- Offer Profile

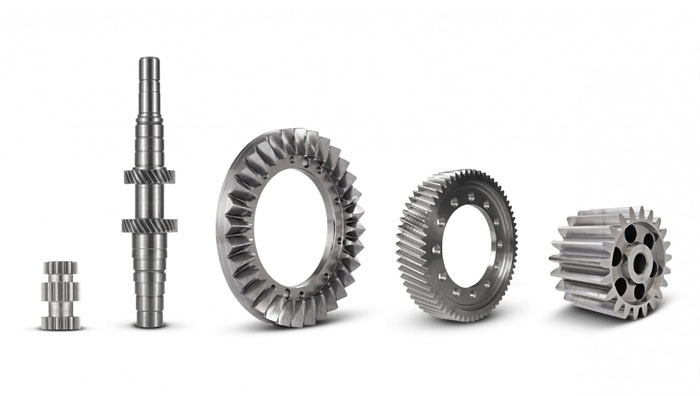

Total Gear Solutions

Gleason offers Total Gear Solutions to its global customer base. We are a leader in the development and manufacture of production systems for all types of gears including design software for gears and power transmission systems, gear production machinery, metrology systems, automation solutions, related equipment and plastic gears.

Gear Design

KISSsoft - Gear Design Software

- KISSsoft® performs strength calculations quickly and accurately, and provides detailed documentation, including safety factors and service life values. KISSsoft is completed by interfaces to all standard CAD programs and links to FE calculations.

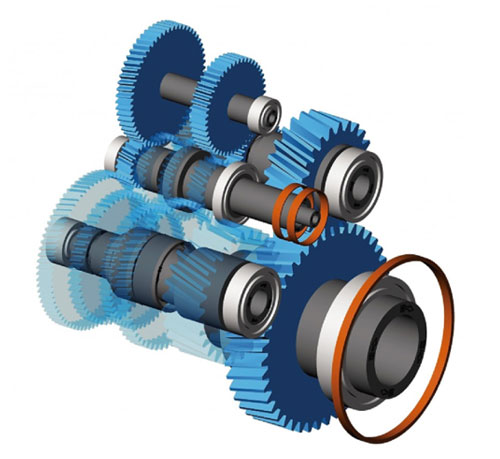

KISSsys - Transmission Design and Simulation

- KISSsys enables users to model complete gear units and drive trains. KISSsys brings together kinematic analysis, 3D graphics, and user-defined tables and dialogs, allowing users to perform system level evaluations in one run while considering the interdependent effects of every single component of the gearbox. System reliability, load spectrum calculation, efficiency and thermal balance evaluation, modal analysis are now available, and more.

About KISSsoft

- KISSsoft AG develops design software for engineers and designers in a wide variety of fields: whether they manufacture cable car systems, gears for construction equipment, Formula 1 race car transmissions or the tiny gears used in Mars rovers. When used in keeping with valid standards (DIN, ISO, AGMA), KISSsoft serves as a quick, high-quality tool for sizing transmission elements, reviewing calculations, determining component strength, and documenting safety factors and service life values.

Seamless Connectivity to GEMS Engineering and Manufacturing System

- KISSsys and GEMS® are linked by a direct interface to exchange gear tooth and system design data. After the design of transmissions with KISSsys, bevel and hypoid gears are calculated and manufactured with GEMS. While designs are simulated more accurately than ever, they can also be optimized in a closed loop system.

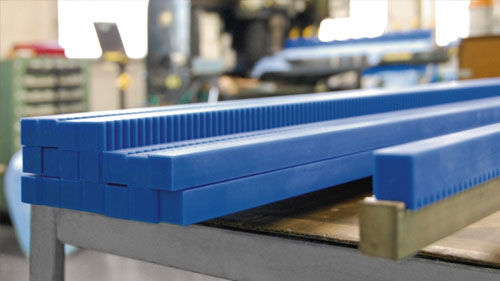

KISSsoft for Plastic Gears

- An expandable database with polymer data is available in KISSsoft, as well as the calculation of the operating backlash, taking into account the influence of manufacturing and mounting tolerances as well as temperature and swelling. Injection molding forms are determined by compensation of the shrinkage and spark gap.

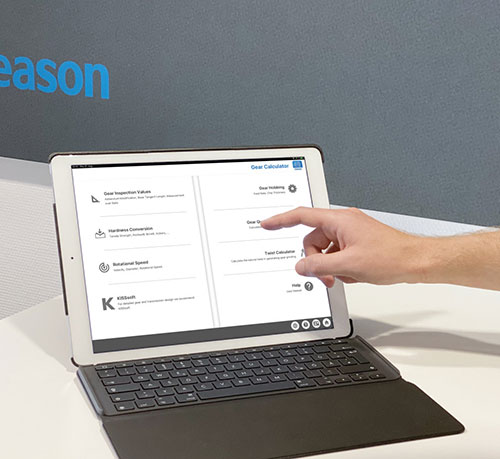

Gear Calculator

- This free mobile app bundles small calculation tools to make gear manufacturer’s daily life more efficient and productive.

Machines

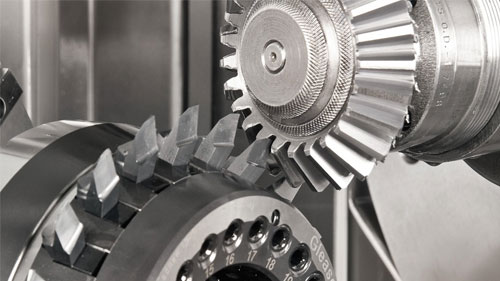

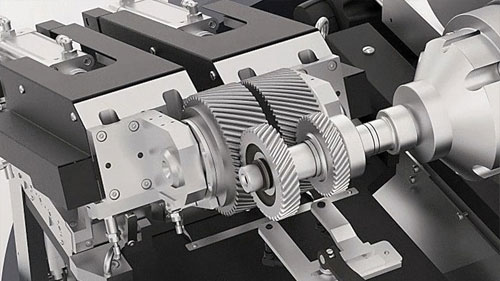

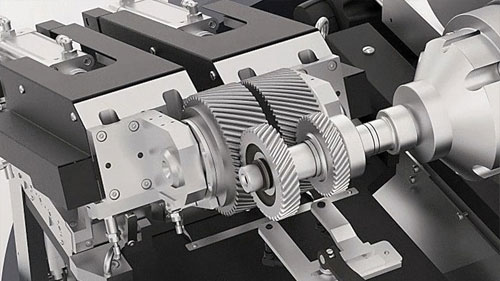

Bevel

Cutting

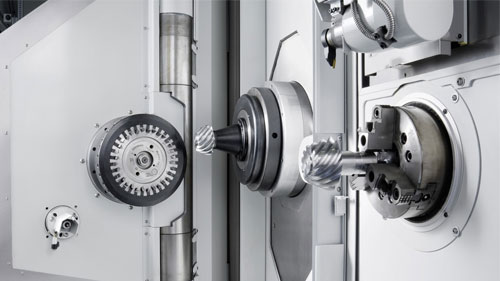

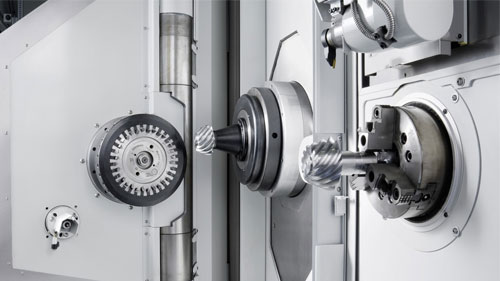

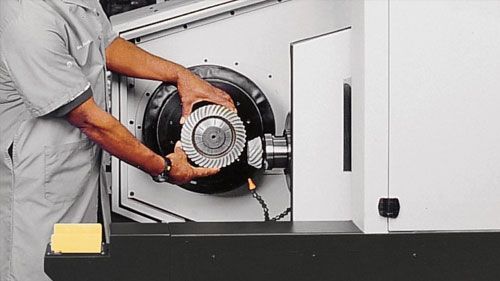

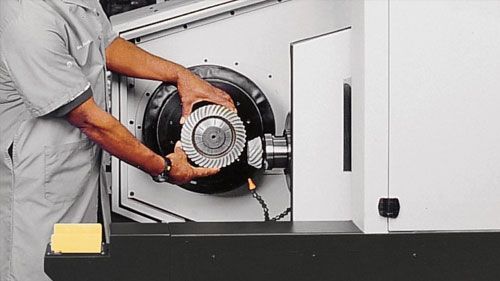

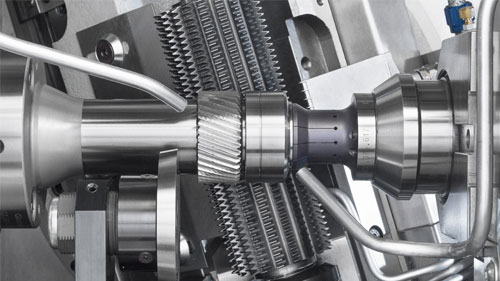

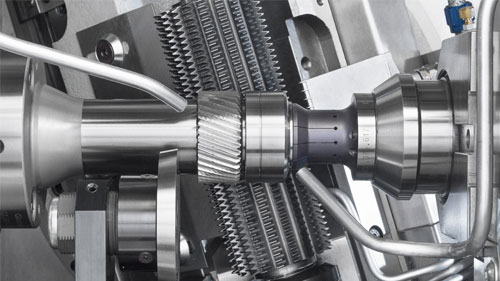

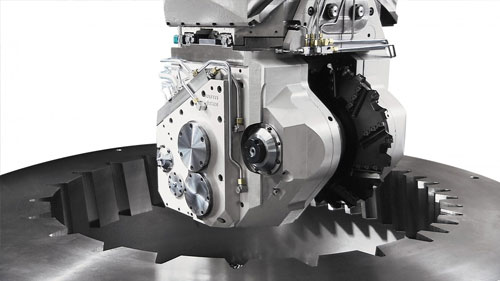

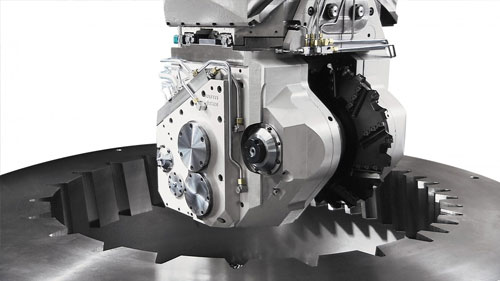

Phoenix 280C & 280CX - Cutting of Automotive and Small Truck Sized Bevel Gears

- The Phoenix® Bevel Gear Cutting Machines are the most productive in their class with cutting cycle times significantly reduced. The 280CX is a highly automated solution for automotive and other gear manufacturers seeking efficient high volume production. The 280C offers jobbers the same performance benefits but in a simpler package without integrated automation.

Workpiece diameter, max. 280 mm

Range of tooth numbers 1-300

Cutter diameter (FM), max. 9"

Cutter radius (FH), max. 105 mm

Phoenix 600HC - Fast and Economical Production of Truck Sized Bevel Gears

-

The Phoenix® 600HC has been developed for manufacturers of bevel gears as large as 600 mm in diameter to feature a host of benefits for the production of truck, bus and industrial gearbox applications.

Workpiece diameter, max. 600 mm

Range of tooth numbers 1-300

Cutter diameter (FM), max. 18"

Cutter radius (FH), max. 210 mm

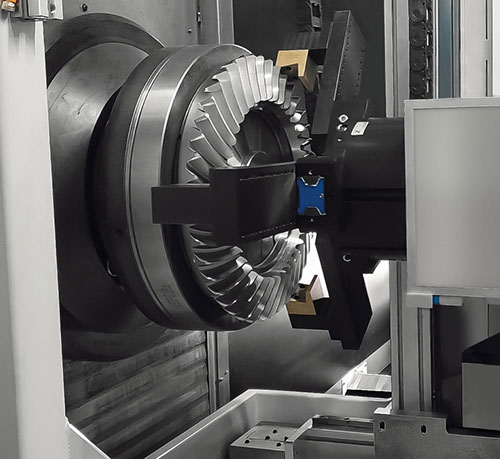

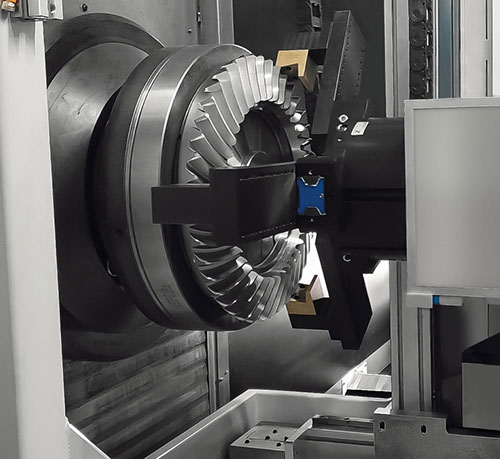

Phoenix 1000HC - Fast and Flexible Production of Large Bevel Gears

- The Phoenix® 1000HC brings speed, accuracy and repeatability to large bevel gear cutting operations. The highly robust machine design and powerful CNC Controls provide maximum flexibility and reduce changeover times.

Workpiece diameter, max. 1000 mm

Range of tooth numbers 1-300

Cutter diameter (FM), max. 18"

Cutter radius (FH), max. 350 mm

Phoenix 500C

- Phoenix 500C - Fast, Agile Production of Truck-Size Gears

Gleason’s Phoenix® 500C Bevel Gear Cutting Machine has been designed to bring speed, flexibility and ease-of-use to medium and high volume production of precision bevel gears for trucks, buses, and other applications of similar size.

- Workpiece diameter, max.: 500 mm

- Range of tooth numbers: 1-300

- Cutter diameter (FM), max.: 14"

- Cutter radius (FH), max.: 210 mm

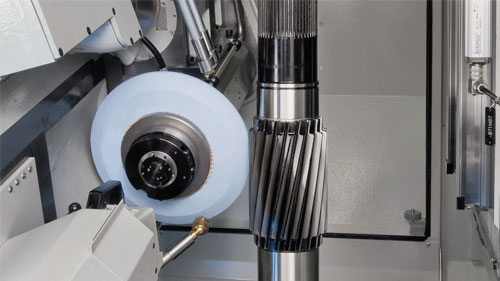

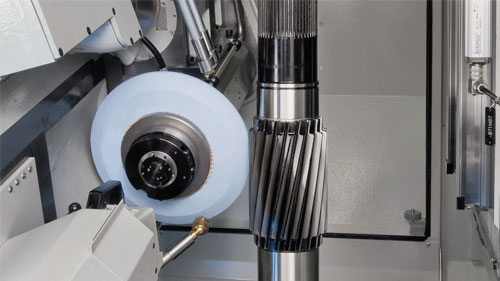

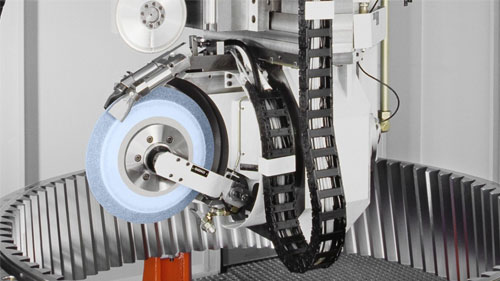

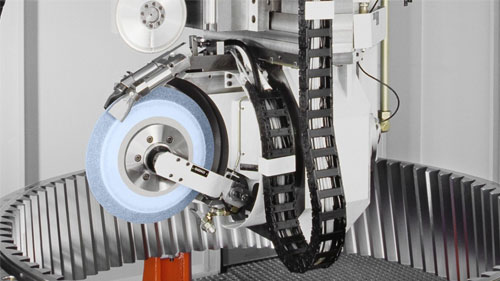

Grinding

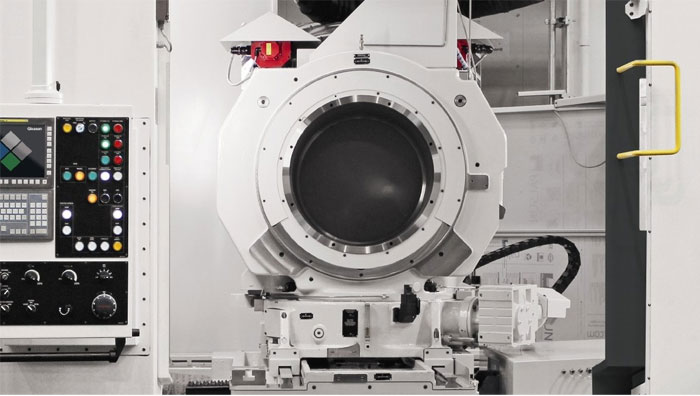

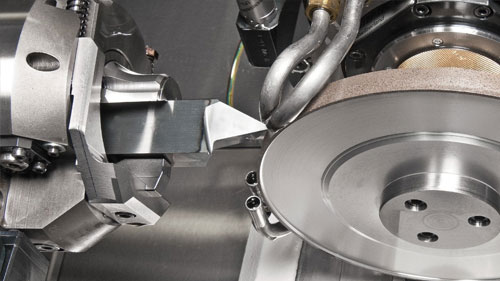

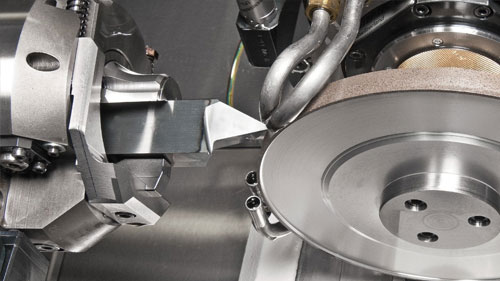

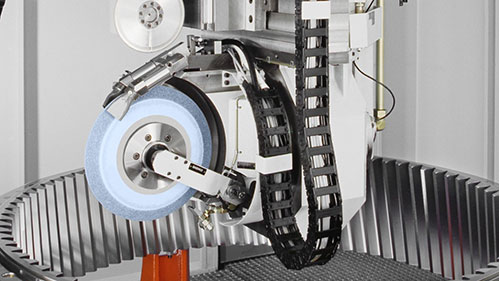

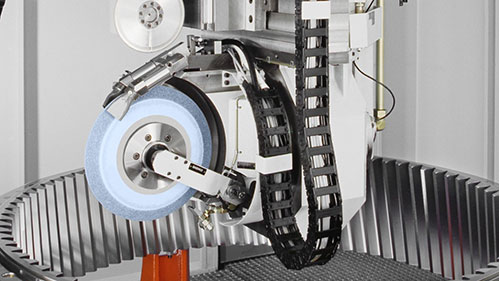

Phoenix 280G - Faster Production of High-Quality for Automotive and Small Truck Sized Bevel Gears

- The Phoenix® 280G meets the need for improved bevel gear grinding performance with a highly productive new design that is simpler, more reliable and easier to operate and maintain.

Workpiece diameter, max. 280 mm

Range of tooth numbers 1-300

Wheel diameter, max. 9"

Phoenix 600G - High Quality for Truck Sized Bevel Gears

- Higher speeds and increased torque, combined with shorter and faster motions dramatically increases productivity.

Workpiece diameter, max. 762 mm

Range of tooth numbers 1-300

Wheel diameter, max. 21"

Phoenix 800G - Grinding Large Sized Bevel Gears and Pinions

- The Phoenix® 800G brings speed, accuracy and repeatability to large bevel gear grinding operations. The highly robust machine design and powerful CNC Controls provide maximum flexibility and reduce changeover times.

Workpiece diameter, max. 600 mm

Range of tooth numbers 1-300

Wheel diameter, max. 20"

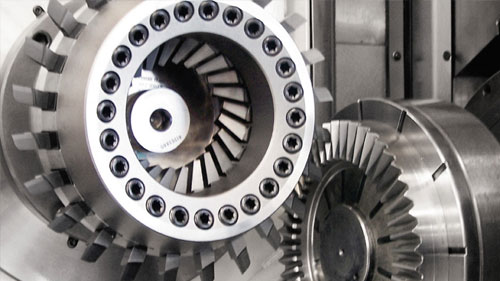

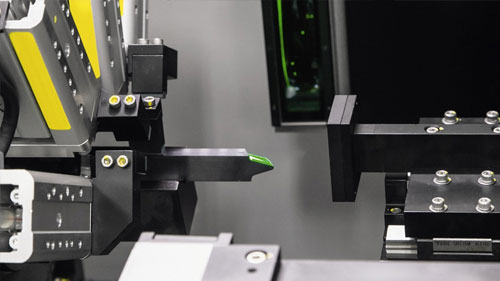

Curvic Coupling Grinding

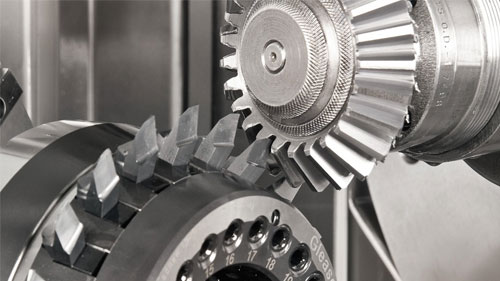

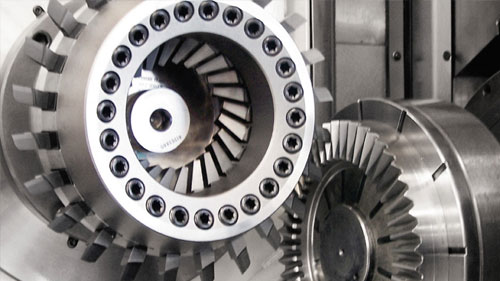

Curvic Coupling Grinding Series

- Gleason Curvic® Coupling Grinding Machines are high-speed large bore spindle machines for grinding curvic teeth in face couplings. A fully-automatic grinding cycle enables the production of extremely accurate and uniform couplings at high production rates.

Workpiece diameter, max. 1,016 mm

Grinding wheel speed range, max. 3,000 mm

Wheel diameter, max. 529.8 mm

Lapping

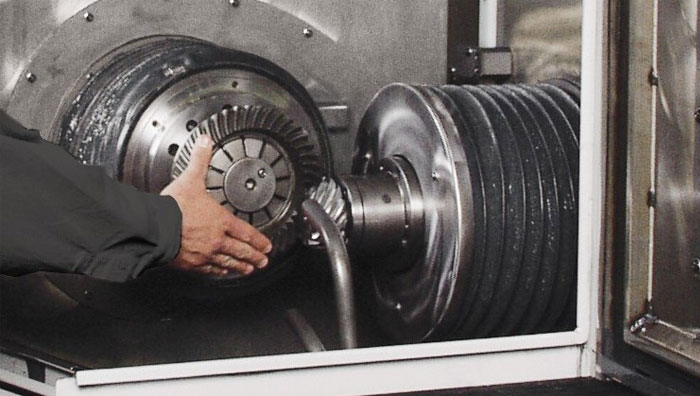

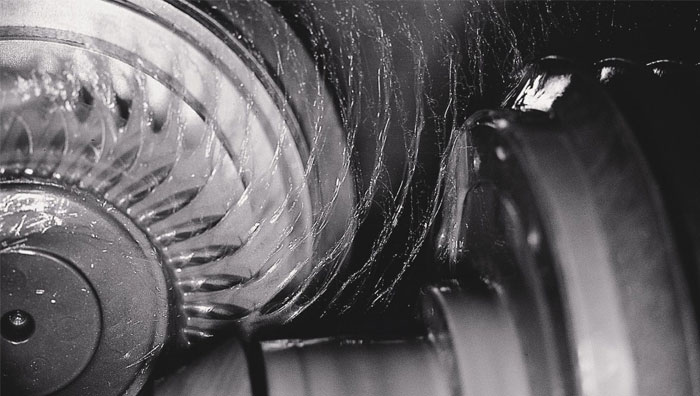

600HTL - Next Generation Turbo Lapping for Spiral and Hypoid Gear Hard Finishing

- The 600HTL Turbo Lapper® combines speed, ergonomics, and compact size with a host of innovations to create the most productive  and reliable  lapping machine ever built.

Workpiece diameter, max. 600 mm

Pinion and gear drive speed, max. 3,000 mm

Testing

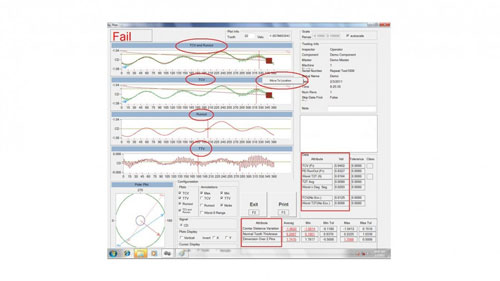

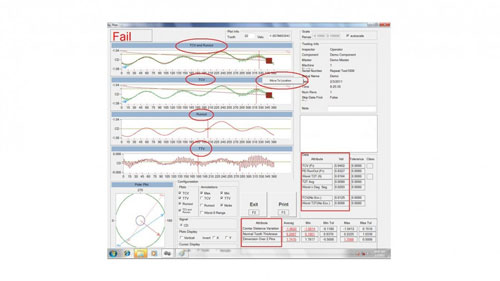

360T - Fast, Flexible Tester for Bevel and Cylindrical Gears

- State of the art CNC-controlled roll testing of just about any gearset type is now possible with the ground-breaking Gleason 360T Universal Gear Tester.

Workpiece diameter, max. 450 mm

Pinion speed, max. 3,000 mm

600HTT - The Industry Standard in Bevel Gear Testing

- The 600HTT Turbo Tester® has set the world standard for CNC-controlled roll testing of spiral bevel and hypoid gear sets. In addition to Basic contact pattern checking, this production- oriented machine provides single flank and structure-borne noise testing capabilities for soft and hard parts.

Workpiece diameter, max. 600 mm

Pinion speed, max. 3,000 mm

1000T to 2500T - Fast, Flexible Roll Testing of Large Gears, all Types

- Gleason 6-axis fully CNC Universal Gear Testers are in a class by themselves. They are the only products that can perform the full range of pattern checking and single flank testing on bevel gears with a wide range of shaft angles for diameters up to 2500 mm, as well as parallel-axis and off-angle cylindrical gears, with diameters as large as 1000 mm.

Workpiece diameter, max. 2500 mm

Range of shaft angle 30 - 180°

Quenching

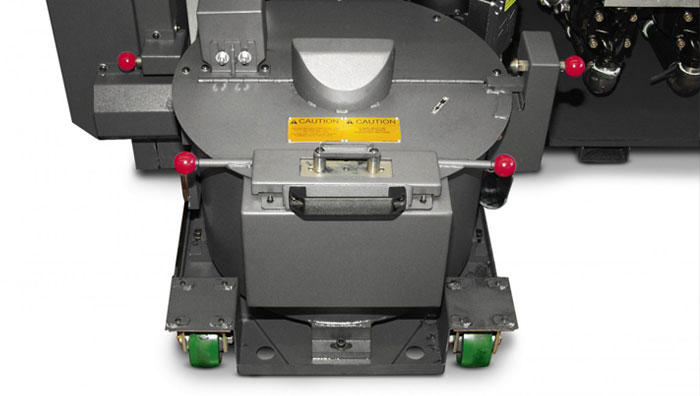

685Q - Process Controlled Quenching Machine

- GleasonÂs new 685Q for production quenching of bevel and cylindrical gears, including aerospace, automotive, truck and tractor main drive gears up to 685 mm in diameter.

Workpiece diameter, max. 685 mm

Workpiece diameter, min. 181 mm

Workpiece height, max. 203 mm

Blade and Cutter Grinding

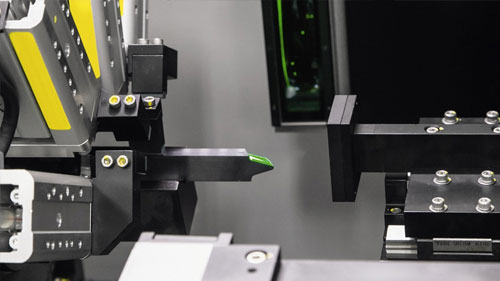

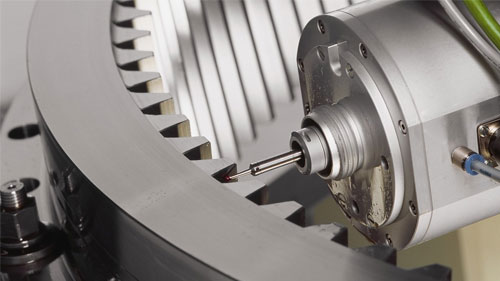

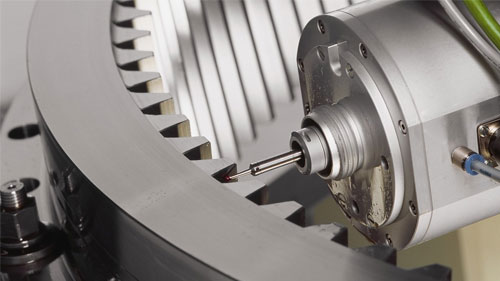

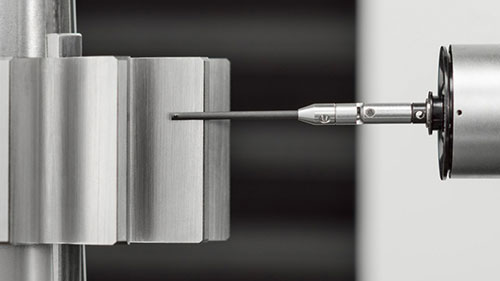

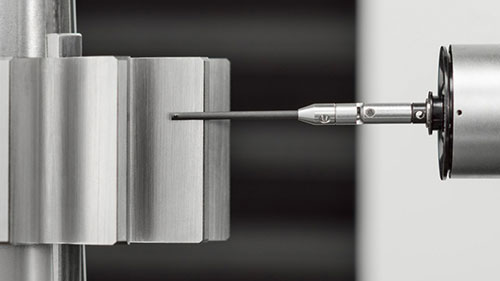

BPG - Sharpening of all Types of Stick Blades

- The Gleason Blade Profile Grinder (BPG) is an advanced bevel gear stick blade sharpening machine, capable of sharpening all blade types and sizes. You benefit from improvements in cycle time, ease of use, and overall cost.

NCG Series - Front Face Sharpening of Face Milling Cutters

- The 125NCG and 205NCG are automatic multi-purpose Sharpening machines for a wide variety of cutter styles.

Cutter diameter, max. 635 mm

Index range 1 - 99

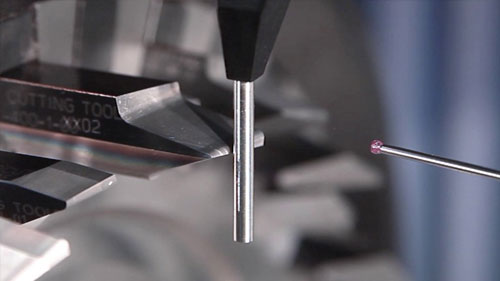

Blade Inspection

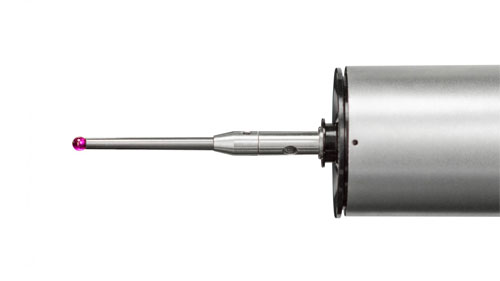

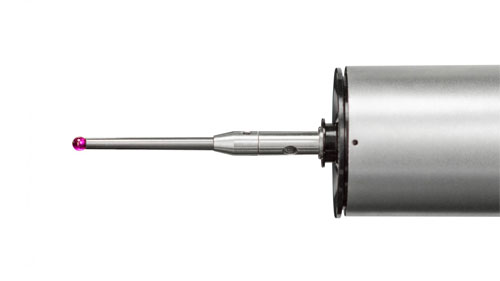

GBX - High Precision Stick Blade Inspection

- For high accuracy checking of new blade geometries, blade development and limited volumes. GBX serves all Gleason and non-Gleason stick blades.

Linear axis resolution 0.1 µm

BIM - Optical Stick Blade Inspection for Small and High Volumes

- For checking of Gleason and non-Gleason stick blades and complete stick blade sets. Available with automation for high volume environments, which can operate under shop-floor conditions.

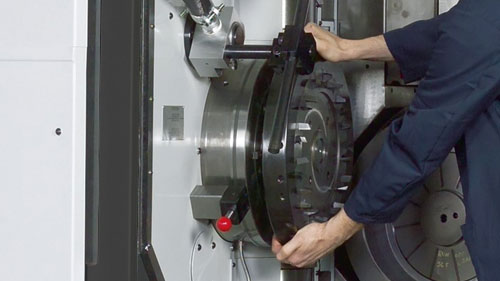

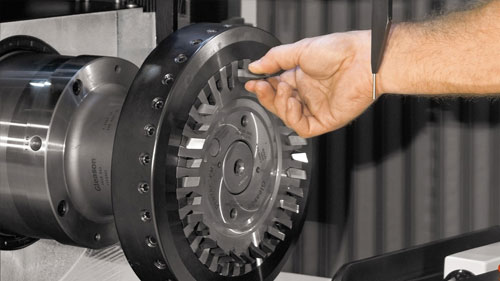

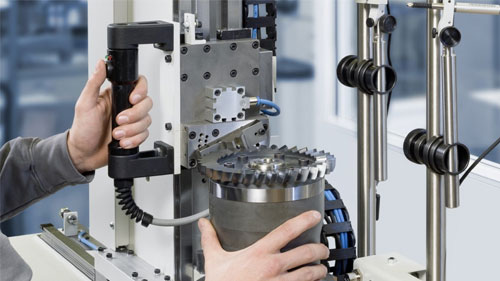

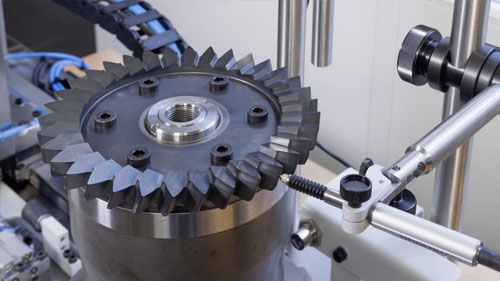

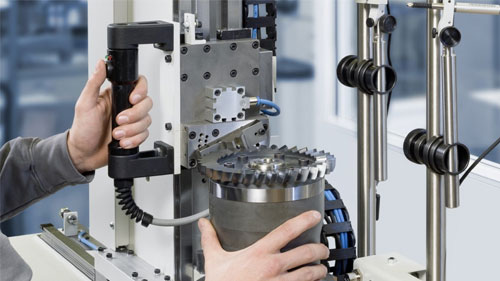

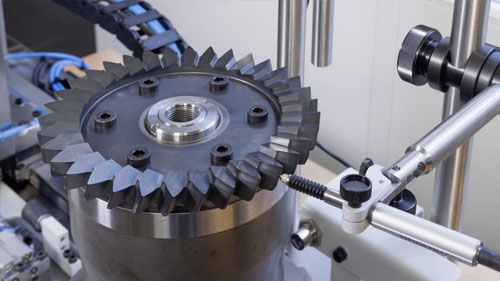

Cutter Build

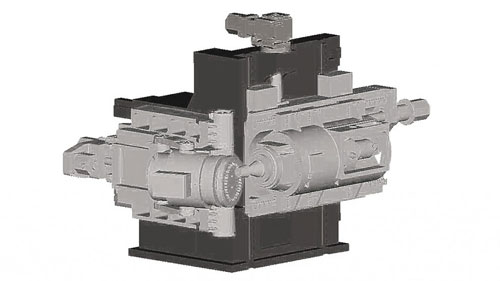

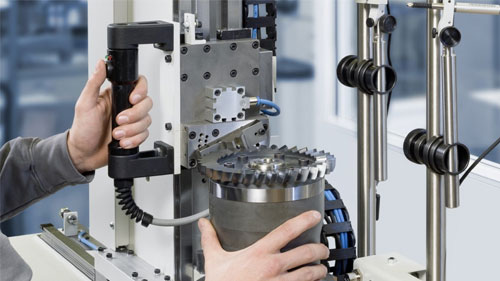

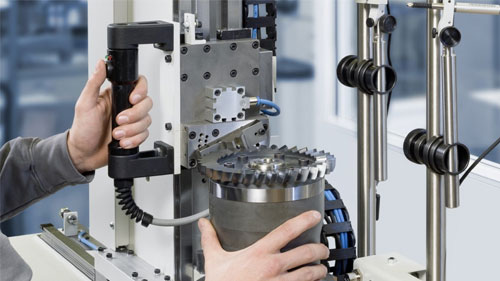

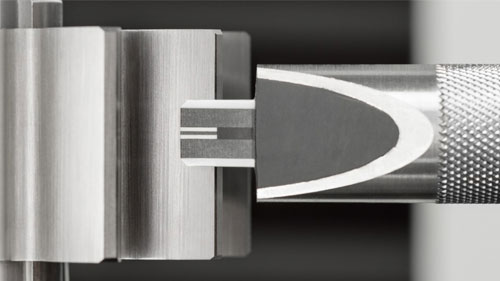

500CB - Automated Cutter Build, Truing and Inspection of Stick Blade Cutter Systems

- The 500CB delivers faster, more accurate, and highly automated build, truing and inspection of stick blade type bevel gear cutters.

Face milling cutter capacity (diameter), max. 533 mm

Face hobbing cutter capacity (radius), max. 210 mm

CB - Manual Cutter Build and Measuring Unit of Stick Blade Cutter Systems

- The Phoenix® Cutter Build Machine is an advanced computer- controlled bevel gear cutter build and measuring unit. The machine can be used to build face mill and face hob cutters to a high degree of accuracy.

Face milling cutter capacity (diameter), max. 533 mm

Face hobbing cutter capacity (radius), max. 210 mm

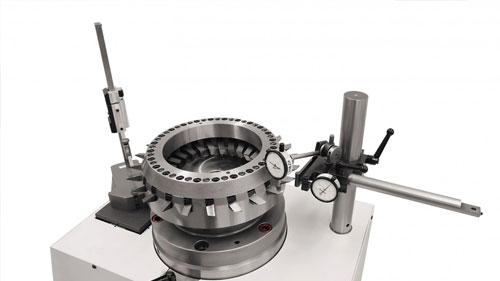

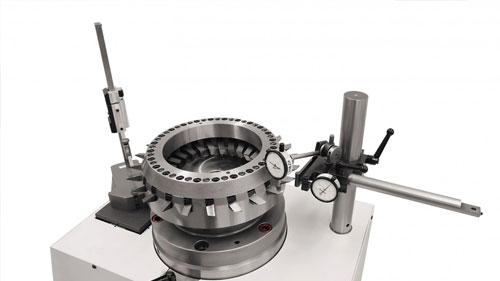

CCB - Designed for Precise Coniflex Plus Cutter Build and Curvic Coupling Inspection

- The Gleason CCB ensures precise Coniflex® Plus cutter accuracy  essential to the production of precise straight bevel gears and the prolonged life of cutting tools.

Coniflex Plus cutter capacity (diameter), max. 381 mm

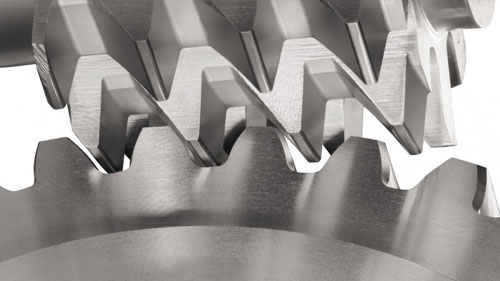

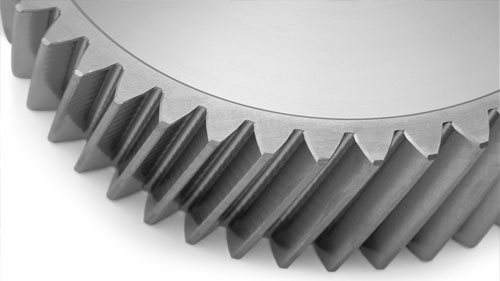

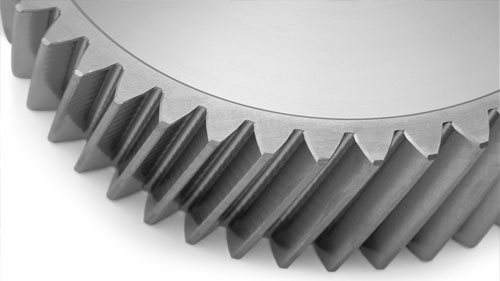

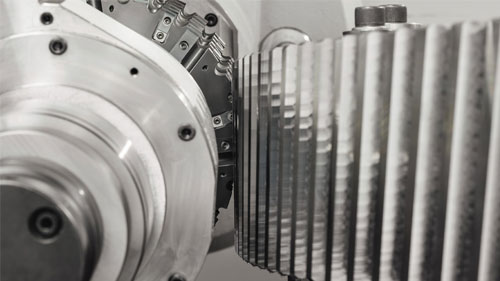

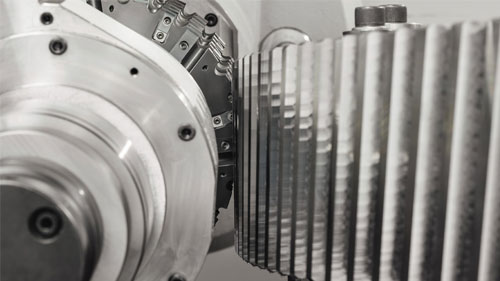

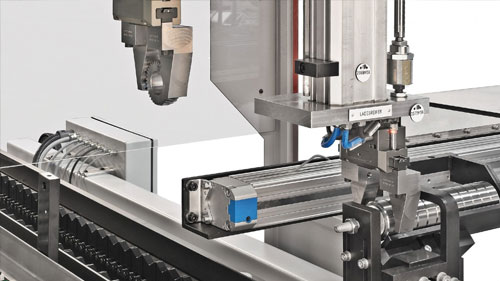

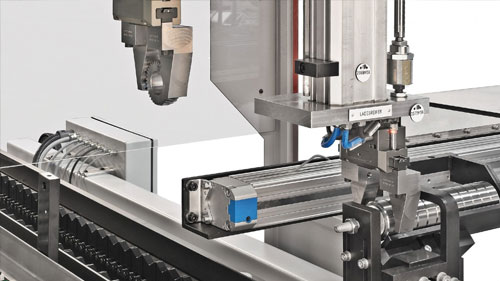

Cylindrical

Hobbing up to 300 mm

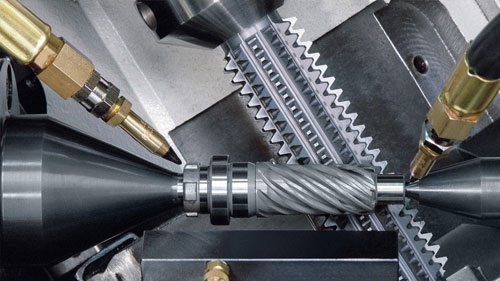

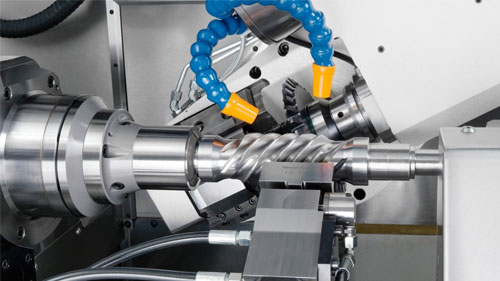

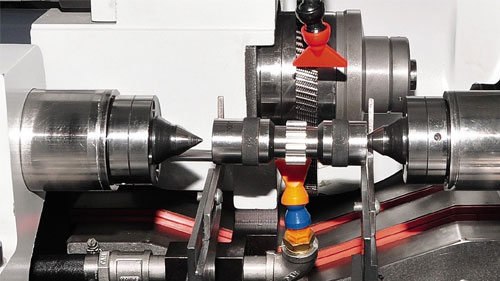

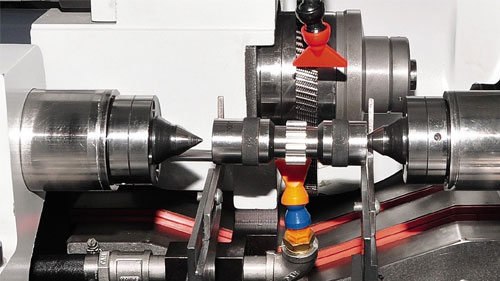

P60 - Compact Solution for Gears, Shafts and Worms

- The P60 is the smallest machine in Gleason's range of horizontal hobbing machines. The P60 cuts geared workpieces with any profile which can be produced by hobbing or profile milling processes. This machine is also the perfect solution for machining steering pinions and worms.

Workpiece diameter, max. 80/120* mm

Module, max. 2.5 mm

Axial slide travel, max. 320/400* mm

* Option

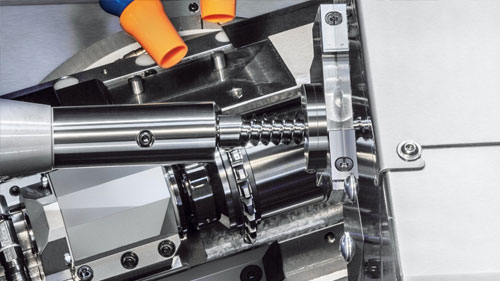

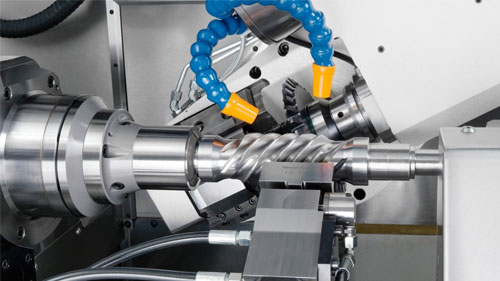

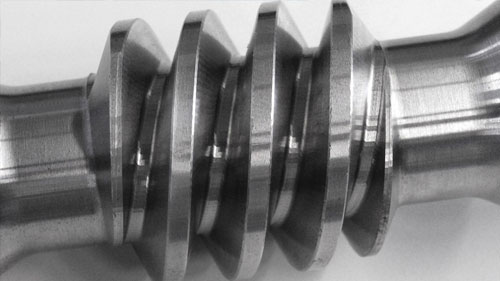

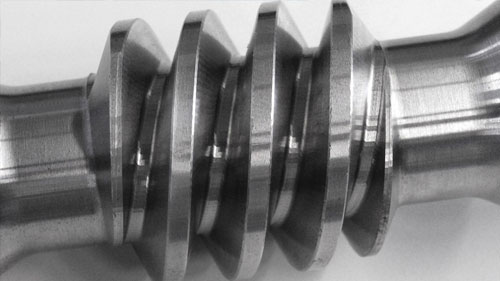

P90WM - The Specialist for Worm Milling

- The P90WM Horizontal Worm Milling Machine is the ideal solution for the machining of any type of worm.

Workpiece diameter, max. 100 mm

Module, max. 8 mm

Axial slide travel, max. 330 mm

100H Series - High Speed Hobbing with Integrated Chamfering/Deburring

-

The 100H Hobbing Machine Series is the next generation of the well-known P90 Series with improvements in design, functionality and operator inferface. This hobbing machine and its variants handle a wealth of geared profiles up to a workpiece diameter of 120 mm, module 4 and a shaft length of 1200 mm.

- Workpiece diameter, max.: 100/120* mm

- Module, max.: 3/4* mm

- Axial slide travel, max.: 400/800* mm

P210L Series - Hobbing and Chamfering/Deburring of Larger Shafts

- The P210L Hobbing Machine and P210LiC Hobbing Machine with Integrated Chamfering/Deburring Unit are designed for the manufacture of large, long shafts which must meet high quality demands.

Workpiece diameter, max. 180* mm

Module, max. 4 mm

Axial slide travel, max. 300/400* mm

* Option

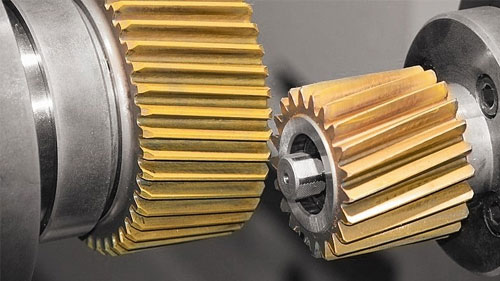

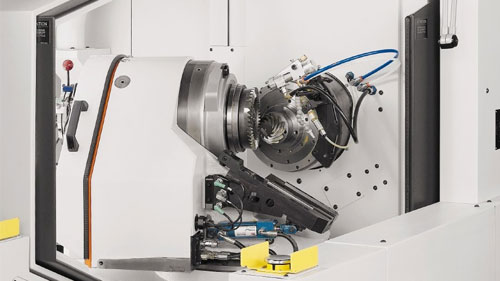

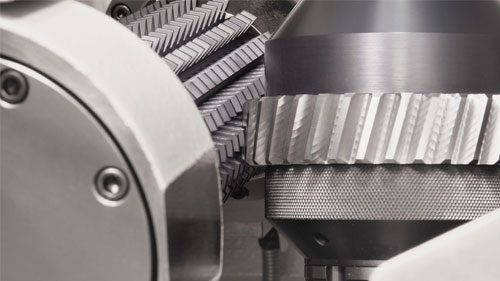

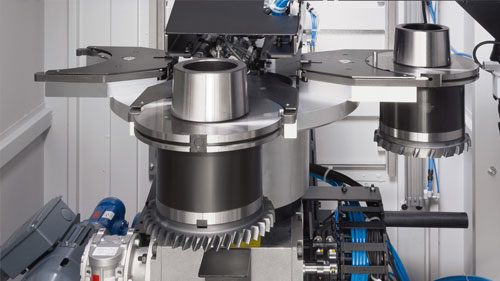

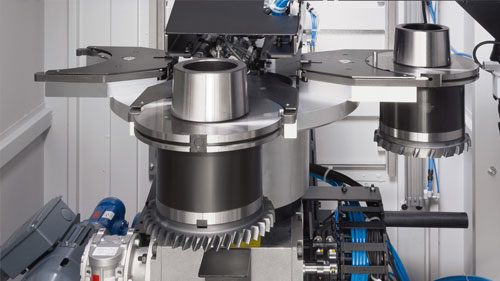

Genesis Series - Compact Power for Your High-Speed Production

- The Genesis® Hobbing Machines with vertical workpiece axis offer highly productive gear hobbing with optional chamfering and deburring capability.

Workpiece diameter, max. 210 mm

Module, max. 3/4* mm

Axial slide travel, max. 350 mm

* Option

Genesis 160HCD/210HCD Series - Hobbing Machine with Integrated Chamfer Hobbing. Fast, Precise and Efficient

- Parallel to the gear hobbing process, workpieces are chamfered by chamfer hobbing, a cutting chamfer technology. The machine is arranged with an integrated chamfer station which is directly linked to the main process by a fast gantry automation, allows minimum cycle times without any productivity loss.

Workpiece diameter, max. 160/210* mm

Module, max. 4 mm

Axial slide travel, max. 380* mm

* Option

Hobbing up to 800 mm

Genesis 400H(CD) - The Productivity Master with Optional Flexible Chamfering

- The Genesis® 400H(CD) Hobbing Machine is designed for many different applications like disc- or shaft-type spur or helical gears, skive hobbing of hardened gears or cutting of special profiles. Whether small batch manufacture or mass production, the Gleason Genesis 400H(CD) can be configured to all your requirements.

Workpiece diameter, max. 400 mm

Module, max. 8 mm

Axial slide travel, max. 650 mm

P-Series - Universal Hobbing Machines for Mid-Size Gears

- The mid-size series of Gleason Hobbing Machines with the P400, P600 and P600/800 is a modern, modular design which can be easily customized to suit individual customer requirements.

Workpiece diameter, max. 800 mm

Module, max. 16 mm

Axial slide travel, max. 1000 mm

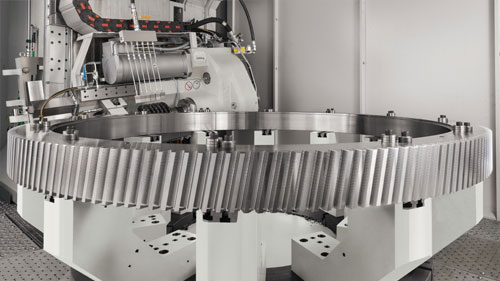

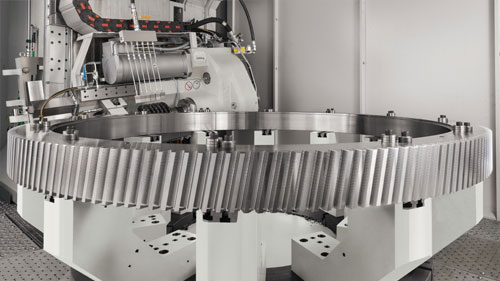

Hobbing up to 10,000 mm

P Series - Flexible All-Purpose Machines for Every Application

- Large Gleason Hobbing Machines offer maximum productivity for roughing and finishing operations on cylindrical gears for many industries. Starting with the P800, the modular construction kit extends all the way up to the P10000 with 10 m in diameter.

Workpiece diameter, max. 10,000 mm

Module, max. 45 mm

Module profile milling, max. 60 mm

Axial slide travel, max. 2200 m

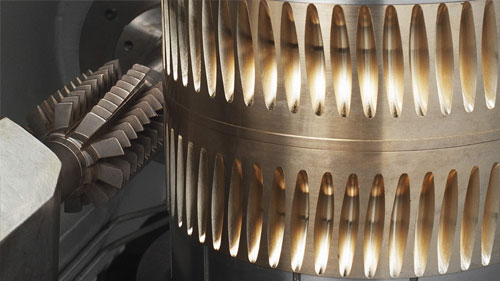

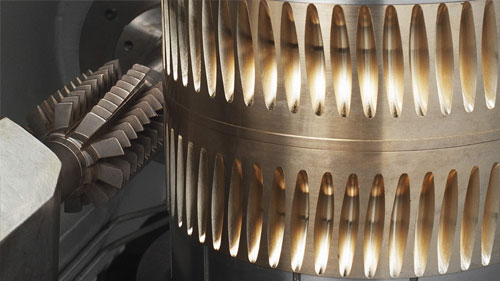

Titan Series - Combine Productivity with High Precision

- The Titan® Series is the benchmark for high-performance internal and external gear hobbing. The modular design covers the machine range 1200H, 1600H and 2000H with up to 2000 mm in workpiece diameter and module 40 mm.

Workpiece diameter, max. 2000 mm

Module, max. 30 mm

Module profile milling, max. 300 mm

Axial slide travel, max. 1600 mm

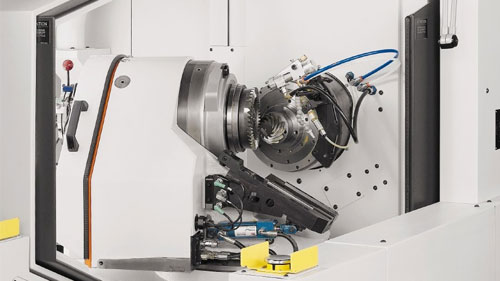

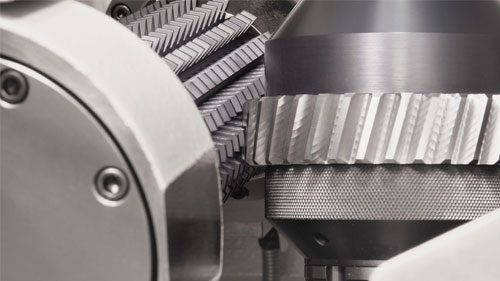

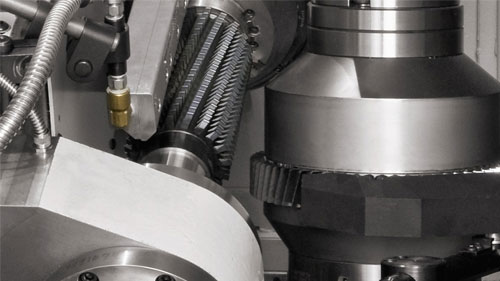

Power Skiving

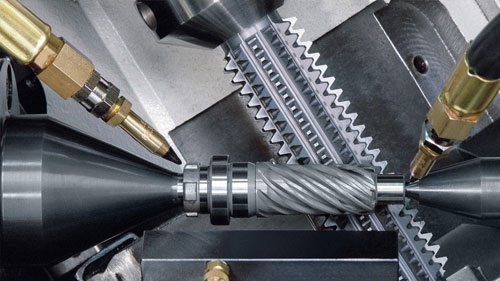

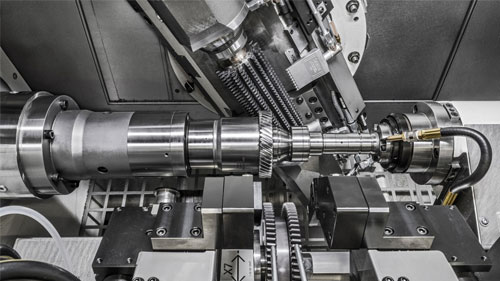

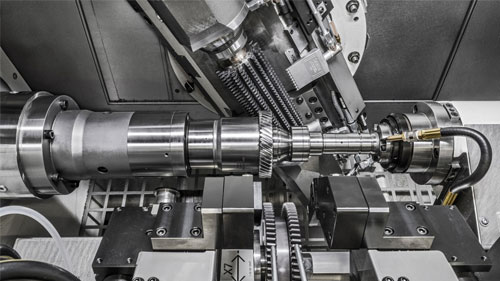

100PS - The Solution for Shafts and Small Internal/External Gears

- Specifically designed for the economical production of gears with interfering contours and internal gears up to module 2.0 mm, its horizontal axis makes this machine also highly suitable for shaft-type parts.

External gears workpiece diameter, max. 100 mm

Internal gears workpiece diameter, max. 150 mm

Module, max. 2 mm

300PS - The Universal, Easily Automated Machine

- Well suited for the highly productive manufacturing of cylindrical internal and external gears with outstanding quality and significant reductions in cost-per-piece.

Workpiece diameter, max. 300 mm

Swing diameter, max. 450 mm

Module, max. 4 mm

400PS to 600PS - The Power House for Medium- and Large-Sized Gears

- Well suited for the highly productive manufacturing of cylindrical internal and external gears with outstanding quality and significant reductions in cost-per-piece.

Workpiece diameter, max. 800 mm

Swing diameter, max. 850 mm

Module, max. 8 mm

160CPS - Getting It Right The First Time

- Preset shaper cutters and Power Skiving cutters on the 160CPS Cutter Presetting Device to get it right the first time.

Measurable outside diameter 340 mm

Cutter weight, max. 50 kg

Gear Shaping

100S - The Sprinter for Gears with Short Face Widths up to 100 mm

- The 100S Gear Shaping Machine is ideally suited for small face widths, for shaping spur and helical gears, internal and external, and for crowned and tapered gears. With only 6 m2 the 100S is one of the most compact machines of its class.

Workpiece diameter, max. 100 mm

Module, max. 3 mm

Stroke length, max. 30 mm

Strokes per minute 3000

GP Series - Shaping Machines with Performance and Flexibility in a Compact Design up to 300 mm

- Designed for shaping spur and helical gears, internal and external gears, crowned and tapered gears and deep recessed internal gears, the GP Series is available in two model sizes GP200S and GP300S. The GP Series can be upgraded with the Electronic Shaping Guide Option.

Workpiece diameter, max. 300 mm

Module, max. 6 mm

Stroke length, max. 110 mm

AM250 - The Robust and Economic Alternative for Job Shops

- The AM250 Gear Shaping Machine is your first choice when it comes to shaping of typical cylindrical spur and helical, external and internal gears, using the generating or single indexing method.

Workpiece diameter, max. 300 mm

Module, max. 8 mm

Stroke length, max. 110 mm

P Series - Shaping Machines for Medium-Sized Gears up to 800 mm

- GleasonÂs mid-range series of shaping machines is easily customized to suit individual customer requirements. The medium-sized P Series comes in three model sizes: P500S, P600S and P600/800S. The P Series can be upgraded with the Electronic Shaping Guide Option.

Workpiece diameter, max. 800 mm

Module, max. 12 mm

Stroke length, max. 250 mm

P Series - Shaping Machines for Large Gears up to 3,200 mm

- Designed for workpiece diameters of up to 3200 mm, our large gear shaping machines ensure fast and economical production of large external and internal gears - especially suited for specific workpiece geometries or highly flexible production environments. Larger machines are available on request.

Workpiece diameter, max. 3,200* mm

Module, max. 24 mm

Stroke length, max. 600 mm

*larger machines available on request

160CPS - Getting It Right The First Time

- Preset shaper cutters and Power Skiving cutters on the 160CPS Cutter Presetting Device to get it right the first time.

Measurable outside diameter 340 mm

Cutter weight, max. 50 kg

Shaving

Genesis Series - Spheric Power Shaving with Optional Integrated Chamfer-Rolling/Deburring

- The vertical workspindle concept is well suited to employ plunge or universal shaving processes as the application demands.

Workpiece diameter, max. 130 mm

Module plunge shaving, max. 3 mm

Module parallel or diagonal shaving, max. 5mm

Workpiece length, max. 350 mm

200SVP - The New Benchmark in Economic Shaving

- The 200SVP Gear Plunge Shaving Machine focuses on medium and high-volume gear production with minimal investment. It is backed by decades of GleasonÂs shaving expertise and process technology.

Workpiece diameter, max. 200 mm

Module plunge shaving, max. 3 mm

Workpiece length, max. 400 mm

ZS Series - The Universal Shaving Machines with Optional Chamfering/Deburring

- Several machine executions in different combinations are available to meet all customer requirements in fine finishing of non-hardened spur and helical gears: ZS150 (universal shaving), ZS150T (plunge shaving), ZSE (chamfer rolling option).

Workpiece diameter, max. 200 mm

Module plunge shaving, max. 3.5 mm

Module parallel or diagonal shaving, max. 5mm

Workpiece length, max. 400 mm

Gear Honing

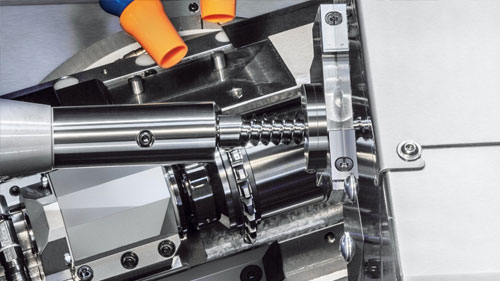

260HMX - The Versatile Double Spindle Honing Solution for Gears and Shafts

- The 260HMX features a double spindle design, an additional B-axis, an integrated tailstock and a generous workspace. It is suited for all gear honing requirements, whether it is shafts, larger and heavy workpieces, or small and complex applications.

Diameter, max. 270 mm

Module, max. 6 mm

Face width, max. 60mm

260HMS - The Versatile Single Spindle Honing Solution for Gears and Shafts

- The 260HMS features a single spindle design, an additional B-axis, an integrated tailstock and a generous workspace. It is suited for all gear honing requirements, whether it is shafts, larger and heavy workpieces, or small and complex applications.

Diameter, max. 270 mm

Module, max. 6 mm

Face width, max. 60mm

HFC- Hard Finishing Cell

- Single Platform, Exciting Possibilities

The versatile GRSL platform is available in three different configurations for use as stand-alone manual, semi-automatic, or as fully automated gauge where high volume throughput is the priority.

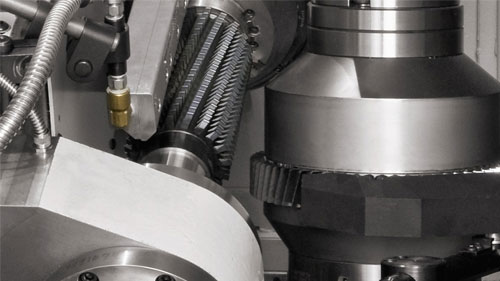

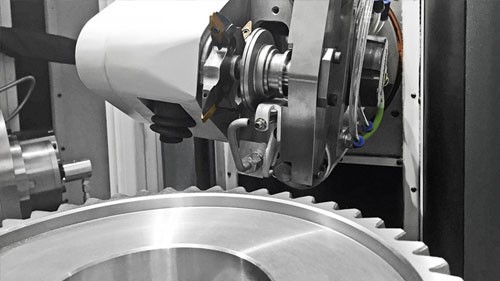

Profile Grinding

P90G - The Universal Solution for Smaller Gears

- The P90G was developed for the highly flexible prototyping and job shopping of smaller gears and features three grinding methods in one machine: Threaded wheel grinding with single plated CBN, dressable profile grinding as well as single index generation grinding.

Workpiece diameter, max. 125 mm

Module, max. 3 mm

Axial travel, max. 220mm

P400G to P600/800G - Profile Grinding of Medium-Sized Gears

- The medium-sized P Series Profile Grinding Machines are destined for applications which demand flexible production of high quality workpieces.

Workpiece diameter, max. 1,000 mm

Profile depth, max. 80 mm

Axial travel, max. 1,000mm

P800G to P6000G - Flexible for Profile Grinding of Large Gears

- The Large Profile Grinding Machines of the P Series are destined for applications which demand flexible production of high quality workpieces.

Workpiece diameter, max. 6,000 mm

Profile depth, max. 120 mm

Axial travel, max. 2,200mm

Titan Series - The Surface Master for Large Gears

- The Titan® Series of large Profile Grinding Machines combines maximum productivity with extremely accurate surface qualities. The fully automatic tool changer paves the path for new gear grinding strategies. The Titan Series is available in three model sizes: 1200G, 1600G, 2000G

Workpiece diameter, max. 2,000 mm

Profile depth, max. 120 mm

Axial travel, max. 1,600mm

Titan Series - The Surface Master for Large Gears

-

P1600G to P6000G - Flexible for Profile Grinding of Large Gears The Large Profile Grinding Machines of the P Series are destined for applications which demand flexible production of high quality workpieces.

- Workpiece diameter, max.: 6,000 mm

- Profile depth, max.: 120 mm

- Axial travel, max.: 2,200 mm

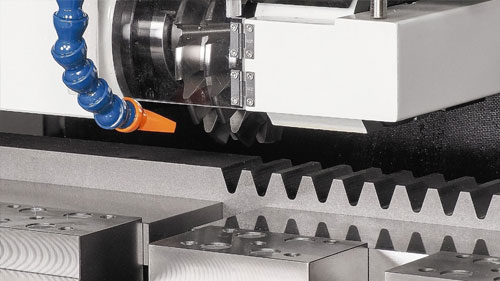

Rack Manufacturing

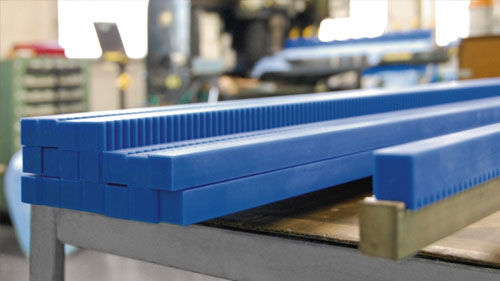

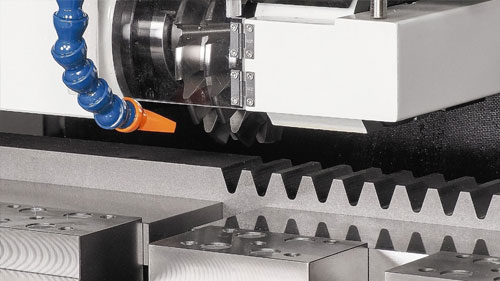

RM and RMP Series - Soft and Hard Milling of Industrial Racks

- We offer a full range of rack milling machines for the manufacture of soft and hardened racks. High-precision rack milling options are available.

Rack length, max. 3,000 mm

Module, max. 12 mm

Rack clamping face width, max. 350mm

850RMS - The Specialist for Steering Racks

- The 850RMS Steering Rack Milling Machine has been specifically designed for the efficient manufacturing of tooth profiles on drive shafts, steering pistons and similar parts. Its dedicated milling head design, several loading options and automatic clamping solutions adapt perfectly to any steering rack manufacturing task.

Rack length, max. 850 mm

Module, max. 3 mm

Rack clamping face width, max. 280 mm

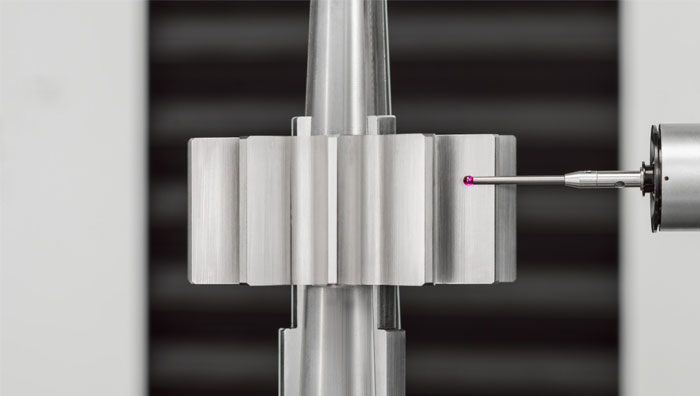

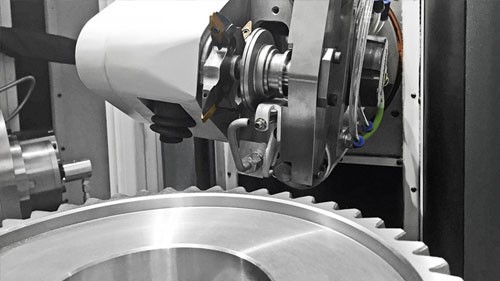

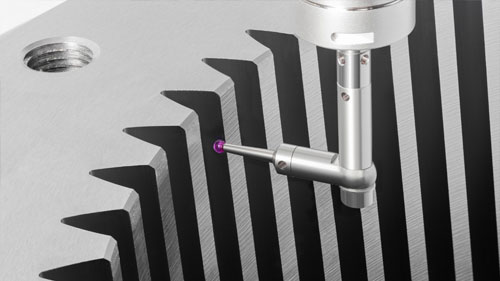

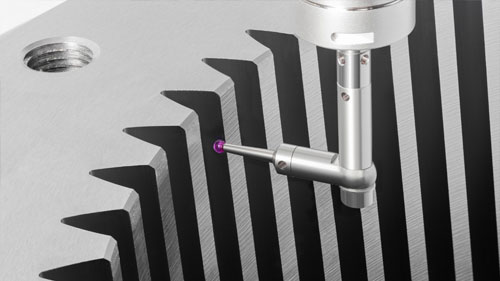

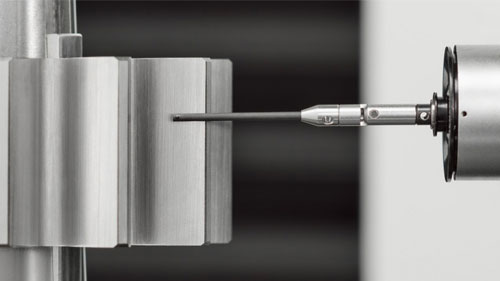

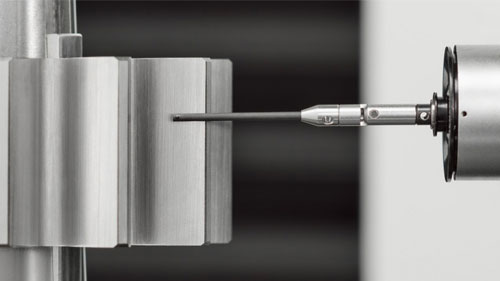

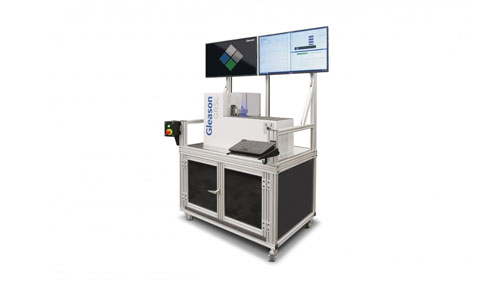

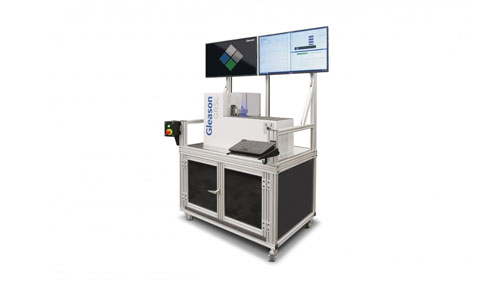

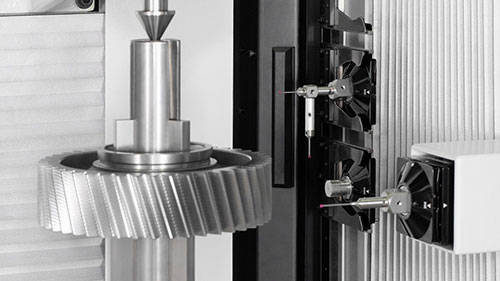

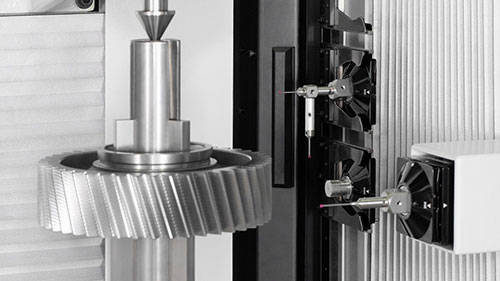

Metrology

Metrology Systems

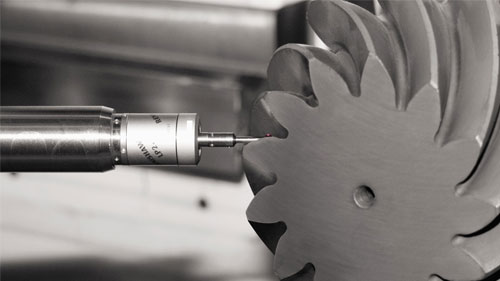

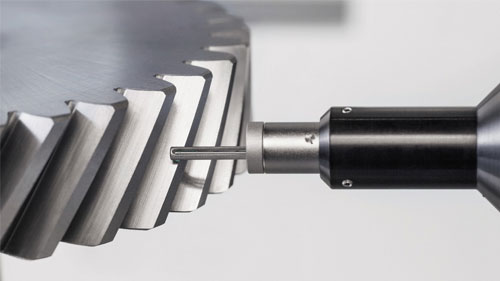

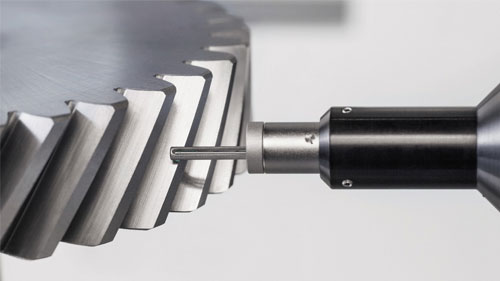

Analytical Inspection

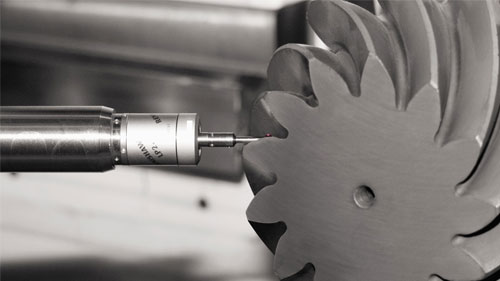

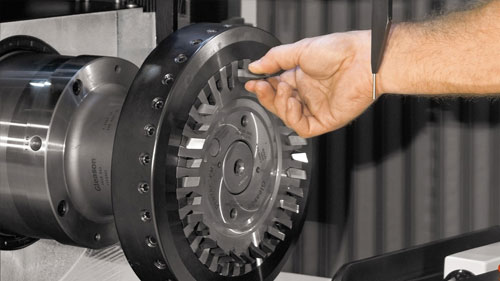

175GMS - Next Generation Gear Metrology System for Small Gears

- The 175GMS® Gear Metrology System has been designed for the complete inspection of all types of gears as large as 175 mm in diameter and shaft-type gears up to 380 mm in length. It offers all necessary features as well as enhanced functionality to improve day-to-day gear measuring with excellent throughput and maximum performance.

Helix angle 0 to 90°

Module range 0.2 to 6.35 mm

Workpiece length, max. 380 mm

Workpiece diameter, max. 175 mm

300GMS - Perfect Fit for Growing Inspection Challenges

- The Gleason 300GMS® Gear Metrology System takes on the fast-growing inspection challenges of high-quality automotive, aerospace and like-size gears: everything from smaller fine pitch gears, to surface finish measurements, CMM measurements, and much more.

Helix angle 0 to 90°

Module range 0.2 to 18 mm

Workpiece length, max. 500 mm

Workpiece diameter, max. 300 mm

475GMS to 3000GMS - Inspection Solutions for Medium-Sized and Larger Gears

- Gleason Metrology Systems offers a complete line of gear metrology systems for the inspection of larger gears and shafts up to 3,000 mm in diameter and lengths up to 2,000 mm. With its wide array of options, the GMS® Series supports any kind of inspection requirement, including surface measurement, Barkhausen Analysis, CMM capability and gear tool inspection.

Helix angle 0 to 90°

Module range 0.3 to 32 mm

Workpiece length, max. 2,000 mm

Workpiece diameter, max. 3,000 mm

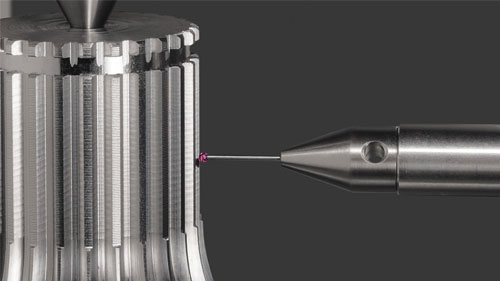

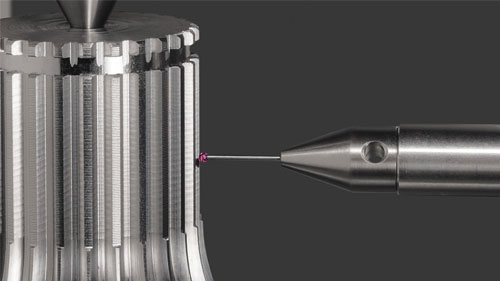

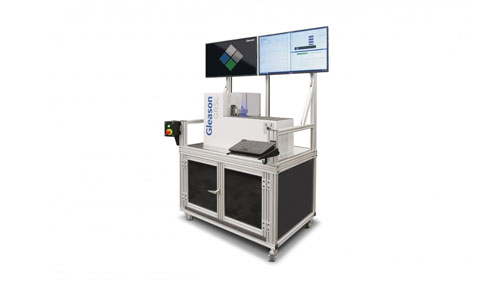

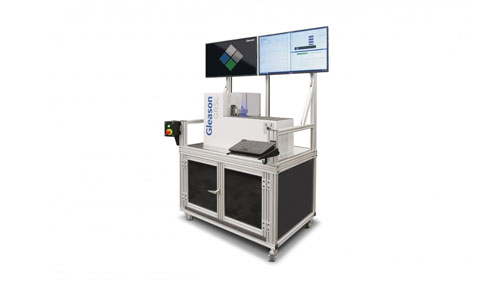

GRSL - Gear Rolling Meets Advanced Laser Technology

- GRSL (Gear Rolling System with Integrated Laser Technology) combines traditional roll testing with advanced non-contact laser technology in a single system. Cycle times for index and profile inspection now takes place in seconds, making 100% analytical inspection a reality for todayÂs toughest applications.

Workpiece diameter, max. 250 mm

Module, max 7.2 mm

300GMSP nano - Inspection at Nano Level

-

300GMSP nano - Inspection at Nano Level

Inspect your parts right on the production floor - with results comparable to the lab. The Gleason 300GMSP nano Gear Metrology System for Production Environments saves time for part transport and standing in line in front of the inspection room. The P version offers all inspection and analysis capabilities of the 300GMS nano. In addition, its integrated compensation systems makes it resistant to typical production floor thermal and vibratory dynamics as well as contamination.

- Helix angle: 0 to 90°

- Module: 0.4* to 18 mm

- Workpiece length, max.: 450 mm

- Workpiece diameter, max.: 300 mm

475GMSP

-

475GMSP - Gear Inspection Right on The Production Floor

Inspect your parts right on the production floor - with results comparable to the lab. The 475GMSP Gear Metrology System for Production Environments saves time for part transport and queues in front of the inspection room and delivers a full range of inspection capabilities including measurement of surface roughness, fine pitch and CMM options.

- Helix angle: 0 to 90°

- Module: 0.4* to 18 mm

- Workpiece length, max.: 650 mm

- Workpiece diameter, max.: 475 mm

Gear Rolling Systems

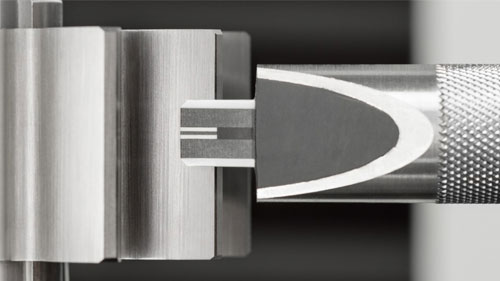

GRS - Double Flank Gear Roller Systems

- GRS Systems offer the flexibility and precision performance necessary to meet the composite testing demands of gear manufacturers. Manual or motorized double flank roller systems are available for inspection of external and internal gears of various materials including powdered metal and plastic.

Workpiece outside diameter, max. 304.8 mm

Workpiece weight, max. 22.7 kg

GRSL - Gear Rolling Meets Advanced Laser Technology

- GRSL (Gear Rolling System with Integrated Laser Technology) combines traditional roll testing with advanced non-contact laser technology in a single system. Cycle times for index and profile inspection now takes place in seconds, making 100% analytical inspection a reality for todayÂs toughest applications.

Workpiece diameter, max. 250 mm

Module, max 7.2 mm

A2LA Accredited Calibration Services

A2LA Accredited Calibration Services

- Get Your Gears and Splines Certified

The only gear and spline calibration laboratory accredited by A2LA for gear and spline index, helix, profile, and dimension over pins.

On-Site Calibration of Gleason Analytical Gear Inspection Systems

Gleason Metrology Systems offers A2LA-accredited on-site calibration services. We remain the only source for on-site calibration of lead and profile testing that is accredited by A2LA in the USA.

Calibration of Master Gears, Spline Gages and Artifacts

Also A2LA-accredited, GMS calibrates master gears, fellows lead or involute masters, helix and involute masters, pitch artifacts, master gears for external or internal involute gears, plug- and ring-type gages as well as tapered master plugs.

Instruments

Master Gears

- High Quality Master Gears

Gleason Master Gears are used in double and single flank gear roll inspection systems, honing machines and gear measuring systems as test gears. We provide different types of master gears, such as cylindrical gears and pinions, for most machines and applications.

Spline Gauges and Spline Arbors

- Gleason is a leading supplier of spline, tapered spline master gears, and variable spline gages. We offer design engineering services for all, with options for calibrations, coatings and setting masters. Submit your requirements today and receive quick turnaround on your quotation  usually 5-7 business days.

Diameter, min. 5 mm

Diameter, max. 500 mm

Number of teeth, max. 500

Variable Spline Indicator Gauges

- Variable spline indicator gauges enable manufacturers to control the fit between mating splines. Numerical values can be obtained for effective and actual tooth thickness or space width. These gauges are available in a large variety of body styles and are highly accurate and repeatable. A digital indicator is available with a serial port that allows the user to download data to a variety of SPC packages.

LeCount - 3-Jaw Expanding Mandrels

- Gleason LeCount Expanding Mandrels - For Exceptional Accuracy and Repeatability and Fast Load/Unload Time

Renowned worldwide as an ideal solution for the extreme precision required in the inspection environment, Gleason LeCount® Expanding Mandrels are available in a wide variety of expansion ranges and types to accommodate a multitude of inspection applications.

Expanding Collet and Rotalock Arbors

- Expanding collet and rotalock-type spline arbors are specially designed for holding components of all types for a variety of applications. They are ideal for use in turning, grinding, gear cutting and inspection.

Automation

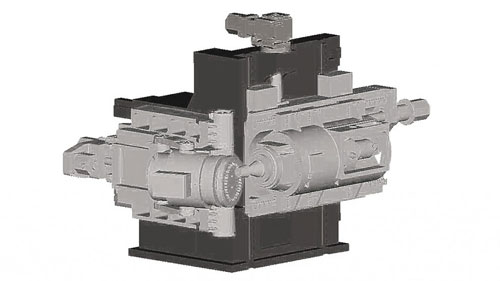

GAMA - Inspection and Analysis Software

-

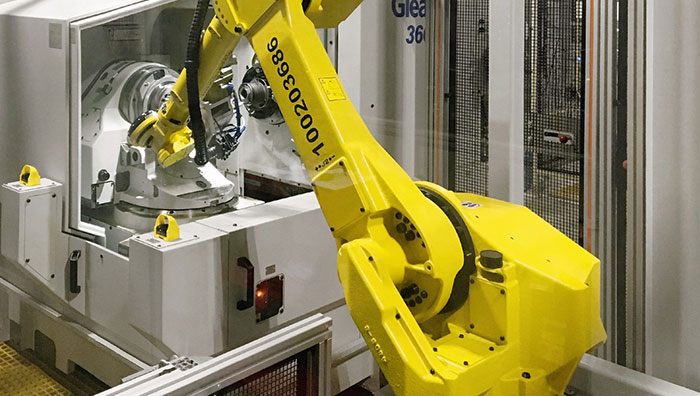

AR Series - Adaptable and Flexible Robotic Material Handling

The AR Series Robotic Material Handling provides flexibility of material introduction, cell foot print, and functionality. By varying the size of the robot, the AR is designed to handle a variety of part sizes.

ARD Series

-

ARD Series - Compact, Fast and Efficient Drawer Loaded Automation

ARD Series Drawer Loaded Automation feed parts directly to machine tool chucks, spindles, or fixtures quickly and economically while using minimum floor space. Double ended configurations are also available to service two machines with a single system.

ARC Series

-

ARC Series - Highly Versatile Cart Loaded Automation with Greater Capacity

ARC Series Machine Tool Loaders provide maximum capability and flexibility to create the ideal cellular automation system for your projects. All ARC systems handle stacks of trays or baskets and include a six axis high-speed robot for maximum flexibility and productivity.

ARP Series

-

ARP Series - Pallet Loading and Unloading Automation

ARP Series complement Gleason Machine Tool Loaders by loading or unloading trays off standard size pallets.

Tools

Bevel

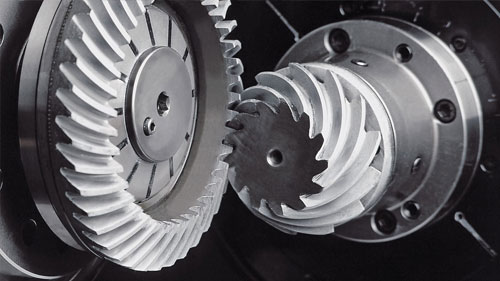

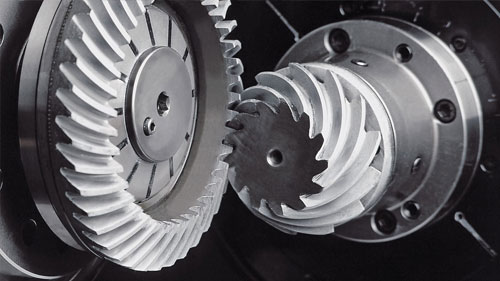

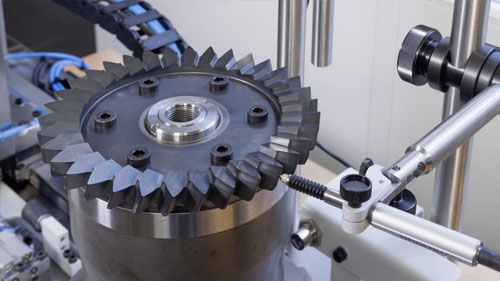

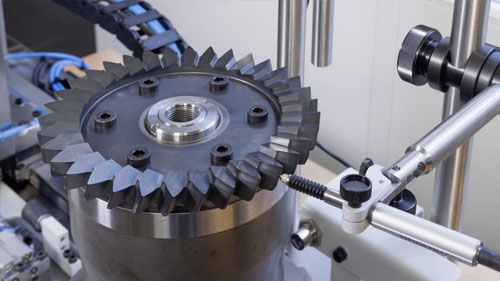

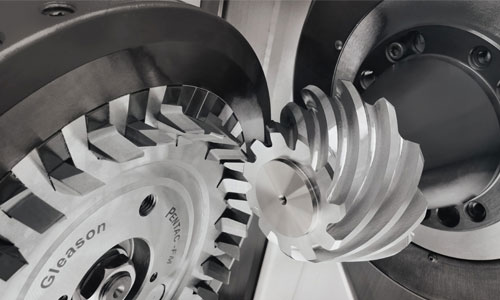

Bevel Cutting Tools

- Improve Your Bevel Gear Cutting Performance

Gleason cutting tool solutions exist to help reduce tool cost per workpiece while ensuring repeatable high quality standards. GleasonÂs solutions are capable for almost all spiral bevel and hypoid gear production applications, face milling or hobbing, wet or dry cutting and at any desired production volume.

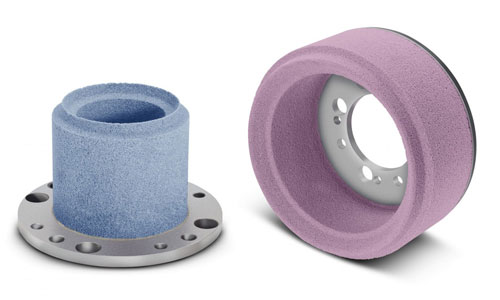

Grinding Wheels

- For grinding bevel gears, featuring advanced designs to deliver faster cycle times and higher quality parts.

Dressing Tools

- For fast and accurate dressing of bevel gear grinding wheels to assure exceptional quality and accuracy.

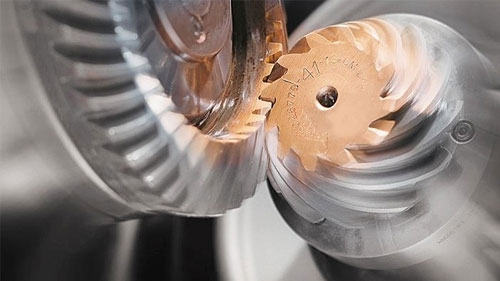

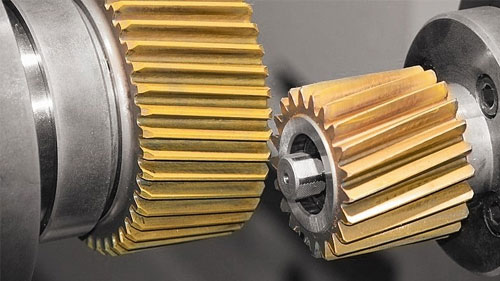

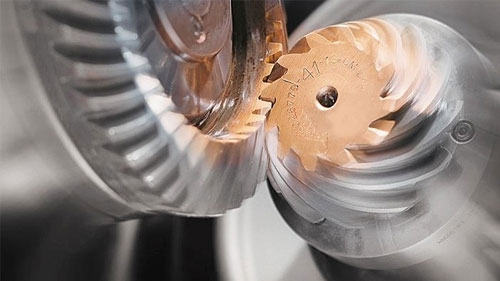

Cylindrical

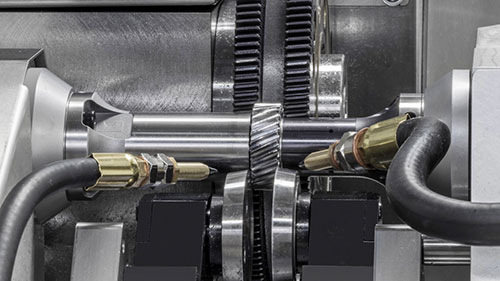

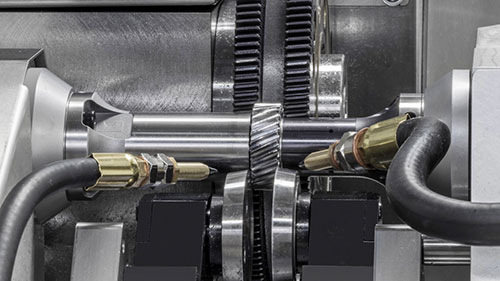

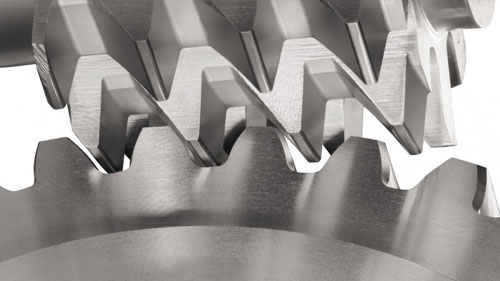

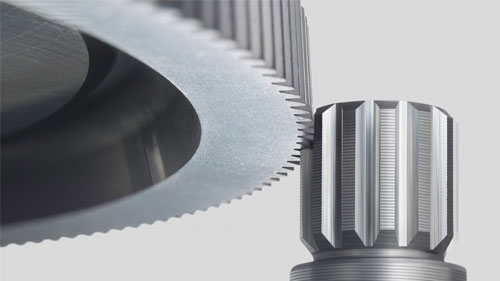

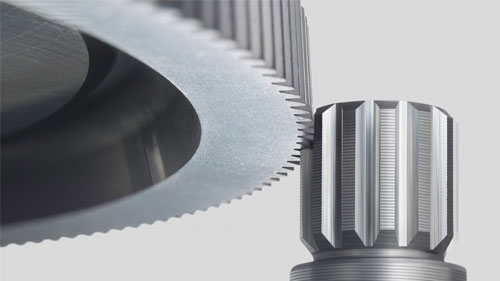

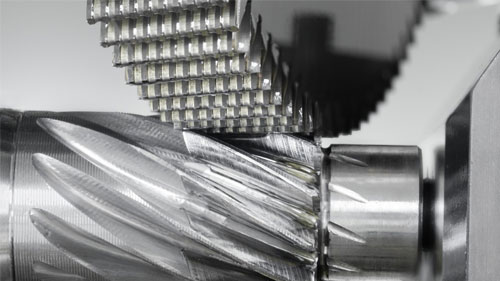

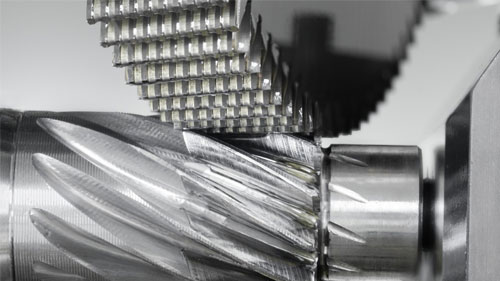

Hobbing & Milling Tools

- Wherever cylindrical gear manufacturers require improved cutting tool performance, longer tool life, and higher quality, youÂll find Gleason cutting tools at work. Gleason is your global source for the industryÂs most complete line of cylindrical gear-making tools.

Chamfering & Deburring

- Gleason rotary chamfering and deburring tools provide consistent, high quality chamfers while reducing burrs to a minimum.

Maximum Economy

- As a market leader in shaving technology, Gleason has extensive experience in the production and use of shaving cutters for every conceivable variant in gear production. This competence ensures you get ideal support and results  from consulting and design, on to selection of the material and manufacture of the shaving cutter, all the way to services to aid in production.

Shaping Tools

- A complete range of highly productive and cost-effective shaper cutters. Shaping is used primarily in situations where the accessibility of the tools of other methods reach their limits. Gleason shaper cutters in different designs are adapted to suit the machining task in question.

Power Skiving Tools

- Superior productivity makes the Gleason Power Skiving process a highly cost-effective alternative to gear shaping and other soft machining processes.

Threaded Wheel Grinding Tools

- GleasonÂs line of grinding worms, dressing discs, and dressing rolls is fast expanding to meet the demand for more productivity, flexibility and the highest quality standards.

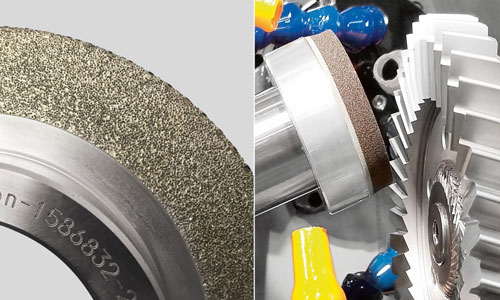

Honing Tools

- Gleason has long standing experience in the design, manufacture and use of diamond dressing masters and honing rings and has been in the market for more than a decade.

Dressing Tools

- Dressing discs, rolls and bars to dress grinding worms for involute and non-involute gears. Dressing solutions are available for Gleason as well as other brand gear grinding and honing machines.

Cylindrical Tool ServicesCylindrical Tool Services

- Gleason offers customers a total system to maximize cutting tool performance.

Plastic Gears

- Gleason Plastic Gears - Where Precision Gears Take Shape

Custom molded gear solutions leverage KISSsoft® Gear Design Software that delivers the smoothest and quietest gear mesh possible.