- Offer Profile

- sssss

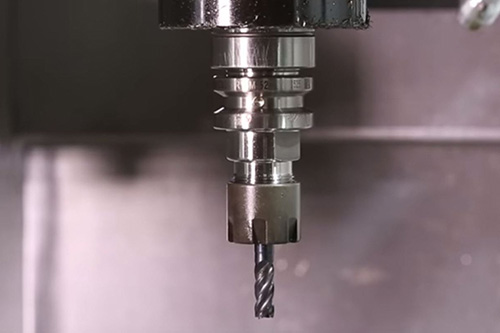

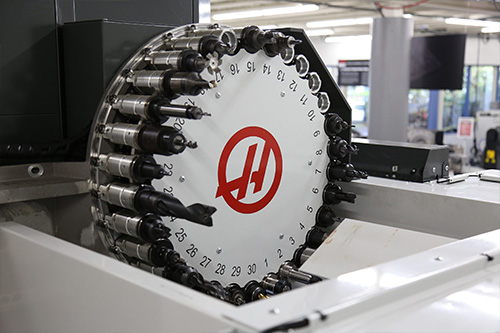

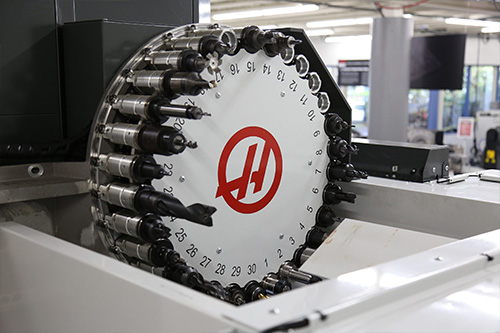

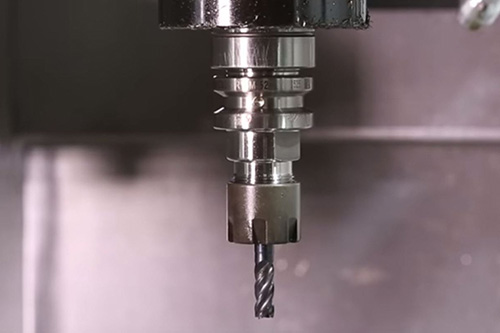

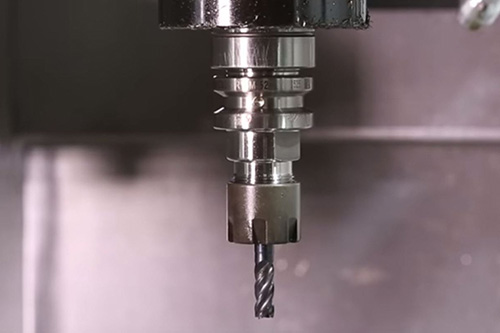

A Versatile Lineup of Vertical Milling Machines

-

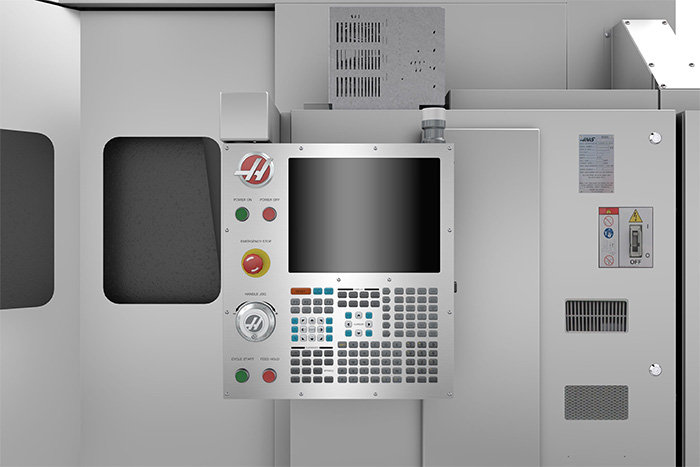

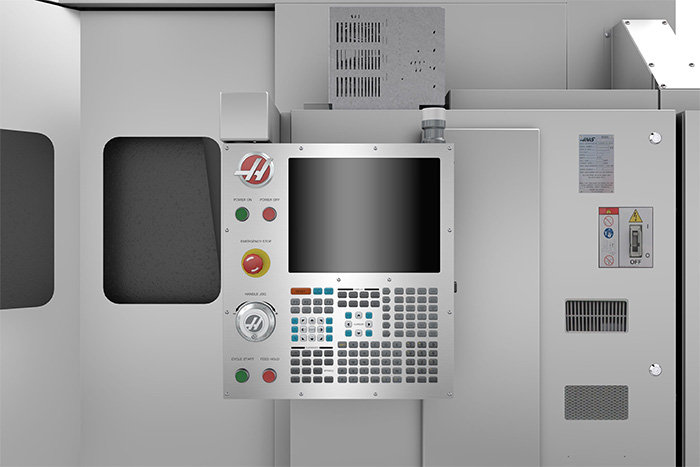

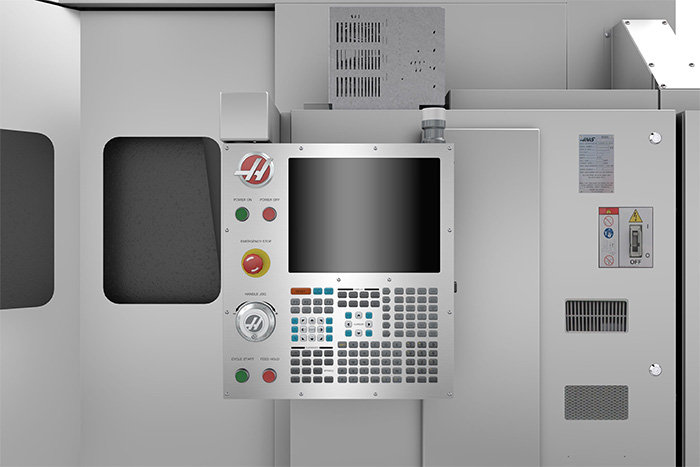

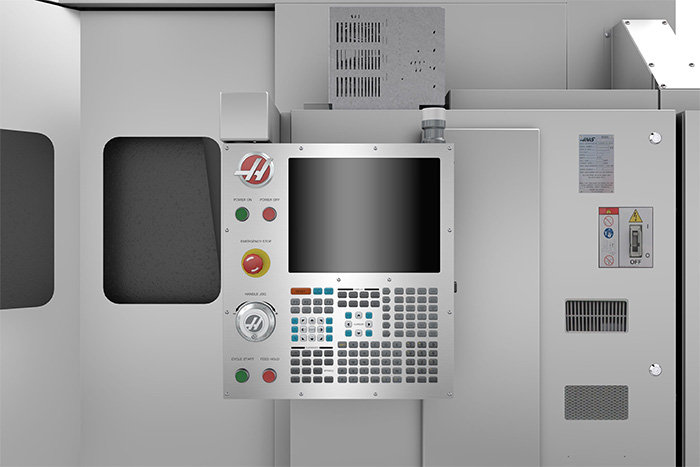

Designed by Machinists

In 1988, we introduced the VF-1, a machine designed specifically by machinists for machinists. Since then, we have continually expanded our product line, with a focus on constant innovation. Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work. We know – because we use them, too.

VF SERIES

-

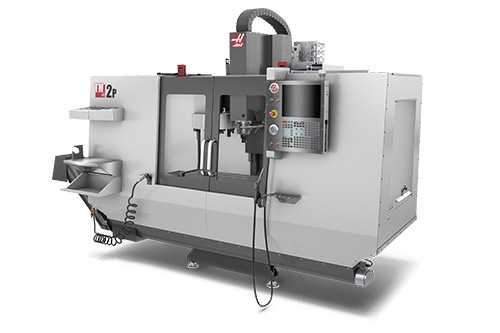

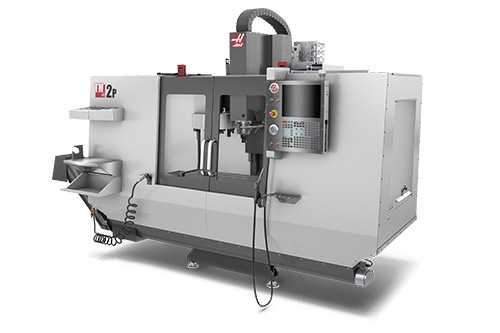

The World’s Most Popular CNC Mills

A Wide Range of Sizes and Features to Fit Any Shop’s Needs

X-Travels from 20" to 150"

What can a VF Series vertical mill handle? With our wide range of available models, the VF Series can match nearly any size and productivity range. Regardless of your requirements, there’s a VF just right to meet the demands of your machine shop.

- 40/50 Taper

- 3/4/5 Axis

- 7.5k-30k RPM

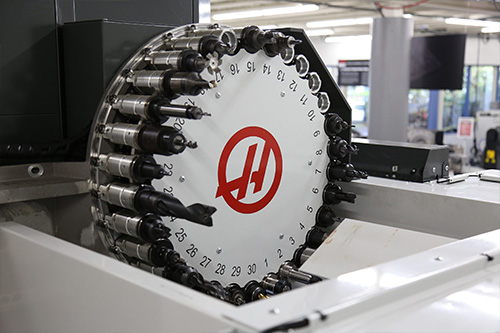

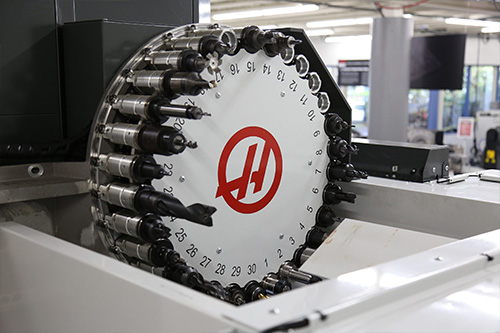

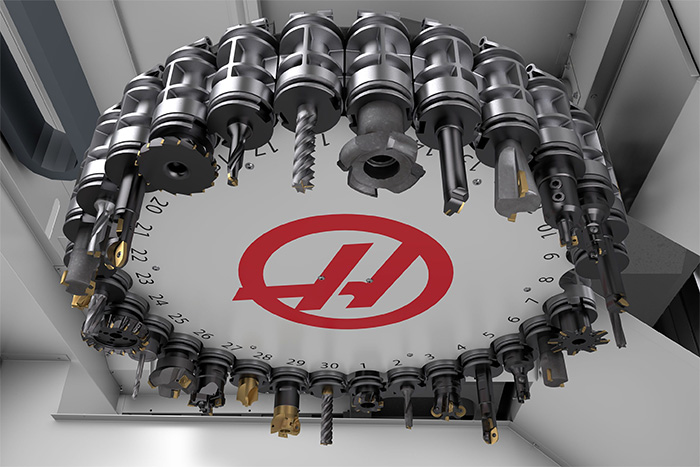

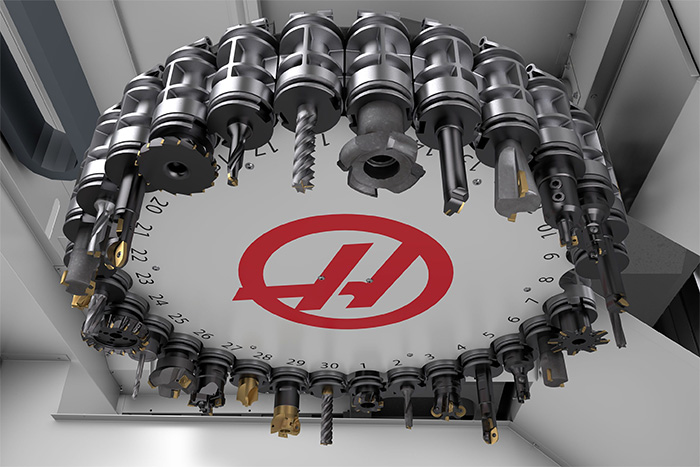

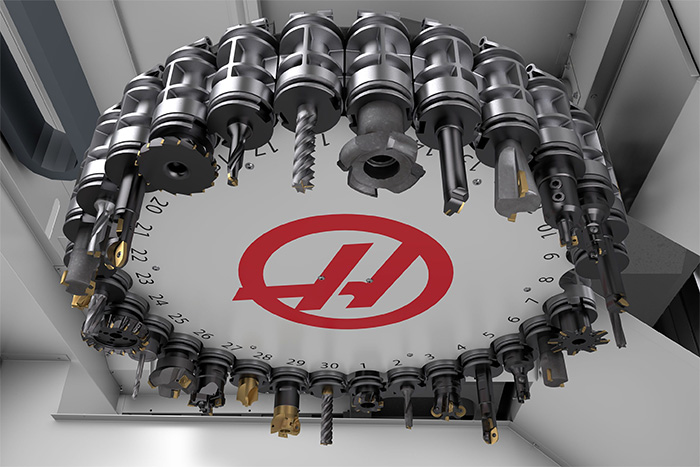

- 20-40 Tool Capacity

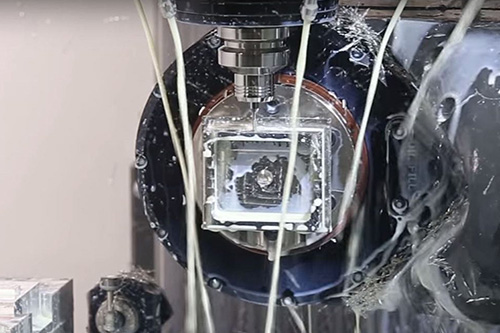

UNIVERSAL MACHINES

-

5-Axis Machining is No Longer Out of Reach

Multi-axis machining used to require exotic machines, expensive options, and complex configurations – until now. We’ve removed those barriers, and simplified 5-axis machines for you.

What Do You Want to Create Today?

5-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts. Haas Universal Machining Centers are cost-effective solutions for 3+2 machining and simultaneous 5-axis machining.

- 40 Taper

- 5 Axis

- 8.1k-15k RPM

- 30-50 Tool Capacity

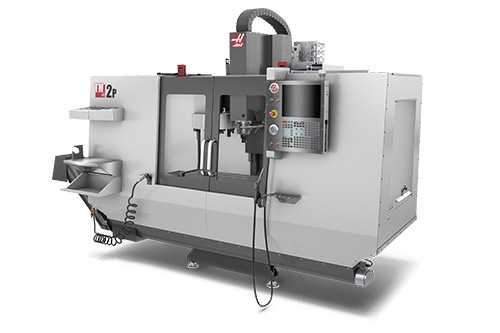

MINI MILLS

-

The Machines that Defined a Category

Mini in Name and Price Only

Machine performance once was paired with size and cost. The Mini Mill Series changed everything, by packing 40-taper performance into small packages at unheard of prices.

The Original Compact Machines

Haas Mini Mills are the industry standard for compact machining centers. They are perfect for schools, start-up shops, or as a first step into CNC machining. Loaded with full-size features, they are valuable additions for shops needing a “second-op” machine, or an additional spindle where space is limited.

- 40 Taper

- 3/4/5 Axis

- 6k-15k RPM

- 10-20 Tool Capacity

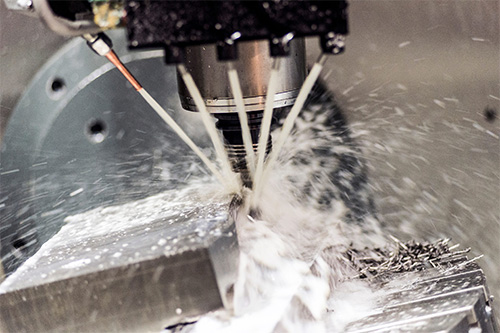

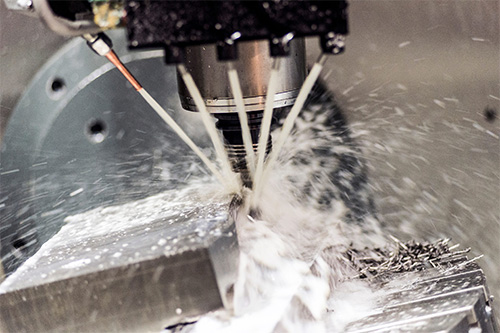

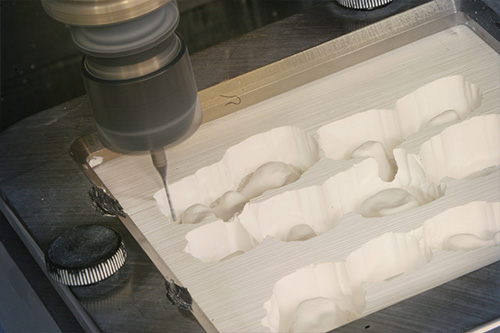

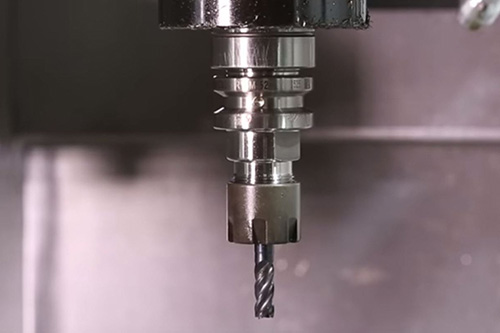

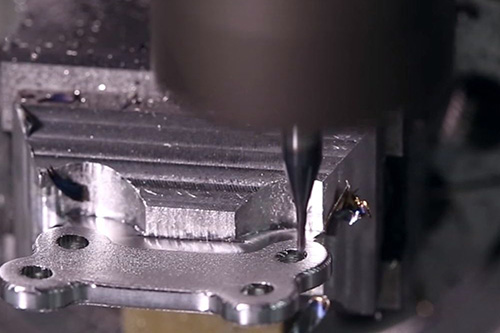

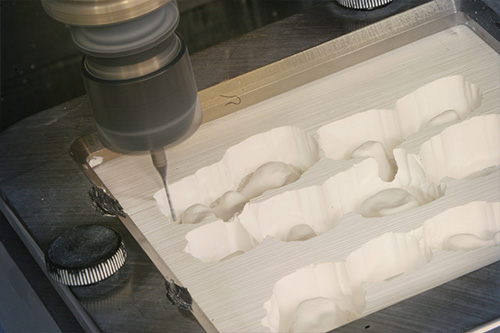

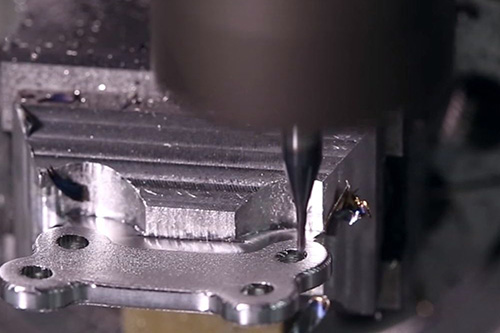

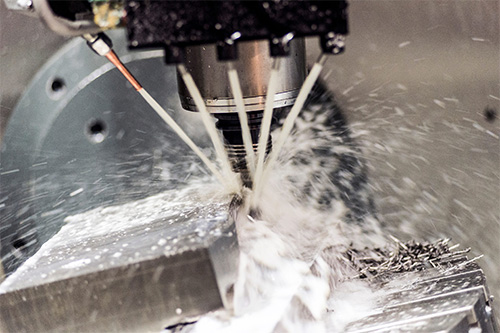

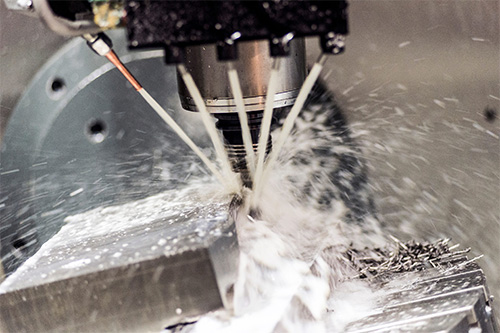

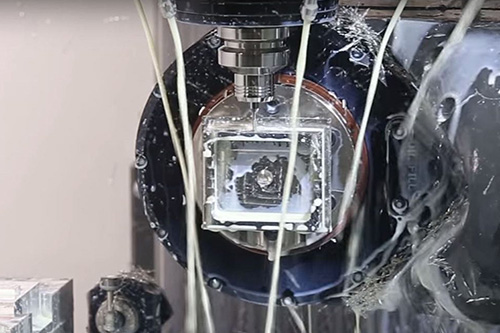

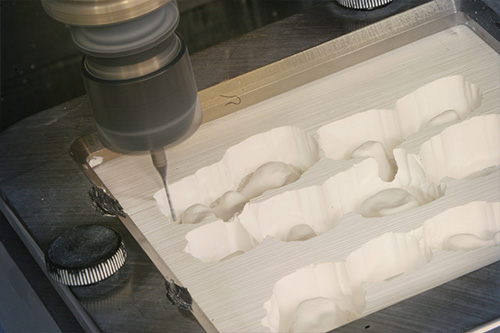

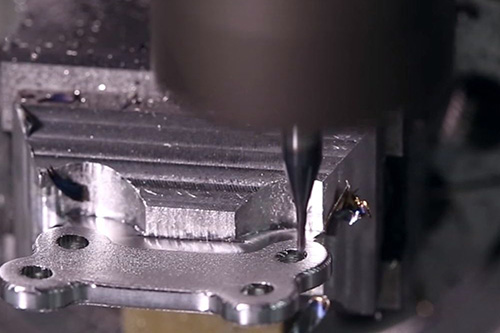

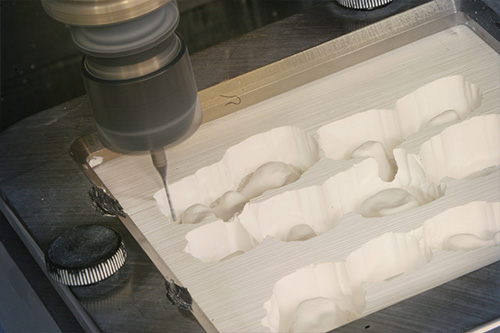

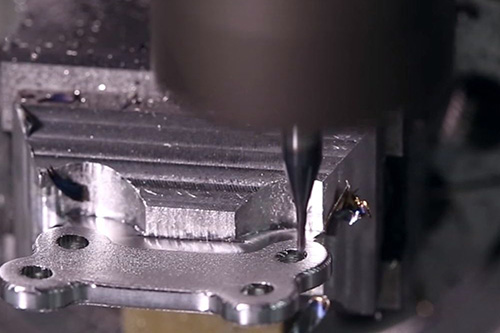

MOLD MACHINES

-

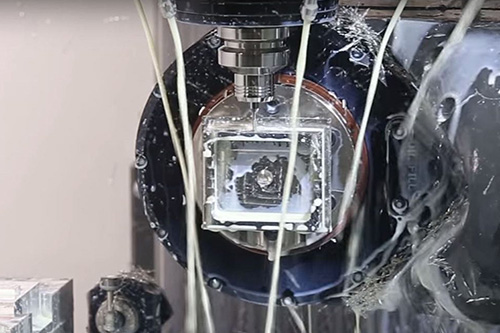

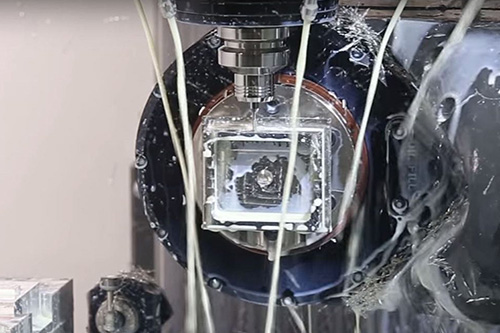

High-Performance VMCs for Mold Making and Tool & Die

Accuracy, Rigidity, and Thermal Stability for the Mold Industry

Haas Mold Machines are the best-value, high-performance, specialty mold & die machines in the industry.

Configured for Mold Making

Making molds has never been easier than with a Haas Mold Machine. We’ve taken our industry-leading VF Series and created custom configurations just for mold making, tool & die work, and other high-precision industries. Mold Machines are also ideal for high-performance job shops looking to increase their versatility.

- 40 Taper

- 3/4/5 Axis

- 12k-30k RPM

- 24-40 Tool Capacity

DRILL/ TAP/ MILL SERIES

-

High-Speed, Lean-Style Machining Centers

Take a Bite Out of Cycle Times

Built on proven Haas designs and technology, the Drill/Tap/Mill Series provides the perfect combination of speed and power to reduce cycle times.

Small, Fast, and Powerful

Drill/Tap/Mill Series machines are high-speed, lean-style machining centers with compact footprints that make very efficient use of valuable shop floor space.

- 30/40 Taper

- 3/4/5 Axis

- 10k-20k RPM

- 18-20 Tool Capacity

TOOLROOM MILLS

-

True CNC Performance at Affordable Prices

Large Travels. Big Capabilities. Small Price.

The Toolroom Mill Series is the true definition of value, providing full CNC capabilities, including available 4th- and 5th-axis functionality, at affordable prices.

A Versatile Starting Point

Haas Toolroom Mills are found everywhere – from schools to high-end production shops. Their versatility is a result of our commitment to using common components across all Haas machine tools. This results in all machines, including the Toolroom Mills, benefitting from improvements in reliability and performance.

- 40 Taper

- 3/4/5 Axis

- 4k-10k RPM

- 1-20 Tool Capacity

COMPACT MILLS

-

High-Accuracy Solution for Machining Small Parts

Small-Footprint, High-Performance Mill for Production and Prototyping

A full-featured, compact CNC perfect for the watch, jewelry, medical, and dental industries.

Small but Mighty

The Compact Mill is a small-footprint, high-accuracy solution for prototyping and producing small, high-precision, 2D and 3D parts, such as those found in the communications, aerospace, medical, and dental industries. It’s small enough to fit into most freight elevators, and can easily be moved with a pallet jack or equipment dolly.

- 20 Taper

- 3/4/5 Axis

- 30k-50k RPM

- 20 Tool Capacity

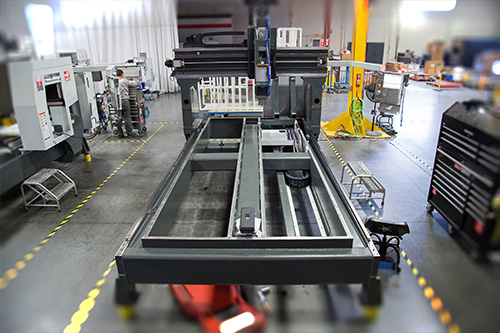

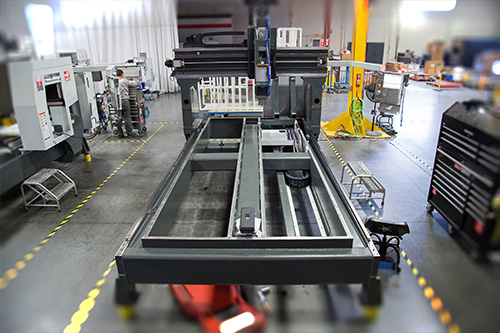

GANTRY SERIES

-

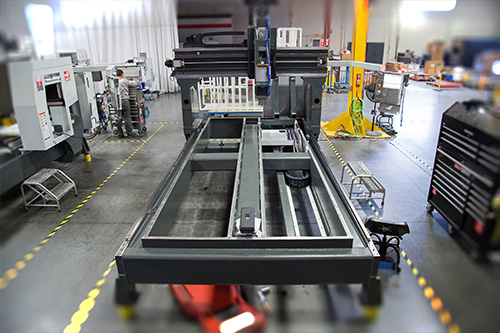

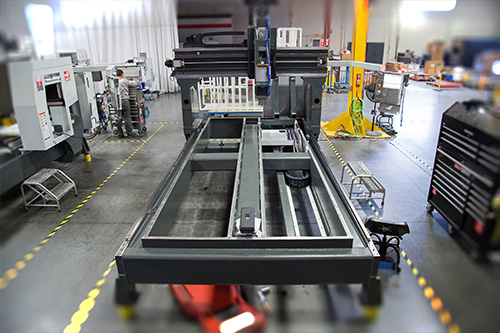

Gantry-Style CNC Machines for Large Workpieces

Large-Platform CNC Routers for Big Jobs

GR Series machines easily handle large sheets, or can machine small parts by the thousand.

Ready for Your Large-Scale Tasks

The Haas GR Series gantry routers have the power to cut aluminum and other metals, as well as the speed to cut plastics and other light materials. These machines easily handle large sheets, or can machine small parts by the thousand.

- 40 Taper

- 3/4/5 Axis

- 8.1k-15k RPM

- 10-20 Tool Capacity

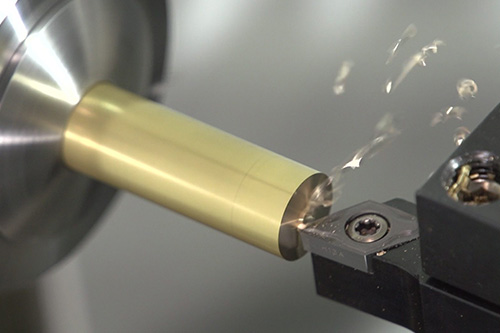

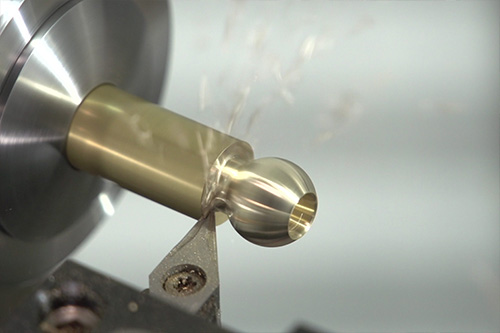

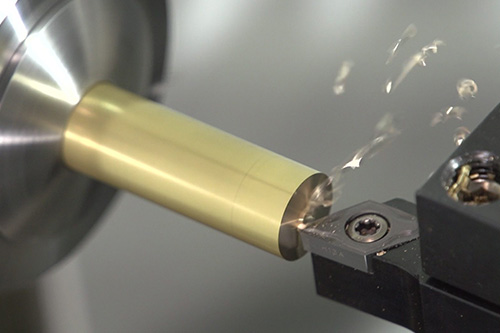

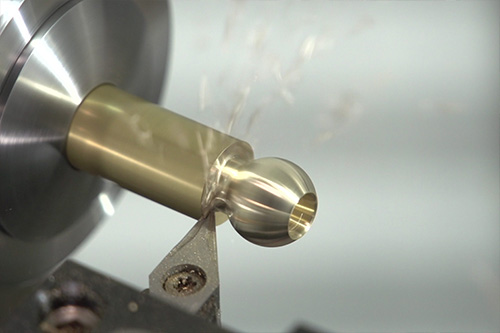

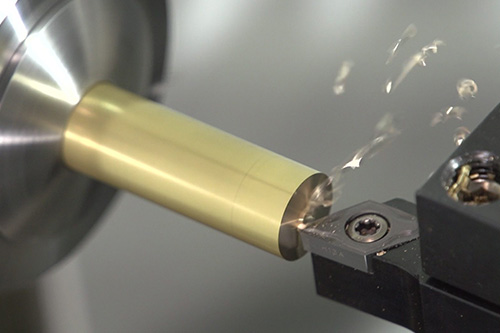

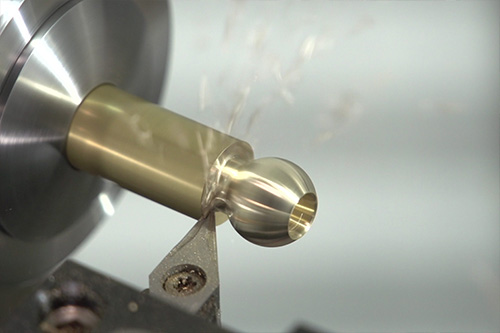

Lathes

-

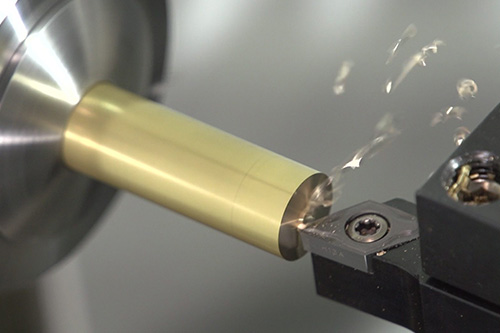

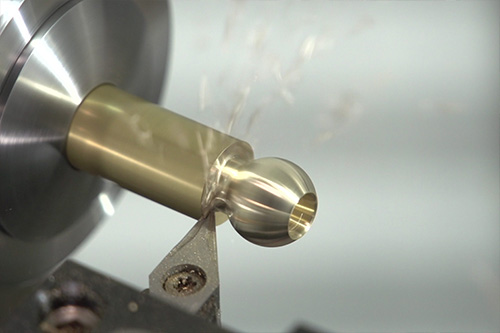

A Turning Center for Every Shop

Haas Automation’s complete line of CNC turning centers is designed to meet the needs of modern machine shops – now and long into the future.

All the Features and Performance You’ve Come to Expect From a Haas

Haas turning centers offer a wide range of capabilities, including toolroom lathes, big-bore versions, dual-spindle models, live tooling with C-axis, and Y-axis capability.

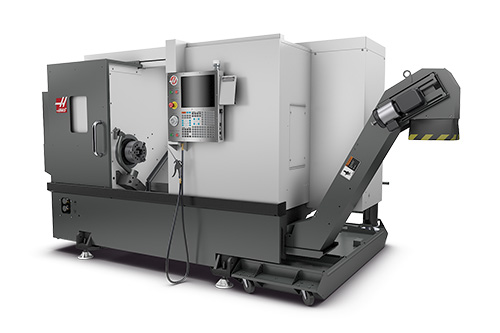

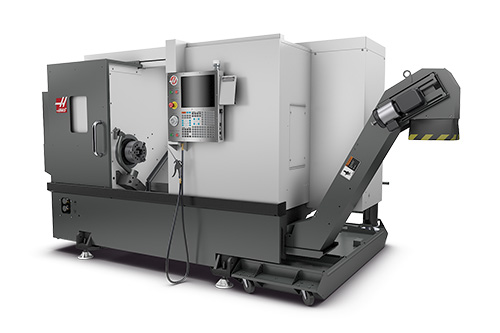

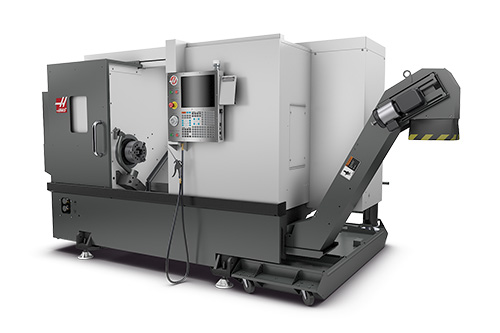

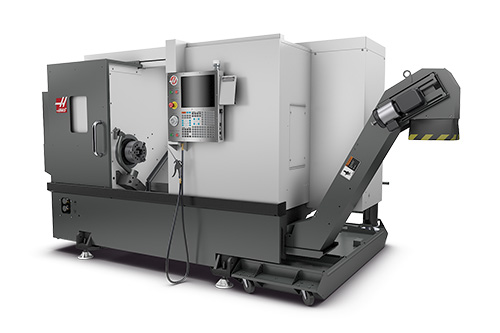

ST SERIES

-

The Best-Value Turning Centers in the Industry

Rigid, high-performance turning centers with a wide selection of available options for every shop.

The Haas ST Series high-performance turning centers were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability. These machines offer the best performance for the money – the best value – in their class.

- 6.5"-18" Chuck Size

- 1.75"-12.5" Bar Capacity

- 1k-6k RPM

- 15-55 HP

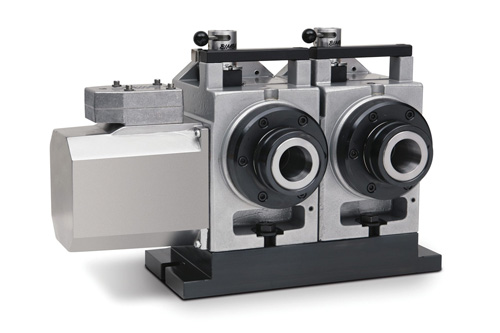

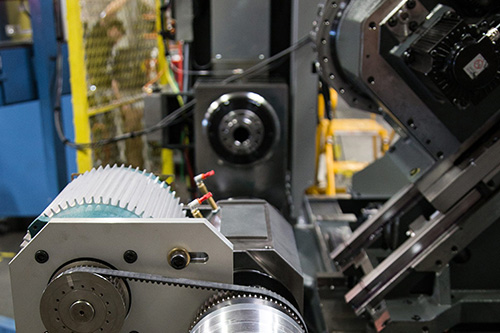

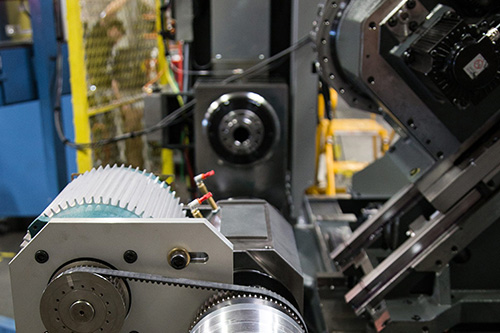

DUAL-SPINDLE LATHES

-

High-Performance, Dual-Spindle/Y-Axis Turning Centers

Easy-to-program dual-spindle lathes for reduced part handling and setups.

Do Even More

Dual-spindle turning combined with Y axis, C axis, and live tooling allows multiple operations in a single setup to reduce part handling and increase accuracy.

- 10" Chuck Size

- 3" Bar Capacity

- 4.5k RPM

- 30 HP

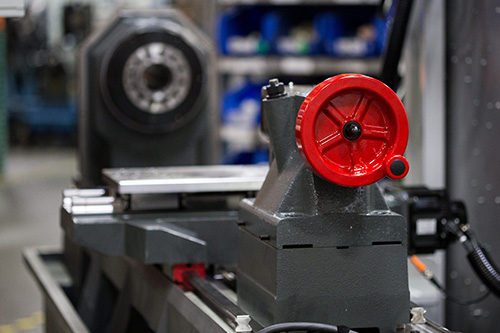

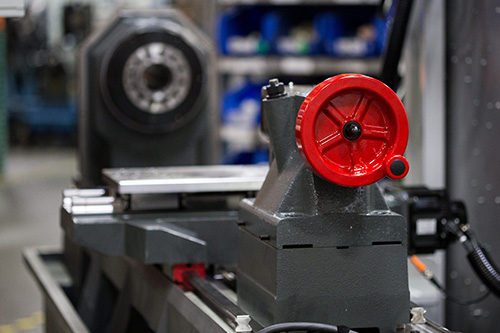

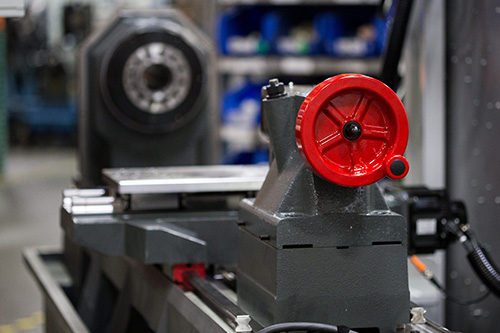

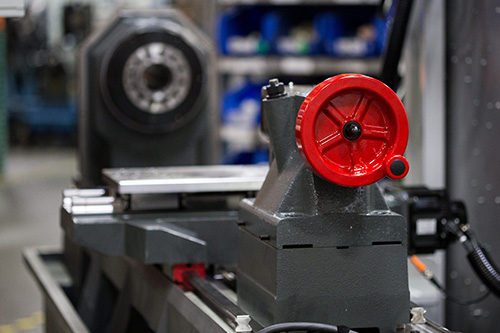

TOOLROOM LATHES

-

From Schools to Large Toolrooms

The true definition of value – full CNC capabilities without significant investment.

A Great Beginner Lathe

The Haas TL Series Toolroom Lathes are affordable, easy to use, and offer the precision control and flexibility of the Haas CNC system. Because they are very easy to learn and operate – even without knowing G-code – they are perfect for start-up shops, or as a first step into CNC machining.

- 8"-10" Chuck Size

- 3" Spindle Bore

- 1.8k-3k RPM

- 10 HP

CHUCKER LATHE

-

Ultra-Compact Chucker Lathe for Small, High-Production Parts

Small footprint, affordable chucker lathe for prototyping or production work.

Chucker Lathe

The innovative Haas CL-1 is an ultra-compact CNC chucker lathe that comes standard with an 8-station automatic turret, making it perfect for high-volume production of small, precision parts, such as those found in the communications, aerospace, medical, and dental industries. The CL-1 can be moved easily with a pallet jack or equipment dolly, and is small enough to fit into most freight elevators.

- 5C Chuck Size

- 1" Bar Capacity

- 6k RPM

- 5 HP

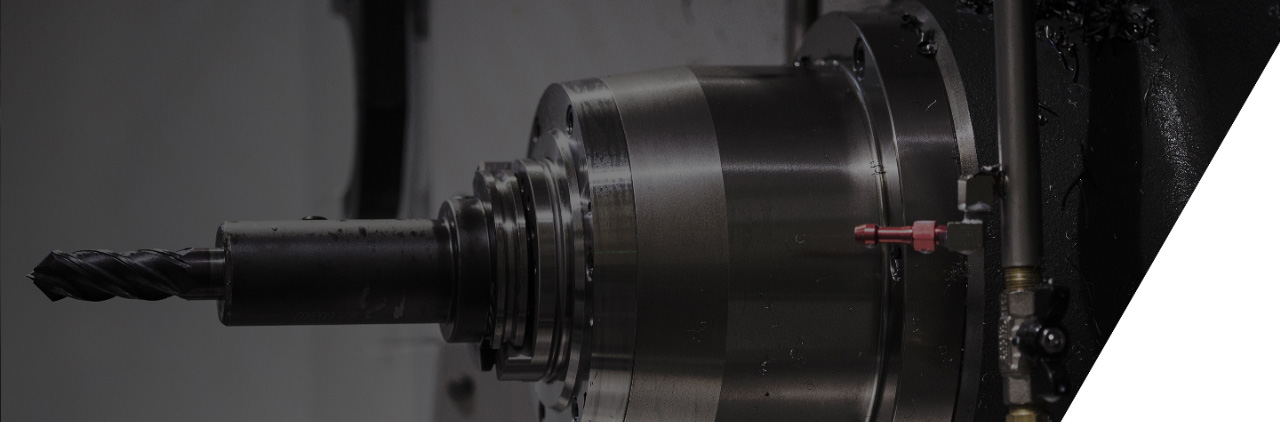

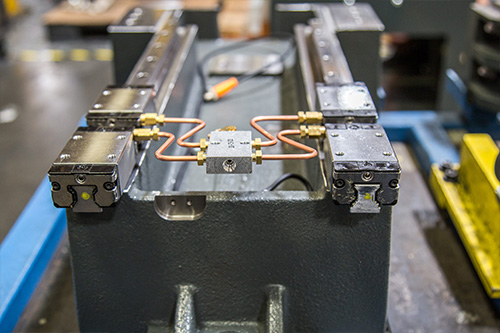

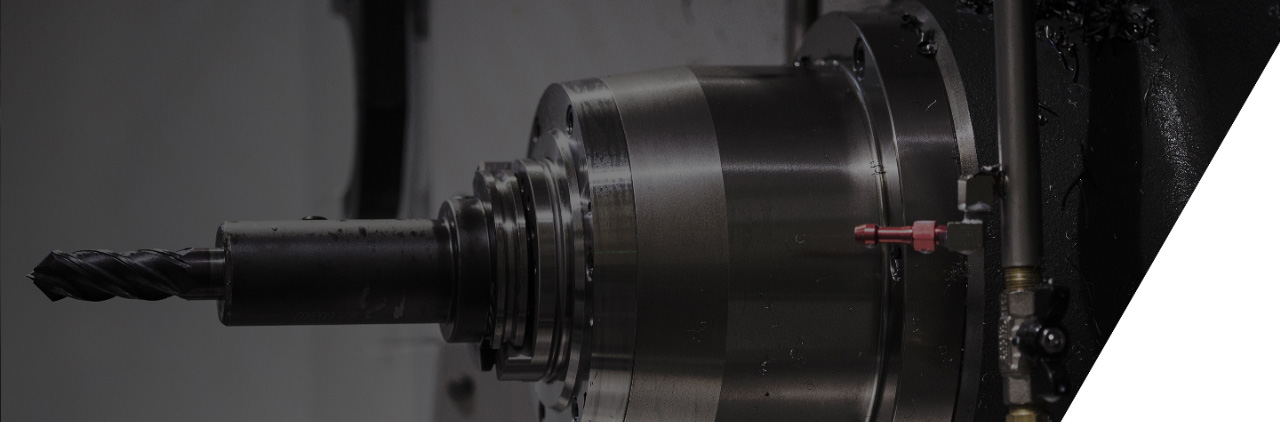

Horizontal Mills

-

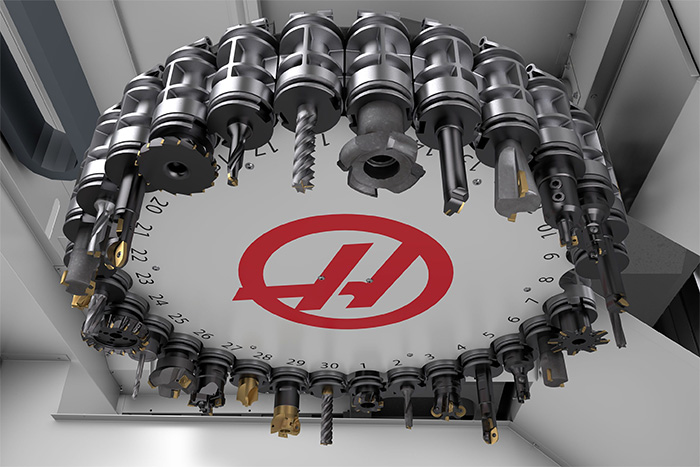

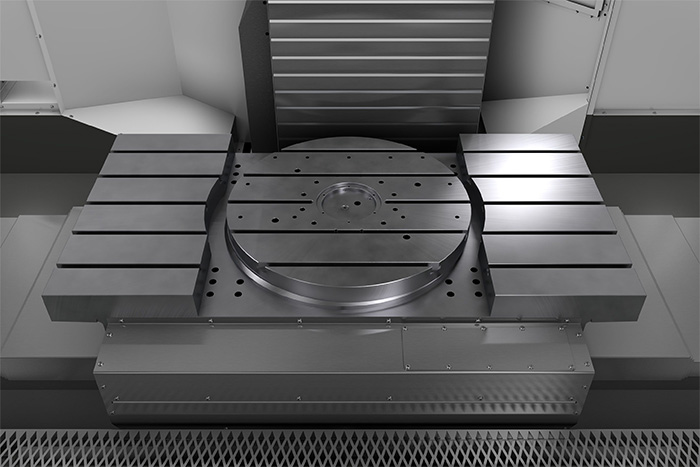

The Best-Value HMC in the Industry

Every Haas HMC provides the features and performance you need to boost your productivity, making it the best investment you have ever considered.

- 50 Taper

- 3/4/5 Axis

- 7.5k-10k RPM

- 30-50 Tool Capacity

50-TAPER

-

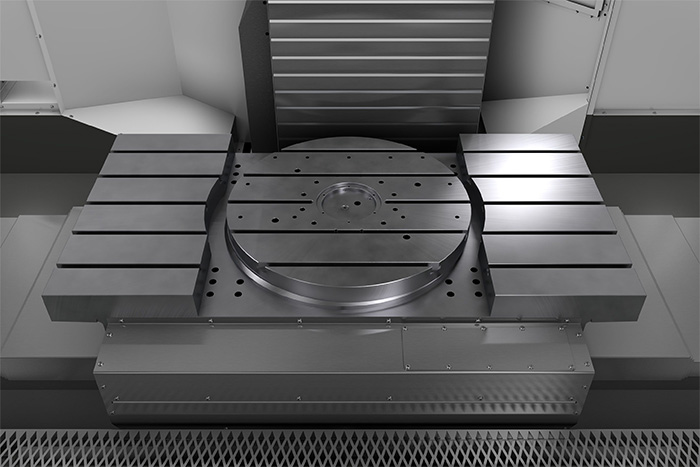

Rugged 50-Taper HMCs with Large Capacities

Haas EC-1600 Series HMCs offer the high performance and large capacity you need to handle larger work.

Your Next Workhorse

The highly popular Haas EC-1600 Series HMCs offer large work cubes and a maximum part capacity of 10,000 lb, making them perfect solutions for your large-part machining requirements. Models are available with an integrated 4th-axis rotary platter.

40-TAPER

-

400 mm Pallet-Changing HMC

The Haas EC-400 HMC offers the high performance and capacity you need for production work, or high-mix/low-volume machining.

Fast. Rigid. Capable.

Built for high-volume production and unattended operation, the all-new EC-400 is faster, more compact, more rigid, and more capable than ever before. It features a larger 22" x 25" x 22" work envelope, 1400 ipm rapids, and full 4th-axis pallet indexing.

- 40 Taper

- 4 Axis

- 8.1k-15k RPM

- 30-100 Tool Capacity

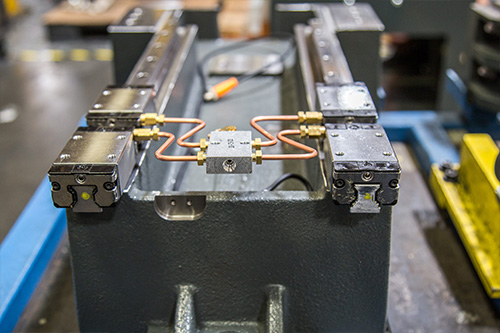

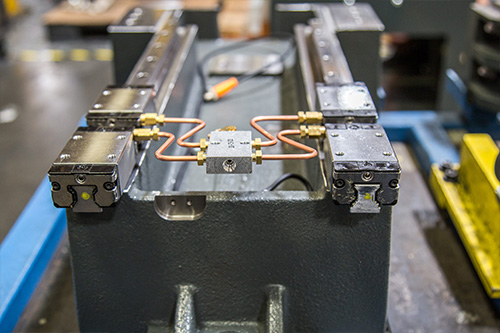

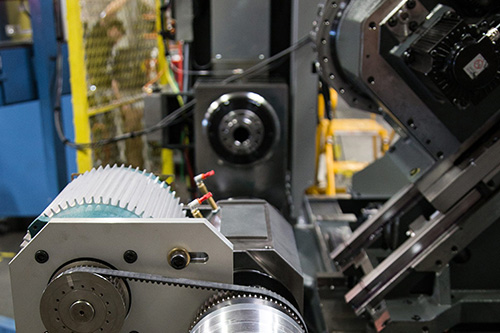

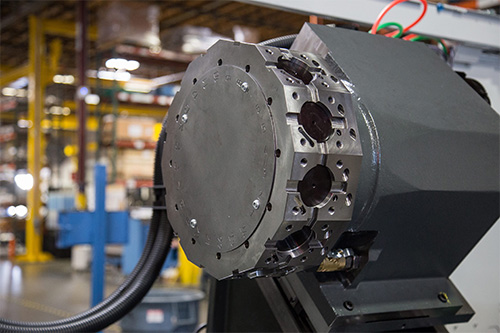

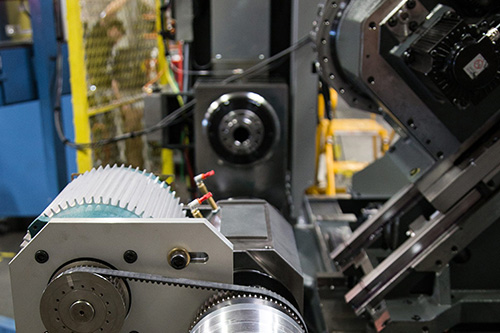

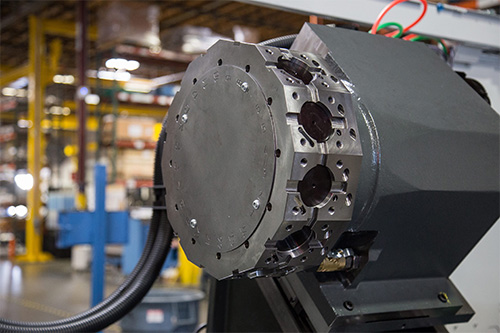

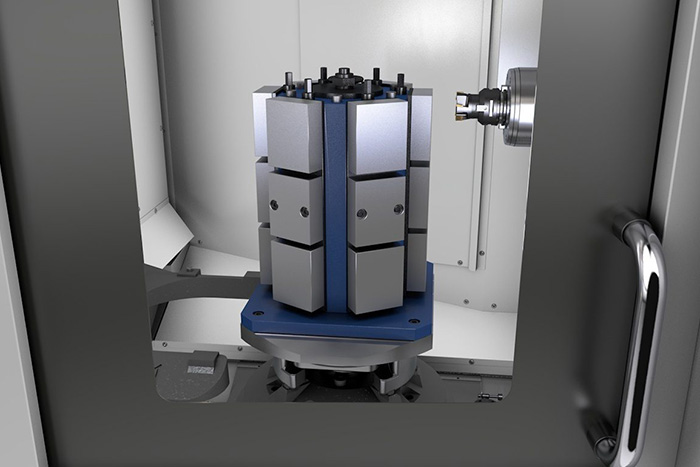

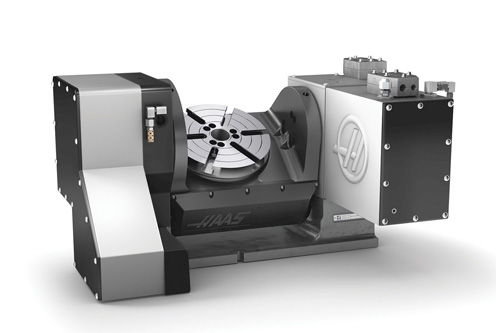

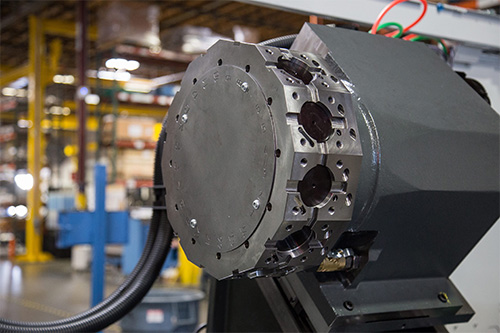

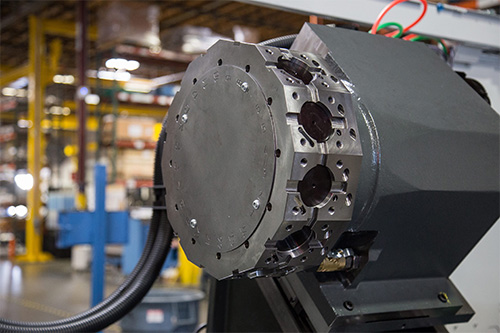

Rotaries & Indexers

-

The Best-Selling Rotary Tables in the Industry

Haas high-precision rotary products provide powerful 4th- and 5th-axis capabilities for every shop – boosting productivity through affordable, plug-and-play simplicity.

Rotary Tables

- For round parts to odd-shaped castings, these T-slotted rotary tables allow for very flexible fixturing. Speeds up to 830 deg/sec.

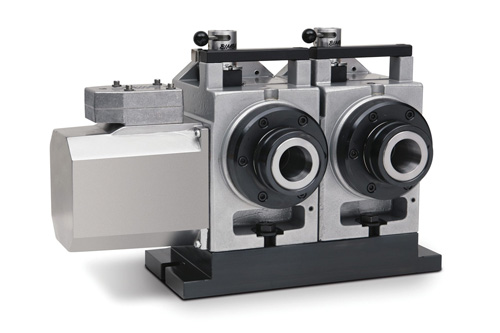

Indexers

- Best suited for parts that can be held in a 5C collet. Single- and multiple-head units are available, with various speed options.

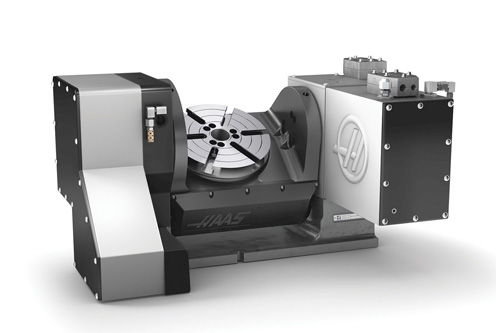

5-Axis Rotary Tables

- For 3+2 positioning or full 5-axis motion, available as indexers or rotary tables, these units increase accuracy and reduce setups.

A Versatile Lineup of Vertical Milling Machines

-

Designed by Machinists

In 1988, we introduced the VF-1, a machine designed specifically by machinists for machinists. Since then, we have continually expanded our product line, with a focus on constant innovation. Whether you need a standard 3-axis mill, a powerful 5-axis machining center, or a small VMC for precision parts, there’s a Haas to do the work. We know – because we use them, too.

VF SERIES

-

The World’s Most Popular CNC Mills

A Wide Range of Sizes and Features to Fit Any Shop’s Needs

X-Travels from 20" to 150"

What can a VF Series vertical mill handle? With our wide range of available models, the VF Series can match nearly any size and productivity range. Regardless of your requirements, there’s a VF just right to meet the demands of your machine shop.

- 40/50 Taper

- 3/4/5 Axis

- 7.5k-30k RPM

- 20-40 Tool Capacity

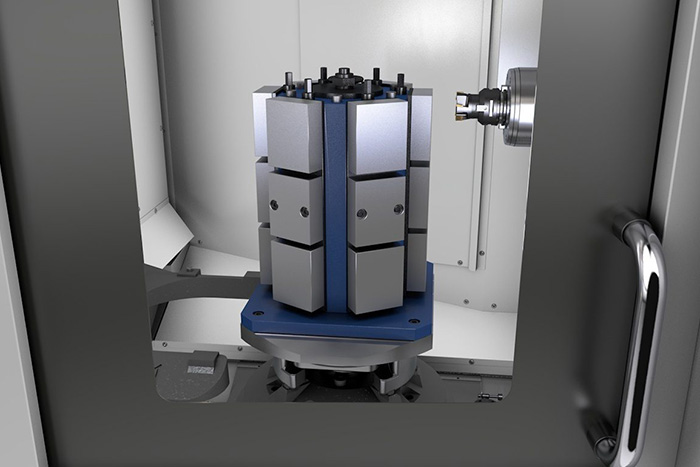

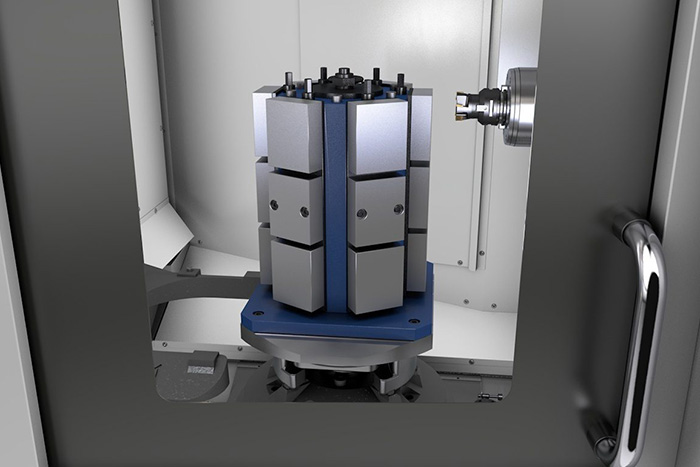

UNIVERSAL MACHINES

-

5-Axis Machining is No Longer Out of Reach

Multi-axis machining used to require exotic machines, expensive options, and complex configurations – until now. We’ve removed those barriers, and simplified 5-axis machines for you.

What Do You Want to Create Today?

5-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts. Haas Universal Machining Centers are cost-effective solutions for 3+2 machining and simultaneous 5-axis machining.

- 40 Taper

- 5 Axis

- 8.1k-15k RPM

- 30-50 Tool Capacity

MINI MILLS

-

The Machines that Defined a Category

Mini in Name and Price Only

Machine performance once was paired with size and cost. The Mini Mill Series changed everything, by packing 40-taper performance into small packages at unheard of prices.

The Original Compact Machines

Haas Mini Mills are the industry standard for compact machining centers. They are perfect for schools, start-up shops, or as a first step into CNC machining. Loaded with full-size features, they are valuable additions for shops needing a “second-op” machine, or an additional spindle where space is limited.

- 40 Taper

- 3/4/5 Axis

- 6k-15k RPM

- 10-20 Tool Capacity

MOLD MACHINES

-

High-Performance VMCs for Mold Making and Tool & Die

Accuracy, Rigidity, and Thermal Stability for the Mold Industry

Haas Mold Machines are the best-value, high-performance, specialty mold & die machines in the industry.

Configured for Mold Making

Making molds has never been easier than with a Haas Mold Machine. We’ve taken our industry-leading VF Series and created custom configurations just for mold making, tool & die work, and other high-precision industries. Mold Machines are also ideal for high-performance job shops looking to increase their versatility.

- 40 Taper

- 3/4/5 Axis

- 12k-30k RPM

- 24-40 Tool Capacity

DRILL/ TAP/ MILL SERIES

-

High-Speed, Lean-Style Machining Centers

Take a Bite Out of Cycle Times

Built on proven Haas designs and technology, the Drill/Tap/Mill Series provides the perfect combination of speed and power to reduce cycle times.

Small, Fast, and Powerful

Drill/Tap/Mill Series machines are high-speed, lean-style machining centers with compact footprints that make very efficient use of valuable shop floor space.

- 30/40 Taper

- 3/4/5 Axis

- 10k-20k RPM

- 18-20 Tool Capacity

TOOLROOM MILLS

-

True CNC Performance at Affordable Prices

Large Travels. Big Capabilities. Small Price.

The Toolroom Mill Series is the true definition of value, providing full CNC capabilities, including available 4th- and 5th-axis functionality, at affordable prices.

A Versatile Starting Point

Haas Toolroom Mills are found everywhere – from schools to high-end production shops. Their versatility is a result of our commitment to using common components across all Haas machine tools. This results in all machines, including the Toolroom Mills, benefitting from improvements in reliability and performance.

- 40 Taper

- 3/4/5 Axis

- 4k-10k RPM

- 1-20 Tool Capacity

COMPACT MILLS

-

High-Accuracy Solution for Machining Small Parts

Small-Footprint, High-Performance Mill for Production and Prototyping

A full-featured, compact CNC perfect for the watch, jewelry, medical, and dental industries.

Small but Mighty

The Compact Mill is a small-footprint, high-accuracy solution for prototyping and producing small, high-precision, 2D and 3D parts, such as those found in the communications, aerospace, medical, and dental industries. It’s small enough to fit into most freight elevators, and can easily be moved with a pallet jack or equipment dolly.

- 20 Taper

- 3/4/5 Axis

- 30k-50k RPM

- 20 Tool Capacity

GANTRY SERIES

-

Gantry-Style CNC Machines for Large Workpieces

Large-Platform CNC Routers for Big Jobs

GR Series machines easily handle large sheets, or can machine small parts by the thousand.

Ready for Your Large-Scale Tasks

The Haas GR Series gantry routers have the power to cut aluminum and other metals, as well as the speed to cut plastics and other light materials. These machines easily handle large sheets, or can machine small parts by the thousand.

- 40 Taper

- 3/4/5 Axis

- 8.1k-15k RPM

- 10-20 Tool Capacity

Lathes

-

A Turning Center for Every Shop

Haas Automation’s complete line of CNC turning centers is designed to meet the needs of modern machine shops – now and long into the future.

All the Features and Performance You’ve Come to Expect From a Haas

Haas turning centers offer a wide range of capabilities, including toolroom lathes, big-bore versions, dual-spindle models, live tooling with C-axis, and Y-axis capability.

ST SERIES

-

The Best-Value Turning Centers in the Industry

Rigid, high-performance turning centers with a wide selection of available options for every shop.

The Haas ST Series high-performance turning centers were designed from the ground up to provide setup flexibility, extreme rigidity, and high thermal stability. These machines offer the best performance for the money – the best value – in their class.

- 6.5"-18" Chuck Size

- 1.75"-12.5" Bar Capacity

- 1k-6k RPM

- 15-55 HP

DUAL-SPINDLE LATHES

-

High-Performance, Dual-Spindle/Y-Axis Turning Centers

Easy-to-program dual-spindle lathes for reduced part handling and setups.

Do Even More

Dual-spindle turning combined with Y axis, C axis, and live tooling allows multiple operations in a single setup to reduce part handling and increase accuracy.

- 10" Chuck Size

- 3" Bar Capacity

- 4.5k RPM

- 30 HP

TOOLROOM LATHES

-

From Schools to Large Toolrooms

The true definition of value – full CNC capabilities without significant investment.

A Great Beginner Lathe

The Haas TL Series Toolroom Lathes are affordable, easy to use, and offer the precision control and flexibility of the Haas CNC system. Because they are very easy to learn and operate – even without knowing G-code – they are perfect for start-up shops, or as a first step into CNC machining.

- 8"-10" Chuck Size

- 3" Spindle Bore

- 1.8k-3k RPM

- 10 HP

CHUCKER LATHE

-

Ultra-Compact Chucker Lathe for Small, High-Production Parts

Small footprint, affordable chucker lathe for prototyping or production work.

Chucker Lathe

The innovative Haas CL-1 is an ultra-compact CNC chucker lathe that comes standard with an 8-station automatic turret, making it perfect for high-volume production of small, precision parts, such as those found in the communications, aerospace, medical, and dental industries. The CL-1 can be moved easily with a pallet jack or equipment dolly, and is small enough to fit into most freight elevators.

- 5C Chuck Size

- 1" Bar Capacity

- 6k RPM

- 5 HP

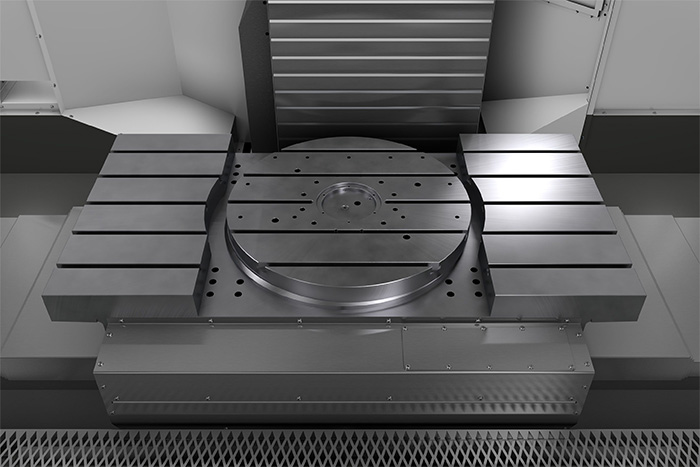

Horizontal Mills

-

The Best-Value HMC in the Industry

Every Haas HMC provides the features and performance you need to boost your productivity, making it the best investment you have ever considered.

- 50 Taper

- 3/4/5 Axis

- 7.5k-10k RPM

- 30-50 Tool Capacity

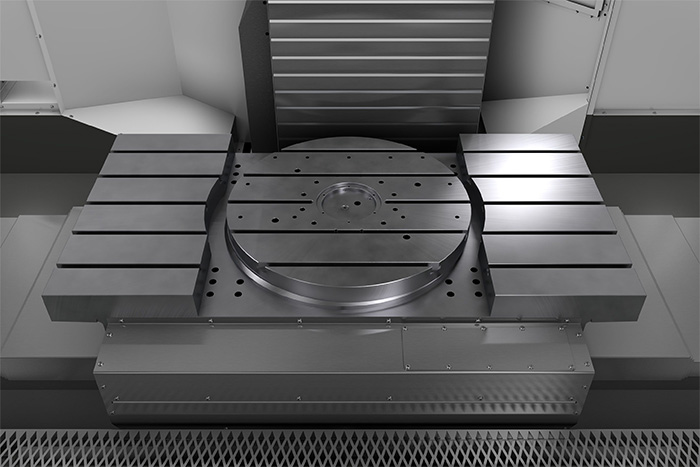

50-TAPER

-

Rugged 50-Taper HMCs with Large Capacities

Haas EC-1600 Series HMCs offer the high performance and large capacity you need to handle larger work.

Your Next Workhorse

The highly popular Haas EC-1600 Series HMCs offer large work cubes and a maximum part capacity of 10,000 lb, making them perfect solutions for your large-part machining requirements. Models are available with an integrated 4th-axis rotary platter.

40-TAPER

-

400 mm Pallet-Changing HMC

The Haas EC-400 HMC offers the high performance and capacity you need for production work, or high-mix/low-volume machining.

Fast. Rigid. Capable.

Built for high-volume production and unattended operation, the all-new EC-400 is faster, more compact, more rigid, and more capable than ever before. It features a larger 22" x 25" x 22" work envelope, 1400 ipm rapids, and full 4th-axis pallet indexing.

- 40 Taper

- 4 Axis

- 8.1k-15k RPM

- 30-100 Tool Capacity

Rotaries & Indexers

-

The Best-Selling Rotary Tables in the Industry

Haas high-precision rotary products provide powerful 4th- and 5th-axis capabilities for every shop – boosting productivity through affordable, plug-and-play simplicity.

Rotary Tables

- For round parts to odd-shaped castings, these T-slotted rotary tables allow for very flexible fixturing. Speeds up to 830 deg/sec.

Indexers

- Best suited for parts that can be held in a 5C collet. Single- and multiple-head units are available, with various speed options.

5-Axis Rotary Tables

- For 3+2 positioning or full 5-axis motion, available as indexers or rotary tables, these units increase accuracy and reduce setups.