- Offer Profile

-

Seco develops tools, technologies and solutions for the most demanding manufacturing tasks. From its foundation in Fagersta, Sweden, to its current global orientation, our business model has always been focused on the specific needs of our customers and characterized by trust. We combine state-of-the-art precision tools with partnership-based customer relationships and technical know-how to advance the world of machining together. We are “Made for Makers” - with innovative ideas and sustainable approaches.

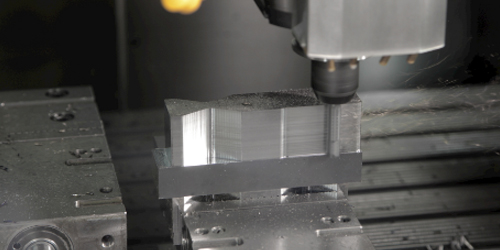

Milling

-

Our wide, innovative and powerful range of solid end mills and milling cutters and inserts is well known in the industry.

We offer a wide selection of milling solutions to handle all workpiece materials – from soft steel to easy-to-machine aluminum to difficult-to-machine superalloys. Regardless of your milling operations, you’ll find what you need. Plus, we offer the support you need to make sure you select the right tool to improve productivity and product quality. Milling Cutters

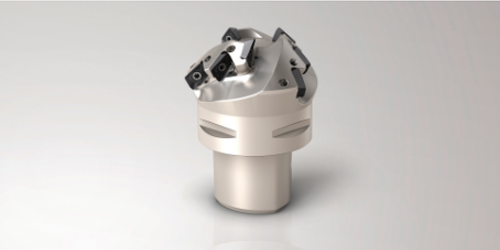

- Seco’s broad variety of indexable milling cutters covers an enormous application area. Including copy mills, disc mills, face mills, helical mills, square shoulder mills and more, this range of options allows manufacturers to achieve the balance of productivity, performance and cost effectiveness required by their specific applications.

Square Shoulder Mills

- We have one of the most comprehensive and versatile selections of advanced square shoulder milling cutters on the market today. So, no matter the workpiece material, depth of cut or tolerance requirement, we have a solution that can optimize your operations, boost your profitability and keep you competitive.

Helical Mills

- Our comprehensive selection of high-performance helical milling cutters incorporate the latest geometries and grades to achieve high feed rates, large depths of cut and aggressive metal removal in contouring and profiling operations.In general, these tools employ a small number of teeth and a large helix angle to produce a shearing action that results in smooth, vibration-free cuts and fine surface finishes. The helix angle allows the cutter to absorb most of the end load so it smoothly enter and exit the workpiece.

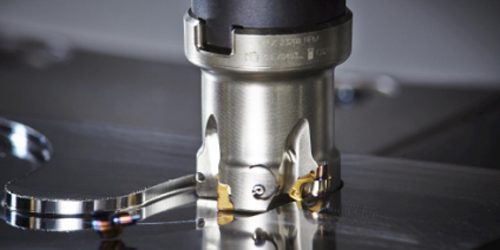

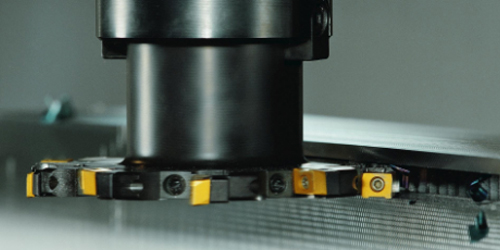

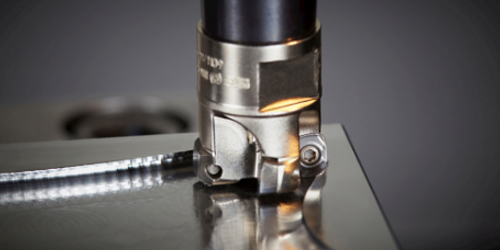

Face Mills

-

Seco offers a myriad of face milling product families to meet varied production needs. While each product offering has unique features and benefits, all are designed to reduce cycle times, and provide quick insert indexing, higher metal removal and consistent quality.

In addition, Seco offers tool selection and cutting data support to help you find the right tools and inserts for your operations.

Disc Mills

-

Our extensive range of standard disc milling cutters, insert radii, geometry and grades tackles any challenges brought by disc milling applications.

With the widest range of inserts, cutter bodies, and attachment types in the industry, we are your single source tooling supplier for sawing, T-slotting, slotting, deep slotting, dual-radius slotting, back facing, circular or helical interpolation, square shoulder milling, circlip grooving and copy milling. And our products are developed with extensive research to ensure they meet the needs to today’s materials and machining processes.

While our full line of standard disc milling cutters covers most applications, we also offer special design and manufacturing solutions for industry-specific needs. This includes cutters for gear machining in the power generation industry, automotive crankshaft milling, large diameters cutter solutions for many typical aerospace components, cutters for oil and gas pipe sawing and cutters with round inserts for hip prosthesis.

Copy Mills

-

At Seco, we offer a wide range of high-performance tools for 3D milling applications, from milling of small components in small machining centers to heavy-duty milling in high-power milling machines.

Our cutting tools are designed and manufactured with exact precision to meet our customers’ demands for superior quality, close tolerances and consistent performance. We offer a complete range of products for all industry segments, including aerospace, mold and die, power generation and more.

High Feed Mills

-

High feed milling is a milling method that permits up to three times faster machining than conventional methods.

It pairs shallow depth of cut with high feed per tooth which gives higher metal removal rates and results in more parts being machined. The cutting forces are directed at the machine spindle in the axial direction, which means greater stability and reduced vibrations, extending tool life. Additionally, high feed milling tools save time by avoiding semi finishing and reducing tool changes.

Our expansive range of high feed milling solutions meets all application needs. Plus, with the help of Seco’s knowledgeable and experienced team, you can seamlessly implement high speed milling techniques to increase your productivity and competitiveness.

Face milling with the high feed milling method is perfect for creating a good platform for further machining operations or a final finishing. In most applications, you’ll often get such fine tolerances that only final finishing is needed.

High feed milling is also very practical for copy mill machining uneven surfaces and is highly effective in cavity milling and creating molds and dies. With copy milling and cavity milling, the application indicates the necessary tool diameter, making selecting the right tool easy.

In helical interpolation, high feed milling is suitable for making large-diameter holes because it often means skipping pre-machining or pre-drilling. It’s also commonly used for plunging operations, especially when machining difficult materials such as titanium and other light alloys.

Plunge Mills

- Seco offers one of the most comprehensive ranges of plunge milling cutters. Plunging is the most efficient milling process in terms of removing significant amount of material in the least amount of time. With their high material removal rates, plunging cutters are ideal for roughing in 3D milling applications.

Spot facing mills

- Seco spot facing mills are cutters for milling spot faces of blind and countersunk holes. Key benefits include smooth cutting, reduced spindle bearing wear via a highly balanced tool and high security through a center-lock clamping system, all engineered in an economical solution.

Chamfer Mills

- Seco chamfer mills offer the same free cutting action as our standard milling cutters, providing strong and reliable performance. With options for through-coolant and 30-degree, 45-degree, 60-degree and 75-degree setting angles, our family of chamfer mills is available with Combimaster™, Arbor and Seco-Capto connections.

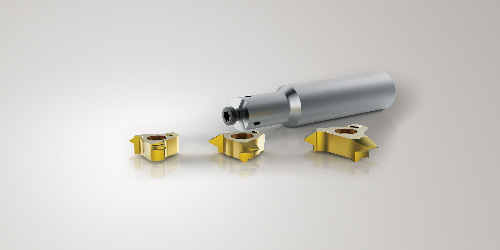

Exchangeable Head Mills

- With Seco exchangeable head cutters, significant cost savings are achieved through the ability to replace worn inserts rather than an entire tool. The use of a highly secure cutter/shank interface ensures stable performance in both roughing and semi-finishing operations. Additionally, the ability to use multiple inserts allows for increased flexibility to minimize tooling inventory.

X-Head Mills

- With the Seco exchangeable head milling system, quickly and easily change between various solid carbide milling head profiles and types to optimize all your milling operations while you reduce manufacturing costs and tooling inventories. X-Head end mills mount to a variety of available shank lengths for even greater versatility, with long-reach capability for overhang lengths of 3-5xDC and above. End mill changes only require a simple turn of a wrench, and the shank could remain in the machine. Eliminate the need to reset tool lengths thanks to a secure and reliable connection that provides exchange accuracies within 50 microns.

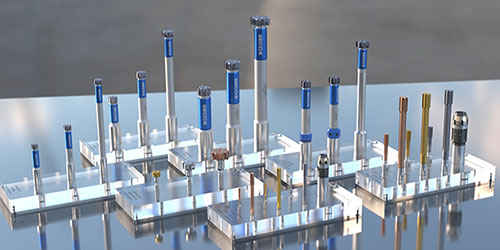

Minimaster

-

Minimaster™ is a unique, versatile end milling system that can combine different solutions for optimum accessibility and maximum stability and security.

The flexible two-piece design combines shanks and inserts to save time, money and create a versatile tool that enables users to find a solution for almost every application – whether they need to minimize the overhang, attain maximum stability, or more. When an insert is worn, users easily replace just the insert, saving the cost of replacing the entire tool and the time for regrinding.

The Minimaster range encompasses a wide range of inserts and shanks, making it the most flexible end milling system in the industry. There are more than 600 combinations of inserts and shanks for each diameter between 6 – 20 mm, and the inserts can be ordered in many different versions such as under-sized inserts for keyway, square shoulder inserts with sharp edges or corner radius, center drilling, chamfering 45–60° or double chamfer, high feed inserts, plunge milling and copy milling inserts in 90–120° ball nose versions.

Seco Minimaster for 3D milling is available in 2- and 3- flute versions, with 3-flute version it is possible to improve the productivity with higher feed rates, and with 2-flute version it is possible to minimize the risk of vibration.

Minimaster Plus

-

Minimaster™ Plus is the next generation line of end mills with replaceable fluted inserts. This replaceable cutting head tool system builds on the success of the industry leading Minimaster system and reaches the highest level of precision and productivity.

A secure cutter/shank interface enables Minimaster Plus to handle higher cutting forces. In turn, these end mills deliver increased metal removal rates in roughing and semi-finishing operations.

Minimaster Plus is a cost-effective solution that enables users to replace only worn inserts rather than the entire tool. Exchangeable inserts for different shanks also allows for higher cutting data, eliminates regrinding and ensures a consistent tool life.

Replacing the insert is fast and easy and can be done without removing the shank from the holder or machine or re-measuring the whole assembly. Once an insert is replaced, the axial and radial positions remain the same for maximum precision.

Available in two-, three-, four-, five-, and eight- flute versions, Minimaster Plus is capable of machining all kinds of materials. Two and three-flute versions feature internal through coolant channels to ensure accurate cooling and efficient chip evacuation.

The four-flute head features larger helix angles and shorter flute lengths measuring 0.7xD, which significantly boosts stability. The added stability makes these heads especially well suited for aggressive material removal in demanding applications and 5-axis machining where cutter ends are used more frequently than the entire flute lengths. They are ideal large radial engagement and small axial engagement conditions.

Five and eight-flute version are recommended for contouring.

Available in diameters ranging from 10 – 16 mm (.39" - .63"), the Minimaster Plus line includes a flexible mix of inserts and shanks.

Solid End Mills

-

Seco’s comprehensive portfolio of solid carbide and HSS-Co end mills can overcome many of the challenges you face. Geometries, grades and coatings are available to optimize the cutting of any workpiece material, from aluminum to exotic alloys to stacked composites.

Whether you need a flexible tool that offers productive performance across a range of conditions or a dedicated tool to maximize productivity in a very specific application, you can find the solution in Seco’s range of solid end mills.

Solid Carbide End Mills

- Premium solid carbide end mills bring unmatched cutting performance, long tool life and high process security to demanding parts production in industry segments such as aerospace, medical, mold and die, and power generation.The high quality, low cost production advantages of these end mills come as a direct result of dedicated micro-grain carbide structures, optimized flute lengths, specialized edge honing and wear-resistant coatings.

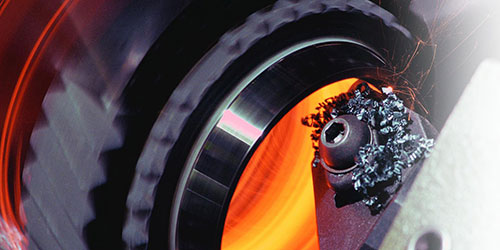

Ceramic Grade End Mills

- Stop letting heat-resistant superalloys (HRSA) slow down your part-production processes. Go faster than ever before with your HRSA milling processes  up to 20-40 times faster  with high-performance Jabro® ceramic solid end mills. Using an advanced SiAlON ceramic designed specifically for HRSA machining, these end mills feature innovative, strong geometries that maximize material removal. And for the highest level of productivity, pair the new ceramic roughing tools with the JHP780 finishing tool and processes optimized with the help of experienced HRSA application specialists at Seco Tools.

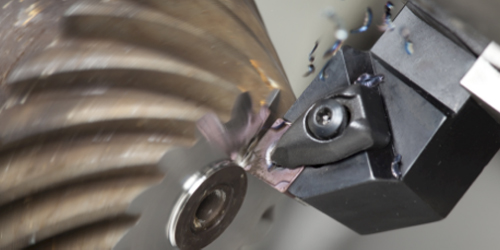

Turning

-

We have one of the most comprehensive selections of turning products in the industry, with more than 5,500 standard inserts and over 3,000 toolholders from which to choose.

Manufacturers from all metalworking segments rely on these products for maximum productivity and profitability. General Turning - ISO

- Seco’s incredibly diverse ranges of holders and inserts for general turning allow us to provide ideal solutions to your specific applications. Whatever your material, set up, part requirements and machine capabilities, our expansive selection ensures a perfect match to your needs.

Duratomic® - General Turning Inserts

-

Duratomic® is an exclusive insert coating technology that brings an exceptional combination of wear resistance and edge toughness to a wide variety of Seco grades.

Nanoscience at its best, the Duratomic CVD aluminum-oxide coating process manipulates coating components at an atomic level to improve the mechanical properties as well as the thermal and chemical inertness of many of the company’s products.

By controlling the atomic structure of its coatings, Seco can ensure the best part of the structure is engaged in the cut. Such control also yields a smoother surface, resulting in less friction and heat during the cut for unmatched tool life and speed capabilities.

General Turning Inserts

- Anything is possible when it comes to our broad selection of general turning grades and chipbreakers. Supporting inserts of different shapes, sizes and thicknesses, we developed each of these solutions with the same goal in mind: to boost the productivity and tool life in your turning applications. Covering all material groups, this comprehensive range allows you to achieve your goals in terms of material removal rates, tool life and surface finish.

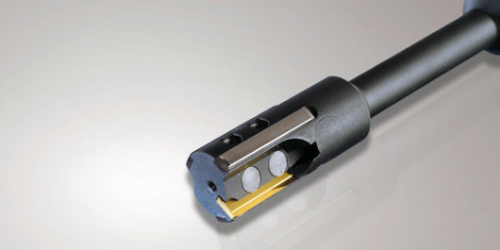

Jetstream Tooling - Toolholders General Turning

- Jetstream Tooling toolholders deliver coolant effectively through the toolholder to the optimum position close to the cutting edge. This improves chip control by lifting the chip away from the rake face and reducing the heat load, enabling longer tool life and drastically increasing cutting data to be applied. A comprehensive range of insert types, shapes and sizes are available.

Seco-Capto - Toolholders General Turning

- Seco-Capto™ is a leading quick-change modular tooling system for quick setup and replacement of cutting edge holders. Its robust product design allows retaining excellent stability and high positioning accuracy. The product range serves a comprehensive range of insert types, shapes and sizes.

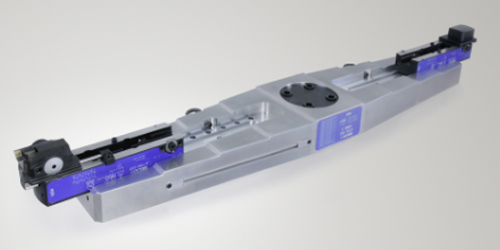

Steadyline Vibration-dampened Bars for Turning and Rotating Boring

- Steadyline is a modular anti-vibration tooling system consisting of dampened bars, providing an easily exchangeable head with the accurate and reliable GL interface. To add applicability, the bars are highly capable both for problem-free long-overhang internal turning as well as rotating boring applications.

Modular GL-heads For Turning

- Modular GL-heads for Steadyline® anti-vibration tooling are easily exchangeable toolholder heads with the accurate and reliable GL interface. GL turning heads are offered for problem-free long-overhang internal turning accommodating a comprehensive range of insert types, shapes and sizes for respective bar diameters.

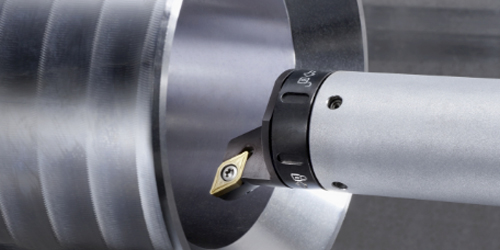

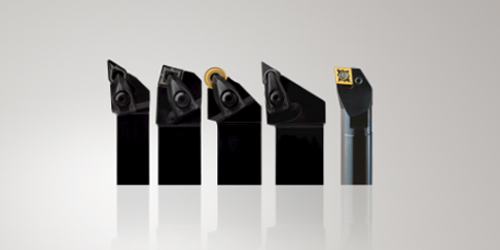

Shank Toolholders and Boring bars

- This wide offering of easily applicable shank and boring bar toolholders adds another level of reliability and productivity to lathe machining. The range of ISO and ANSI toolholders accommodates a comprehensive range of insert types, shapes and sizes, also allowing choice of several leading clamping methods.

Cassettes for Railway Machining

- This railway machining product line consists of exchangeable cassettes for stable and highly reliable wheel turning. The product range serves most available machine setups, insert types, shapes and sizes.

Cartridges For Turning Inserts

- These highly applicable turning cartridges include radial and axial adjustment. The comprehensive toolholder range serves a variety of applications and wide selection of insert types, shapes and sizes.

QC MODULAR TOOLHOLDER

- Insert indexing and chips can bring your high-volume, small-part turning operations on Swiss-style machines to an immediate halt. Constrictive work spaces and multiple tools situated in extremely close proximity to one another make insert indexing difficult, time consuming and inefficient. At the same time, poor chip evacuation leads to reduced tool life for toolholders and cutting inserts.

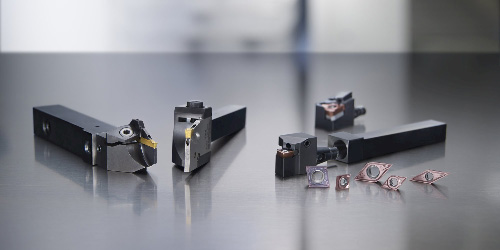

Grooving and Parting-off

- No matter the material, component size, surface finish or accuracy requirement, we have a grooving or parting-off solution that can enhance your productivity and profitability – from flexible products that work across a variety of part types to dedicated tools that solve unique challenges.

MDT - Multi-Directional Turning and Grooving

- The Seco MDT (Multi-Directional Turning) is universally suitable for variety of applications including grooving, profiling, turning, parting-off, and threading. The unique Secoloc™ clamping delivers the best stability and safety in addition to high productivity and performance. Applications include turning parts with many different diameters, complicated profiles and grooves, replacing the need for several standard and special tools with a single Seco MDT. Further savings can be achieved through fewer tool changes and reduced tool stock. The unique insert clamping method – Secoloc™ -- combines a V-shaped top clamp with serrated contact surfaces between the underside of the insert and the toolholder for superb stability. The relatively long insert also increases stability. MDT is available also in combination with Jetstream Tooling®, a high-pressure cooling system directing coolant supply to the cutting edge.

150.10 - Parting-Off

- Optimized for parting-off applications, the Seco 150.10 consists of a high-speed steel blade that holds the insert and a holder that retains the blade. This setup provides maximum stability, while the hot strength of the high-speed steel ensures the insert will be securely retained especially when the blade is hot. 150.10 is also available in combination with Jetstream Tooling® Duo, a high-pressure cooling system that provides directed coolant to the cutting edge by two streams to rake and clearance surfaces.

X4 - Shallow Grooves And Parting-Off

- The Seco X4 system with a 4-cutting-edge insert is optimized for parting-off and grooving primarily small parts. It consists of indexable tangential inserts and a highly stable clamp design. These strong, dependable system components achieve high accuracy, repeatability, productivity and surface quality in external grooving and parting-off operations involving small parts and slim bars and tubes made from a wide variety of work materials.

K-Style - Precision Grooves

- The Seco K-Style system is intended for radial and axial as well as external and internal precision grooving. The range of grooving inserts includes inserts for most groove profiles, such as circlip profiles, O-ring profiles, thread undercut and radius grooves.

Mini-Shaft - Small Diameter Internal Grooving

- The Seco Mini-Shaft™ system consists of holders and inserts for internal turning, grooving, precision grooving, profiling, backfacing and threading. It can be used in holes as small as 8 mm (Mini-Shaft™ 08) or 11 mm (Mini-Shaft™ 11). Seco Mini-Shaft™ also features a new type of joint, with a double serration, making the connection both stable and secure. It also gives very good repeatability (±0.02 mm).

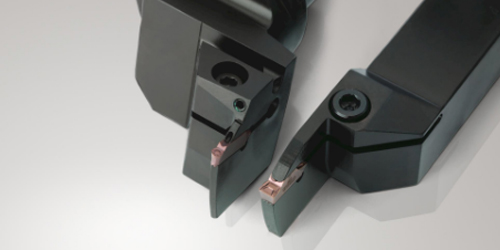

X2 - Grooving And Parting-Off

-

The Seco X2 System with a 2-cutting-edge insert is optimized for parting-off, grooving, turning and back turning primarily small parts on sliding-head machines. It consists of indexable tangential inserts and a highly stable clamp design. This strong dependable system achieves high accuracy, repeatability, productivity, and surface quality in external operations involving small parts such as medical components, slim bars and tubes made from a wide variety of work materials with high precision standards.

- Inserts with 2 cutting edges

- Good insert repeatability up to +/- 0,025 mm / 0.001 inch

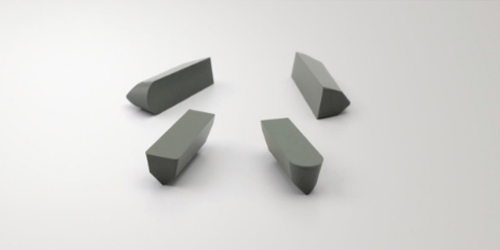

Advanced Cutting Materials (PCBN PCD Ceramic)

-

Our team of advanced cutting materials experts is continuously looking for new ways to use PCBN, PCD and ceramics to develop Secomax™ cutting tools that bring exceptional productivity and tool life to the machining of difficult, highly abrasive materials.

PCBN (Polycrystalline Cubic Boron Nitride)

This advanced material comes as a result of sintering micron cBN powders with various ceramic binders to create extremely hard and thermally stable cutting tools. Within this category, we have a wide variety of grades specifically developed for machining hardened steel, pearlitic cast iron, hard iron and superalloys.

PCD (Polycrystalline Diamond)

This advanced material has a level of hardness that is comparable to natural diamond. Within this category, we have several tools that can handle both hard and tough materials as well as plastics, graphite, copper and brass.

Ceramics

The high-speed capabilities of this advanced material result in metal removal rates that are four to eight times greater than carbide. Within this category, we have grades that offer optimized wear resistance and toughness in the machining of nickel-based heat-resistant superalloys.

PCBN General Turning - ISO Inserts

-

We formulate our Secomax™ PCBN grades to significantly reduce production costs when machining hardened steel, pearlitic cast iron, hard iron and super alloys.

PCBN (polycrystalline cubic boron nitride) is an advanced material that comes as a result of sintering micron CBN powders with various ceramics to create extremely hard and thermally stable cutting tools.

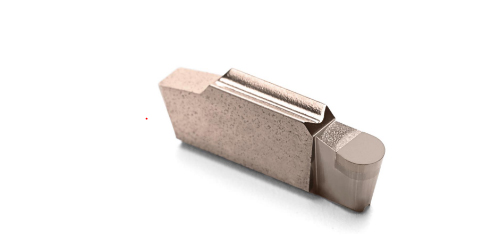

PCBN Grooving and Parting-Off Inserts

-

Secomax™ PCBN grades for grooving and parting off significantly reduce production costs for applications in hardened steel, pearlitic cast iron, hard iron and superalloys.

PCBN (polycrystalline cubic boron nitride) is an advanced material that comes as a result of sintering micron CBN powders with various ceramics to create extremely hard and thermally stable cutting tools.

PCD General Turning - ISO Inserts

-

We formulate our Secomax™ PCD grades to significantly reduce production costs when machining aluminum alloys, titanium and other non-ferrous materials.

PCD (polycrystalline cubic diamond) is an advanced material that comes as a result of sintering together selected diamond particles at high pressure and temperature.

Ceramic General Turning - ISO Inserts

-

Our Secomax™ ceramic insert grades provide optimized wear resistance and toughness when cutting parts from heat-resistant superalloys, such as Inconel, MAR, RENE, Nimonic and Waspaloy, at high speeds.

In fact, the high-speed capabilities of ceramics result in metal removal rates that are four to eight times greater than carbide. But to effectively utilize ceramic grades at high speeds, the workpiece setup and machining conditions need to be as stable as possible to prevent chipping of the grade.

Ceramic Grooving and Parting-off Inserts

- Our Secomax™ ceramic insert grades for grooving and parting off provide optimized wear resistance and toughness when working with heat-resistant superalloys, such as Inconel, MAR, RENE, Nimonic and Waspaloy, at high speeds. Effective application of these grades requires an extremely stable workpiece setup and machining conditions to prevent the possibility of chipping.

Crossbill PCBN General Turning - ISO Inserts

- PCBN Solid Inserts for finish hard turning  Crossbill Â, Wiper from Seco  unique and patented design.

Seco Capto Cassette

-

RANGE OVERVIEW

- 4 Seco-CaptoTM holders (Right and Left C5 and C6)

- 5 cassettes (R1203, R1204, R1207, C1204 and C1207)

Holemaking

-

When it comes to holemaking, selecting the most appropriate tooling and machining strategies for your application is critical. Therefore, we offer one of the industry’s most comprehensive selections of drills, reamers and boring tools. So, whether your focus is on volume, accuracy or cost savings, we have a tool that is perfect for your needs.

Our applications experts can also help you identify the best tool for producing your desired hole size and quality in the most cost efficient and productive way possible. Drilling

-

Seco has a full range of drilling products, including solid carbide drills, exchangeable tip drills and indexable insert drills. This wide portfolio of products provides solutions for all applications and workpiece materials across all industry segments, including automotive, energy, medical and more.

With optimized coatings, tip geometries and insert designs, Seco drills create high quality holes with high productivity.

Diameter range 0.1 – 160 mm (.004 – 6.299 inch) with hole tolerances from IT7 to IT12.

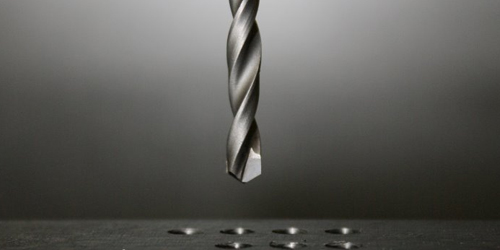

Solid Carbide Drills

-

Incorporating a wide range of geometries, coating and diameters, Seco’s diverse portfolio of solid drills excels across a broad spectrum of workpiece materials, from steel to stacked composites and difficult-to-machine materials. With diameters as small as 0.1 mm (.003 inch), our range covers a comprehensive array of applications for varied industry segments, including medical and aerospace.

Optimized geometries provide options for challenging applications, including irregular exit shapes. With these tools you can use high feeds and cutting speeds and achieve close hole tolerances with geometries suitable for all workpiece materials.

Diameter range 0.1 – 20 mm (.003 – .787 inch) with hole tolerances from IT7 to IT12.

Exchangeable Tip Drills

-

Seco’s exchangeable tip drills incorporate geometries and coatings that ensure high performance and productivity, while minimizing cost by eliminating the need to regrind or replace drills. Additionally, the ability to change tips for different workpiece materials and application requirements reduces the amount of tooling inventory that must be kept on hand.

Diameter range 10 – 25.99 mm (.393 – 1.023 inch) with hole tolerances from IT9 to IT10.

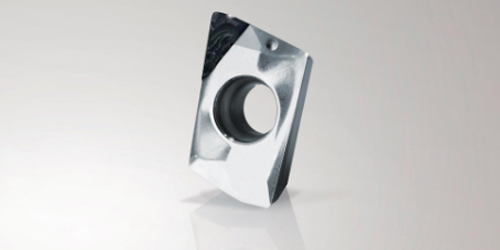

Indexable Insert Drills

-

Seco’s range of Perfomax™ indexable insert drills features strong square inserts with four cutting edges, high drill body stability, a low friction coating, unique chip flute design and inserts with modern grades that use Duratomic® technology.

The DP3000 Duratomic grade provides Perfomax an edge when it comes to strength. This extremely tough grade offers superior heat resistance, allowing it to be used in a wider application range to give you increased versatility and a greater output.

DP2000 is the easy choice if you are interested in decreasing your costs and boosting productivity. With Seco’s Duratomic technology providing the grade with a thicker coating, you will find it to be extremely resistant to heat and exceptional for drilling at high speeds in steel and cast iron.

T250D is the first choice for heat resistant materials and inserts in this grade feature sharp cutting edges to minimize heat generation during the drilling process. This results in long tool life and excellent hole quality.

Perfomax has continuously improved over the last two decades, leading to a highly productive, reliable and economical solution for drilling holes. Through its unique features, Perfomax offers you significant cost reductions through high application security, versatility, higher output and reduced tool cost.

Diameter range 15 – 160 mm (.590 – 6.299 inch)

Boring Heads

-

Boring requires use of the right tool to achieve the desired hole characteristics of position accuracy, hole geometry and surface finish. Our extensive line of boring heads and bridge bars gives you right solution for your particular holemaking applications.

We offer one-stop shopping for all your boring needs:

Rough boring heads

Axial and radial fine boring heads

Bridge bars and Jumbo bridge bars for large diameter boring

Vibration damping boring solutions

And when our standard boring product range meets its limits, we also offer custom boring solutions to meet your difficult machining challenges.

Rough Boring

- Seco’s range of rough boring products maximize material removal rates and accuracy through strong, highly rigid performance. Available in symmetrical and staggered designs, these boring heads pair well with Steadyline™ vibration damping holders for even greater levels of stability.

Fine Boring

- Covering a wide range of hole sizes and materials, Seco’s fine boring product families allow for precision adjustments within microns and achieve surface finishes of Ra

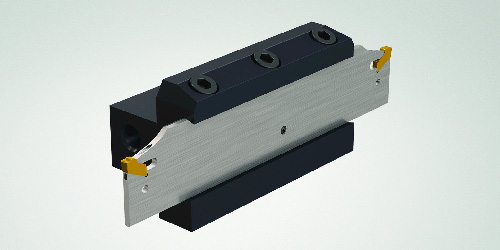

Bridge Bars

-

Seco offers a complete range of Bridge Bars and Jumbo Bridge Bars for large diameter boring, overturning and grooving. Seco Bridge Bars and Jumbo Bridge Bars feature internal through-coolant capabilities towards the cutting edge.

Offering better results and higher quality than milling by interpolation, use of Bridge Bars and Jumbo Bridge Bars lowers machining times and creates less stress on the machine spindle.

Designed for maximum flexibility, Bridge Bars are offered in a large range of diameters as standard products, covering a diameter range of 204 - 655 mm (8.03 - 25.78 inch). A variety of boring blocks is available for each operation, including rough boring blocks for symmetrical or staggered rough boring, fine boring blocks and counterweight block for fine boring and a Graflex block to mount A78050 fine boring heads for overturning operations. Bridge Bar holders are designed for an angular orientation every 30 degrees, making it easy to store bars in machine magazines.

Seco Jumbo Bridge Bars are made of high tensile aluminum with steel interfaces, and cover the 654 - 2155 mm (25.75 - 84.843 inch) diameter range. The modular concept of the Jumbo Bridge Bars uses standard Bridge Bars and boring blocks for excellent flexibility, precision and reliability. The boring blocks are easily clamped and adjusted within the Bridge Bar using a CAM driving mechanism, then the Bridge Bars are clamped within the Jumbo body.

Through-coolant supply of up to 70 bars directly to the cutting edge is available on the A731S Bridge Bars and Jumbo Bridge Bars.

Reaming

-

Our broad selection of high quality, easy-to-use reamers are perfect for advanced machining and large batch production.

These holemaking products range from 3 – 154.5 mm in diameter and feature optimized cutting grades and geometries for achieving high productivity in all workpiece materials.

Precimaster Plus - Exchangeable Head Reamer

-

Precimaster™ Plus is a modular reamer system that boosts reaming speed, stability and versatility for more precise, cost-effective hole production.

Building on the success of the original Precimaster, the system features an innovative high-precision connection, solid-carbide disposable heads as well as common holders for blind and through-hole applications. Such enhancements enable size tolerances held to between 15 and 25 microns and surface finishes of Ra. 4 to Ra. 8.

Nanofix - Solid Carbide Reamer

-

Nanofix Solid Carbide Reamers are designed for small diameters from 2.97 to 12.05 mm (.117" - .474").

These versatile reamers have internal coolant with a simple adjustable system so the outlet style can be set for either through or blind bore, depending on application. The Nanofix produces hole quality of IT7.

Featuring the patented Quick-Fit clamping system, Nanofix holds the entire diameter range with only two holders. This precise quick tool changing system reduces the time needed to change tools and eliminates the need to recheck the overall length and positioning when replacing reamer. Plus with only two shank sizes, only two sizes of Quick-Fit holders are needed thereby reducing the number of items in stock.

This multi-tooth solid carbide reamer is available in three geometries: EB45, EB845 and EB25. The range includes coated and uncoated grades. Nanofix is also available in a shorter length, which is great for lathe and compact applications.

Bifix - Single Blade Adjustable Reamer

-

Bifix™ indexable blade reamers bring high-precision performance to all workpiece material groups. These products can achieve a hole tolerance of IT6 and a surface finish of Ra 0.25 thanks to three cermet guide pads and an accurate adjusting system.

These reamers are highly cost effective in that their indexable blades feature two cutting edges per blade. They are also extremely versatile thanks to their optimized geometries, various grade options and two coolant designs for producing either through holes (chips push forward) or blind holes (chips push backwards).

Production security is also a top priority for these reamers as they come with a strong clamping system as well as provide optimal chip evacuation via internal through-coolant channels.

Xfix - Large Diameter Adjustable Reamer

-

Xfix™ large-diameter, multi-tooth reamers are all about bringing the highest possible performance and precision to hole production. And, thanks to a modular construction shank and extension program, they can achieve cutting depths up to 6.5xD within a diameter range of 39.5 – 154.5 mm.

These reamers are quick and easy to adjust. A precision manufactured insert pocket for the back taper requires no adjustment, while only one screw is required to set the diameter and secure the insert.

The patented pre-loaded guiding pads system used with these reamers guarantees the stability of the cutting process and ensures reliable tool life.

Xfix reamers come with inserts that have either four or eight numbered edges and take advantage of the latest in coatings technology for an overall cost-effective holemaking solution.

Four edges inserts are to be used when cutting long chipping material to guarantee optimal chip control. Eight numbered edges inserts will offer low cost consumable cost in short chipping cast iron.

Nanojet - Solid Carbide Reamer

-

Nanojet Solid Carbide Reamers are designed for small diameters from 1.461 to 9.960 mm (.057" - .391").

They hold tolerances from 10 µm-15µm (.0.0005"-0.0007”)

Seco Nanojet offer an innovative coolant outlet that delivers a precise and powerful stream right to the cut.

Exeptionnal coolant performance contributes to optimize chip control, tool life and production safety for greater productivity.

Bifix - Single Blade Adjustable Reamer

- Bifix™ indexable blade reamers bring high-precision performance to all workpiece material groups. These products can achieve a hole tolerance of IT6 and a surface finish of Ra 0.25 thanks to three cermet guide pads and an accurate adjusting system.

These reamers are highly cost effective in that their indexable blades feature two cutting edges per blade. They are also extremely versatile thanks to their optimized geometries, various grade options and two coolant designs for producing either through holes (chips push forward) or blind holes (chips push backwards).

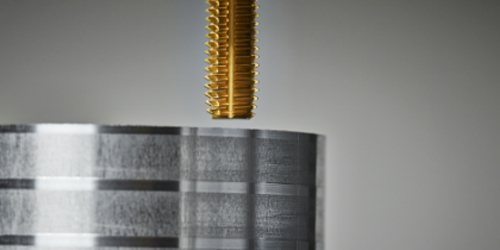

Threading

- Seco’s incredibly diverse and comprehensive array of threading products can help you optimize your application, whether you’re turning, milling or tapping threads. Regardless of the thread form you require, we offer a product that will maximize your productivity, minimize cost and achieve the level of quality your customers require. Additionally, our unique Threading Wizard software assists with selecting the right tool for your application and then generates code that can be used directly on your machine

Thread Turning

-

Our comprehensive selection of thread turning solutions for internal and external applications make it possible to produce high-quality threads in all sizes and profiles. From direct-pressed single-point inserts to innovative toolholders to intuitive software, we have everything you need to increase your productivity and profits.

To help take the guesswork out of threading operations, our Thread Turning Wizard software eliminates complicated programs and calculations. Requiring minimal input, the Wizard selects the best holder and insert for the application, identifies the best operating parameters and then downloads the information to the machine tool’s CNC.

Snap-Tap - Laydown Insert Threading System

-

We use advanced manufacturing processes to produce the precision cutting edges on our Snap-Tap® thread turning tools. The process eliminates the need for secondary grinding or honing operations, which makes these tools a highly economical choice. Pair these tools with our Anti-Twist Toolholders and solid suggestions from our Thread Turning Wizard software and there’s no thread turning application you can’t handle.

Our popular range of Snap-Tap® thread turning tools are available in three insert chipbreaker geometries for the successful machining of steel and stainless steel. While each geometry serves a unique purpose, they all feature the CP500 grade that features a highly wear resistant PVD coating to provide dependable machining for a large majority of common thread turning applications.

The innovative toolholders made for use with Snap-Tap® inserts offer the best possible holding power available for long tool life and high accuracy. They employ an Anti-Twist insert locking system that features a carbide pin in the back of the insert pocket that resists wear and prevents the insert from turning or twisting under pressure during machining. For added insert and toolholder rigidity, a D-style clamp securely pulls the insert down and into the pocket.

Multi-Directional Turning - Thread Turning

- The highly stable and reliable Seco MDT (Multi-Directional Turning) system consists of holders and inserts that offers excellent performance in thread-turning operations. Products are available for both external and internal threads. Its unique clamping method is a combination of V-shaped top clamp and serrated contact surfaces between the underside of the insert and toolholder, resulting in superb stability.

Mini-Shaft - Small Diameter Internal Thread Turning

- The highly versatile Mini-Shaft™ consists of inserts and holders providing stable, high-precision internal threading operations. Mini-Shaft features a special double-serrated joint that creates a secure connection point for its exchangeable inserts and toolholders, resulting in a repeatability of +/- 0.02 mm ( +/- .0008 inch). All toolholders can accommodate R- and L-handed inserts and have through-coolant possibility. Possible for use in holes as small as 8 mm ( 0.315 inch).

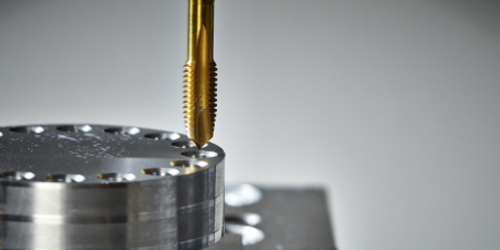

Thread Milling

-

Thread milling is a versatile, cost-effective process for anyone cutting a variety of threads, parts and workpiece materials on the same machine. Our solid carbide thread mills, multi-tooth indexable insert cutters and Threading Wizard software make it easy to adopt this process and produce high-quality threads with excellent form and finish.

In general, thread milling generates superior burr-free surface finishes and reduces tool inventory costs. Shops can use the same tool for both left and right-hand threads as well as for different thread tolerances. A broad range of materials and hole diameters can also be thread milled with the same tool. Unlike tapping, threads produced through milling can be machined to full depth at high accuracy, even in hardened materials.

Threading Wizard

This software takes the guesswork out of thread milling operations by eliminating calculations and simplifying the programming process. With minimal data input, the software selects the right tool for the job, identifies the best operating parameters and then downloads the information to the CNC.

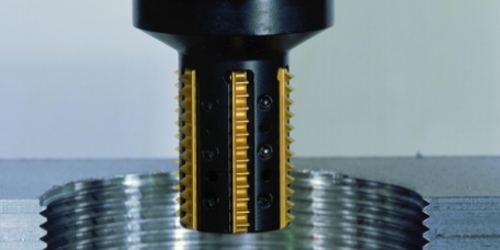

396.18/19/20 - Insert Cutters

- Seco 396.18/19/20 thread mills are versatile, cost-effective process tools for anyone facing a variety of threads, parts and workpiece materials on the same machine. Multi-tooth indexable insert cutters use a double sided multi-tooth insert usable above Ã14 mm for both internal and external threads. Note the 396.20 has only one cutting side usable from Ã70 mm. The mills have up to 9 inserts for faster production time. A 40-mm insert is available with different thread profiles and pitches. Precision ground for perfect thread forms, it is available in our tough and durable F30M grade.

Threadmaster - Solid Thread Mills

-

Threadmaster™ thread mills provide high thread quality at low cost per hole. Machining up to 100 percent depth, Threadmasters have high helix angles that reduce cutting forces and eliminate chatter. They feature an excellent carbide substrate and TiCN-coating for high toughness and wear resistance milling aluminum, steel, stainless steel and cast iron. For high-temperature alloys, versions with through-coolant holes further improve chip evacuation, tool life and surface finish. Threads range from M4 to M20 in M, MF, UNC, UNF, NPT, NPTF and BSP thread profiles.

Threadmaster – H thread mills are designed for hardened materials from 45 – 60 HrC. Threads range from M4 – M16 in M and MF thread profiles.

Threadmaster – 900 thread mills are designed for steel and stainless steel with a tensile strength of >900 N/mm2. Threads range from M4 – M14 in M and MF thread profiles.

Threadmaster – Mini thread mills are designed for thread sizes from M1 – M2.5 in hardened materials from 45 – 60 HrC.

Threadmaster - Drilling Thread Mills

- Drilling Threadmaster is a multi-tool producing a thread by drilling and chamfering in a single pass for high thread quality at a low cost per hole. Short chips are effectively evacuated at the spiral flutes. These tools feature an excellent carbide substrate and TiAlN-coating for high toughness and wear resistance milling aluminum and cast iron. Threads range from M4 to M16 in M, MF, UNC, UNF and BSP thread profiles.

335.14 - Mini Disc - Thread Milling Cutters

-

Generate precision threads in holes as deep as 106 mm with SecoÂs new single raw Disc Mill 335.14 interchangeable threading heads and matching holder shanks. You will also be able to boost processing speed and versatility, as each head performs both chamfering and threading operations. Additionally, performing two operations with the same tool helps reduce required tooling inventories.

Other threading tools are limited in terms of either thread size and/or maximum hole depths they can thread. The new heads, unlike standard thread mills, are single raw disc mills that circular interpolate an entire hole depth and create threads pitch by pitch, which allows for greater achievable depths. The cutting action of the new heads also keeps chip sizes to a minimum and ensures taper-free deep-hole threading.

Smaller, less powerful machine tools can now easily generate big threads because the new heads cut with a single point. The heads thus require less machine power and torque.

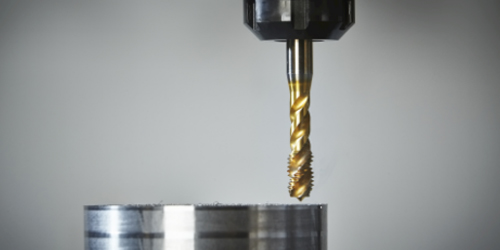

Thread Tapping

- With over 300 unique products, Seco’s range of threading taps covers a broad range of ISO P, M, N and K materials. Including straight-flute, spiral helix, helix point and form-type taps, this family incorporates specially engineered coatings that boost performance, lengthen tool life and maximize versatility. Tap are available for all common thread sizes and pitches and can produce blind and through holes.

Threadmaster Taps – Blind Holes

- Seco’s range of 351 helix- and 73 straight-threading taps for blind holes are available for general-purpose and material-specific applications. Many are available in both with and without internal coolant in both helix- and straight-fluted taps. Tap dimensions for general purpose range from 3 mm to 64 mm and in thread profiles M, MF, UNC, UNF, G, NPT and NPTF. Material-specific (ISO P, M, and N) helix taps cover 1.6 mm to 30 mm in thread profiles M and MF. Straight fluted (ISO-K) thread profiles cover 3 mm to 42 mm in thread profiles M, MF, UNC, UNF and G.

Threadmaster Taps – Through Holes

- Seco’s range of 280 helix point- and 73 straight-threading taps for through holes are available for general-purpose and material-specific applications. Most come with or without internal coolant in both helix point- and straight-fluted taps. The tap dimension range for general purpose covers 2 mm to 36 mm in thread profiles M, MF, UNC, UNF, G, NPT and NPTF. For material-specific (ISO P, M, and N) helix-point taps, the range is from 1 mm to 30mm in thread profiles M and MF. Straight-fluted (ISO-K) thread profiles range from 3mm to 42mm in thread profiles M, MF, UNC, UNF and G.

Threadmaster Taps - Forming

- Seco’s range of 120 general-purpose forming threading taps for both blind- and through hole are available with and without internal coolant. The range is from 1 mm to 48 mm in thread profiles M, MF, UNC, UNF and G.

Tooling Systems

-

Seco allows you to get the most out of both your machine and tools by offering a comprehensive range of toolholders to connect them.

Our diverse range includes workpiece-side types with Steadyline built-in vibration damping, high precision collet chucks, a broad selection of hydraulic chucks and all common types. Seco’s modular holders feature Graflex, Combimaster, Seco-Capto and BA/GL connections. These products feature machine-side connections for HSK-A-E-T, DIN, BT, ANSI, PSC (Seco-Capto) and Cylindrical.

Rotating Holders

- Seco range of rotating holders allow you to get the most out of both your machine and tool by offering a comprehensive array of solutions to connect them. This diverse portfolio includes Steadyline tooling with built-in vibration damping. The range covers all standard workpiece side connections, as well Seco’s unique connections. Machine side connections are included for most of the norms, including HSK-A-E-T, DIN, BT, ANSI, PSC (Seco-Capto) and Cylindrical.

Stationary Adapters

- Seco offers a comprehensive product range of stationary adapters that can be used in horizontal or vertical lathes, machining centers and sliding-head and multi-tasking machines. These products can be used in spindles, turrets, sub-spindles and half-turrets.

Operating Accessories

- Seco offers a wide variety of operating accessories to ensure you get the most out of your tooling systems.

Setting Accessories

- Seco’s range of setting accessories allow you to quickly and correctly set tools to ensure your application benefits from the full accuracy capabilities of your tooling and holder.

Shrinkfit Devices

- Our range of Shinkfit devices can meet the needs of any manufacturer, offering fast performance and incredibly reliable precision. These systems incorporate automatic heating cycles and efficient cooling cycles that use forced air or water cooling bells. Additionally, the use of stop rods for height setting further ensures stability, reliability and accuracy.