GÜHRING

Videos

Loading the player ...

- Offer Profile

- High productivity, excellent

economic efficiency and optimal machining results are principles to which

our products have been designed and manufactured to for in excess of 100

years.

High productivity, excellent economic efficiency and optimal machining results are principles to which our products have been designed and manufactured to for in excess of 100 years. Our customers put their trust in our precision products where tool material, geometry and coating are perfectly matched to one another. Our in-house carbide production, our machine and equipment division, Guhring’s coating technology as well as our state-of-the-art research and development centres ensure our technological leadership in rotary cutting tools is maintained. Our service division offers flexible support in all tooling matters up to the complete tool management.

Product Portfolio

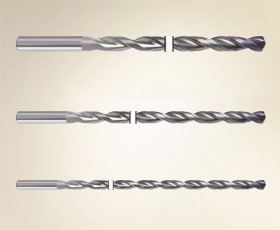

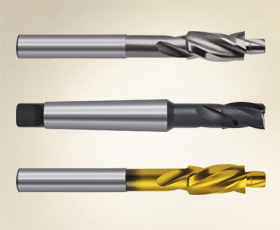

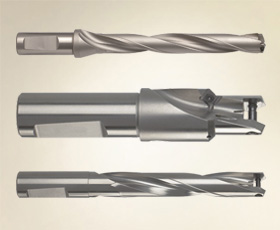

Drilling

- Sophisticated drill technology!

Our variety of drills covers micro-precision drills Ø 0.1 mm to special drills of Ø 180 mm, HSS to solid carbide.

25.000 products for every application: Who offers more?

Solid carbide ratio drills

T 800 inserts drilling system

Straight shank twist drills

Taper shank twist drills

Set of jobber drills

Step drills

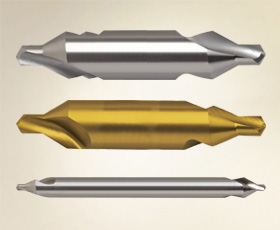

Center drills

Core drills

Chamfer collar FR 90

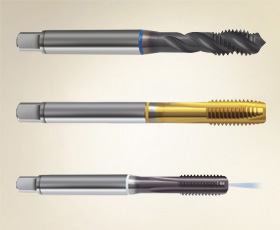

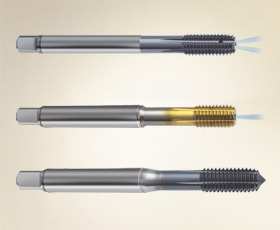

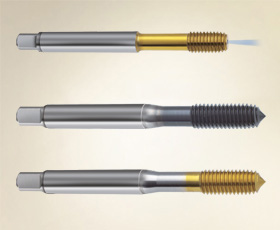

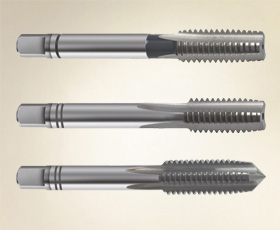

Threading

- Perfect Threads!

Whether taps, fluteless taps or thread milling cutters – Guhring has the suitable threading tools for standard threads as well as special threads such as EG or form-E.

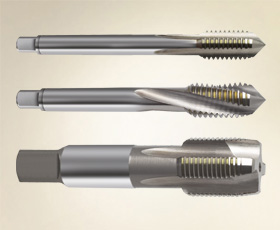

Machine taps

Fluteless taps with oil grooves

Fluteless taps w/o oil grooves

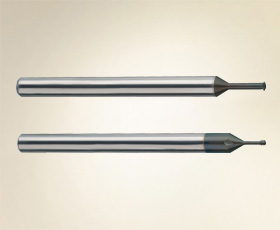

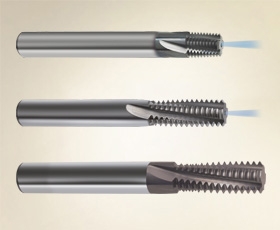

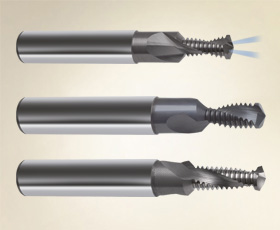

Micro-Thread-Mills

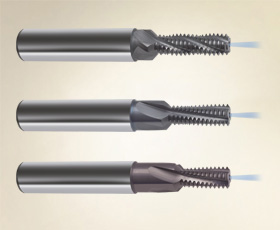

Thread milling cutters with chamfer

Thread milling cutters without chamfer

Universal thread milling cutters

Drill thread milling cutters

Machine nut taps

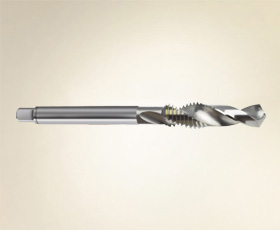

Combination drill taps

Short machine taps

Hand taps

Dies

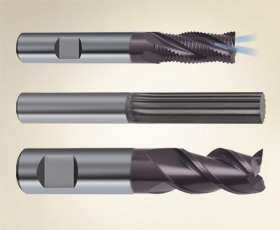

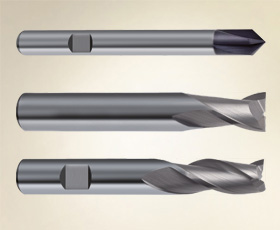

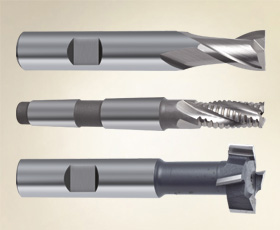

Milling Cutters

- Near infinite tool life!

Guhring milling cutters for the mould and die industry, with ball-nose, Torus form or corner radius.

RF 100 high performance end mills

HPC high performance end mills

Solid carbide universal end mills

HPC radius end mills

End mills, PCD-tipped

High performance end mills made from HSS-E-PM

M42 universal end mills

Face milling cutters

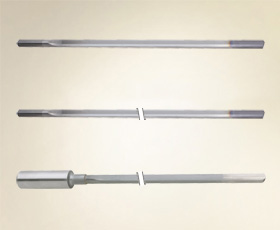

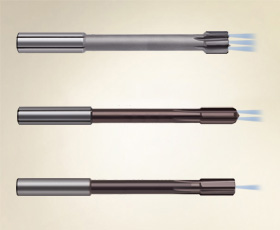

Gun Drills

- The Drill with Universal Applications

Single and two-fluted gun drills for up to 3000mm applications. PKD/CBN

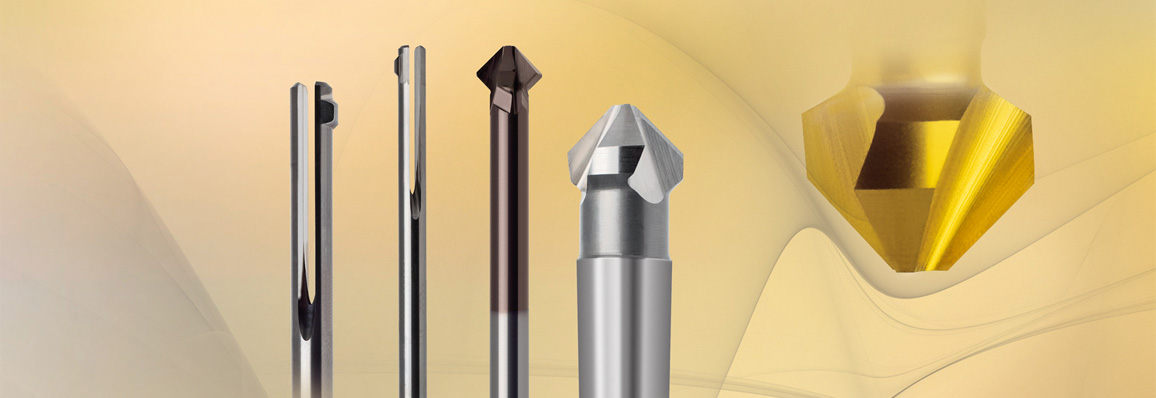

- Energy

efficient and µ-accurate solutions for demanding tasks

Our PCD/CBN tool range includes standard tools as well as complex special designs such as PCD-tipped fine reaming tools or combination tools enabling different machining operations with just tool. Advantages:- Intelligent solutions for the reduction in tool variety as well as primary and secondary times

- Highly accurate tools for µ-accurate precision machining

- Extremely efficient tools for maximum cutting data and considerably reduced machining times

- Wear-resistant tools for maximum tool life

Countersinking

- More than Countersinking!

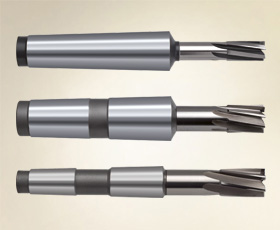

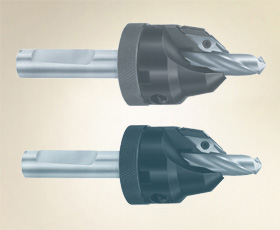

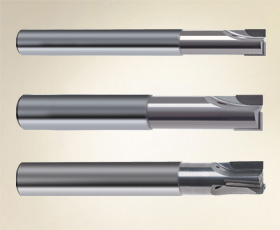

Reaming

- Hole Perfection!

Extremely high feed rates are no problem with Guhring’s Power reamers! Perfect surface quality even with interrupted cutting and in any material.

High performance reamers

Carbide reamers

High speed steel reamers

Taper reamers

Hand reamers

Tool Holders

- From the spindle to the cutting edge

Innovations for the Metal-Cutting Industry

Tools from Ø 3mm direct hydraulic clamping

Axially and radially µ-adjustable precision clamping