- Offer Profile

-

Robotics

Whether standalone, collaborative or mobile, we’ve got the robot needed to move your application into top gear.

Robotics

- Whether standalone, collaborative or mobile, weve got the robot needed to move your application into top gear.

Articulated Robots

- The speed and precision of Omron's Viper six-axis robot makes them ideal for operations requiring fast and precise automation.

Viper

-

The speed and precision of Adept Viper six-axis robots make them ideal for operations requiring fast and precise automation.

The Adept Viper™ six-axis robot is a high-performance articulated robot ideal for assembly, material handling, packaging, machine tending, and many other operations requiring speed and accuracy in a 650mm or 850mm reach.

- Rapid deployment using familiar ladder logic programming languages of existing PLC (IEC 61131-3)

- Diagnostics display enables faster trouble shooting

- Ethernet TCP/IP capability to control the robot through a PC, PLC, or robot controller

- High-resolution, absolute encoders to provide high accuracy, superior slow-speed following, and easy calibration

- High-efficiency, low-inertia Harmonic Drives and a lightweight arm to deliver maximum acceleration

- Maximum payload 5 kg

Viper 650

- Reach: 653mm

- Weight: 28 kg

- Reapeatability: ±0.02°

- Max payload: 5 kg

- Table floor or inverted mount

Viper 850

- Reach: 855mm

- Weight: 28 kg

- Reapeatability: ±0.03°

- Max payload: 5 kg

- Table floor or inverted mount

Viper Intelligent Force Sensor

-

The Intelligent Force Sensor (IFS) is the next generation of force control by Omron combining a state-of-the-art force sensor from JR3 with a superior suite of enterprise robots. The resulting system provides the following benefits for advanced tactile applications:

- Precise measurement of forces in all three dimensions

- Quick and easy installation for all robot categories, including SCARA, parallel and articulated

- Simple integration with Omron’s ACE software platform

- Multiple operating modes for comprehensive control force monitoring

Sample applications and associated processes that can benefit from this solution include:

- Assembly applications, including screwdriving, riveting, friction welding, press fitting, alignment and face matching.

- Machining and forming applications, including grinding, deburring, contouring, polishing, cutting, drilling and tapping.

- Material handling applications, including tool exchange, component loading and fragile product packaging.

- Inspection and quality control applications, including contour validation, product testing and force monitoring.

- Force-guided part insertion is a key application for the force sensor, which can be used to automatically locate the edges of a box and determine its orientation for holding shafts. After generating a frame of reference, the shaft can be inserted into the target box while ensuring that the application force does not exceed a predefined threshold.

Title

- Description

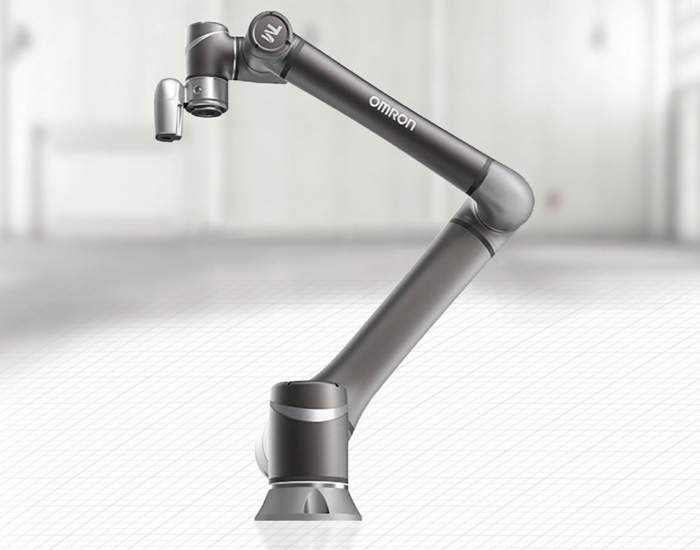

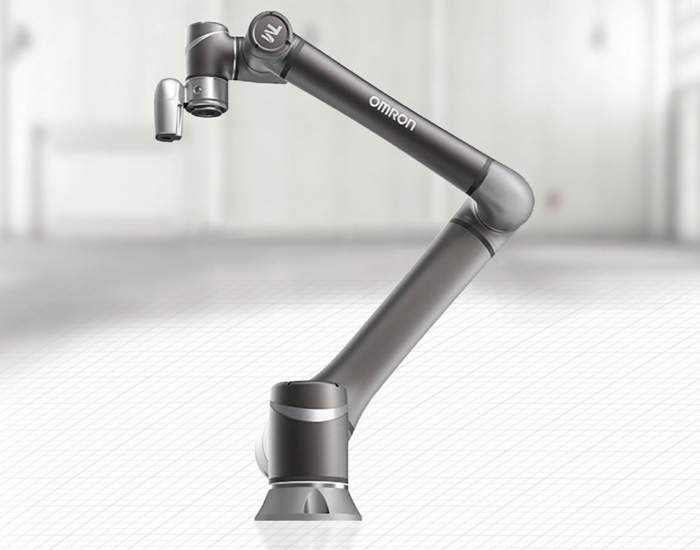

Collaborative Robots

- Omrons collaborative robots are easy to train on new tasks and capable of adapting to a wide variety of application needs.

Collaborative Robots

-

Built for the future of automation / Designed for modern manufacturing / Industry 4.0 Ready.

- Fast and simple programming

- Built-in intelligent vision

- This product complies with the combined scope of ISO 10218-1:2011 and ISO/TS-15066

- Fast changeover using TMvision and Landmark

- Advanced collaborative control

- External Camera Support: Optional software to support 2 additional GigE vision cameras

Digital I/O:

- 16 Digital inputs and 16 outputs at the controller

- 4 Digital inputs and 4 outputs at the tool

Analog I/O:

- 2 Analog inputs and 1 output at the controller

- 1 Analog input at the tool

I/O Interface:

- 3 communication ports

- 1 HDMI port

- 3 LAN ports

- 4 USB 2.0 ports

- 2 USB 3.0 ports

Communication:

- RS232

- TCP/IP (Master)

- Modbus TCP/RTU (Master & Slave)

Integrated Vision:

- 5M pixels, color (AOI tasks: 5M; Others: 1.2M)

Options:

- SEMI S2 Certification

Omron TMFlow Software

-

Software Options for Omron TM Collaborative Robots

The built-in functionality of the TMFlow software on the Omrom TM line of collaborative robots provides powerful, industry leading capabilities that are also easy to use, but for customers who need a bit more, Omron offers several add-on software options that enable even greater functionality over the standard function set.

External Vision

Expands the powerful machine vision capabilities of the Omron TM robot to 2 additional external cameras, enabling even more vision guidance and inspection possibilities. (Camera hardware sold separately).

Optical Character Recognition (OCR)

The OCR software option enables the Omron TM collaborative robot to identify and measure alphanumeric characters. With this added function, the robot can be setup to output the characters it recognizes with any of the attached cameras in string format or use the information it “reads” to make program decisions.

The OCR function supports 94 characters in 9 common fonts including:

- Numerals 0-9

- English upper and lower case A-Z

- 32 ASCII symbols (@/:#$&, etc..)

Identify and Measure

Traditional manual inspection can entail error issues caused by personnel fatigue or negligence. The identification function can provide comprehensive improvement.

Capabilities of the identification module include:

- Pose change (shape)

- Pose change (image)

- Specific color area size

- Subtract reference image

- Line burr

- Circle burr

Mobile Robots

- Omron solves a variety of materials transport issues with its innovative mobile robots that self-navigate throughout dynamic environments.

LD Series

-

Self navigating Autonomous Intelligent Vehicle (AIV)

The Omron LD Mobile Robot is a self navigating Autonomous Intelligent Vehicle (AIV) designed for dynamically moving material in challenging environments that may include confined passageways as well as dynamic and peopled locations. Unlike traditional autonomously guided vehicles (AGVs), Omron Mobile Robot requires no facility modifications, such as floor magnets or navigational beacons, saving users up to 15% in deployment costs. The LD includes Omron’s proprietary software and controls allowing it to intelligently navigate around people and unplanned obstacles, that render traditional AGVs incapacitated and it can be programmed and functional within a day. Designed for developers, integrators, and end-users the system can be customized for a variety applications and payloads. Manufacturing, warehousing, clean tech, and laboratories are just a few environments ideal for the mobile robot.

- Self-navigation software safely avoids people and obstacles

- Reliable drive system optimized for self-navigation

- Structural support of payloads up to 130kg on level surfaces

- Navigates through the use of a digital map

- Easy to deploy, no facilities modifications required

- Manages power and self charging operations

Benefits

- User-friendly software

- Runtime of up to 15 hours a day

- On-board power supply

LD Cart Transporter

-

The Omron mobile robot LD Cart Transporter is an Autonomous Intelligent Vehicle (AIV) designed to attach to movable carts and transport them from a pickup location to a drop off location. Applications include line-side inventory replenishment, moving flow racks, transporting Work in Progress (WIP) between process steps, and moving finished goods to the warehouse.

The Omron mobile robot LD Cart transporter leverages Natural Feature Navigation to autonomously find a path through the facility without the need for any facility modifications necessary. The LD Cart Transporter is safe to operate in existing doors and aisle ways as it can sense and avoid people, fork trucks and other objects in its path.

ESD Mobile LD Skins

- The ESD LD mobile robots maintain exceptionally high levels of protection thanks to its intuitive design that creates a protective shield around the robot that not only protects your investment, it dissipates excessive energy through the unit’s casters. Allowing in-process product handling of static sensitive devices reduces material costs while freeing human resources for other value added tasks that maximize productivity, improve operational efficiencies while decreasing the total cost of ownership.

Localization & Position

-

High Accuracy Positioning System

The Omron LD mobile robot excels at self-navigating throughout your facility. However, some applications require that the vehicle stops with a well-defined repeatability, especially when the vehicle payload needs to interface with conveyors, feeders or test equipment to offload or on load cargo. For these applications, the High Accuracy Positioning System (HAPS) option provides the capability to consistently move through a defined space with enhanced precision and/or precisely stop at predefined goal.

By leveraging magnetic tape affixed to the floor in front of a goal and a HAPS sensor underneath the vehicle, the LD mobile robot is able to smoothly transition onto the path defined by the tape. The robot can then sense markers placed along the path and align itself precisely at the defined stopping locations.

Unlike AGV’s which require magnetic tape to guide all of their motion, the LD mobile robot can enter and depart a magnetic tape path at any point. This unique capability enables the LD mobile robot vehicle to transition between natural feature navigation and magnetic tape guidance. The vehicle can also drive along the path accurately in both forward and reverse when configured with a dual sensor configuration. The High Accuracy Positioning System option opens up a whole new world of precision motion for the LD mobile robot product family.

Dynamic Localization (Acuity)

- Acuity is an additional method of “localization” for the AIV that identifies lights (or high contrast objects) in the roof and overlays the “light map” with the “floor map”. This option also allows the AIV to move easily across wide-open areas in large warehouses.

Parallel Robots

- The Omron Quattro robot excels at high-speed applications in packaging, manufacturing, assembly, and material handling.

Sysmac Delta

-

The fastest picking system integrated in the Sysmac platform

The Delta solution can achieve up to 200 cycles per minute and can be synchronised with multiple conveyors to perform on-the-fly Pick & Place operations. There are 3 types of Delta robot arms available as Washdown, Delta and Mini Delta robot. The NJ controller offers a response time of 2 ms when controlling 8 Delta robots or 1 ms when controlling 4 robots.

- Control of up to 8 robots by one controller

- Degrees of freedom: 3 + 1 (rotational axis optional)

- Up to 200 cycle per minute

- Model range from 450 to 1600 mm working range

- Payload range: 1 to 8 kg

- IP class range: IP65, IP67, IP69K

Quattro

-

The Omron Adept Quattro robot is the only parallel robot in the world with patented features and USDA-accepted for meat and poultry processing.

The Quattro™ Parallel robot excels at high-speed applications in packaging, manufacturing, assembly, and material handling. It is the only parallel robot (or "delta robot") in the world with our patented four-arm rotational platform, delivering maximum speed, maximum acceleration and exceptional performance across the entire work envelope. Ultra-compact controls and embedded amplifiers improve footprint efficiency while simplifying installation.

Hornet

-

Designed for Primary and Secondary Food Packaging

The Hornet 565 is a parallel robot for high-speed picking and packaging applications. The powerful controls are fully embedded into the base of the robot, saving valuable floor space and reducing installation costs and complexity. It features a hygienic design that minimizes contamination risks, including a standard IP65 rated work area and corrosion resistant materials for easy wash down.

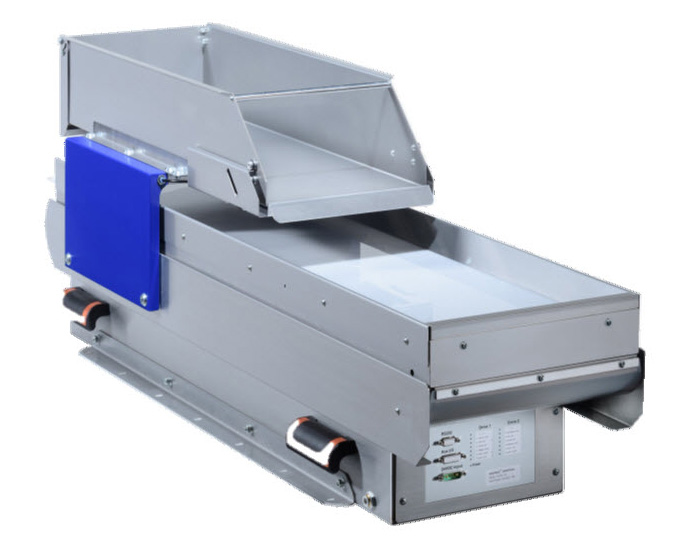

Part Feeders

- Omrons intelligent part feeding solutions help keep your robotic applications as efficient as possible even on flexible production lines.

AnyFeeder

-

Complete Flexible Feeding System optimized to work together with vision, motion and robots.

Designed to work with a variety of robots and in combination with Omron Vision software and controller, the AnyFeeder Solution provides an efficient and fast feeding solution. Its flexibility in feeding small parts of various size, shape and material allow for fast line changeover and significantly reduced tooling costs, to give you a crucial competitive advantage.

SCARA Robots

- eCobra SCARA Robot Series offers a compact system footprint, saving valuable floor space while minimizing installation costs and complexity.

eCobra

-

eCobra SCARA Robot Series offers a compact system footprint, saving valuable floor space while minimizing installation costs and complexity.

Omron's Adept eCobra 600/800 SCARA robot series features 600 or 800-mm reach and is available in three performance tiers, each designed to address different application complexity and throughput requirements. eCobra offers a compact footprint, saving valuable floor space while minimizing installation costs and complexity. This unique family ensures that users receive the highest quality, most durable robots at every performance level.

Cobra

-

Omron's Adept Cobra robot deliver performance unmatched in the industry.

High-performance SCARA robot system for mechanical assembly, material handling, packaging, machine tending, screw driving, and other applications that require fast and precise automation. Omron Adept Cobra Series robots deliver performance unmatched in the industry with the included SmartController™ motion controller.