Raise safety and security: Our pallet racking systems are robust and meet industry safety standards for weight capacity and stability.

- Scale up easily: Our pallet racking system can be easily expanded or modified to accommodate future growth in your inventory or storage needs.

Conventional Pallet Racking

-

Pallet racking offers a multitude of benefits that significantly contribute to warehouse efficiency. Pallet racking allows you to store pallets vertically, maximising the use of your warehouse height and increasing overall storage capacity. Pallet racking creates designated storage locations for each pallet, eliminating clutter and wasted space. By implementing pallet racking, warehouses can achieve significant improvements in efficiency. From maximising storage space and streamlining picking processes to enhancing inventory control and safety, pallet racking systems are a valuable investment for any warehouse operation.

The stow Pal Rack® system consists of a full range of basic components and accessories to fulfil all of your requirements. The system is designed for the optimised storage of goods of all sizes and weights. All components have been thoroughly tested in specialised laboratories to determine their mechanical properties.

Advantages:

- Flexible pallet storage

- Easy installation

- High quality

- Quick ROI

Drive-in racking

-

Increased storage space with drive-in racking

Drive-in pallet racking systems take warehouse efficiency to another level by maximising storage density and streamlining processes. Drive-in racks minimise the number of operating aisles needed for forklifts. They allow you to store pallets directly next to each other, significantly increasing storage capacity compared to traditional pallet racking systems. Drive-in racks are typically used for storing large quantities of similar items. Overall, drive-in racking systems offer a powerful solution for warehouses seeking to maximise storage capacity and optimise space utilisation. And they provide safe block stacking for goods, that are not stable enough to be stacked one on top of the other.

- Increased storage space

- Safe block stacking of fragile goods

- Very high installations possible

- High level of safety

Pallet live stocking

-

Efficient and ultra-dense storage

Pallet live storage, also known as gravity flow racking or pallet flow racking, optimises warehouse efficiency by utilising gravity and a dynamic storage system. Pallet live storage eliminates the need for workers or forklifts to travel within storage bays to retrieve pallets. Pallets are loaded on one side and gently roll down slightly inclined lanes due to gravity, positioning them at the picking zone on the opposite side. This significantly reduces picking times and expedites order fulfilment, i.e. the tour preparation for trucks.

Overall, pallet live storage offers a dynamic solution for warehouses seeking to significantly improve picking efficiency, optimise space utilisation, and promote FIFO inventory management. stow’s pallet live storage system provides efficient and ultra-dense storage of palletised goods with fewer aisles. This increases your storage capacity considerably.

- Increased storage space

- High density storage

- Saves time

- Reduces energy costs

High Bay AS/RS racking

-

More storage capacity, more efficiency

High bay AS/RS racking from stow is a cutting-edge storage solution that integrates advanced automation technology with high-rise racking systems. This combination enables the efficient and systematic storage and retrieval of pallets, significantly enhancing the productivity and safety of warehouse operations. stow high bay AS/RS racking utilises the full vertical space of a warehouse and can be built higher than manual pallet racking system. The system comprises automated cranes that operate on floor-mounted rails and are stabilised by guide rails at the top of the mast, supported by a robust racking structure. With stow’s high bay AS/RS racking solutions, you can store more, store higher, and store denser, maximising the utilisation of your available space.

- High density, high throughput

- Less errors

- For ambient and cold store temperatures

- 24/7 operation

Silo

-

The racking is the warehouse

A racking silo, also known as a silo rack or clad rack warehouse, is a unique storage system that combines the functionality of industrial pallet racking with the structural elements of a warehouse building. stow Silo offers several advantages for warehouses looking to optimise storage space and efficiency.

The core of the racking silo is a robust pallet racking system, typically designed for high-bay applications. This allows for storage of pallets on multiple levels, maximising the use of vertical space within the warehouse. Unlike traditional pallet racking which exists within a separate warehouse building, the racking itself becomes the load-bearing structure of the warehouse. Wall and roof cladding materials are directly attached to the racking uprights, eliminating the need for a separate building frame. By eliminating the need for a separate building structure, racking silos offer a potentially more cost-effective storage solution. Construction time can also be significantly reduced compared to traditional warehouse construction. Since the racking itself forms the building structure, construction time for a racking silo can be faster than building a traditional warehouse with a separate racking system.

- Meets the most stringent safety standards

- Cost-efficient customised solution

- No need for supplementary structures

- Individually engineered according to your needs

Semi-automated solutions

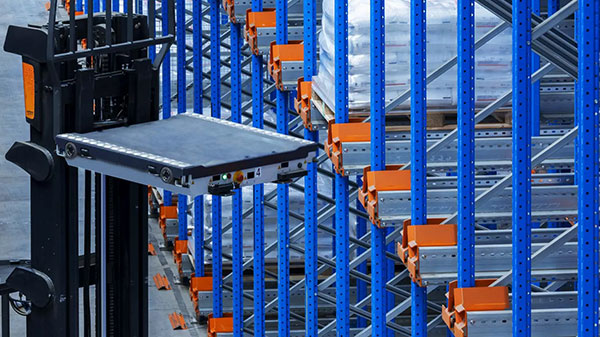

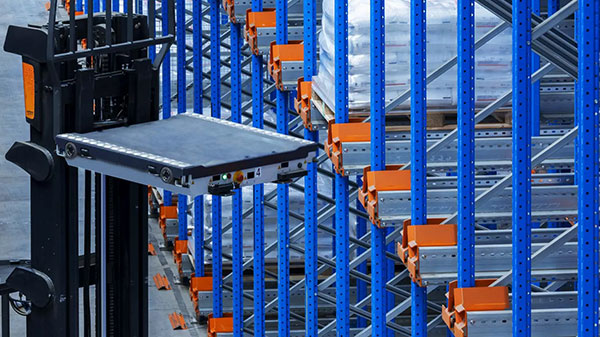

1D pallet shuttle

-

High performance, maximum autonomy

The stow Atlas® pallet shuttle is a semi-automated storage and retrieval system. It's essentially a motorised carriage that moves along rails within a designated pallet rack channel. The pallet shuttle can slide under a pallet and transport it within the rack channel. An electronic control system allows operators to send commands to the pallet shuttle for automated movement and positioning.

The stow Atlas® pallet shuttle eliminates the need for forklift aisles between each rack bay, allowing you to store more pallets within the same racking footprint. By automating the movement of pallets within the rack, retrieval times are reduced compared to manual forklift operation inside each channel. By minimising forklift travel within dense racking areas, pallet shuttles can also help reduce the risk of forklift accidents. Once the shuttle has received its loading and unloading instructions, it performs its tasks with maximum autonomy, operating without further human intervention.

- Optimised storage capacity

- Unlimited lane depth

- Up to 10 hours of battery capacity

- Ideal for cold storage application

Mobile Racking

-

Increase storage capacity up to 90%

Mobile racks or sliding storage rack systems, offer several advantages that can significantly enhance storage efficiency and operations within a warehouse or storage facility. Mobile racks eliminate the need for permanent aisles between static racking units. By placing mobile racks on rails embedded in the floor, you can create a single access aisle that moves powered by an electric motor, granting access to various shelving bays as needed. This allows you to store more products within the same warehouse footprint compared to traditional static shelving. With mobile racks, you can quickly move the rack to the desired storage bay, minimising travel time and expediting picking and retrieval processes. This can significantly improve overall warehouse productivity and efficiency.

- Compact storage with full accessibility

- Manual or automatic operation

- Significant decrease in lighting, heating or cooling costs

- Perfect solution for cold storage

Small goods racking

-

Maximising productivity and efficiency

While small goods racking offers several advantages for storing and organising a large number of smaller items, there are also some challenges to consider:

- Wasted space Small items can leave a lot of empty space between them on shelves, reducing overall storage density. Traditional racking may not be efficient for irregularly shaped items. Double stacking

- Double stacking items can increase storage density, but it can also lead to instability and make it difficult to access lower-level items.

- Accessibility Densely packed shelves can make it difficult to access and pick individual items, especially for those stored deeper within the racking.

- Labelling Proper labelling of small items is crucial for efficient picking and inventory management, but limited space on shelves can make this challenging.

Industrial shelving

-

The industrial shelving system

Choosing the right industrial shelving for your needs involves considering several factors to ensure optimal storage, safety, and efficiency. Different shelving options cater to various needs, depending on the type of products you'll be storing, their weight, their size etc. stow always offers you a suitable industrial shelving system to ensure safe, efficient, and well-organised storage in your warehouse.

stowshelf® is a modular and versatile shelving solution developed for hand-loaded light to medium-duty storage, up to 250 kg/shelf and 8000 kg/bay. stowshelf® can be applied in many environments. As a traditional shelving system, high-rise shelving, or a multi-tier installation. For manually picking goods or as part of an automated central store. The new stowshelf® system was completely redesigned for the e-commerce industry and has become the go-to storage solution for picktowers.

Long span shelving

-

Storage system for medium-heavy loads

When choosing longspan racking for your warehouse, there are some key factors to consider to ensure it meets your specific needs and provides optimal storage solutions. The most crucial factor is, of course, weight capacity, followed by material strength and durability, size and adjustability, and safety and stability. By carefully considering these factors, you can choose long span shelving that is robust, adaptable, and meets your specific storage requirements for long-term functionality and safety in your warehouse.

The fully adjustable stow Minirack® long span racking system is designed for storage of medium-heavy loads. It lends itself to use in almost any situation: shelf racking, long span racking, multi-tier and high-rise constructions. stow Minirack® is built for the storage of hand loaded heavy products, such as large cartons, plastic containers, machinery equipment and tools. We even offer custom-built solutions for tyre storage and hanging garments.

- High flexibility for many applications

- Quick assembly

- High stability

- Low cost

Multi-tier racking

-

Save space, multiply storage area

Some key aspects to consider when choosing multi-tier shelving for your warehouse, besides ceiling height and product weight and dimensions, are the safety and stability of the racking system as well as the accessibility and efficiency. Additional factors are the material and durability as well as the scalability of the system. By evaluating these factors, you can select a multi-tier shelving system that optimises your warehouse space, ensures safety for your workers, and facilitates efficient storage and retrieval of your inventory.

With stow’s multi-tier shelving, you can easily expand the storage capacity of your warehouse without the need to automate. stow offers an intelligent industrial flooring system as an extension to the stowshelf® system to create multi-tiered shelving applications. Two types of industrial flooring systems are commonly used: either intermediate walkways or floor-over systems, or a combination of both.

- Increased Storage Capacity: By utilising the full height of the warehouse, multi-tier shelving significantly increases storage capacity compared to traditional single-level systems. This is especially beneficial for warehouses with limited floor space. Multi-tier systems can double or even triple the storage capacity compared to traditional shelving, allowing you to store more inventory without expanding your warehouse footprint.

- Improved Space Utilisation: By utilising vertical space, multi-tier shelving frees up valuable floor space for other purposes, such as production lines, packing areas, or employee walkways. Multi-tier systems can be customised to accommodate different product types and sizes, leading to more efficient and organised storage.

Miniload single-store

-

Miniload shelving systems are designed for warehouses storing and handling a high volume of small to medium-sized items. Key considerations when choosing a miniload system are the storage capacity and throughput, the level of automation, space utilisation and storage density and the safety and efficiency of the system.

The automated storage and retrieval system (AS/RS) Miniload Single-store from stow is used for storage of small goods, mostly totes or cartons, with loads varying from 5 to 250 kg/unit. The goods are handled automatically by AS/RS cranes. The cranes, guided at both top and bottom, retrieve the totes from their location and present them at the picking location or deliver them directly onto the picking conveyor. The rack can be adapted for a Fine Positioning System of the crane.

- Different sizes of totes can be combined

- Utilises available building height to nearly 100%

- Highest level of safety

- Supports Fine Positioning System of crane

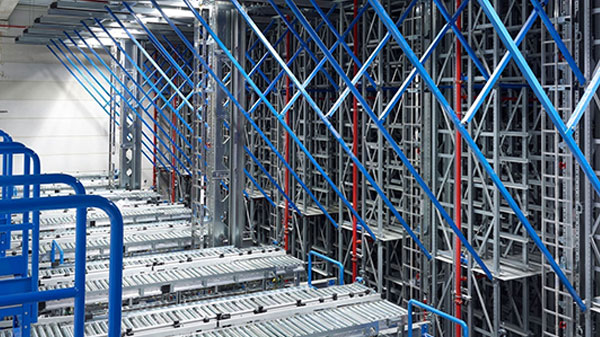

Miniload multi-store

-

An AS/RS system for totes, cartons or trays

An AS/RS system, also referred to as an Automated Storage and Retrieval System, is a technology used in warehouses and distribution centres to automatically store, manage, and retrieve goods. It essentially automates the process of storing and picking up items, replacing manual labour with machines for greater efficiency and accuracy. With an AS/RS system you get increased storage density, improved picking efficiency, enhanced accuracy, improved safety, and reduced labour costs.

stow’s automated storage and retrieval system (AS/RS), called the Miniload multi-store, is used for storing totes, cartons or trays (goods) in a beam typed rack with depth supports between the beams. The advantage of this system is that different sizes (width/depth/height) of goods can be stored within the same system.

- Can be customised to optimise the storage density

- Single, double or multi-deep storage

- Variety of add-ons can be integrated

- Wide range of different extracting mechanisms

Cantilever Racking

-

Reaching new heights for long goods

Cantilever racking systems are a unique storage solution designed for warehouses that deal with long, bulky, or oddly shaped items. Unlike traditional racking with shelves, cantilever systems utilise horizontal arms that project outwards from a single upright structure. Cantilever racking excels at storing long and bulky items. Beyond typical uses in lumberyards or construction supply stores, cantilever racking can be beneficial in various industries. It's suitable for storing furniture, appliances, aerospace components, pipes, carpets, or even car parts. Since items are stored on single-sided arms, cantilever racking offers excellent accessibility. You can easily load, unload, and pick items from any bay without obstruction.

Cantilever Racking

-

stow’s Kanti-stow® was designed to maximise your storage space while giving you easy access to your products. With cantilever racking you can work by the safest storage practices. stow offers a complete range of cantilever racking systems for the storage of long goods up to 1000 kg per cantilever arm.

- Bolted, not welded

- Up to 1000 kg per cantilever arm

- Single or double sided use

- Up to 12 m column height

Mezzanine platforms

-

Additional space without losing floor space

Mezzanine floors are a clever space-saving solution for businesses looking to expand their functional area without the hassle and cost of a complete building extension. The primary advantage is the creation of additional usable floor space within your existing building. This allows you to expand operations, storage capacity, or office areas without significant structural changes.

Compared to building a whole new floor or extension, mezzanine floors are a much more cost-effective way to gain additional space. The installation is quicker and requires less disruption to your business operations. And: Mezzanine floors can be designed to fit your specific needs. You can choose the size, layout, and weight capacity to accommodate various functions, from office space to storage areas or even production lines. Overall, mezzanine floors offer a practical and cost-effective way to maximise your existing space. They provide valuable flexibility and can be adapted to suit various business needs, leading to increased efficiency and improved functionality.

Mezzanine platforms

-

Mezza-stow® – the flexible mezzanine system from stow

The Mezza-stow® system has been developed for the construction of system floors. Unlike conventional steel constructions, it can be easily expanded, moved or modified for future requirements. Combined with a full range of accessories, such as staircases, handrails and safety gates, it lends itself to use in almost any situation: multitier flooring systems, shelving and pallet racking systems combined with flooring, etc. Using the modular components of the Mezza-stow® flooring system a wide variety of span lengths are possible, with loads from 350 kg/m² up to 800 kg/m².

Mezzanines from stow provide a modular flooring system

The mezzanine floors can be connected onto the standard pallet racking frames using specially designed connectors. Pallet racking combined with mezzanine flooring is often applied for picking applications or to support in- and outfeed conveyors for automated racking systems.

Industries

-

Storage and racking solutions from stow can be found all over the world in a wide variety of industries. Numerous global market leaders work with us and benefit from the advantages of our systems. Today, stow is represented with its expertise in many industries, from food production to mechanical engineering.

The reliability and durability of our systems and the excellent service we offer, from the initial consultation to the delivery of spare parts, guarantee smooth warehouse operations and optimum utilisation of the available space for maximum productivity and efficiency.

eCommerce & 3PL

-

E-commerce and 3PL (third party logistics) warehouses face a unique set of challenges due to the dynamic nature of online shopping and the pressure to deliver a fast and efficient customer experience. Warehouse racking needs to be adaptable to fulfil orders from various channels, including online stores, physical stores, and marketplaces. 3PL companies need flexible storage systems and processes which work flawlessly while at the same time keeping costs low.

By addressing these challenges and embracing new technologies, e-commerce and 3PL warehouses can ensure a smooth and efficient customer experience, contributing directly to a company's success in the competitive online retail landscape.

Retail & FMCG

-

Warehouses in the retail and FMCG (Fast-Moving Consumer Goods) industry face a unique set of challenges due to the high volume, fast-paced nature of these sectors, and the need to balance efficiency with accuracy.

By addressing these challenges and embracing new solutions, retail and FMCG warehouses can ensure efficient operations, meet customer demands, and contribute to the success of their businesses in the competitive retail landscape.

Fashion retail

- The fashion industry's warehouses face several unique challenges, stemming from the fast-paced nature of the industry and the specific characteristics of clothing.

Pharmaceutical

-

The pharmaceutical industry faces unique challenges in warehousing due to the nature of the products they handle, from warehouse capacity to product safety regulations and fluctuating demand. Furthermore, typical pharmaceutical and cosmetics industry products will vary in size from large drums to small bottles.

Sensitive goods such as pharmaceutical or cosmetic products require logistical and racking solutions that guarantee safe handling of the items and can adapt flexibly to new forms of packaging.

Automotive

- The automotive industry's warehouses grapple with a unique set of challenges due to the complex nature of car parts and the ever-evolving automotive landscape. Nowadays, consumers can configure their car in detail before production and the necessary production steps are planned accordingly. This has a major impact on logistics and intralogistics.

Manufacturing

- Manufacturers typically require storage for raw materials used in the production process as well as storage for the finished product prior to distribution. Manufacturers' warehouses face a complex set of challenges that impact efficiency, accuracy, and overall production. By addressing these challenges and embracing new technologies, manufacturers' warehouses can play a vital role in streamlining production processes, reducing costs, and ensuring timely delivery of finished goods.

Cold storage

-

Cold storage solutions are required for temperature-controlled warehouses storing fresh and processed foods for chilled or frozen storage. SKUs include meat products, fruit and vegetables, milk products, beverages and other perishable goods. Products must be easily accessible for quick distribution.

Cold storage warehouses grapple with a unique set of difficulties compared to regular warehouses. These challenges stem from the very nature of their function: maintaining specific low-temperature environments for preserving perishable goods.

Food & Beverage

- Productivity requirements in the food and beverage industry have increased significantly in recent years. A growing variety of products and constant innovations in packaging make handling in conventional block storage systems uneconomical. This increases the need for efficient storage solutions.

Rack stories

- We are proud to share the experiences of our satisfied clients and how our tailored racking solutions have delivered efficiency and satisfaction for their businesses. As a leading provider of storage solutions, we strive to continuously improve and innovate in order to meet the ever-evolving needs of our customers. Our focus on delivering quality products and exceptional service has resulted in numerous success stories from a diverse range of industries worldwide.

Gompels UK

-

Gompels UK upgrades warehouse efficiency with powerful racking solutions from stow

Gompels, a leading supplier of care and education products, faced the challenge of accommodating rapid company growth with limited warehouse space. stow, leveraging its expertise in racking systems, delivered a solution tailored to Gompels’ needs. With precisely designed pallet racking, including mesh decks and upright protection, stow ensured the project was completed seamlessly within a strict three-week timeline. This partnership empowered Gompels to optimize their new warehouse extension, significantly boosting storage capacity and operational efficiency.

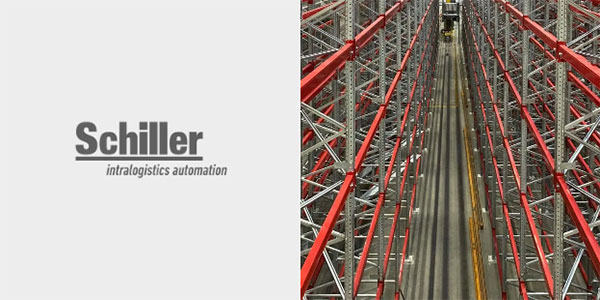

Schiller Automatis

-

Advanced high bay racking solution for Schiller Automatisierungstechnik

Schiller Automatisierungstechnik GmbH, in collaboration with a well-known Bavarian automobile manufacturer, faced the challenge of constructing a storage warehouse capable of efficiently handling production supplies for parts of varying sizes. To address this, stow implemented innovative high bay racking system and mini load multi-store designed for maximum storage density and automation compatibility. The result was a state-of-the-art facility offering optimized storage for over 50,000 units, boosting efficiency and reliability for the end-customers.

stow France

-

Optimizing storage with precision-engineered racking solutions

A leading global logistics service provider recently expanded its operations with the construction of an 84,000 m² warehouse in France. To fulfill the storage and picking needs for a major e-commerce client, the facility required advanced racking systems tailored for large-scale operations. Divided into 14 storage areas of 6,000 m² each, the warehouse presented a unique challenge. Each rack system included 14 levels with dual-sided access, designed to maximize storage efficiency and streamline logistics operations. To offer real-time updates on construction progress, stow equipped its fleet with tracking devices, enabling continuous supervision of truck routes and ensuring all systems were assembled with precision and delivered on time.