ASM Dimatec

Videos

Loading the player ...

- Offer Profile

- In the last 25 years, ASM has

positioned itself as a cutting edge company in the applications of advanced

technology in the field of automated machinery for the automobile industry

and the aerospace industry.

We always use the latest and most innovative technologies to provide the

highest standards to our customers. Our strength lies in our ability to

provide a comprehensive service that offers the most outstanding

price-quality ratio.

ASM has grown from 50 employees in 1994 to 260 in 2003. ASM not only competes at European level, but also in the American and the Asian markets. ASM Dimatec currently runs 6 overseas subsidiaries in Great Britain, Germany, France, China and Brazil.

Product Portfolio

Business areas

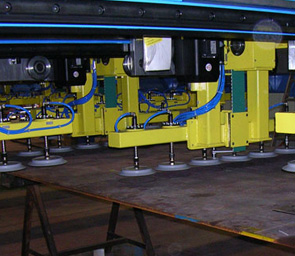

Press automation

- From board stacking units to press links and board

feeders. ...

When it comes to board stacking units, you'll profit from our many years of experience as one of the leading board stacking unit manufacturers in Europe. There are currently more than 70 of our board stacking units being put to use worldwide by our most sophisticated and demanding customers.

Included among these presses in our versatile product program are automatic part stacking units featuring camera systems and buckling arm robots as well as board flipping units and complete links for production lines.

Materials handling

- Belt, roller and chain conveyors - from part conveyor

belts to complete transport systems

We provide you with a wide spectrum of materials-handling technology. When it comes to belt conveyors, we deliver individual belt conveyors with height and width adjustment options up to the complete part conveyor belt lines. If you require the use of roller conveyors, we can provide you with the right selection. We produce both powered and non-powered roller conveyors for easy to difficult applications.

For the manufacturers of intersecting lines, we offer an ideal connection of your unit components with the proper materials-handling technology. We guarantee you an exact integration with your line, all the while taking the possibly existing, disturbing contours or intersections into consideration.

Fine Lubrication devices

- Contact-free lubricant or medium application on

surfaces from top and bottom; quantity and latitude regulated

Our fine lubrication device was developed to apply any fluid medium consistently on surfaces without the annoying haze that usually accumulates with nozzle systems. Due to the good, precisely repetitive adjustability, the device is suitable for many applications.

The lubrication device works in a contact-free manner. This makes it possible to also lubricate sensitive or abnormal surfaces. Depending on the model, our fine lubrication device can lubricate from top to bottom, from bottom to top or on both sides

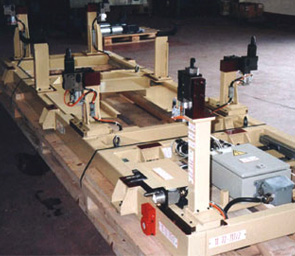

Mechanical processing

- Welding assembly group manufacturing and fixture

construction with mechanical processing according to customers’ request

In addition to the delivery of complete automation solutions and machines, we offer our customers the possibility to have individual assembly sub-groups, welding assembly groups or fixtures manufactured.

We can manufacture these individual welding assembly groups as well as conduct the mechanical processing according to customer drafts and drawings. You can select as to whether you'll choose to commission us with a mechanical construction or whether we should manufacture the individual assembly groups of your construction. Provide us with a pattern request for the individual manufacturing of the parts - you'll be pleasantly surprised.

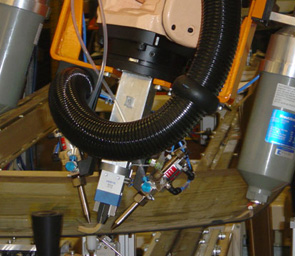

Adhesive and primer application

- Whether for individual application or as an adhesive technology supplier for complex automatic units for OEM customers – we offer you a wide spectrum of adhesive and primer application technologies. You'll find our units for adhesively attaching diverse glass fittings worldwide in automobile, truck and bus production.

Skeleton construction work and final assembly

- From installing cockpits and manipulators right up to

fully automatic system solutions in skeleton construction work and in the

final assembly…

The manufacturing areas of skeleton construction work and final assembly belong to one of our core area in plant manufacturing for the automobile industry. The multitude of the automatic procedures and production processes required in these fields build the proper foundation for the use of our automation. We optimize the processes with innovative complete solutions. With respect hereto, we can serve as your system supplier or as a sub-contractor.

Customer service

- One of our priorities is the attention we give to the

people we work with. For this reason, it is very important for us to offer

the customer a service that does not end once a sale has been completed.

Within our customer service department, we dispose of over three different service areas:- The sale of replacement parts: here, all customer replacement part orders are processed and the parts are delivered in the quickest possible time.

- Special services:

- In urgent cases, we offer a delivery time between 24 and 48 hours, should the order is made online (per Internet).

- In emergencies, an assembly of heat-resistant hoses in 24 hours.

- Technical consultation.

- Industrial assembly: assembly and disassembly or relocation of production plants.