- Offer Profile

- For over 30 years Sodick has been manufacturing EDM machines that are the best in the world. As the industry leader, we are committed to the highest quality standards. For Sodick, this commitment does not stop at sales, but applies equally to providing advice and support in all the technical aspects of applications, training, customer and after-sales service.

Our Product World

- As an EDM pioneer, Sodick offers a wide range of linear EDM machines. High Speed Milling machines and EBM machines also feature in the Sodick product line up. More than 90% of all machine components including CNC and Linear motor are in-house developed by Sodick to ensure the highest quality.

Die Sinking EDM

- The entire Sodick die-sinking EDM range features linear motors. They also incorporate Sodick's new LP Control, enabling Parasolid files (solid models) to be directly imported into the control. This maximises cutting efficiency, reduces workflow and programming errors.

AD35L

-

Sodick’s expertise in EDM innovation using 3D design systems, the latest CAE technologies and numerous simulations have made it possible to create an improved basic machine structure of optimised rib arrangements which increase rigidity by approximately 70%. Using the new AD35L machine deformation is minimised, allowing optimum performance at high-speed and rapid acceleration linear motors. Furthermore the original design of an independent X and Y-axis plus an efficient machine layout leads to a longer stroke, smaller footprint and highly accurate machining capability.

AD55L

-

Die sinking EDM with the dynamic response of linear technology – the Sodick AD series has set a new standard in the category of entry-level machines.

It comes with all the latest technologies such as linear motors, ceramics, motion controller and discharge unit.

AG40L

-

The most popular Linear Die sinker EDM range in the market, “AG series” ensures that machining in half the time has become an economically efficient reality.

The series features linear drive technology and simplified control mechanisms, which provide a direct link between the drive and the control. This ensures the fastest possible servo-response and optimal spark gaps at all times.

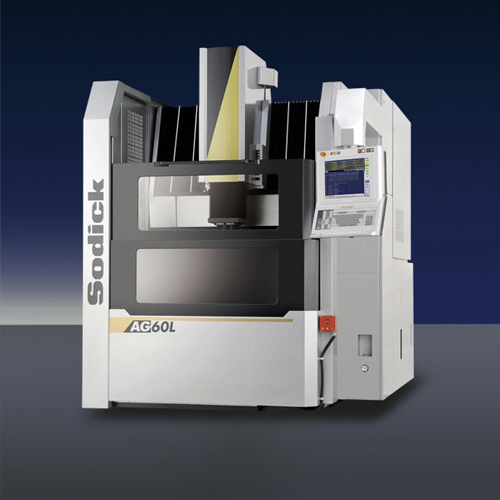

AG60L

-

The AG60L, the best selling model in AG series of range, realises high speed and high accurate cutting.

The series features linear drive technology and simplified control mechanisms, which provide a direct link between the drive and the control. This ensures the fastest possible servo response and optimal spark gaps at all times.

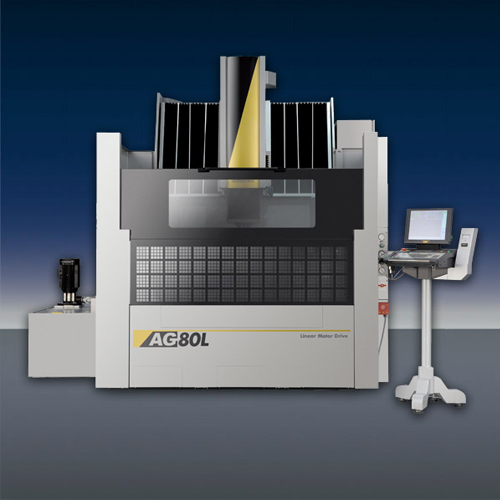

AG80L

-

Sodick’s largest size Die sinker EDM machine in the range is the “AG80L”. It is suitable for cutting large work pieces in a very short space of time, thanks to the Sodick’s in-house fabricated technologies.

The series features linear drive technology and simplified control mechanisms, which provide a direct link between the drive and the control. This ensures the fastest possible servo response and optimal spark gaps at all times.

AG80L LST

-

AG80L LST (LargeSize Tank) is available for machining larger workpieces. Needless to say, the machine comes with all the latest Sodick in-house made technologies such aslinear motors, ceramic components and communication technology of 1Gbit/sec which ensure the accuracy and quality.

Custom Size Worktank on Demand

The dimension of the standard worktank is 1,800 x 1,000 x 500mm. The worktank is a separate unit of the machine tool, this innovative design allows the flexibility of any size or shape worktank as required by your application.

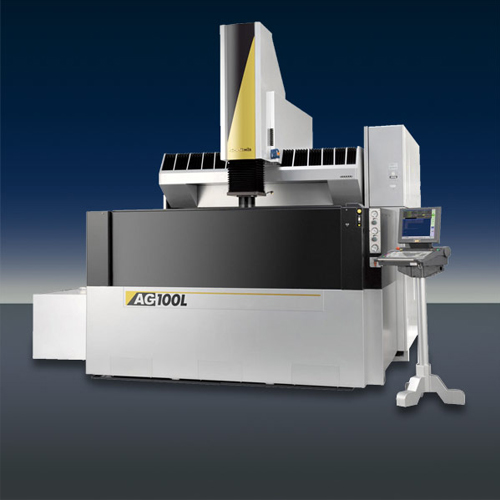

AG100L

-

Sodick presents the large AG Sinker-EDM, the AG100L. Needless to say, the model features all the in-house made technologies of Sodick.

The AG series features linear drive technology and simplified control mechanisms, which provide a direct link between the drive and the control. This ensures the fastest possible servo response and optimal spark gaps at all times

AQ15L

- Linear Motor Drive Large Size Die Sinker EDM

A large size die sinker EDM specialising in the highly efficient production of large size moulds such as those for automobile parts and large flat display panels, making it possible to fully utilise the high speed, high precision machining capability of linear motor drive machines.

AQ20L

-

The XXXXL Linear

The AQ20L is available in Sodick Linear EDM range for even bigger parts. Its work-tank is separated from machine unit; the weight of work-piece does not affect the movement of linear motor drive, which promises to make the most of linear motors’ performance.

AP1L

- Premium High End EDM Machine

Responding to the need for a higher level of machining accuracy, Sodick's AP1L Premium offers solutions to ultra precision machining requirements based on achieved superiority in mini and microscopic machining. Production is improved through advanced functions for automation and labour saving operation. Revolutionary technology is needed for electrode dressing to support ultra precision high speed machining of hard and difficult materials in order to achieve manufacturing capability of mini and micro moulds.

AP3L

- Premium High End EDM Machine

Responding to the need for a higher level of machining accuracy from a larger size of machine, Sodick's AP3L Premium offers solutions based on proven superiority in Micro machining. Production is improved through enhanced construction of machine and efficient operation. The machine has the double column symmetric structure and aero harmonic system to minimize the thermal effect. Furthermore, the AP3L is equipped with the high-rigidity roller guides which improves Z axis positioning accuracy and stability.

Precision Wire EDM

- The Sodick wire EDM range features linear motors. Using Sodick's new LP Control, Parasolid files (solid models) can be directly imported into the control. This feature maximises the cutting performance, reduces the wirkflow and eliminates programming errors.

VL400Q

VL600Q

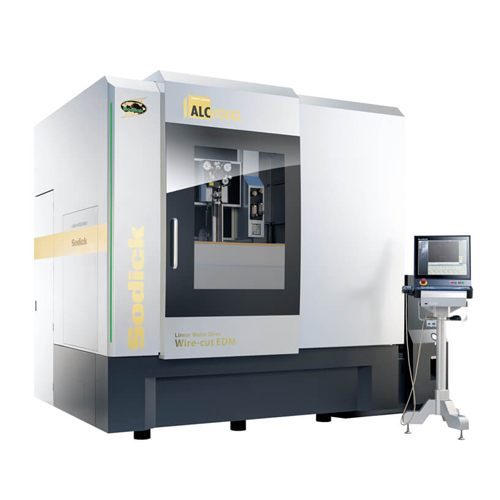

ALC400iGE

-

Sodick’s ALC400/ ALC600 range of machines comes with a new standard – the “i Groove” edition with wire rotation mechanism. This new innovative technology, patented by Sodick, rotates the wire during the skim cut operation, so that workpieces are machined from top to bottom with the “unconsumed” surface of the wire.

Conventionally, wire electrodes are controlled solely by tension and running speed, while being constrained by a die. Sodick’s i Groove rotation mechanism provides additional control over the wire, resulting in increased surface quality and improved geometric accuracy, whilst at the same time minimising wire consumption – combining the best ecological solution with the highest quality of EDM machining.

ALC600iGE

-

Sodick’s ALC400/ ALC600 range of machines comes with a new standard – the “i Groove” edition with wire rotation mechanism. This new innovative technology, patented by Sodick, rotates the wire during the skim cut operation, so that workpieces are machined from top to bottom with the “unconsumed” surface of the wire.

Conventionally, wire electrodes are controlled solely by tension and running speed, while being constrained by a die. Sodick’s i Groove rotation mechanism provides additional control over the wire, resulting in increased surface quality and improved geometric accuracy, whilst at the same time minimising wire consumption – combining the best ecological solution with the highest quality of EDM machining.

ALC800G

-

Based on the latest digital innovations in generator technologies and the use of advanced electrode materials, the new ALC range demonstrates considerable advances in cutting speed, accuracy and surface finish. This achievement was made possible through 15 years of Sodick Linear Technology.

To capitalise on the advances of the digital Smart Pulse generator and Sodick’s linear motor system, a new mechanical design was required. This new design resulted in a compact and fully enclosed machine tool which furthermore uses the latest human interface with a 19-inch touch screen colour control.

AQ900L Premium

- Large size wire cut EDM machine

Large size wire cut EDM machine with all accuracy and quality you would expect from Sodick. High speed, precision and accuracy with linear motors plus LP control technology. Solid models can be directly imported maximising cutting efficiency, reducing work flow and programming errors.

In response to the growing demand for large dies spurred by the huge popularity of large screen TV's, the AQ900L Premium, also equipped with LP Power supply have been designed especially for machining large size dies for large size components as well as for automobile parts such as instruments, panels and bumpers.

AQ1200L Premium

- The World’s Biggest Linear Motor Drive Wire-cut EDM

Sodick’s largest size wire cut EDM machine AQ1200L is now available in the range.

The machine comes with all accuracy and quality which you would expect from Sodick. High speed, precision and accuracy with linear motors plus communication technology of 1Gbit/sec.

The AQ1200L is suitable for larger parts in industry; such as automobile, aerospace and energy. Cutting height of up to 600mm submerged is also available as a factory option.

AQ1500L Premium

- The World’s Biggest Linear Motor Drive Wire-cut EDM

Sodick has now developed an even bigger linear wire-cut EDM; the AQ1500L Premium is now available in the product range.

The machine comes with all accuracy and quality which you would expect from Sodick. High speed, precision and accuracy with linear motors plus communication technology of 1Gbit/sec. It allows the work-piece with up to 600mm height as standard.

AP250L

- Linear motor drive precision Wire-cut EDM

Linear Motor Drive System

Combination of linear motor drive system and a gantry structure has achieved great improvement of positioning and machining accuracy by taking full advantages of backlash free quick axis movement, while minimizing the deformation of the machine structure during axis movement. The new dielectric chiller and the surface level adjustment function ensure stable machining performance from the moment the machine is turned on.The New "SPW" Controller

The new generation electrical discharge technology "SPW" has adopted the "Perfect Active Control," enabling simultaneous control of high-speed electrical discharge and axis-movements by using serial communication technology of 1Gbit/sec. The oil machine features Eco Cut O, which allows oil dielectric to realize a same cutting speed as water dielectric to achieve the surface finish of less than 0.15μmRa.Improved Operability

The machine features 3-sided automatic tank door and a worktable with 3 frames to realize the user friendly operations. The optimum layout of a valve unit and a controller allows an operator to handle every work at the same place.

Hole Drilling EDM

- Sodick's K-series range of machines can produce very small wire EDM start holes quickly and efficiently, as well as other small diameter drill holes. The K series line up features K1C, K3HN, K1BL and K3BL, with a wide range of capabilities determined according to the application needs.

K1C

- High-speed hole EDM by Sodick

Sodick’s K-series range of machines can produce very small holes quickly and efficiently.

The manually operated K1C model is ideally suited for the production of small diameter holes with a machining range of 0.25 to 3.0 mm diameter, particularly in materials which cannot be machined by traditional methods, and without high tooling cost.

Features- Improved Ease of Operation

- Guide set 0.8 mm

- Electrode tube 20 pcs. 0.8 mm

- Splash guard

- Workpiece fixtures

K3HN

- High-speed hole EDM by Sodick

Sodick's K-series range of machines can produce very small holes quickly and efficiently.

NC-device equipped high-end model, K3HN is advantageous in cutting multiple initial holes for wire EDM or in automated parts machining.

As an option, the K3HN can be equipped with a additional rotary and/or indexing axes making it the ideal product for Aerospace and Medical applications.

Features- CNC control LK1 with SMC (Sodick Motion Control)

- LN assist software for optimum condition search

- Automatic depth measurement

- AEF (Automatic electrode feeder)

- Improved Ease of Operation

- Guide set 0.8 mm

- Electrode tube 20 pcs. 0.8 mm

- Splash guard

- Workpiece fixtures

- USB

- Ethernet

Additive Manufacturing

- The OPM250E is a fully automatic machine which performs high precision finish machining.

OPM250L

-

The OPM250L is a fully automatic machine which performs high precision finish machining where a

metal powder is spread uniformly (recoating process), the metal powder is scanned with a laser beam

to solidify the melted powder, and a rotary tool is used to perform high-speed milling. The adoption

of an Yb fiber laser with a maximum output of 500W for the laser oscillator which solidifies the

melted metal powder, realized high-speed metal 3D printingFeatures

- Linear Motor for X, Y and Z axis

- Linear Glass Scale Feedback

- Sodick LN2RP Control

- HSK-E25 Spindle

- Automatic Laser Tool Length Measuring System (Blum)

- Yb fiber laser

- Fume Collector

- Nitrogen Gas Supply Unit

- 16-station Automatic Tool Changer

- LAN Interface

OPM350L

-

The OPM series is a fully automatic machine which performs high precision finish machining where a metal powder is spread uniformly (recoating process), the metal powder is scanned with a laser beam to solidify the melted powder, and a rotary tool is used to perform high-speed milling. The adoption of an Yb fiber laser with a maximum output of 500W for the laser oscillator which solidifies the melted metal powder, realized high-speed metal 3D printing. Read the article about OPM250L.

Features- Linear Motor for X, Y and Z axis

- Linear Glass Scale Feedback

- Sodick LN2RP Control

- HSK-E25 Spindle

- Automatic Laser Tool Length Measuring System (Blum)

- Yb fiber laser

- Fume Collector

- Nitrogen Gas Supply Unit

- 16-station Automatic Tool Changer

- LAN Interface

- Parallel cutting mode

High-speed Milling

- All the Sodick high-speed milling range, the “HS series” features linear motors. To compete successfully in today's global market, manufacturers are looking for milling solutions wich combine very high accuracy with minimum cycle times. The HS Series satisfies the most demanding application requirements.

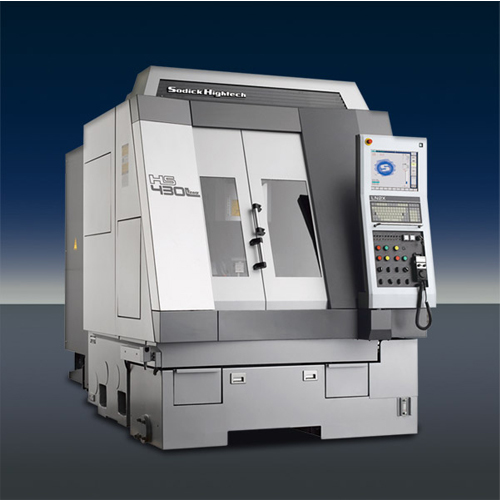

HS430L

- Sodick's high-speed linear machining centre.

As a pioneer in the use of highly dynamic linear drives in machine tools, and based on years of experience with over 10,000 linear EDM machines, Sodick is presenting a new generation of high-speed linear machining centres with linear drives in all axes – the HS L series

High acceleration rates > 1G, maximum stability and the highest degree of precision down to the nano realm are the top attributes of this innovation, which heralds a new era in milling tools. Not least because the handling of the machine is extremely easy and safe, thanks to the Windows-based CNC controller combined with Sodick Motion Control software.

Unlike the conventional method of separately executed rough and fine milling, this new technology combines both these machining passes in the one operating mode. The solution is a rapidly rotating and traversing tool of small diameter that cuts to fine depths.

HS650L

-

The Sodick dynamic linear technology comes into operation with the new Sodick high-speed milling machine HS650L as well.

The very high specification for the HS650L results in extremely high levels of accuracy, far beyond those normally associated with high speed milling, making it particularly appropriate for mould and die applications which call for maximum precision and surface quality, for example in the optical and electronic communication sectors.

This high precision, linear motor drive machining centre offers the high rigidity, accuracy and performance that customers have come to expect of the smaller HS430, but with a larger table, extended stroke and open height, increased maximum tool length, and double the linear motor output power.

HS650L 5 Axis

-

The Sodick dynamic linear technology comes into operation with the new Sodick high-speed milling machine HS650L as well.

The very high specification for the HS650L results in extremely high levels of accuracy, far beyond those normally associated with high speed milling, making it particularly appropriate for mould and die applications which call for maximum precision and surface quality, for example in the optical and electronic communication sectors.

This high precision, linear motor drive machining centre offers the high rigidity, accuracy and performance that customers have come to expect of the smaller HS430, but with a larger table, extended stroke and open height, increased maximum tool length, and double the linear motor output power