Licon

Videos

Loading the player ...

- Offer Profile

- Licon mt is a highly

regarded supplier of production line systems for the processing of complex

components. Our customers are well-known automotive manufacturers and

sub-suppliers in America, Asia and Europe.

In addition to machine product development, our expertise extends to manufacturing the core components of our machines as well as system integration and software development.

Product Portfolio

Machining Centers

- Many configurations. Many possibilities.

The modules of the LiFLEX modular system are primarily used to configure machining centers and rotary transfer machines. It forms the basis for flexible machine concepts, which are nevertheless application-specific for the machining of medium and large workpieces. Various configuration possibilities form the basis of single and multi-spindle machining centers for 4-axis and 5-axis machining.

Intelligent part-mounting configurations allow for direct loading and simultaneous loading during machining as well as the fully automated interlinking of individual machining centers. The modular configuration of the various machine concepts provides the decisive advantage for implementing customers’ specific requirements at an attractive price-performance ratio. Single-Spindle Units

- Great success, even with small quantities.

The efficient machining of smaller lot sizes is often not possible with standard machining centers that produce in large quantities. We therefore also offer single-spindle concepts, a selection of which is depicted here. Further individual configurations can be viewed on request.

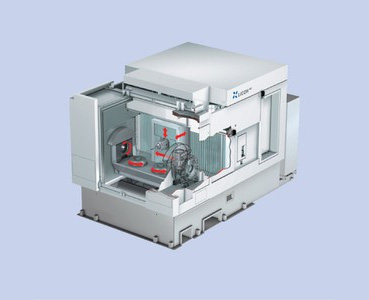

LiFLEX I 1277 2U

- Tailor-made solutions pave the way for your success! Our

wide range of different machine concepts is based on the LiFLEX modular

system. It forms the basis of the comprehensive solutions that we offer our

customers – which are economic solutions complying with flexibility,

precision and productivity.

Strokes (mm) X 1,200 / Y 700 / Z 700 Spindle Motor spindle, 16,000 min-1 Tool change Disc magazine on top Acceleration Max. 5 m/s² Rapid traverse rate 50 m/min B-axis swing diameter 320 mm Loading Front and top Suitable for dry machining

LiFLEX I 1477 1U PC

- This single-spindle 5-axis machine concept is used for

the machining of extremely large workpieces, such as lightweight

construction and chassis parts. A pallet-changing unit increases

productivity whilst enabling quick fixture changeovers.

Strokes (mm) X 1,400 / Y 700 / Z 700 Spindle Motor spindle, 16,000 min-1 Tool change Dual grippers and disc magazines on top (2 x 30 pockets) Acceleration Max. 5 m/s² Rapid traverse rate Max. 60 m/min Suitable for wet and dry machining

LiFLEX I 1546

- The LiFLEX I 1546 is our 4-axis machining center for

crankshaft machining with a large (machining) space on a small area. The

clamping concept specially developed by Licon is an integral component and

provides the highest degree of flexibility for changeover.

Strokes (mm) X 1,500 / Y 400 / Z 630 Spindle LiFLEX DSP 90, HSK 80 Tool change Pick-up disc magazine Acceleration Max. 5 m/s2 Rapid traverse rate 50 m/min Rotary table diameter 630 mm, vertical swiveling axis Top loading and front loading Suitable for wet and dry machining

LiFLEX I 1578

- The LiFLEX I 1578 is a 3-axis machining module for

transfer line machining. It is the perfect partner for large tasks.

Strokes (mm): X 1,500 / Y 700 / Z 800 Spindle LiFLEX DSP 100, SK 50 Tool change Dual grippers and side mounted disc magazine Additional shelf magazine for tool lengths up to 600 mm Acceleration Max. 1g Rapid traverse rate 60 m/min Front interface for incorporation with transfer systems and different table systems

Twin-Spindle Units

- Savings with regard to purchase price, floor space and the number of operators required make this twin-spindle machine an attractive alternative to single-spindle units. Three different machine platforms with spindle distances of 1,000 mm, 700 mm and 450 mm provide appropriate solutions for 4-axis and 5-axis machining in HSK 63, HSK 80 and HSK 100. The ability to correct spindles in all three axes is a truly unique feature of machines with 700 mm and 1,000 mm spindle distances.

LiFLEX II 444 i 2U PC

- The LiFLEX II 444 i 2U PC offers the best performance at

a highly attractive price. Regardless of the complexity of the application,

our 5-axis powerhouse with 5-sided machining and independant Z-axes leaves

nothing to be desired. Particularly impressive is the high degree of

rigidity and machining speed during simultaneous loading of this HSK 100

machine, which is suitable for dry machining.

Strokes (mm) X 450 / Y 400 / Z 420 Spindle distance 450 mm Spindle Motor spindle – LiFLEX MSP 110, HSK 100, optional MSP 80, HSK 63 Pickup chain magazine 2 x 30 positions Acceleration up to 10 m/s² Rapid traverse rate up to 100 m/min A-axis swing diameter 765 mm B-axis swing diameter 440 mm Suitable for wet and dry machining

LiFLEX LiFLEX II 444 i DT

- The LiFLEX II 444 i DT offers the best performance at a

highly attractive price. Regardless of the complexity of the application,

our 4- / 5-axis powerhouse with 5-sided machining and independant Z-axes

leaves nothing to be desired. Particularly impressive is the high degreee of

rigidity and machining speed during simultaneous loading of this HSK 100

machine, which is suitable for dry machining.

Strokes (mm) X 450 / Y 400 / Z 420 Spindle distance 450 mm Spindle Motor spindle – LiFLEX MSP 110, HSK 100, optional MSP 80, HSK 63 Pickup chain magazine 2 x 30 positions Acceleration up to 10 m/s² Rapid traverse rate up to 100 m/min A-axis swing diameter 600 mm B-axis swing diameter 440 mm Suitable for wet and dry machining

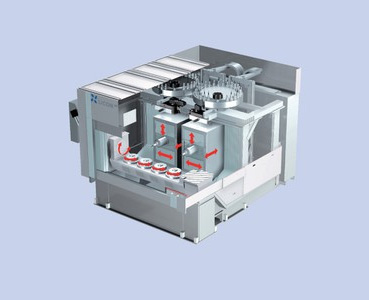

LiFLEX II 777 4U

- The independently correctable axes of the LiFLEX II 777

4U make tight machining tolerances using twin-spindle units possible. The

larger machining cubes permit the machining of complex workpieces in a

single setting. These require appropriate strokes and swing diameters, which

are offered by Licon. The LiFLEX II 777 4U is two machines in one.

Consequently, it is possible to avoid quality problems in production that

are virtually preprogrammed in conventional twin-spindle units with their

larger spindle distances and coupled axes.

Strokes (mm) X 700 / Y 700 / Z 700 Spindle distance 700 mm Spindle Motor spindle HSK 63 Tool change Dual grippers and disc magazines on top Acceleration Max. 5 m/s² Rapid travers rate Max. 50 m/min A-axis swing diameter 1,028 mm B-axis swing diameter 345 mm Individual compensation of all axes Suitable for wet and dry machining

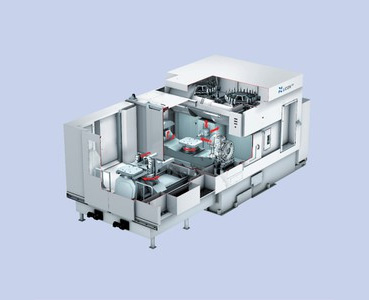

LiFLEX II 1078 2U

- With the LiFLEX II 1078 2U twin-spindle, 5-axis machining

center, Licon offers one of the largest twin-spindle machines available on

the market. Two machines operate in tandem, creating the perfect solution

for all machining requirements. The LiFLEX II 1078 2U is optimal for large,

cubic parts with a maximum load of up to 1,800 kg on the swing trunnion.

This machine is suitable for use in a range of fields, including the

automotive, energy and aerospace industries.

Strokes (mm) X 1,000 / Y 700 / Z 800 Spindle distance 1,000 mm Spindle LiFLEX DSP 110, HSK 100 Tool change Dual grippers and disc magazines on top Acceleration Max. 5 m/s² Rapid traverse rate Max. 50 m/min A-axis swing diameter 1,710 mm B-axis swing diameter 990 mm Individual compensation of all axes Suitable for wet and dry machining

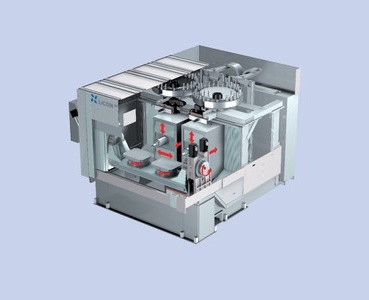

LiFLEX II 1078 4U

- The LiFLEX II 1078 4U allows four parts to be machined in

a single clamping in XXL format, making it possible to machine even large

workpieces efficiently.

Strokes (mm) X 1,000 / Y 700 / Z 800 Spindle distance 1,000 mm Spindle LiFLEX DSP 110, HSK 100 Tool change Dual grippers and disc magazines on top Ergonomic tool loading via an elevator Acceleration Max. 5 m/s² Rapid traverse rate Max. 50 m/min A-axis swing diameter 1,580 mm B-axis swing diameter 490 to 990 mm Individual compensation of all axes Suitable for dry machining Equipment variations: 3-axis configuration – top loading and front loading 4-axis configuration – simultaneous top and front loading during machining 5-axis configuration – direct top loading and front loading

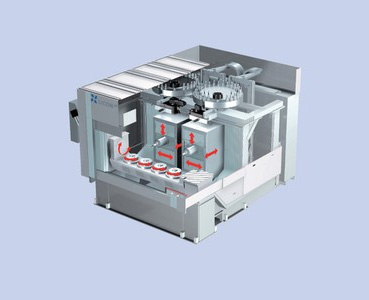

LiFLEX II 1078 2Z

- The LiFLEX II 1078 2Z provides a twin-spindle, 4-axis

machining center with simultaneous loading during machining for the

heavy-duty machining of large cubic pieces. This machine minimizes

unproductive auxiliary processing times, even when machining large and heavy

workpieces.

Strokes (mm) X 1,000 / Y 700 / Z 800 Spindle distance 1,000 mm Spindle LiFLEX DSP 110, HSK 100 Tool change Dual grippers and disc magazines on top Acceleration Max. 5 m/s² Rapid traverse rate Max. 50 m/min Individual compensation of all axes Suitable for dry machining Equipment variations: 4-axis configuration 5-axis configuration

Special Solutions

- Reduce auxiliary processing times using dual

machining units.

We have configured our standard LiFLEX modules for specific applications – and have thereby achieved the maximum changeover flexibility for the end machining of crankshafts.

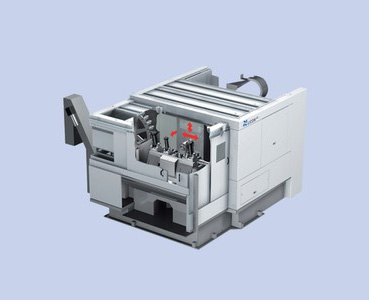

LiFLEX II 846- We have configured our standard LiFLEX modules for

specific applications – and have thereby achieved the maximum changeover

flexibility for the end machining of crankshafts.

Strokes (mm) X 800 / Y 400 / Z 630 Spindle distance 1,000 mm Spindle LiFLEX DSP 90, HSK 63 Two machining centers opposite each other Tool change Dual grippers and disc magazine on the side Acceleration Max. 6 m/s² Rapid traverse rate Max. 60 m/min Double-fixture for fast changeovers in the end machining of commercial vehicle crankshafts Top loading

Rotary Transfer Machines

- Flexibility to meet

requirements.

For many years, rotary transfer machines were regarded as single-purpose machines. In periods of market uncertainty, the advantages of such production systems regarding quality and productivity do not outweigh the investment risks.

This provided the motivation for designing the LiFLEX rotary transfer machines. The productivity improvements of a rotary transfer machine are combined with flexible machining units that have 3, 4 or 5 axes, as well as an additional innovation from the incorporation of dry or MQL machining. RTM

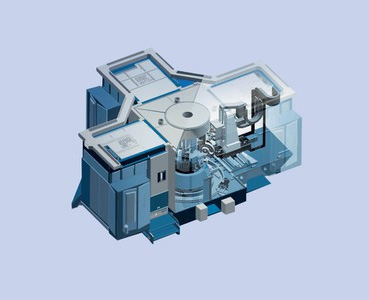

RTM 4 – MQL

- The RTM 4 offers maximum productivity and flexibility

within a single machine frame. This means that you profit from extremely low

auxiliary processing times and a total processing time of at least 50%. The

machine is equipped for dry machining with minimum quantity lubrication.

Chips are removed by the LiFLEX rotary conveyor. The workpieces are

transported via a rotary table, on which LiFLEX planetary tables of the PLI

series are mounted. Using two swiveling axes at each station, any compound

angle on the workpiece can be machined. The machining units are mounted on

three axes.

Acceleration in all three axes 5 m/s² Rapid traverse rate Max. 60 m/min Stroke in X 600 mm Stroke in Y 800 mm Stroke in Z 600 mm Chip-to-chip time <1 sec Max. spindle speed 15,000 rpm Tool receiver HSK 63 Dynamic packages on request

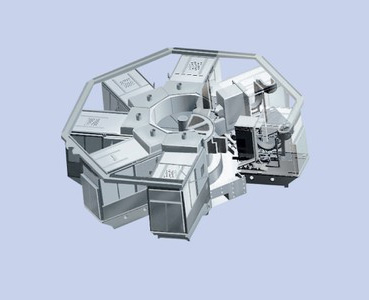

RTM 6 – PLI

- The RTM 6 PLI sets the benchmark for 5-axis machining of

cubic parts. One RTM 6 PLI can be used in place of five single spindle

5-axis machining centers. Six fixtures are mounted on the RTM 6 and while

five are in the machining position, one is always available for loading and

unloading during machining. This model provides a generous machining area

that permits 5-axis machining on five sides in a single clamping. This

machining concept is unrivalled for cycles that are often required to last

less than one minute.

Acceleration in all three axes Up to 6 m/s² Rapid traverse rate Up to 60 m/min Stroke in X 400 mm Stroke in Y 400 mm Stroke in Z 600 mm Tool change time <1.3 sec Max. spindle speed 12,000 rpm Tool receiver HSK 63 Dynamic packages on request

RTM 8 – PLH / PLV

- In comparison with other machining concepts, only one

tool set and eight clamping jigs are required for this model. This ensures

the highest process reliability in manufacturing. Dry machining with minimum

quantity lubrication is possible through the addition of the (optional)

horizontally-mounted swiveling axes to this machine concept.

Acceleration in all three axes 6 m/s² Rapid traverse rate Max. 60 m/min Stroke in X 400 mm Stroke in Y 400 mm Stroke in Z 600 mm Chip-to-chip time 1.3 sec Max. spindle speed 12,000 rpm Tool receiver HSK 63

Special Machines

- Reduce auxiliary processing times using dual

machining units.

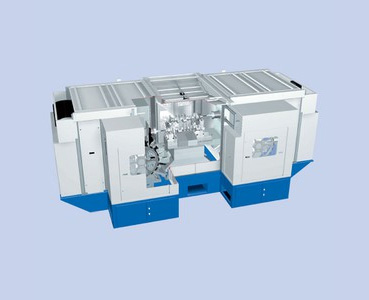

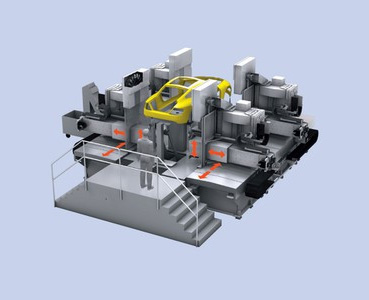

We have configured our standard LiFLEX modules for specific applications – and have thereby achieved the maximum changeover flexibility for the end machining of crankshafts. Duplex Lateral Milling Center

- End machining made easy.

The fixture concept is the most critical factor for successful machining of large and extremely light workpieces with limited rigidity. Licon’s expertise acquired through various lightweight construction projects has been successfully applied to large workpieces, resulting in individually configurable solutions such as the duplex lateral milling center.

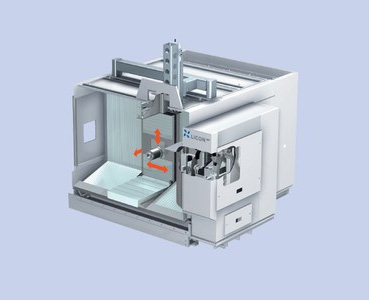

Duplex lateral milling center- In the reference project shown here, the floors of welded

aluminum passenger car frames are machined in the final stages of an

assembly line. From both sides of the frame, two autonomous motor spindles,

each respectively mounted on traveling columns, perform milling and drilling

operations.

The duplex lateral milling center can be reconfigured according to individual requirements. Depending on the materials to be machined, such as CFRP or aluminum, Licon offers appropriate solutions. For 5-axis machining, an NC swivel head can be used.Strokes (mm) X up to 4,000 / Y 1,150 / Z 650 Spindle distance 1,830-4,000 mm Spindle Motor spindle HSK 63 Tool change Pick-up disc magazines (20 pockets) Individual compensation of all axes

Modules

- The beneficiary of our expertise is you, the

customer.

Our comprehensive product spectrum is the result of experience gained over decades in the manufacture of machining spindles and accessories.

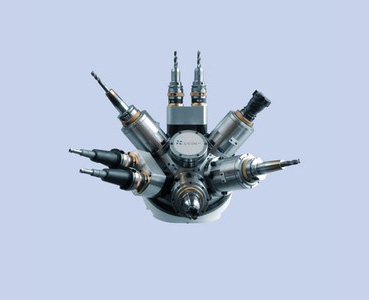

An overview of the performance of our spindle range: Crown-Type Turret

- A tool turret: The clever alternative.

Crown-type turrets can be used as an alternative to conventional machining spindles using tool magazines. Our many years of experience and innovative further developments are a guarantee for the total reliability of our 6 and 8-fold turrets. A broad range of spindle attachments with torque capability of up to 300 Nm ensure that the specific application is catered for in each case.

Crown-type turrets are equipped with two-channel minimum quantity lubrication (MQL) through the spindle for near dry machining. The advantages of two-channel minimum quantity lubrication (MQL):- Fast-reacting and precise dosing

- Optimal supply of air when changing tools

In addition, the rotary plate allows two-channel MQL on angular heads and multi-spindle drilling heads.

RTC 6 & RTC 8

- Crown-type turrets can be used as an alternative to

conventional machining spindles using tool magazines. Our many years of

experience and innovative further developments are a guarantee for the total

reliability of our 6 and 8-fold turrets.

Tool positions 6 or 8 Nominal width of connecting flange 350 mm Bearing diameter 65 mm Power Max. 27 kW Spindle speed 12,000 rpm Tool receiver HSK C-63 Face Ø 80 mm Tool changing time 1.3 sec

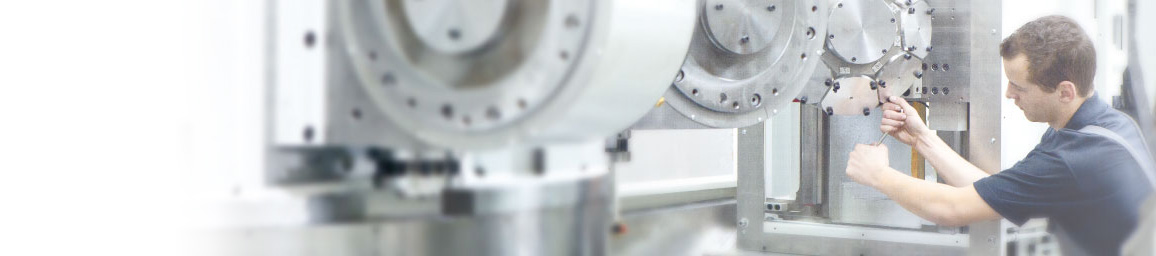

Units

- The use of our units ensures round-the-clock

operation.

For more than 40 years, we have been manufacturing and enhancing machining units, which are also used successfully by other machine manufacturers.

Spindle units: Cylindrical and box design

- In the standard version, the spindle units are available

in the U or Z configurations with automatic tool retention. The air purge is

contactless and is released into the atmosphere. Positioning is facilitated

either electromechanically or hydraulically.

The spindle bearing is lubricated for life. An internal coolant supply is an optional extra. The drawbar for facing heads is available for application-optimized drives up to 63 kW and bearing speeds up to 20,000 rpm.

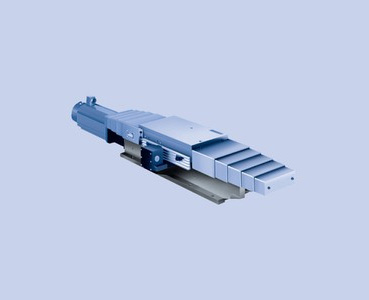

Slide units: Single axis slide units

- The slide units are suitable as feed units for the spindle units, drill heads and much more. They are optionally available with way covers, switches and servomotors.

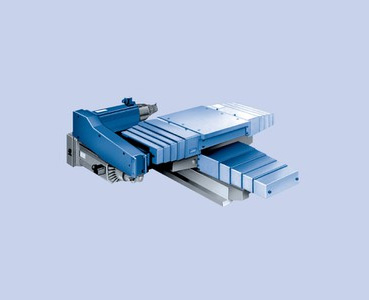

Slide units: 2-axis slide units

- The slide units are optionally available with way covers, electrical interfaces and servomotors.

Slide units: 3-axis slide units

- The slide units are optionally available with way covers, electrical interfaces, servomotors and turrets.

Drilling units: Cylindrical design

- In this standard version, the drilling units are available in the U or Z configurations for drilling, countersinking, grinding and much more. The drive, spindle and stop block are on a single axis to avoid flexural stress that could cause premature wear. It is also an option to attach multi-spindle heads and special devices as well as clamping elements.

Tapping units: Cylindrical design

- In the tapping units for cutting and shaping, the lead screw is positioned directly in the feed axis to avoid flexural stress that could cause premature wear. It is also an option to attach multi-spindle heads and special devices as well as clamping elements.

Special units: Machining stations

- In addition to our standard product range, modifications for all kinds of applications are also possible. We would be more than happy to provide the relevant information on request.

Fixtures

- In-house technological expertise.

There are many good reasons why fixtures are an integral part of our technical solution. A reliable machine tool is required for the economical successful production of complex workpieces in bulk and the fixture used also plays a crucial role. This is why we exclusively develop and manufacture the clamping devices for our solutions in-house. Our customers therefore benefit from our constantly growing technological expertise. Service

- We are there for you when you need us. No matter where

you are.

A globally active service team supports our customers in performing preventive maintenance and repairs. Any electrical problems can be solved extremely quickly because of the remote diagnostic modules, which are delivered as standard.