- Offer Profile

- Marking is indispensable

today in virtually all areas: Batch data on medical packaging, data on

production and shelf life on your yoghurt tub, logistics information on

parcels for dispatch...

Weber Marking Systems are ubiquitous – whether as end user, in industry, in the trade or as service provider, they are with you every day and virtually everywhere. Our innovative coding and labeling systems are behind all these variable data. From laser and inkjet systems via printing dispensers and special labeling systems, all the way to RFID solution concepts: The Weber Marking name always stands for easy recognition, clarity, traceability, control and safety through individual marking.

Labeling Systems

-

Labelers for your perfect Print and Apply solution

Our labeling systems will automatically label your products and packagings of all kinds. Weber Marking Systems manufactures efficient labelers to meet the most stringent demands of logistics and industry. We also develop customised solutions for specific print-apply applications. Please contact us for personal consultation!

- For all shapes, sizes and surfaces

- Simple integration into production lines

- Modular design for increased flexibility

- 2 in 1: printing and dispensing labels

- Linking to external databases

- Service incl. assembly / commissioning

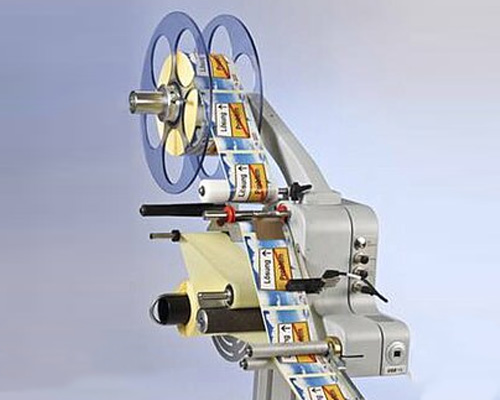

Label applicators

-

A label applicator is a type of labeling system that applies pre-printed labels to products or packaging – fast and accurately. Our various label dispensers are the solution to virtually any industry and logistics application. The label applicators can be adapted to suit the demands of the customer, thanks to our cutting-edge modular system made in Germany. Contact us for a free expert consultation!

- Modular design for maximum flexibility

- Easy integration into production lines

- Robust dispenser enclosure

- High positioning accuracy

- Continuously variable speed control

- Short set-up times during batch changes

Alpha Compact

-

Alpha-Labelers work quick, reliable and without any difficulty. The system is characterized by a simple handling and an enhanced scope of operation.

The operation concept is consistently modular designed. Changing the label size via calibration function is as easy within a few seconds possible as changing the label roll. Furthermore calibrated sets of parameter can be memorized and remain also in case of an interface change. Generally there are three different types of interface. A simple and uncomplicated operation via simply designed panel. Enhanced operation field and full parameter access via display. Professional mode without display or panel controlled via USB and parametered. The cabinet indicates consciously similarities to Alpha V40. This ensures a simple exchangeability.

Advantages:

- In the cabinet integrated controller

- Modular user interface (operation panel, display, PC-parametered)

- User menu also available in Cyrillic

- USB-Interface allows up- and downloadof labeler set-up

- Enhanced reliability and performance

- Modular system concept

Technical Key-Features:

- Label Size max. 120 x 300 mm

- Application Speed max. 50m/min

- Rotating shaft encoder of 0-50m/min (infinitely speed adjustment)

- Application Rate up to 600 pcs./min possible

- Application Accuracy +/‐ 0,8mm

- Weight 22 kg

- Environmental Temperature 10‐38°C

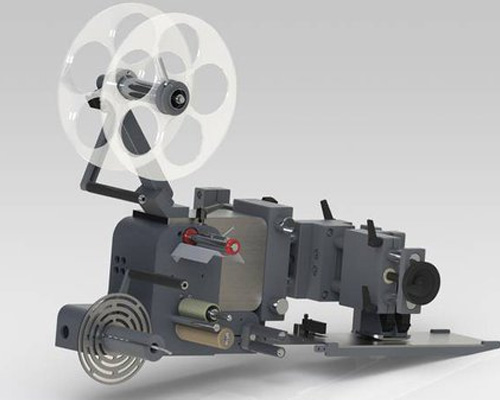

Labeler Alpha HSM

-

Extremely flexible within limited space

More power, higher speeds, easier operation: Our label dispenser Alpha HSM offers more than just excellent performance. Almost like a chameleon, it perfectly adapts to its environments thanks to its unique modular design. It applies pre-printed labels to products and packaging in high speed. High performance servomotors offer very high accuracy in automatic labeling.

All main components and functions can be customized to meet your specific demands. Thanks to their own drives and special adapters, for example, the label feeders and unwinders can be mounted location-idenpendently, while the basic module with the dispensing unit is integrated directly into the production line. In addition, different basic modules and dispensing tongues can also be selected. This creates maximum flexibility in the integration in confined spaces. Plus: With its special housing, Alpha HSM achieves IP65 protection and does not need to be covered when used in damp and dusty environments or during wet-cleaning.

Depending on the system, labels with widths of 10 mm to 320 mm can be dispensed and label rolls with a diameter of up to 500 mm can be processed. Labeling speeds of up to 150 meters per minute or clocking frequencies of up to 2,000 labels per minute can be achieved.

Both the input and the storage of different labeling parameters as well as functions and the calibration of the sensors can be stored in the Alpha HSM. The system can be controlled with the aid of various PLC modules. A web-based control is also possible.

- Protected against dust and moisture (protection rating IP65)

- About 65 modules allow individual adjustment of all functions

- Feeders and rewinders can be mounted anywhere thanks to their own drives

- Labeling speeds of up to 2,000 labels or 150 meters per minute

- Short set-up times for product changes

- All adjustable parts of the device are highlighted in color

- Can store up to 10,000 parameter settings

- Automatic parameter settings via Datamatrix codes

- Suitable for connection to customer-specific PLCs

- Web-based control possible via Wi-Fi

- Individual service portal with support documents

Alpha Quadro

-

The right label at the right time

The new Alpha Quadro label dispenser offers you totally new possibilities in the field of labelling products and packaging. This system’s special feature: several different label rolls can be processed simultaneously. The Alpha Quadro guarantees high labeling performance and application accuracy, combined with high processing speeds at production and conveyor lines.

An innovation addressing the growing market demands for labelling of a multitude of different products. Diverse product shapes can be labeled in the most confined of spaces – from rectangular to round. Up to four different labels may be kept ready for automatic application to passing products, in arbitrary sequence and combination. The special belt applicator enables compensation for tolerances in product position. Integrated detection of the height of different products allow labels always to be applied at a specific position relative to the size of the product. The Alpha Quadro can also be fitted with well-known standard applicators such as blow or tamp-blow units.

Tamper Evident labeler

-

A core requirement of the European Directive 2011/62/EU that will come into force by 2016 is to equip the outer packaging of medicals with a tamper evident feature. Which should ensure the customer that he is the first opening the package.

Demands form different markets worldwide are showing the need for combined and integrated solutions to cover latest developments in industrial production and supply chain.

Counterfeiting is the illegal production and sale of goods, including packaging, bearing without authorization a trademark which is identical to a validly registered trademark or which cannot be distinguished from such a trademark.

Weber’s unique scope of supply are turn-key soloutions including, but not limited to:

- Labeling systems; in-line and off-line

- Inkjet printers / Coding Systems

- BarCode reading / verfication

- Database software labels (verification and security labels)

- Full Service and installation supplies

A Track and Trace system is a mass serialization solution for pharmaceutical, cosmetics and food companies that prints a unique identifying code onto each product. By this, each individual product could be tracked throughout the whole supply chain, from production to the end consumer, and helps manufacturers significantly reduce counterfeiting by ensuring products can be easily identified.

Weber Marking Systems combines Tamper evident (first opening verification) PLUS traceability or serialisation PLUS anti counterfeiting protection.

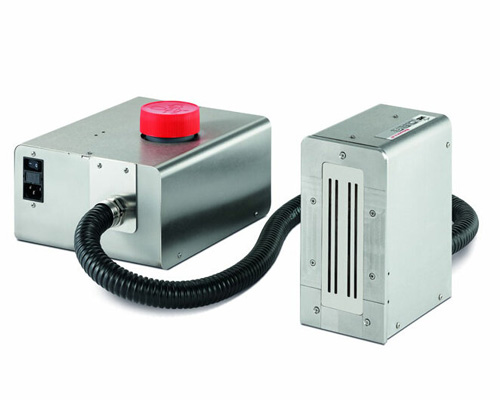

Laser applicator: Alpha-Laser

-

Cost-effective, reliable marking with laser dispenser Alpha Laser

The laser labelling solution comprises an Alpha label dispenser and a Solaris CO2 laser. The Alpha-Laser writes variable additional information such as best before dates, graphics or logistics data on pre-printed labels immediately before application.

The compact Alpha-Laser labels reliably and cost-effectively especially where large batches are processed and must be traced. This technology is ideally suited especially for harsh environments since the laser, as the printing unit, is considered virtually non-wearing compared to conventional printing methods.

The laser has a significantly longer service life by comparison and guarantees significantly higher availability, with no consumables or pressure bars. It ensures uninterrupted production. The laser writes all information – also batch and lot numbers – on any part of the labels, with or across the direction of travel. The laser can write in black on laser-activable labels with a special finishing coat. No decomposition products are created and the labels are not damaged. The print is smear- and scratch-resistant.

The advantages of the Alpha-Laser in a nutshell:

- Any type of label made of paper or foil or foil-laminated material can be used

- Printing on a coating that can be activated exclusively by laser

- Printing of information in pre-printed color fields

- Writes codes and graphics

- No consumables

- Low maintenance

- Smear- and scratch-proof marking

- High marking speeds

- High process reliability and low running costs.

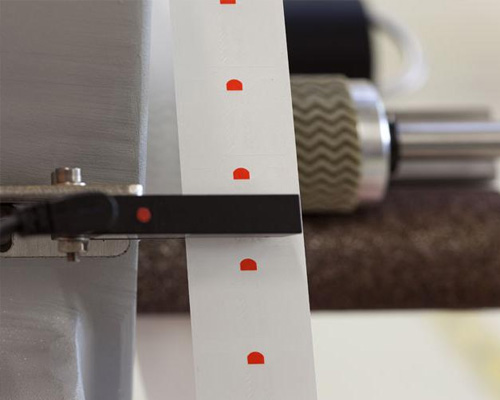

Alpha TIJ

-

Label dispenser Alpha with multifunctional inkjet-printer

The Alpha TIJ comprises a label dispenser of the proven and renowned Alpha series and a thermal inkjet printer. With the Alpha TIJ variable information is printed without physical contact onto possibly pre-printed labels immediately before dispensing. No labels are wasted/lost when print data changes and previous data are automatically excluded when the product changes. Using the cartridge ink technology, labels with up to 50 mm high symbols and a resolution of up to 600 dpi can be printed neatly and quickly. Data transmission to the print heads is 1:1. Real time printing without batch processing is also possible. A wide variety of quick drying inks and colors is available for a wide range of applications on diverse surfaces.

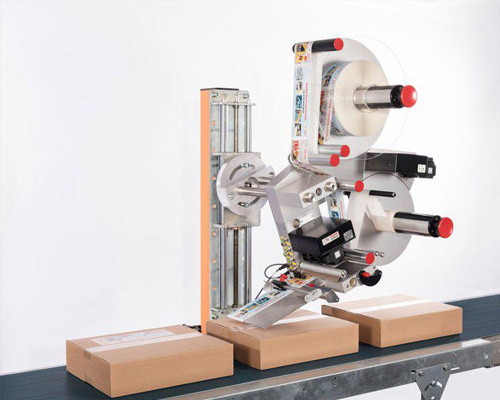

Print-apply systems

- Label printer and applicators that meet your demands!

Our print-apply label machines print labels with variable data before they apply them fully automatically to your products or packages.

Print-and-apply labeling systems combine a label printer and a label dispenser in one single machine. Our label printer applicators will automatically print and apply labels to your products, cartons or pallets – in one single process. Since each production process is customised, we use a clever modular system to guarantee you the optimal labeling solution that meets your specific demands.

- Modular design for maximum flexibility

- For labels of any sizes and shapes

- Top precision at high speed

- For running or clocked operation

- Connectable to external databases

- Service incl. assembly / commissioning

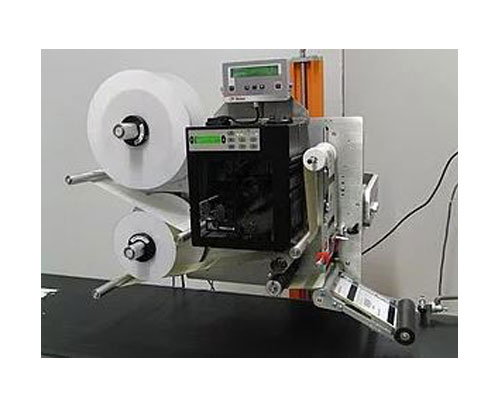

Label printer and applicator Legi-Air 2050

- The inexpensive Legi-Air 2050 label printer applicator is a compact reliable workhorse. Contactless, reliable and accurate labelling for simple production and packaging lines. It can also be used in semi-automatic mode at workstations, such as in the electronics industry, mechanical engineering or in the automotive and supply industry.

The Legi-Air 2050 is available with three different print resolutions (203 dpi, 305 dpi or 609 dpi). Select one of five starter kits with four label rolls and a corresponding stamp plate to suit your label format.

Contactless and variable labelling

From stamp format to DIN-A6 size: The Legi-Air 2050 has a robust Tamp-Blow label applicator, which applies the labels to products and packaging contact-free. Depending on the label material, format and application, cycle rates of up to 30 labels per minute can be achieved. The variable dispenser hub allows automatic labelling of products of different heights. The system constantly monitors whether the labels are in the correct position until they are applied.

Long range, easy operation

When it comes to performance until the next reel change, the Legi-Air 2050 comes easily out ahead of similar solutions in the market because it can handle larger label rolls (outer diameter of 218 mm) and thus apply an average of 20% more labels. The large ribbon length of 600 m also ensures exceptional durability. The easily accessible design makes it quick and easy to replace ribbon or labels.

Label printing without compromise

The printer used is a SATO of the CLNX series with 300 dpi resolution. The printer works with many programming languages such as ZPL, DPL, IPL, and TPL without having to change any settings. In case of an error message, you can watch a video on the printer's screen to help you troubleshoot the problem.

Label printer and applicator Legi-Air 6000

- Endurance, speed and precision are important features ‒ not only in sports, but they are often pivotal in industry and trade as well. In the mail order business, for instance, cartons must be labelled quickly and reliably. At 2,400 cycles/hour, the high performance labelling machine Legi-Air 6000 from Weber Marking Systems will rapidly and accurately label passing product cartons with heights varying up to 500 mm.

After a sensor upstream has measured the height of the approaching product to label, the applicator will travel to its correct position at lightning speed. This reduces the travelling distance during labelling, whilst simultaneously also dispensing labels more accurately and up to 50 percent faster than applicators using pneumatically driven cylinders. Its consistently lightweight design sporting carbon fibre components for the moving parts is also instrumental. The applicator is ca. 80 percent lighter than conventional models.

Powerful lightweight saves energy

Another advantage: Since the dispensing applicator needs no compressed air, but travels by servo-motor, it also saves costs. Compressed air is used only for the application of labels with the tamp-blow method.

Enduring, easy-care and adaptable

A microprocessor controller optimises cost and space requirements. No separate control cabinet is required, allowing perfect integration of the compact unit into the production environment.

Productive time will also be longer and maintenance time shorter. The Legi-Air 6000 can process large rolls up to 350 mm in diameter - this means 600 m of labels in line – the maximum ergonomically justifiable size of roll! System availability between roll changes is therefore increased.

The industrial printing modules used in the applicator are state-of-the-art. Due to their special design, the most important components are easily accessible for servicing or maintenance. Overall, the Legi-Air 6000 distinguishes itself through its outstanding availability, since the modular design allows a high degree of customisation, thus hardly ever requiring the attendance of a service technician. The applicator will also travel to a service position above the print head in the event of an error, allowing convenient exchange of labels and foils and easy cleaning of the print head.

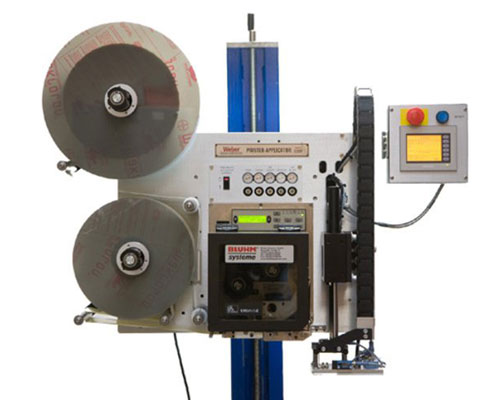

Legi-Air 4050 E

- Legi-Air 4050 E is a robust and proven print & apply system that meets all the requirements of a modern labeling system far beyond what is demanded today. Thanks to its consistent modular design, the system can be individually adapted to the particular application:

Printing modules from all leading manufacturers can be used in the Legi-Air 4050 E. The wide range of labeling applicators available and very stable. They allow any labeling position and apply very precisely even in high-speed applications. The latest version of the Legi-Air 4050 E has proven technology as well as some new highly interesting technical features.

BENEFITS-

Reduced compressed air consumption

The modulated vacuum reduces air consumption by up to 80 %: To do this, the integrated sensors measure permanently the pressuse. The valve technology makes adjustments, if needed. -

Minimum wear

Due to the motorized operation of not only the winder but also the unwinder, the print module wears out less. At the same time, this makes the prints extremely precise. -

No maintenance parts

The print & apply system is designed completely without maintenance parts. Components are only replaced as required. Only the print modules need to be maintained according to the relevant manufacturer's specifications. -

Modular design

The Legi-Air 4050E has a consistently modular design and can thus be individually adapted to the requirements of the respective application. The labels can be printed with print modules from all leading manufacturers. -

Machine safety according to EN415-10

Legi-Air 4050 E meets all EN415-10 requirements as standard and is safe for the operator. For applications requiring higher dynamics, the system can be upgraded with an emergency stop system. -

Unique support concept

The revolutionary service concept enables Bluhm Systeme service technicians to see the ACTUAL status of the machine offline from a distance: At the push of a button, the machine generates three QR codes in which all machine-relevant information is encoded. The operator photographs these and sends them to the Bluhm service team. -

Industry 4.0. capability

Optionally, Legi-Air 4050 E is available with an additional N-Controller. Furthermore, it is OPC UA-capable (Open Platform Communications United Architecture). With this state-of-the-art Industry 4.0 interface, advanced connectivity with other devices is possible, as well as the exchange of information that goes beyond simple signals. -

Convenient handling

Legi-Air 4050 E can easy be operated via the multilingual 7" LCD touch display. Messages like error diagnostics, productivity and maintenance status as well as other events can be monitored. The pneumatics are easily accessible outside the system.

-

Reduced compressed air consumption

Pallet labeling system AP 182

- Label pallets on up to three different sides without protective fence

This compact print-and-apply system marks pallets from one position on up to three different sides with the help of a highly flexible applicator arm.

Seven triggerable positions not only allow GS1-compliant pallet labeling on the front and side of the pallet, but also applying two different labels on one side. In addition, a three-sided labeling of pallets (forehead, side, back) is possible.

The system achieves a top speed of 120 pallets per hour when labeling of two sides and 90 pallets per hour when labeling three sides.

AP 182 not only reduces costs, but also customer expenditure, since it does not require a protective fence or protective barrier due to its intrinsically safe design.

The standard version already includes special features such as the usability of label rolls with a diameter of 350 millimeters, the possibility of connecting a scanner for barcode verification, as well as electrical slides and spring-loaded stamps for optimal label application in your logistics.

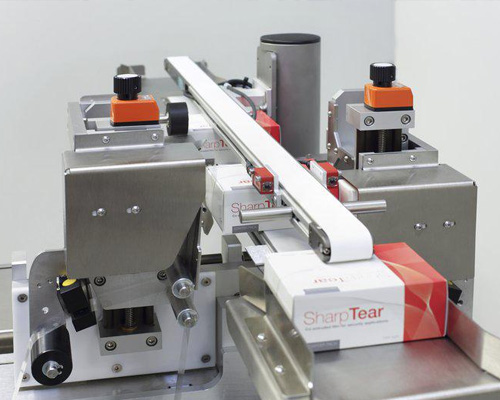

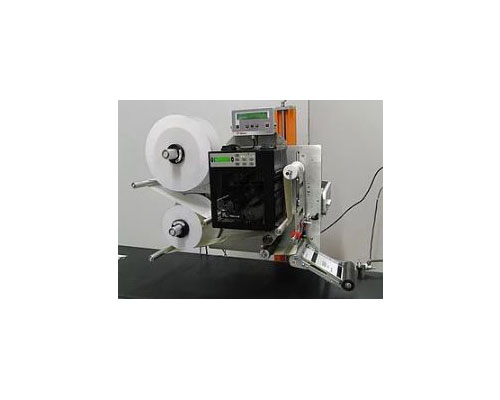

Label printer and applicator Legi-Air 4050 AC Shuttle

- The new Legi-Air 4050 AC Shuttle Label Print and Apply System is a high-performance labeller for maximum speeds. Systematic refinement of the Alpha Print is evident via a whole series of technical features, making the system a particularly fast labeller, at the same time as ensuring consistently high print quality.

On Print and Apply Systems it is often the print module which determines the working rate. This is not the case with the new Legi-Air 4050 AC Shuttle. A loop device ensures a ready supply of labels which are custom-printed before being dispensed at unusually high speeds onto the passing products. The capacity of this storage device means that even higher cycle speeds of short duration can be achieved. A check is kept on the loop by a dancer roller to ensure there is a supply of labels present. The benefits of this variant are ease of use and the compact system design. Labelling capacity may be up to 20 times greater than printing capacity. Print speeds of up to 16 m per minute and conveyor speeds of up to 50 m per minute can be achieved.

Label printer and applicator Legi-Air 5300

- Legi-Air 5300, the modular label printing and application system from Weber Marking Systems, stands for extreme versatility with high operator convenience and long operating time. It offers flexibility, quality and effectiveness for all labeling tasks.

Operator convenience

This is given by numerous functions, such as the service interval indicator and operating status display, both of which report the forthcoming service date and any malfunction, for example due to the exhaustion of consumables, among other options via signal or by e-mail to a pre-determined e-mail address. The multilanguage, plain text display can be positioned as desired and is thus always easily accessible to the operator, even in cramped production conditions. The built-in web browser offers the option to view the current service status, including by remote diagnosis.

Flexibility

A range of labeling options is available for the widest variety of tasks, for example linear, rotating and corner applicators as well as applicators for two-sided labeling. As far as the printing of labels is concerned, there is a choice of tried and tested industrial print modules from several manufacturers – RFID print modules for programming radio chips are also available in this context.

High quality

Labels are printed in very high resolution in a single operation. Due to its robust, durable design, LEGI-AIR 5300 is also suitable for installation in harsh production environments.

Versatility

Selection can be made from a variety of operating modes – including the label air blast process (Tamp-Blow, Blow-Box) for contactless high-speed labeling.

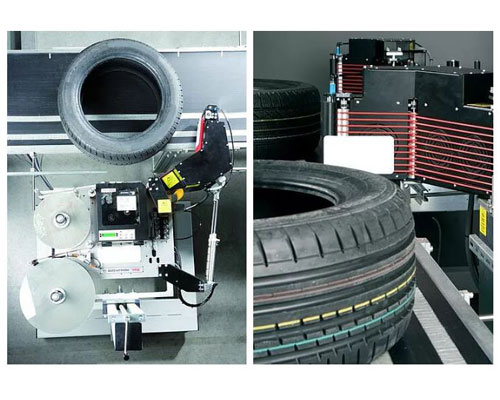

Tire label printer and applicator Legi-Air Tyre

- Fast, accurate, safe

Effective in 2012, the EU Commission will require tire manufacturers to comply with new labelling guidelines aimed at clarifying the safety and performance characteristics of tires. The Legi-Air 5300 Tire Labelling System from Weber Marking Systems is ideally suited to meet the new EU guidelines. The system is fast, reliable and easy to integrate into any existing production process. In addition, we offer custom, pressure-sensitive labels specifically designed for any type of tire. Let us show you how to transform this new labelling obligation into your advantage!

Identification is Weber Marking’s specialty. As your partner in Labelling and coding, we have developed a unique label printing and application solution that features flexibility, quality and efficiency in addressing the needs of tire manufacturers. The LEGI-AIR 5300 Tire Labelling System safely, quickly and consistently produces perfectly positioned labels. It also optimizes the product identification process to provide a positive impression on consumers, thanks to accurate label placement and a strong brand impact.

The system prints top-quality labels at very high resolution in a single operation. The robust and durable construction of this unique Labelling system makes it ideal for use in the challenging environment of the tire production industry. Successive products always are properly labelled, even with changing product identification requirements, and the system detects any loss of labels or faulty triggering.

Continuously changing products and information can be accommodated without wasting labels. The LEGI-AIR 5300 Tire Labelling System is versatile enough to communicate via existing data controllers or interfaces. Functions like service interval alerts or operating mode display are very user-friendly. These functions will, among others, report via a signal or by e-mail when service is due or report a malfunction caused by depletion of a consumable. The plain text, multilanguage display can be freely positioned. The installed web browser also enables the current servicing status to be inspected by remote diagnosis.

Pallet labeling system

AP 182

- Label pallets on up to three different sides without protective fence

This compact print-and-apply system marks pallets from one position on up to three different sides with the help of a highly flexible applicator arm.

Seven triggerable positions not only allow GS1-compliant pallet labeling on the front and side of the pallet, but also applying two different labels on one side. In addition, a three-sided labeling of pallets (forehead, side, back) is possible.

The system achieves a top speed of 120 pallets per hour when labeling of two sides and 90 pallets per hour when labeling three sides.

AP 182 not only reduces costs, but also customer expenditure, since it does not require a protective fence or protective barrier due to its intrinsically safe design.

The standard version already includes special features such as the usability of label rolls with a diameter of 350 millimeters, the possibility of connecting a scanner for barcode verification, as well as electrical slides and spring-loaded stamps for optimal label application in your logistics.

Tamper evident labeler

Label dispenser Tamper Evident

- A core requirement of the European Directive 2011/62/EU that will come into force by 2016 is to equip the outer packaging of medicals with a tamper evident feature. Which should ensure the customer that he is the first opening the package.

Demands form different markets worldwide are showing the need for combined and integrated solutions to cover latest developments in industrial production and supply chain. As a label dispenser, our Tamper Evident machine can be integrated in your production line and help you fulfill the requirements set in the European directive.

Automatic labeling machines

Adapt your labeling system to individual requirements and local conditions with up to 50 different modules!

Geset 200: Economical labeling line with adjustable parameters

- Our Geset 200 series is a cost-efficient solution for common labeling positions, e.g. all-round labeling of cylindrical products. The labeling systems manage without an additional control cabinet and have a frequency converter for uniform control of the transport and winding belt. Commissioning is particularly easy and intuitive thanks to the start/stop button. Proven label dispensers such as the Alpha Compact or Alpha HSM are used in the system.

Geset 300: Rotary labeling machine / two-side labeler

- Our Geset 300 automatic labeling machine basic concept is for two-sided labeling of odd-shaped bottles without using shaped sets. The adaptation to specific products is achieved by simple adjustment of the machine's components. Geset 300 labeling machines can handle label sizes up to 250 mm high and at clocking rates up to 250 labels per minute. Alignment and therefore highly accurate positioning of the labels is achieved in transport.

Geset 700: Customised solutions to meet specific requirements

- Whether special guidelines apply or oddly shaped products need to be labelled: We will develop your optimal labeling machine based on our unique modular system comprising more than 50 modules. This allows us to ensure that your solution will be economical even for highly specialised applications.

Industrial inkjet printers

-

Markoprint: drop on demand inkjet printers

Look forward to better print results and increased uptime! Our industrial inkjet printers distinguish themselves from other labeling systems through exceptionally high efficiency and innovative features. With our wide range of printing systems and technologies, Markoprint coding solutions meet every system environment and customer requirement. Whether large or small fonts, high-speed applications in pharmaceutical or automotive industries, rough industrial environments, we offer the right system for every application. The best materials, the most innovative ideas, this is Quality made in Germany. Our developments result in first-class, highly complex solutions that are still extremely easy to use. Aluminium is our preferred product material, preferably made of one piece. A guarantor for durability, sustainability and your success!

- Top performance on all substrates

- Compatible with leading ink technologies

- Ideal for uneven and sensitive products

- Robust design for industrial applications

- Compact systems for easy integration

- Simple to operate and maintain

Markoprint integra One / integra One IP

-

Compact thermal inkjet printer for system integrators

Our Markoprint Integra One inkjet printer was specifically developed for an easy system integration for when space is limited. Its integrated display allows system settings to be changed and checked as well as variable fields to be edited directly on the system.

The Markoprint Integra One IP is also available with IP65 rating (dust and splash water protected), making it safe for use in harsh production environments. Equipped with the well-proven HP inkjet technology, the system will print text, bar codes, 2D codes, expiration dates, batch numbers, etc. up to 12.5 mm high and with up to 900 dpi. With various water- and solvent-based inks available for the system, high-quality prints can be achieved on almost any surfaces such as paper, cardboard, painted surfaces, foils and plastics.

The intelligent HP SmartCard cartridge monitoring ensures consistently excellent printing results. It identifies the current ink type and automatically sets the appropriate ink parameters, which makes the changing of ink cartridges significantly safer, easier and faster. The printing system detects opened cartridges and always reports the current ink level to the controller. So there are no unexpected production stops and the operator can provide replenishment in time! Thanks to the patented Click'n'Print cartridge holder, replacing is quick and easy done with just one click.

integra Ultimate

-

HP printhead with IP65 protection and for up to 25 mm print height

Our Markoprint integra Ultimate is a particularly efficient inkjet printer with an innovative HP printhead. With print heights of up to 25 mm and IP65 enclosure rating, this system takes your coding tasks to a completely new level!

Since the printhead closes itself at standstill and automatically cleans the nozzle plate every time it is closed and opened, it is immediately ready for use even after a longer break. This makes it ideal for use in wet-cleaned or dusty production environments, such as those found in wood industry, pharmaceutical industry or food industry.

Markoprint integra Ultimate also scores good marks in integrated systems with closed or difficult-to-access areas: Its cartridges can easily remain in the printhead during downtimes. After a production stop of several days, an error-free printing can be carried out without first wiping the cartridge or having to do a spitting.

Markoprint integra Ultimate is also suitable for UV inks when printing on smooth surfaces. Due to its special features, the open times will increase immensely: With the right ink from Markoprint it is possible to have decap times of up to (and even more than) 72 hours, instead of just 15 minutes!

Advantages of the Markoprint Ultimate HP printhead:- IP65 protection when the printhead is in sleep mode: perfect for use in humid, dusty and wet-cleaned environments.

- Cartridges do not need to be removed during long breaks, e.g. at weekends.

- Cartridges do not require "spitting" during short breaks, in hard-to-reach installations.

- Due to the closed system, the cartridges are not exposed to external influences during standstill.

Markoprint IP-JET HP Mk2

-

Compact inkjet printer with IP 65 protection rating

The IP-JET HP Mk2 inkjet printer was specially developed for use in harsh environments with high exposure to dust and moisture. Unlike many other printers on the market, the printhead has excellent protection and requires no cover or dismantling during washdown.This solution is particularly well suited for use in Food & Beverage and also in industries such as plastics, pharmaceutical and chemical industries. The compact system combines the printhead and controller in one.

Tolerant against dust and moisture

The sealed enclosure and waterproof interface prevent moisture ingress and dust particle contamination. The unit is also powered via a special mains power unit with a waterproof M8 plug. The external connections have plug-in connectors with IP67 class protection.

Proven HP printing technology

With the latest in Hewlett Packard printing technology, the system will print text, barcodes, 2D codes, best-before data, batch numbersetc. up to 12.5 mm high and with resolutions up to 600 dpi. The water- and solvent-based inks used by the system open the door to many applications: paper, cartons, varnished surfaces, foils and plastics are printed with highly legible and permanent print. The system is operated via only 3 buttons with LED status lights, for ease of operation and user friendliness.

SmartCard: intelligent cartridge monitoring

Intelligent SmartCard cartridge monitoring ensures consistently good print results. It will identify the current type of ink and adjusts the relevant ink parameters automatically. The SmartCard will also capture and store the specific ink fill level. The printing system detects used cartridges and reports current ink fill levels to the controller. This eliminates unexpected production downtimes, allowing the operator to arrange for replacements in good time. Quick and easy with a single hand movement - thanks to the patented Click'n'Print cartridge holder!

Markoprint integra PP 108

-

We proudly present the first Markoprint inkjet printer with SEIKO printing technology. Markoprint integra PP 108 has a circulating ink system. It automatically removes air from the nozzle rows to ensure durable, clean print images. The system is level independent which means that the ink tank can be installed above, below, or at the same height as the print head without any problems. The new SEIKO printhead has a print height of 108 mm and achieves a remarkable speed of up to 150 meters per minute (with a high resolution of 360 dpi).

Your benefits with Markoprint integra PP 108:

- No air pockets in the nozzle rows

- High resolution of up to 360 dpi vertical

- High printing speed of up to 150 m / min (at 360 dpi)

- Prints small fonts from 1 mm as well as high-resolution graphics and logos

- Prints grayscaleEasy start-up and airing of the ink system

- Internal ink tank with large ink supply

- Printing height of up to 108 mm without offset

- Pigmented MOF oil ink (mineral oil-free): ideal for printing on absorbent surfaces in the food industry

Markoprint X2JET plus Touch

-

The particularly compact and cost-effective Markoprint X2JET plus Touch system is ideal for the foodstuffs, chemical, building materials and pharmaceutical industries. The innovative inkjet printing system marks absorbent and semi-absorbent surfaces. Fast, accurately and reliably.

Intelligent high speed control system for demanding marking applications. Four printing technologies can be controlled simultaneously.

- Touch surface to operate the system easily

- Parallel operation using a standard keypad and function keys

- Networking possibilities using TCP/IP, USB and EIA232

- Possibility of printing on up to two production lines

- Simultaneous marking of primary and secondary packaging using a controller

Piezo (MX, XR)

- 50/100 mm with one printhead

- robust industrial printer

- absorbent surfaces

- coloured inks

- secondary packaging

- large volume of ink

Thermal Inkjet (HP, LX)

- New printhead on each cartridge

- Wide selection of inks

- Absorbent, hardly absorbent and non-absorbent surfaces possible

- Robust industrial printer

- High resolution (600 dpi)

- Different colours

Markoprint X4JET plus Touch

-

The intuitive input unit of the new high performance Markoprint X4JET plus Touch inkjet printer is a boost to operator convenience. All system parameters can be entered easily and quickly, to be stored and called up later.

Markprint X4JET plus Touch is an intelligent high-speed control system for demanding marking applications. Four printing technologies can be controlled simultaneously, printing 3 to 400 mm high fonts and barcodes, as required. This new, compact solution enables printing on both sides of primary as well as secondary packaging and on one or two independent production lines.

- Touch surface to operate the system easily

- Parallel operation using a standard keypad and function keys

- Networking possibilities using TCP/IP, USB and EIA232

- Possibility of printing on up to two production lines

- Simultaneous marking of primary and secondary packaging using a controller

High print results

Markoprint X4JET plus Touch offers high availability and print results of the highest quality. Datamatrix, MHD and batch marking can, for instance, be printed on primary packaging and particularly large barcodes, company logos and certification marks may be applied to secondary packaging.

And all this blindingly fast: Because the Markoprint X4JET plus Touch manages up to 3 000 serializations per minute. The compact control unit can be conveniently integrated into existing conveying systems or into control cabinets.

The Markoprint X4JET plus Touch targets not only the foodstuffs industry, but especially also the pharmaceutical industry and system integrators - wherever reliable, fast and flexible printing is required. Using the iDesign software, print layouts can be quickly and intuitively designed by anyone. With simultaneous 1:1 data transmission, the high demands of the pharmaceutical industry are satisfied. No batch processing or downloads necessary. The number of conventional interfaces guarantees fast and smooth communication with higher level data systems.

Markoprint Integra Quadro

-

Highspeed-Controller for up to 4 inkjet printheads

The new print controller Markoprint integra Quadro controls up to four inkjet printers, at up to four printing positions simultaneously or alternately. For example, it makes it possible to print on both primary and secondary packaging on one or two independent production lines. You could even use two different printing technologies (HP, Trident, Funai or Xaar).

Thanks to its compact design, Markoprint integra Quadro can easily cope with confined spaces. The existing mounting options make installing within or directly on the industrial line very easy. It has been specifically designed to be integrated into cabinets and machines.

Printing barcodes, text, numbers, symbols and 2D codes with an inkjet printer has never been faster! Depending on the print content and the printing technology used, a fast printing speed of up to 240 m / min at 300 dpi is possible. The intuitive control panel makes it easy to change the print and label settings locally. The powerful Markoprint iDesign software is available for designing and managing print layouts.

The Markoprint integra Quadro has all common interfaces such as Ethernet and USB, which allows the data to be transferred to the printheads 1: 1 and printed in real time without batch processing.

Markoprint Integra Quadro²

-

Compact and robust inkjet printing controller for up to 8 printheads

Markoprint integra Quadro² is an inkjet system controller similar to the X4JET, but without a user interface. It is the "big brother" to our Markoprint integra Quadro. Integra Quadro² is ideal for applications where data and task information is entered from another source, whether it is a local PC, network location, PLC or other integrated device.

By controlling up to 8 print heads, integra Quadro² is able to mark packages on two sides, or simultaneously mark products at 4 different production lines. The system is perfectly suited for fixed installation in control cabinets by top hat rail mounting. It has a dual-channel controller that can print on both primary and secondary packaging simultaneously. The controller supports 4 different printing technologies: HP Class, LX Class, MX Class and XR Class.

Key benefits- Simultaneous marking on primary and secondary packaging

- Controls up to 8 printheads for up to 4 production lines

- Ideal for fixed installation in control cabinets since fully remote-controlled from different interfaces

- Transfer print layouts via network connection, EIA232 or USB

Markoprint X1JET

-

A small, compact, independently operating printhead for an easy integration in already existing production lines: Inkjet printer Markoprint X1JET is designed for different range of applications i.E. food & beverage, chemical, coated / uncoated materials, timber and the pharmaceutical industry.

- Easy to use: No training necessary: printing with the Markoprint X1JET is simple, due to 3-logic intuitive operation with LED status light. Data transmission is is initialized with USB stick / interface.

- Universal and flexible use: Markoprint X1JET uses True Type fonts for printing. All conventional 1- and 2-dimensional codes* can be printed. The controller is fully integrated into the print module.

- Control: Different performing system versions are available, with different functional features, depending on application requirements: Print, Basic, Advanced and Pro. The basic system version allows data transmission via USB stick. Each controllerhas a network connection (LAN) or a standard EIA-232 interface. Print layouts are created with iDesign software.

- Wide range of standard accessories such as rotary/shaft encoders, flexible bracket and mounting brackets. Also a wide range of water- and solvent-based inks to work with many applications.

Markoprint X1JET MX

-

With Trident technology: perfect for large character coding

The Markoprint X1JET MX is an independently operating industrial inkjet printer, especially suitable for the coding of large printing images. The Trident Piezo Inkjet technology codes on flat, absorbant surfaces, quickly, accurately and reliably. This compact & well-priced system is designed for different ranges of applications i.E. food & beverage, chemical and building material industry.

- Well-priced technology for the printing of layouts directly on carton material

For each application the right system

The print heads are available in two different versions: For printings at 50 mm maximum height and for printings at 100 mm maximum height. The Markoprint X1Jet MX is available in 3 different variations: Compact, Vario and Top. The Compact version has a vertically fixed print head. The print head of the Vario version can be turned up to 90°C to the left, and allows therefore also a coding on rising conveyor belts. The Top version codes from above onto the packaging or the product.

- Printing heights up to 50 or 100 mm (depending on version)

- Simple integration into packaging systems and conveyors for printing from side or top

Universal and flexible use

Markoprint X1JET MX uses True Type fonts for printing. All conventional 1- and 2-dimensional codes can be printed. The controller is fully integrated into the print module.

- The robust and highly compact design ensures maximum application availability

- High immunity against electrical discharge

Markoprint X1JET XR

-

With innovative Xaar Piezo printhead technology

Markoprint X1JET XR 71 is a stand-alone industrial inkjet printer for controlling a Xaar Piezo printhead. The Xaar printhead belongs to the latest printhead generation with 500 individually controlled jets for a print height of 71 mm. This corresponds to a print resolution of 180 dpi. The compact “all-in-one” Piezo printer combines printhead, ink system, cleaning station, control circuitry and mains unit in one enclosure.

Operation, parameter setting and data transmission occurs via the simple and intuitive 3-key arrangement with LED indicator lamps. USB stick and Ethernet / EIA 232 interfaces are available for data transmission. The oil-based XR 980 ink is suited particularly well for printing on slightly absorbent and absorbent product surfaces. The short drying time also allows optimal printing on painted folding boxes.

Three different versions are available for varying applications:

- In the Compact version, the printhead is mounted fixed, for horizontal labelling.

- For more flexibility, the Vario version printhead is rotatable by 90° anti-clockwise.

- The Top version offers maximum flexibility ‒ the printhead is connected to the ink system via a 1 000 mm long hose.

Markoprint X1JET HP HandHold

-

Powerful handheld inkjet printer for use in multiple locations

Battery operated, the lightweight and compact inkjet printer will print high resolution text and images in multiple locations without being in a fixed position to the production line. The long-life battery has sufficient power for printing over and extended period of time. Setting up the device and upload of print images is a simple task via the use of a USB stick.

Mobile marking made easy

The compact design makes the Markoprint X1JET HP HandHold lightweight and easy to use for various marking purposes. Setting up the device and upload of print images is a simple task via the use of a USB stick.

HP ink cartridge with SmartCard feature

The cartridge technology of the X1JET HP HandHold has proven its merits a million times over and will ensure on demand, high quality, high resolution printing up to 12.5 mm. The system detects the inserted cartridge, ink and filling level automatically and sets the ideal parameters. No more manual adjusting or unexpected loss of producton!

The printer and its accessories are secured neatly in a durable case. Included in delivery:

- battery

- charger

- USB stick

- instructions

- iDesign software

Markoprint inks

-

Ink cartridges for Markoprint inkjet printers

Whether you want to increase your current print volume, improve your print results, or simply desire more flexibility and efficiency in inkjet coding, we deliver the most powerful, reliable, and cost-effective inks for industrial printing with our thermal and piezoelectric Markoprint inkjet printers. As the only manufacturer in the world, we are able to control five leading printing technologies: Our inkjet systems are compatible with the innovative ink cartridges from HP, Seiko, Funai, Trident and Xaar!

Piezo Inkjet Technology- NonStopPrinting integrated

- Efficient with 500 ml ink tank

- Optimized maintenance intervals

- High speed coding

- Font sizes from 1 to 108 mm

- Print on different materials

idesign8+ Software

-

Inkjet printer software for label design and management

Markoprint idesign provides one software package for all Markoprint printers featuring a simple user interface, update service and multi language support.

Features:- Administrating and creating print images

- Ink consumption calculator

- Unicode support: Implementation of international symbol sets for global marking

- Clear display of all connected print systems

- Unlimited number of administrated systems

- Control via Ethernet, USB or EIA232

- Start/stop of printing with database connectivity

- Status window with indication of all operational statuses via protocol function, e.g. ink levels and current printing label

- Working with overview of all running printing processes for one or more devices

- Set-up of printing parameters and configuration of print systems

- Online administration of parameters for all networked systems

- Parameter backup

- Password protection/user administration incl. GAMP 5 regulations

- Optional: iDesign Touch – optimised for Touchscreen IPCs

- Protocol function for user actions and operational statuses

- Transfer of external data, or triggering of active fields for fast and secure data transfer

- Print image change via XML or text files

- DB print for variable database printing at more than 3 000 printouts/min. of e.g. lottery codes or address labels

Markoprint ZTV HP bulk system

-

Central ink supply for Markoprint inkjet coding systems

For Markoprint inkjet printers, a new bulk ink system for central ink supply (CIS) is available for coding applications with a high consumption of ink. ZTV HP MK2 is suitable for quickly drying or solvent-based inks from Hewlett Packard.For Markoprint inkjet printers, a new bulk ink system for central ink supply (CIS) is available for coding applications with a high consumption of ink. ZTV HP MK2 is suitable for quickly drying or solvent-based inks from Hewlett Packard.For Markoprint inkjet printers, a new bulk ink system for central ink supply (CIS) is available for coding applications with a high consumption of ink. ZTV HP MK2 is suitable for quickly drying or solvent-based inks from Hewlett Packard.

Benefits of the Markoprint ZTV HP bulk system- Easy mounting of ink system

- Reliable ink delivery

- Manifold design

- Electronic interfacing to the bulk ink cartridge Ink level sensing

- Large ink system minimize operator interventions

- Advanced electronic functions enable operators to build in ink level monitors and signals to provide virtually uninterrupted printing during longer print runs

NonStop Printing

-

Forget about downtime due to cartridge changes! Our NonStop-Printing feature enables our Markoprint inkjet printers to continuous printing in ongoing production.

- Cartridge replacement or cleaning without interrupting production

- Ideal for continuously running systems such as deep-drawn packaging with several users

- Ink does not dry up since both cartridges print alternately on the same position

- Designed for HP and LX printheads

- Printing ratio 2:1 – at least 50% still remaining in one cartridge if the other is empty

- Maximum printing height 12.5 mm or 25 mm depending on printhead

- Option: Cartridge stops automatically if a connected camera detects misprints. Error-free printing with the second cartridge until replaced.

Shutter Printhead HP

-

Attention, dust and heavy air! These are the enemies of thermal inkjet cartridges: the pressure nozzle closes or the ink dries up. The result: a poor quality printed image. Weber Marking Systems offers the solution with its industry-grade self-sealing Markoprint thermal inkjet printhead with HP printing technology.

Excellent prints, under all conditions

The print head for the tried and tested HP cartridges is designed to prevent dust from entering or accumulating. And the ink does not dry out when the printing system is paused or not being used. The cartridge does not need to be cleaned in between or removed when not in use.

Automated sealing technology

Herbert Jesse, Head of Markoprint Product Development at Weber Marking Systems, explains: "During standstill of the production line, the print head automatically retracts the cartridge and closes the open nozzle plate after an exactly defined period of time - but no later than after 6 seconds". The print head receives the information via an upstream sensor or the machine control system (PLC).

As soon as a light barrier detects the restart of the production line and it is reported to the print head, the cartridge is returned to the printing position and the standard high quality printing is continued.

Inkjet printer Markoprint integra Ultimate

- HP printhead with IP65 protection and for up to 25 mm print height

Our Markoprint integra Ultimate is a particularly efficient inkjet printer with an innovative HP printhead. With print heights of up to 25 mm and IP65 enclosure rating, this system takes your coding tasks to a completely new level!

Since the printhead closes itself at standstill and automatically cleans the nozzle plate every time it is closed and opened, it is immediately ready for use even after a longer break. This makes it ideal for use in wet-cleaned or dusty production environments, such as those found in wood industry, pharmaceutical industry or food industry.

Markoprint integra Ultimate also scores good marks in integrated systems with closed or difficult-to-access areas: Its cartridges can easily remain in the printhead during downtimes. After a production stop of several days, an error-free printing can be carried out without first wiping the cartridge or having to do a spitting.

Markoprint integra Ultimate is also suitable for UV inks when printing on smooth surfaces. Due to its special features, the open times will increase immensely: With the right ink from Markoprint it is possible to have decap times of up to (and even more than) 72 hours, instead of just 15 minutes!

Label printers

- Label printers and printing modules are used in industry, logistics and trade. We can offer you the ideal label printers and barcode printers to print your own professional labels in-house. Suitable for occasional printing in the office and for ongoing production. As your official trade and service partner for renowned manufacturers of label printers such as Zebra, Sato, Epson and Datamax, we will be at your disposal for comprehensive personal consultation.

Labeling machines to print labels

For every product and purpose, there is a label to match. Whether you need a label with an elaborate design, or space for further information on a primary label, there are different ways to customise appearance, durability and stability. If the latest technology in marking and labelling is an important necessity, many of our labels are RFID-capable. With such a variety of formats available to you, Weber Marking Systems offers labels for virtually every application.

Our range of desktop printers offers you the best-possible solution in terms of resolution, label width, interface, label quantity and available options, such as blades or RFID capability. An interface handles printing of labels individually, e.g. with lot numbers from in-line production, an EAN code or barcode. Their size means they can be used whatever the time and place. The desktop printer is ready when- and wherever a label is required.

Due to the growing diversity and specialisations, Weber Marking Systems understands that every business has its unique requirements for labels and offers a wide range of labeling machines to help fulfill them. Where retail traders need plain display symbols, authorities and pharmaceutical companies demand forgery-proof markings. Some labels have to be water resistant; others must be resistant against tear and wear. With Weber Marking Systems, you will find the best solution for your business.Barcode printers

Weber Marking Systems offers you a range of barcode printers, including labelling systems and inkjet printing control systems. Barcodes have been used successfully in many industries since the 1970s and can be printed on packaging or directly on the products themselves, simplifying ordering, storing and stocktaking for various businesses.

Representing data about an item or article, barcodes are printed using optical codes that are readable by a special bar code scanner or interpretive software on computers, smartphones and other data processing devices. Weber Marking Systems provides barcode printer solutions for every requirement: bar code label printers for logistic units, quality assurance systems or for industrial processes. Additionally we supply different input units and software variants for barcode printing as well as technical support and services.Industrial label printers – sturdy with metallic housing

Weber Marking's industrial label printers are the perfect solution for automatic printing and labelling. From small systems with a broad range of applications to high-end demands with specialised needs, every industrial label printer is durable and can operate to maximum efficiency.

All applications despite complexity can be accomplished accurately and swiftly. State-of-the-art technology will streamline your operations and implement every labelling task. Once set, our industrial label printers can print and position the labels automatically on every product, tray, package or pallet that is applied to your area of business.

Due to modular construction, Weber Marking's industrial label printers can be set up for more than 1,500 different areas of operation. Depending on the label size of the rewinder or unwinder, Weber Marking can provide up to 600 linear metres per roll. Printing is available either as a direct thermal or a thermal transfer method. The standard resolution amounts to 203 dpi (8 dots per mm), but can be increased up to 600 dpi (24 dots per mm). Colour label printers

- Do you want to use a label printer to print in colour? Companies can use our colour label printers to produce their own colour labels – cost-effectively, fast and as needed. The label printers are ideal for ongoing industrial label printing and also for occasional needs in shipment, trade or the health industry. They will print multicolour graphics and images and also customised text, barcodes and sequential numbers.

- Brilliant print quality

- For every print volume

- Robust under toughest conditions

- Highly user-friendly

- Official trading & service partner

- Consumables from supplier

RFID label printers

- Label printers and printing modules are used in industry, logistics and trade. We can offer you the ideal label printers and barcode printers to print your own professional labels in-house. Suitable for occasional printing in the office and for ongoing production. As your official trade and service partner for renowned manufacturers of label printers such as Zebra, Sato, Epson and Datamax, we will be at your disposal for comprehensive personal consultation.

- Brilliant print quality (black or colour)

- For every print volume

- Robust under toughest conditions

- Wi-Fi, remote and RFID-capable

- Official trading & service partner

- Consumables from supplier

What is RFID?

RFID stands for Radio Frequency Identification. This means remote identification by radio frequency. The technology is used by send-receive systems that can automatically and remotely identify or localise objects and living beings. These RFID systems are used in a diversity of fields – in logistics, for instance.How does RFID work?

Every RFID system comprises an electronic data carrier (RFID label) and a reader (RFID reader). Both components have an antenna for communication of data. Data is communicated via electromagnetic waves.

The reader generates an AC electromagnetic field. Two-way communication takes place should the transponder be located within range. The reader can now write data to the chip or read data in memory.What are the advantages of RFID?

- Contactless process: Data are transmitted from transponder to reader/writer and vice versa via RF antennae. This requires no physical or visual contact. The RF signals can penetrate various materials. Not only does this allow for faster reading of goods, but it also facilitates reading inaccessible parts.

- Fast data exchange: The time delay between transmission and reception is virtually negligible with RF transmission.

- Bulk reading: RFID readers are capable of reading large numbers of RFID tags simultaneously. All the products on a pallet or in a shipping container can theoretically be read in a single scanning process. Virtually error-free: The initial read success of RFID labels approaches 100%. Additional reliability is offered by RFID systems that detect and eject faulty tags.

- Security through encryption: Data may be encrypted instead of transmitting in clear text, to allow access control.

- Robust: RFID tags are resistant to extreme ambient conditions such as high temperature fluctuations, heat, cold or moisture. Products that will later require special reworking or cleaning may be reliably marked using RFID.

- Reusable: As opposed to printed barcodes, RFID chip data can be edited and supplemented later.

- Invisible: The tiny RFID transponders may be inconspicuously integrated into most labels.

Where are RFID chips used?

RFID applications are many and varied. The technology is fundamentally suited for automatic marking, identification, registration, storage and monitoring of components or shipping containers. A few examples:- Production control: In industrial manufacturing, RFID chip data may be used to document a product’s production status. Further process parameters may be specified based on this information. This procedure is widely used already, especially in the automobile industry.

- Traceability: RFID tags can store all production and source data, allowing unequivocal and complete traceability along the supply chain down to location and time of production.

- Inventory management: Libraries use RF labels, among other, to control borrowing and return of media through self-service terminals.

- Store management: RFID may be deployed to automatically capture pallets at goods receipt, book them in the inventory control system and transport them to their designated shelf.

- Product protection: High-grade branded products use RFID transponders to differentiate between originals and counterfeits during authenticity checks.

- Access control and clocking: Many companies use RFID chips for automatic access control at entrances and/or to record staff working hours at designated terminals.

RFID label reader

- Portable RFID reader

- Reading barcodes

- Creating and writing EPC codes

- Checking smart labels

- Bad tag reject (manual)

RFID label printer

- Mobile desktop printer

- Reading barcodes

- Creating, writing and printing EPC codes

- Checking smart labels

- Bad tag reject (manual)

RFID label applicator

- Automatic RFID labelling

- Reading barcodes

- Creating, writing and printing EPC codes

- Checking smart labels

- Bad tag reject (automatic)

Print & Apply

- Print-and-apply labeling systems combine a label printer and a label dispenser in one single machine. Our label printer applicators will automatically print and apply labels to your products, cartons or pallets – in one single process. Since each production process is customised, we use a clever modular system to guarantee you the optimal labeling solution that meets your specific demands.

- Modular design for maximum flexibility

- For labels of any sizes and shapes

- Top precision at high speed

- For running or clocked operation

- Connectable to external databases

- Service incl. assembly / commissioning

Legi-Air 2050

- Easy to integrate, easy to operate!

The inexpensive Legi-Air 2050 label printer applicator is a compact reliable workhorse. Contactless, reliable and accurate labelling for simple production and packaging lines. It can also be used in semi-automatic mode at workstations, such as in the electronics industry, mechanical engineering or in the automotive and supply industry.

The Legi-Air 2050 is available with three different print resolutions (203 dpi, 305 dpi or 609 dpi). Select one of five starter kits with four label rolls and a corresponding stamp plate to suit your label format.

Contactless and variable labelling

From stamp format to DIN-A6 size: The Legi-Air 2050 has a robust Tamp-Blow label applicator, which applies the labels to products and packaging contact-free. Depending on the label material, format and application, cycle rates of up to 30 labels per minute can be achieved. The variable dispenser hub allows automatic labelling of products of different heights. The system constantly monitors whether the labels are in the correct position until they are applied.

Long range, easy operation

When it comes to performance until the next reel change, the Legi-Air 2050 comes easily out ahead of similar solutions in the market because it can handle larger label rolls (outer diameter of 218 mm) and thus apply an average of 20% more labels. The large ribbon length of 600 m also ensures exceptional durability. The easily accessible design makes it quick and easy to replace ribbon or labels.

Label printing without compromise

The printer used is a SATO of the CLNX series with 300 dpi resolution. The printer works with many programming languages such as ZPL, DPL, IPL, and TPL without having to change any settings. In case of an error message, you can watch a video on the printer's screen to help you troubleshoot the problem.

Legi-Air 6000

- Sporty performance with up to 2,400 labels per hour!

Endurance, speed and precision are important features ‒ not only in sports, but they are often pivotal in industry and trade as well. In the mail order business, for instance, cartons must be labelled quickly and reliably. At 2,400 cycles/hour, the high performance labelling machine Legi-Air 6000 from Weber Marking Systems will rapidly and accurately label passing product cartons with heights varying up to 500 mm.

After a sensor upstream has measured the height of the approaching product to label, the applicator will travel to its correct position at lightning speed. This reduces the travelling distance during labelling, whilst simultaneously also dispensing labels more accurately and up to 50 percent faster than applicators using pneumatically driven cylinders. Its consistently lightweight design sporting carbon fibre components for the moving parts is also instrumental. The applicator is ca. 80 percent lighter than conventional models.

Powerful lightweight saves energy

Another advantage: Since the dispensing applicator needs no compressed air, but travels by servo-motor, it also saves costs. Compressed air is used only for the application of labels with the tamp-blow method.

Enduring, easy-care and adaptable

A microprocessor controller optimises cost and space requirements. No separate control cabinet is required, allowing perfect integration of the compact unit into the production environment.

Productive time will also be longer and maintenance time shorter. The Legi-Air 6000 can process large rolls up to 350 mm in diameter - this means 600 m of labels in line – the maximum ergonomically justifiable size of roll! System availability between roll changes is therefore increased.

The industrial printing modules used in the applicator are state-of-the-art. Due to their special design, the most important components are easily accessible for servicing or maintenance. Overall, the Legi-Air 6000 distinguishes itself through its outstanding availability, since the modular design allows a high degree of customisation, thus hardly ever requiring the attendance of a service technician. The applicator will also travel to a service position above the print head in the event of an error, allowing convenient exchange of labels and foils and easy cleaning of the print head.

Overview of the Legi-Air 6000:- High performance applicator: Extraordinary fast and accurate labelling of passing cartons of varying height

- Up to 2250 cycles per hour (with DIN A6 label format and 500 mm difference in product height)

- Servo motor driven dispensing applicator: Cost reduction

- Up to 50 percent faster than applicators with pneumatically driven cylinders

- Consistent lightweight design

- Carbon fibre material for moving parts

- Longer productive times, shorter maintenance times 600 m of labels in line

- Modular design: individually adaptable to specific demands

Legi-Air 4050 E

- Legi-Air 4050 E is a robust and proven print & apply system that meets all the requirements of a modern labeling system far beyond what is demanded today. Thanks to its consistent modular design, the system can be individually adapted to the particular application:

Printing modules from all leading manufacturers can be used in the Legi-Air 4050 E. The wide range of labeling applicators available and very stable. They allow any labeling position and apply very precisely even in high-speed applications. The latest version of the Legi-Air 4050 E has proven technology as well as some new highly interesting technical features.

BENEFITS- Reduced compressed air consumption

The modulated vacuum reduces air consumption by up to 80 %: To do this, the integrated sensors measure permanently the pressuse. The valve technology makes adjustments, if needed. - Minimum wear

Due to the motorized operation of not only the winder but also the unwinder, the print module wears out less. At the same time, this makes the prints extremely precise. - No maintenance parts

The print & apply system is designed completely without maintenance parts. Components are only replaced as required. Only the print modules need to be maintained according to the relevant manufacturer's specifications. - Modular design

The Legi-Air 4050E has a consistently modular design and can thus be individually adapted to the requirements of the respective application. The labels can be printed with print modules from all leading manufacturers. - Machine safety according to EN415-10

Legi-Air 4050 E meets all EN415-10 requirements as standard and is safe for the operator. For applications requiring higher dynamics, the system can be upgraded with an emergency stop system. -

Unique support concept

The revolutionary service concept enables Bluhm Systeme service technicians to see the ACTUAL status of the machine offline from a distance: At the push of a button, the machine generates three QR codes in which all machine-relevant information is encoded. The operator photographs these and sends them to the Bluhm service team. I - ndustry 4.0. capability

Optionally, Legi-Air 4050 E is available with an additional N-Controller. Furthermore, it is OPC UA-capable (Open Platform Communications United Architecture). With this state-of-the-art Industry 4.0 interface, advanced connectivity with other devices is possible, as well as the exchange of information that goes beyond simple signals. - Convenient handling

Legi-Air 4050 E can easy be operated via the multilingual 7" LCD touch display. Messages like error diagnostics, productivity and maintenance status as well as other events can be monitored. The pneumatics are easily accessible out

- Reduced compressed air consumption

Pallet labeling system AP 182

- Label pallets on up to three different sides without protective fence

This compact print-and-apply system marks pallets from one position on up to three different sides with the help of a highly flexible applicator arm.

Seven triggerable positions not only allow GS1-compliant pallet labeling on the front and side of the pallet, but also applying two different labels on one side. In addition, a three-sided labeling of pallets (forehead, side, back) is possible.

The system achieves a top speed of 120 pallets per hour when labeling of two sides and 90 pallets per hour when labeling three sides.

AP 182 not only reduces costs, but also customer expenditure, since it does not require a protective fence or protective barrier due to its intrinsically safe design.

The standard version already includes special features such as the usability of label rolls with a diameter of 350 millimeters, the possibility of connecting a scanner for barcode verification, as well as electrical slides and spring-loaded stamps for optimal label application in your logistics.

Label printer and applicator Legi-Air 4050 AC Shuttle

- The new Legi-Air 4050 AC Shuttle Label Print and Apply System is a high-performance labeller for maximum speeds. Systematic refinement of the Alpha Print is evident via a whole series of technical features, making the system a particularly fast labeller, at the same time as ensuring consistently high print quality.

On Print and Apply Systems it is often the print module which determines the working rate. This is not the case with the new Legi-Air 4050 AC Shuttle. A loop device ensures a ready supply of labels which are custom-printed before being dispensed at unusually high speeds onto the passing products. The capacity of this storage device means that even higher cycle speeds of short duration can be achieved. A check is kept on the loop by a dancer roller to ensure there is a supply of labels present. The benefits of this variant are ease of use and the compact system design. Labelling capacity may be up to 20 times greater than printing capacity. Print speeds of up to 16 m per minute and conveyor speeds of up to 50 m per minute can be achieved.

Label printer and applicator Legi-Air 5300

- Legi-Air 5300, the modular label printing and application system from Weber Marking Systems, stands for extreme versatility with high operator convenience and long operating time. It offers flexibility, quality and effectiveness for all labeling tasks.

Operator convenience

This is given by numerous functions, such as the service interval indicator and operating status display, both of which report the forthcoming service date and any malfunction, for example due to the exhaustion of consumables, among other options via signal or by e-mail to a pre-determined e-mail address. The multilanguage, plain text display can be positioned as desired and is thus always easily accessible to the operator, even in cramped production conditions. The built-in web browser offers the option to view the current service status, including by remote diagnosis.

Flexibility

A range of labeling options is available for the widest variety of tasks, for example linear, rotating and corner applicators as well as applicators for two-sided labeling. As far as the printing of labels is concerned, there is a choice of tried and tested industrial print modules from several manufacturers – RFID print modules for programming radio chips are also available in this context.

High quality

Labels are printed in very high resolution in a single operation. Due to its robust, durable design, LEGI-AIR 5300 is also suitable for installation in harsh production environments.

Versatility

Selection can be made from a variety of operating modes – including the label air blast process (Tamp-Blow, Blow-Box) for contactless high-speed labeling.

Tire label printer and applicator Legi-Air Tyre

- Fast, accurate, safe

Effective in 2012, the EU Commission will require tire manufacturers to comply with new labelling guidelines aimed at clarifying the safety and performance characteristics of tires. The Legi-Air 5300 Tire Labelling System from Weber Marking Systems is ideally suited to meet the new EU guidelines. The system is fast, reliable and easy to integrate into any existing production process. In addition, we offer custom, pressure-sensitive labels specifically designed for any type of tire. Let us show you how to transform this new labelling obligation into your advantage!

Identification is Weber Marking’s specialty. As your partner in Labelling and coding, we have developed a unique label printing and application solution that features flexibility, quality and efficiency in addressing the needs of tire manufacturers. The LEGI-AIR 5300 Tire Labelling System safely, quickly and consistently produces perfectly positioned labels. It also optimizes the product identification process to provide a positive impression on consumers, thanks to accurate label placement and a strong brand impact.

The system prints top-quality labels at very high resolution in a single operation. The robust and durable construction of this unique Labelling system makes it ideal for use in the challenging environment of the tire production industry. Successive products always are properly labelled, even with changing product identification requirements, and the system detects any loss of labels or faulty triggering.

Continuously changing products and information can be accommodated without wasting labels. The LEGI-AIR 5300 Tire Labelling System is versatile enough to communicate via existing data controllers or interfaces. Functions like service interval alerts or operating mode display are very user-friendly. These functions will, among others, report via a signal or by e-mail when service is due or report a malfunction caused by depletion of a consumable. The plain text, multilanguage display can be freely positioned. The installed web browser also enables the current servicing status to be inspected by remote diagnosis.

Labels

Blank labels

-

Blank labels on a roll

Looking for blank labels for printing? We can offer you high-grade label rolls for your label printer – customised to suit your needs. Whether permanently adhering or peeling off without residue: Our wide range of adhesives for labels will offer you many options. We look forward to discussing your ideal solution with you.

- Top quality at attractive prices

- Personal consultation with professionals

- Customised sizes and shapes

- Wide selection of materials