- Offer Profile

- Part of global industrial engineering group Sandvik, Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry now and into the next industrial era. Educational support, extensive R&D investment and strong customer partnerships ensure the development of machining technologies that change, lead and drive the future of manufacturing.

Inserts and grades

- Regardless of component size, material or design, the insert grade you use can make all the difference in your manufacturing productivity. Selecting the right insert grade for your specific machining operation helps you stay ahead of the competition.

Concept inserts

- In the world of cutting tools, inserts play a crucial role in enhancing performance and precision. Our concept inserts, available in multiple geometries and grades, are the cornerstone of our cost-efficient and performance-driven solutions.

ISO inserts

- We have a wide range of ISO inserts that cater to various machining needs, from external and internal turning to profiling and pocketing. These inserts, available in different shapes, sizes, and grades such as CoroTurn® 107 and T-Max® P, are engineered for precision and efficiency, making them ideal for working with a variety of materials including steel, cast iron, heat-resistant super alloys and hardened steel.

Turning Tools

- For any application our turning tools control chips, tool life and vibration. This makes sure you stay in control, maximize your machining time, and stay ahead of the competition.

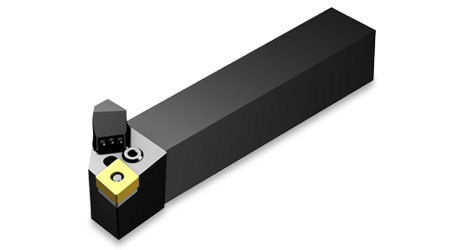

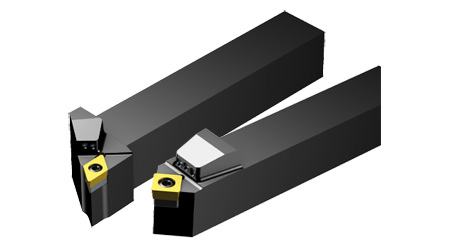

External turning tools

- Do you want a turning tool that delivers chip control, process security and the highest component quality? Use our tool holders and inserts to achieve the best performance possible. Whether you are making a long cut or need a high metal removal rate, our tools will get the job done.

Internal turning tools

- In this constantly changing manufacturing world, the passion for metal cutting is crucial to stay ahead. We share that passion. With a keen understanding of your business realities, we provide you with cutting tools and solutions that match the ambitions of your company. Together, we shape the future of manufacturing.

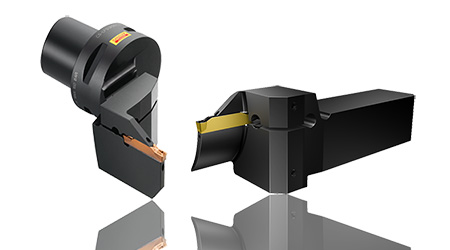

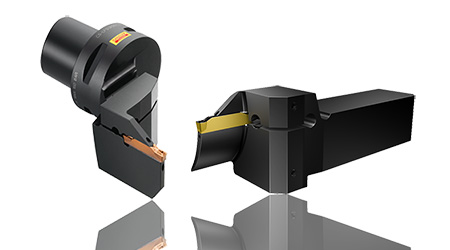

Parting and grooving tools

- With our cutting tools for parting and grooving, you get high productivity and long tool life, helping you deliver plenty of components out of the workshop door.

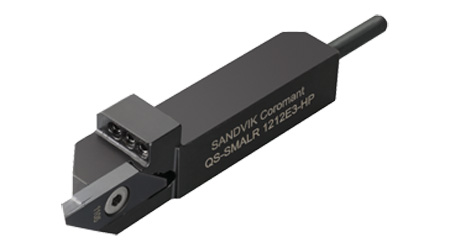

Parting off tools

- Get peace of mind with parting off tools that deliver chip control, long tool life and machining efficiency. Here you will find smart coolant solutions, tough inserts and rigid clamping mechanisms that will help you excel in this critical part of the machining process.

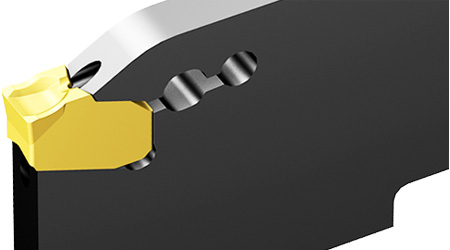

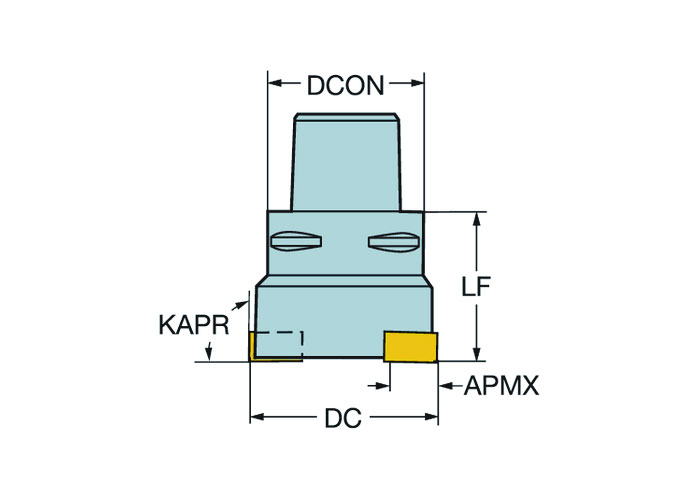

External grooving tools

- Our grooving tools, including high-precision coolant, wiper inserts and any conceivable radius, will help you successfully machine any type of groove, resulting in chip control and excellent surface quality.

Internal grooving tools

- Long overhangs and difficult chip evacuation are part of everyday life when machining internal grooves. That is why we offer dampened boring bars and light cutting inserts in all sizes. If you want internal grooving tools that promise quality and repeatability, this is where to look.

Face grooving tools

- In this constantly changing manufacturing world, the passion for metal cutting is crucial to stay ahead. We share that passion. With a keen understanding of your business realities, we provide you with cutting tools and solutions that match the ambitions of your company. Together, we shape the future of manufacturing.

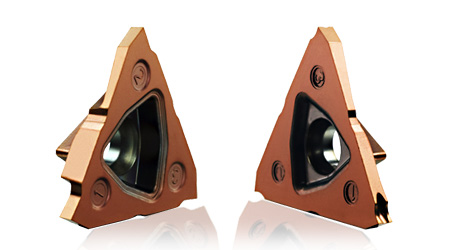

Milling tools

- Whether you are milling flat surfaces, shoulders, slots, gears or complex 3D shapes, you will find the milling cutter you need here. Our efficient milling tools will give you a competitive edge and help you stay productive.

Shoulder milling tools, edging tools

- Whether you are milling deep shoulders, trying to avoid vibration, or require specific and precise contours, you will find the shoulder milling tools or edging tools you need here. Our comprehensive assortment of CoroMill® shoulder milling cutters provide top-quality performance and reliability.

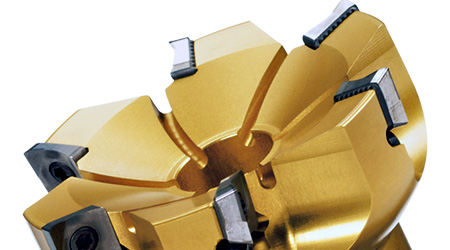

Face milling tools

- If you need a face milling tool to efficiently machine flat surfaces, look no further. From heavy duty roughing in tough conditions to the final finishing required for high-quality surfaces, we have the face milling cutter to get the job done.

High-feed milling tools

- The main advantage of high-feed face milling is extremely high productivity. In order to use high-feed milling, you need a small entering angle. We have a range of high-feed milling tools, including indexable, solid, and exchangeable head, that enable you to take advantage of this fast process.

Ball nose milling cutters

- In this constantly changing manufacturing world, the passion for metal cutting is crucial to stay ahead. We share that passion. With a keen understanding of your business realities, we provide you with cutting tools and solutions that match the ambitions of your company. Together, we shape the future of manufacturing.

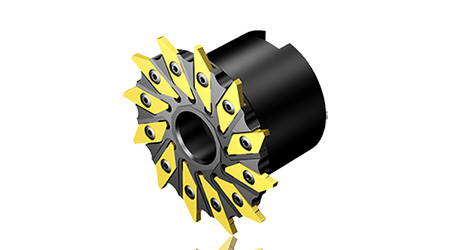

Slot milling cutters

- In this constantly changing manufacturing world, the passion for metal cutting is crucial to stay ahead. We share that passion. With a keen understanding of your business realities, we provide you with cutting tools and solutions that match the ambitions of your company. Together, we shape the future of manufacturing.

Groove milling cutters

- In this constantly changing manufacturing world, the passion for metal cutting is crucial to stay ahead. We share that passion. With a keen understanding of your business realities, we provide you with cutting tools and solutions that match the ambitions of your company. Together, we shape the future of manufacturing.

Thread milling cutters without chamfering

- In this constantly changing manufacturing world, the passion for metal cutting is crucial to stay ahead. We share that passion. With a keen understanding of your business realities, we provide you with cutting tools and solutions that match the ambitions of your company. Together, we shape the future of manufacturing.

Chamfer milling cutters

- In this constantly changing manufacturing world, the passion for metal cutting is crucial to stay ahead. We share that passion. With a keen understanding of your business realities, we provide you with cutting tools and solutions that match the ambitions of your company. Together, we shape the future of manufacturing.

Angle profile milling cutters - indexable

- In this constantly changing manufacturing world, the passion for metal cutting is crucial to stay ahead. We share that passion. With a keen understanding of your business realities, we provide you with cutting tools and solutions that match the ambitions of your company. Together, we shape the future of manufacturing.

Plunge milling cutters - indexable

- In this constantly changing manufacturing world, the passion for metal cutting is crucial to stay ahead. We share that passion. With a keen understanding of your business realities, we provide you with cutting tools and solutions that match the ambitions of your company. Together, we shape the future of manufacturing.

Drilling tools

- Drilling is a critical operation carried out late in the production cycle when the component value is already high. It can therefore make or break your productivity and profitability. Investing in drilling is an easy way to improve your bottom line. Here you can find drilling tools and solutions to help you achieve excellent hole results for a variety of machining conditions, materials and application types.

Indexable drills

- When manufacturing economy is your biggest concern, indexable drills are the right solution. Whether it is general drilling, plunge drilling or stack drilling, find the indexable drill that suits your specific needs here.

Exchangeable tip drills

- Exchangeable tip drills are an extremely productive, accurate and economical option for drilling. A single tool body can hold a variety of tips with varying geometries and sizes allowing greater flexibility for optimum performance across multiple materials and applications.

Solid carbide drills

- Solid carbide drills are a great option for excellent process security, manufacturing economy and good hole quality. They provide the best combination of penetration rate and precision. Our wide product range of solid carbide drills includes micro drills, versatile drills, optimized drills and drills for deep holes.

Taps

- Our tapping tools produce threads in a wide range of thread forms and sizes. Choose various taps for blind or through holes.

Solid Round Tools

- The solid round tools range covers all applications types within the areas of solid carbide drilling, milling, tapping, reaming and threading. Each solid round tool is designed to fulfill the demands of high quality, precision and maximum productivity so you can get the most out of your machining process.

Solid carbide end mills

- The full assortment of our high-quality solid carbide end mills includes tools from roughing to finishing and thread milling within Versatile, Optimized and Customized product categories. Every end mill is carefully designed to fulfill demands of high quality, precision, and maximum productivity so you can get the most out of your machining process.

Solid ball nose end mills

- Our assortment of ball nose end mills are engineered for smooth, silent, and secure machining across a variety of materials and applications, ensuring high-quality finishes and reliable performance. These tools are ideal for both roughing and finishing operations, providing flexibility and efficiency in every machining task.

Solid carbide drills

- Solid carbide drills are a great option for excellent process security, manufacturing economy and good hole quality. They provide the best combination of penetration rate and precision. Our wide product range of solid carbide drills includes micro drills, versatile drills, optimized drills and drills for deep holes.

Taps

- Our tapping tools produce threads in a wide range of thread forms and sizes. Choose various taps for blind or through holes.

Threading tools

- Our comprehensive range of threading tools will help you produce complex component features with ease. We offer a variety of tools suited to different components, thread profiles and pitches, for both external and internal threads. For productive, high-quality threading, you’ve come to the right place.

Thread turning tools

- Thread turning is a demanding operation, where chip control and consistent tool life are critical to success. Our extensive assortment of thread turning tools covers a wide range of thread profiles and pitches. Choose one of these tools and ensure efficient, secure thread turning.

Thread milling tools

- Thread milling is ideal when machining asymmetric or tough materials, and when you’re experiencing chip-breaking problems. Whatever your project or method, we have the right thread milling tool for you. Our range of tools covers internal and external machining, small part machining, medical solutions and other applications.

Taps

- Developed for through holes and blind-hole operations, CoroTap tools feature an enhanced edge design and material grade to ensure reduced axial forces and torque. The CoroTap line, covering a variety of different thread profiles, has two areas: taps optimized for specific materials and taps optimized for flexibility.

Tooling systems

- If you are looking for a world-class modular tooling system that provides efficiency and flexibility, you’ll find what you need here. Our leading interfaces, Coromant Capto®, CoroTurn® SL and Coromant® EH, will help you get the job done right. Our quick change options will also increase your machine utilization.

Rotating holders

- Experience the efficiency and precision of our rotating holders. These products are designed to maximize machine utilization and offer flexibility across different machining operations. With high stability, accuracy, and minimized tool inventory, our rotating holders enhance productivity in your workshop.

Stationary adapters

- These high-precision tools offer a seamless integration between your machine and cutting tools, enabling efficient, versatile, and high-quality machining operations. With their distinct features and benefits, these adapters significantly contribute to increased productivity and reduced setup times.

Collets

- Our range of collets, featuring renowned products such as EasyFix™, delivers precision and durability for diverse applications. These high-quality collets ensure quick setup times, extended tool life, and exceptional performance even under high coolant pressure.

Silent Tools™

-

Silent Tools™ is the trademark for a family of tool holders for turning, milling, boring and drilling. The tool holders are designed to minimize vibrations through a dampener inside the tool body. The majority of Silent Tools customers’ use these tools for long overhangs however, even with shorter overhangs, large productivity increases and surface quality improvements are to be gained.

Whether you increase your metal removal, improve your surface finish, secure your process or reduce your production costs you will certainly enjoy the silence.

Turning

- Silent Tools damped boring bars and adaptors make it possible to maintain good productivity and close tolerances also for long tool overhangs beyond 3 x bar diameter. Silent Tools damped steel bars make it possible to machine up to 10 x bar diameter, and our damped carbide reinforced bars go even higher; up to 14 x bar diameter tool overhang.

Milling

-

Many components and machine tools require long tool assemblies to reach down in large components. Vibration risk is high and the remedy is either slow machining or damped tools.

With Silent Tools, chatter and vibration are eliminated, the machining rate can be increased and process security improved.

Boring

- Problems that originate from vibrations are frequently encountered in boring and other operations, especially when machining with long overhangs. The vibrations may cause bad surface texture, insufficient accuracy, loss of productivity, increased insert and machine tool wear, as well as noise.

Rotating adaptors

-

Silent Tools is the trademark for a family of tool adaptors for turning, milling and boring. The tool adaptors are designed to minimize vibrations through a damper inside the tool. The majority of Silent Tools customers’ use these tools for long overhangs. However, even with shorter overhangs, large productivity increases and surface quality improvements are to be gained.

Whether you increase your metal removal, improve your surface finish, secure your process or reduce your production costs you will certainly enjoy the silence.

Turning adaptors

-

Silent Tools is the trademark for a family of tool adaptors for turning, milling and boring. The tool adaptors are designed to minimize vibrations through a damper inside the tool. The majority of Silent Tools customers’ use these tools for long overhangs. However, even with shorter overhangs, large productivity increases and surface quality improvements are to be gained.

Whether you increase your metal removal, improve your surface finish, secure your process or reduce your production costs you will certainly enjoy the silence.

Boring and reaming tools

- Boring is a machining process for enlarging or finishing of an existing hole. When fine boring, achieving excellent surface finish and close tolerances are the main goal. Reaming is a finishing operation performed with a multi-edge tool giving high-precision holes with great surface finish, superb hole quality and close dimensional tolerances.

Rough boring tools

- Roughing is primarily focused on metal removal and is performed to open up an existing hole made by methods such as pre-machining, casting or forging. Rough boring prepares the hole for finishing. For optimized boring, general boring, large diameter- and lightweight boring see the selection of tools, presented below in the overview. To eliminate vibration when machining with long overhangs, damped tools are available.

Fine boring tools

- Fine boring operations are performed to complete an existing hole to its final hole tolerance with high quality surface finishes. Our tool range offers products for dedicated as well as flexible diameters, large and small diameters as well as light weight boring. For vibration-free machining, choose Silent Tools™ damped boring tools for best results.

Other applications with boring tools

- Adjustable head with boring bars for finishing operations

Reamers

- Precision reamers are designed to slightly enlarge the size of a previously formed hole with a high degree of accuracy that leaves the sides smooth. You’ll find the reaming tools you need here for a variety of applications and materials.

Digital machining

- In already optimized processes it may be challenging to find room for further improvement. The solution can be found in the advanced software and tools that support your digital manufacturing, all the way from planning and design to in-machining and machining analysis.

CoroPlus® Tool Guide

-

- Find a cutting tool based on your workpiece material

- Find the cutting tool based on a given task

- Find machining process and cutting data

- Find recommended cutting data for your specific tool

Build tool libraries from any cutting tool supplier’s standard data

-

- Manage tool libraries

- Share with colleagues

- Send to CAM, simulation, and tool management software

CoroPlus® Tool Path

-

- A easy-to-use software as a service, designed to streamline and simplify CNC machining programming

- Provides seamless integration and optimized performance using Sandvik Coromant tooling

CoroPlus® Tool Supply

- Tool management software and hardware for inventory control

- Organize and manage your inventory and tools

- Create reports to track assets, consumption and cost to build insights of your inventory

- Streamline and automate your tool purchasing process

- Get started fast, with an intuitive and user-centric interface

- Access the cloud-based software anywhere, anytime, with or without vending cabinet

CoroPlus® Machining

-

Planning for availability in your workshop requires transparency into all operations. While manual collection of data and documentation becomes tedious and time-consuming, a connected machine will offer new possibilities for transparency, optimized planning and a streamlined production. These are only a few examples of the benefits created in the organization:

- Plant management: Increase overall efficiency and meet delivery demands with quality and profitability.

- Production engineering: Improve processes, facilitate capacity planning and secure that operations are carried out in a cost-efficient manner.

- Production management: Optimize operations and collaboration within workshops and between factories in order to reduce cost.

- Operators: Feedback and contribute to insights for optimization of the manufacturing process and machine operations.

Silent Tools™ Plus

-

A properly mounted tool reduces the risk of undersized holes that require re-work but also improves the cutting ability of the insert to ensure maximum tool life.

The Silent Tools™ Plus center height indicator helps the operator to set up the tool quicker and with increased accuracy.

Available in all feature packages.

Coromant Capto®

-

When maintenance is driven by schedules, not by need, efficiency doesn’t stand a chance. Too late, and tools are over-used and prone to damage. Too soon, and it leads to wasted resources.

Imagine, then, if each driven tool holder told you precisely when it needs maintenance? And what if you could book it directly from the software. You could plan ahead, service effectively, and know your driven tool holders are always in the best possible condition for optimal productivity.

CoroPlus® Connected

-

CoroPlus® Connected, fully integrated into the machine tool, provides high-level process security for your manufacturing operation.

With full integration into your machine's NC control, you can set limits on tool load, bar deflection, vibration, and damping system temperature. If something unexpected happens, the system will initiate a "stop & retract" to a safe position avoiding machine downtime and costly repairs.

Consultancy services

- Do you use tried-and-tested methods for identifying production bottlenecks? And what's your team's approach to unblocking them? How does digitalization affect the way you carry out changes and improvements?

Whether you're mostly digital or halfway there — you are in charge of realizing your full potential. And that's where we can help.

Miscellaneous

- To get the best performance out of our products, it is important to use the correct insert tightening torque. In the Sandvik Coromant assortment there are different kinds of torque hand tools. The 5680 105-series is used for bits and can be adjusted to the correct torque value. The 5680 100-series is preset and torque is matched to the TORX PLUS® size. The Coromant web have torque information for all tools to get the correct fastening of the insert and most of our tools are marked with tightening torque.

Torque tools and bits

- To get the best performance out of our products, it is important to use the correct insert tightening torque. In the Sandvik Coromant assortment there are different kinds of torque hand tools. The 5680 105-series is used for bits and can be adjusted to the correct torque value. The 5680 100-series is preset and torque is matched to the TORX PLUS® size. The Coromant web have torque information for all tools to get the correct fastening of the insert and most of our tools are marked with tightening torque.