- Offer Profile

-

Hermle is all about milling and achieving outstanding results.

This is clearly demonstrated by the slogan "milling at its best". It stands for high-performance, highly innovative machining centres which have risen to a leading position nationally and internationally. It stands for a far-reaching and closely meshed sales and service network and for a worldwide presence.Globally there are more than 27000 machines in use, mainly at suppliers of medical technology, in the optical industry, in aviation, in the automotive industry and in motor sport.

Hermle produces small to medium-sized three to five-axis milling centres for a wide range of applications.

Even machines for applications with increased demands on precision or machining volumes are manufactured. The different machine models are available with magazine extensions and a pallet changer. Furthermore, various handling systems are offered directly from the manufacturer.

Product overview

-

In the CNC milling machine sector, HERMLE AG is a leading manufacturer of portal milling machines, machine tools and CNC special machines. As a machine manufacturer, our claim of “milling at its best” underlines our dedication to delivering products that consistently exceed expectations in terms of performance, machining precision and service.Moreover, with almost 90 years of experience as a machine manufacturer, HERMLE AG comprehensively meets the demand for heightened precision and machining capacity across all sectors requiring advanced machine performance. We develop and produce CNC milling machines and special machines for the medical technology sector and general tool and mould making, as well as for the optical, aerospace and automotive industries. We also manufacture bespoke CNC machine tools as special machines, which are customised to suit our customers’ unique set of needs.

HIGH-PERFORMANCE-LINE

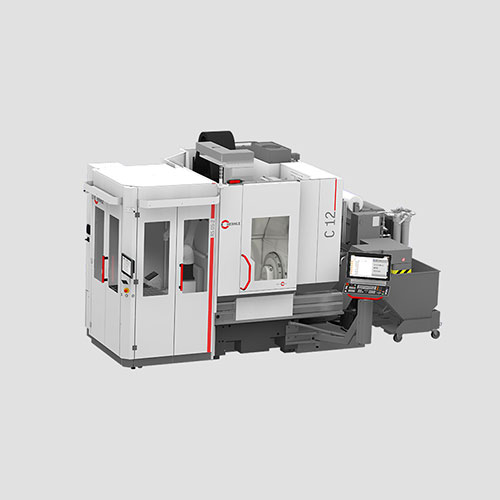

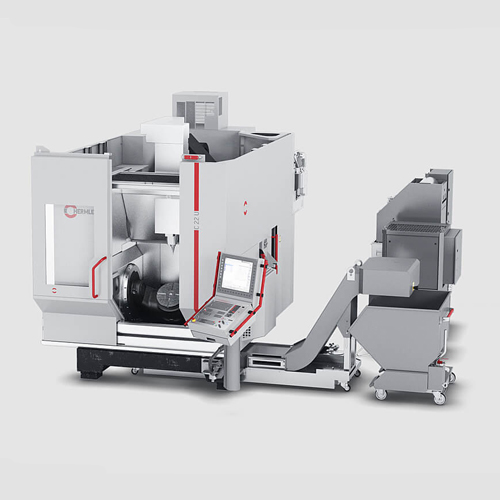

C 12 GEN2

-

Maximum efficiency combined with a small footprint: The C 12 GEN2 is the most compact HERMLE machining centre in the High-Performance Line.

Designed for machining cubic parts up to 100 kg and is more than a match for larger models. The right speed is available for practically every application. The especially compact and space-saving C 12 GEN2 machining centre meets the ever increasing demands placed on speed and precision thanks to the corresponding HERMLE setups. It goes without saying that there are also many options available for more complex applications.

From the comprehensive fluid technology to the optimised chip management system and a wide range of cooling lubricant units: The entry-level model of the High-Performance Line has a number of highlights to offer, e.g. the right chip disposal equipment for removing all types of chip from the working area. The especially compact and space-saving machining centre can be transported without being dismantled and set up without a foundation.

Machining centre C 22 GEN2

-

As the C 12’s bigger brother, the C 22 GEN2 High-Performance Line machining centre has the same collision circle with longer traverse paths and larger component dimensions – and that means a huge degree of flexibility.

This equipment impresses with a large number of features. This makes the C 22 GEN2 ideal for a particularly wide range of applications. Short process cycles, quick workflows and the highest possible machine dynamics: The flexible C 22 GEN2 machining centre is ideal for machining high-quality parts with excellent accuracy and small tolerances. As with most HERMLE machining centres, the height-adjustable control panel can be adjusted to suit the operator’s working height.

Cooling units, fluid cabinet and switch cabinet are fully integrated into the compact machine enclosure. The space-saving deployment of the chip conveyor helps both in daily operation and for maintenance and servicing. The especially flexible machining centre can be transported without dismantling and set up without a foundation.

Energy efficiency in manufacturing and operationHERMLE manufactures many components using lightweight construction and mineral casting technology. The high degree of own production, local suppliers and components with high efficiency factors also promote energy efficiency. Energy recuperation, high-quality servo drives and the legendary long service lives are all proof of the same high standards during actual operation.

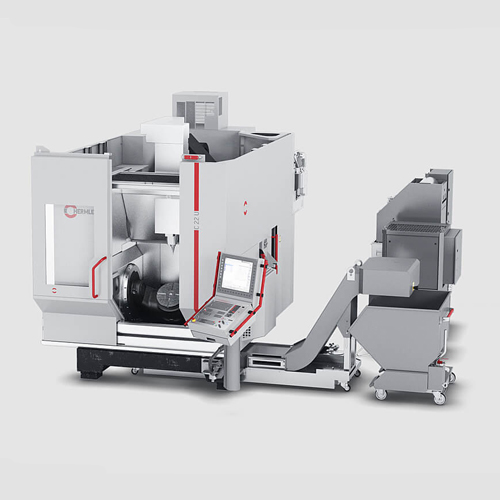

Machining centre C 32 GEN2

-

The C 32 GEN2 machining centre is able to workpieces weighing up to 1000 kg and cutting is undertaken in five axes simultaneously.

The machining centre mills even difficult-to-machine materials in record time and with perfect precision – even fully automated and always with unbeatable operating comfort! The range of applications for the C 32 GEN2 is extensive. The C 32 GEN2 machining centre has two axes in the workpiece and three axes in the tool. Dynamic positioning, short non-productive periods and secure holding in the desired machining position all go without saying. As does the very large working area in relation to the installation space. During this change process, the mechanics, which is fundamental to the precision and long-term accuracy of HERMLE products, was not altered. The key values of the machine remain exceptionally high, thereby clearly reaffirming its dominance in the field of 5-axis technology.

Numerous software and hardware components now feature cutting-edge technology. The entire electrical architecture has been revamped to incorporate ProfiNet as the communication bus, while a significant number of the sensors have been converted to IO Link (international standard). Furthermore, the entire drive network of Heidenhain machines has been revised and equipped with the latest generation of converters. These are all components that make the machines even more efficient. The entire platform introduces new technologies and functions, including cutting-edge interface technology and evaluation/diagnostic capabilities for enhanced service analysis in case of errors.

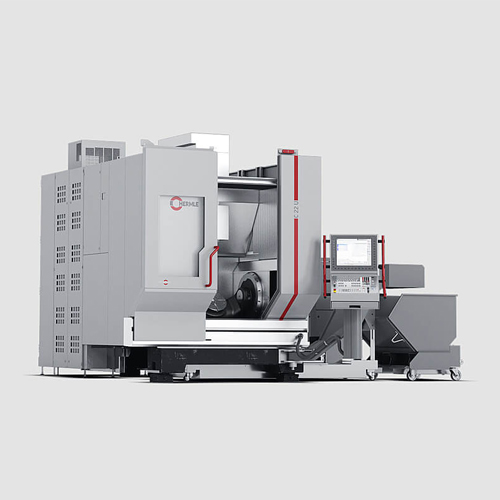

Machining centre C 52

-

C 52 / C 52 U MT Machining centre

The C 52 machining centre is a flexible multi-talent with an especially large working area and a very small footprint.With the C 52, workpieces weighing up to 2000 kg can be machined in 5 axes simultaneously – with unbeatable precision and accuracy. The C 52 sets new standards: These are particularly valued in demanding industries such as machine construction, the automotive sector and aerospace. In short: wherever the highest precision and maximum efficiency are required. Ample dimensions, high-performance spindle drives and many useful innovations for practical work turn the C 52 / C 52 U MT machining centre into a top performer.

From the comprehensive fluid technology to the optimised chip management system and a range of cooling lubricant units to the hinged belt conveyor: This High-Performance Line model has a number of highlights to offer, e.g. the right chip disposal equipment for removing all types of chip from the working area. This high-performance machining centre can be transported without being dismantled and set up without a foundation.

Energy efficiency in manufacturing and operationHERMLE manufactures many components using lightweight construction and mineral casting technology. The high degree of own production, local suppliers and components with high efficiency factors also promote energy efficiency. Energy recuperation, high-quality servo drives and the legendary long service lives are all proof of the same high standards during actual operation.

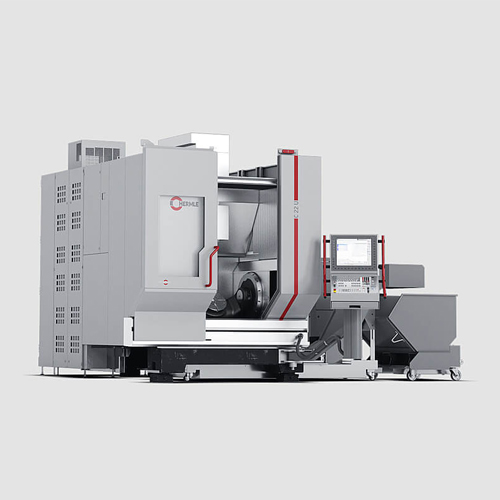

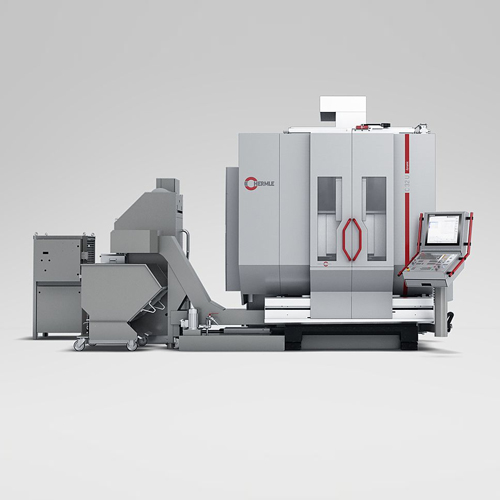

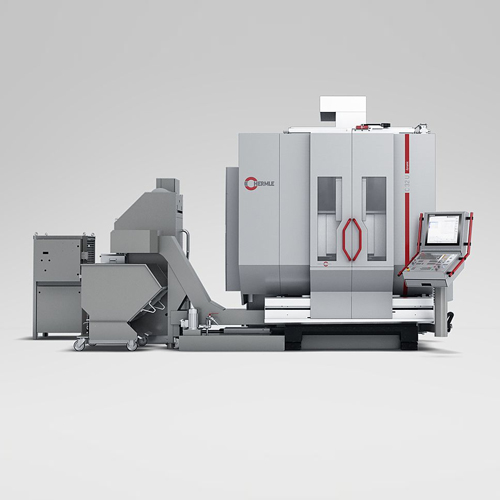

Machining centre C 62

-

C 62 / C 62 U MT Machining centre

"State of the Art" CNC machining – this is what the C 62 / C 62 U MT stands for as the top model of the Hermle High-Performance Line and the entire product range.The highly dynamic machining centre represents ultimately consistent design for efficient machining of CNS milled parts and CNC turned parts. Numerous features ensure high-precision and cost-effective working on workpieces up to 2500 kg in weight. Various optional extras simply add to the capabilities for innovative advanced machining. As with all Hermle machining centres, the C 62 / C 62 U MT offers various workpiece loading options to guarantee optimum operation.

From the comprehensive fluid technology to the optimised chip management system and a range of cooling lubricant units to the hinged belt conveyor: This High-Performance Line model has a number of highlights to offer, e.g. the right chip disposal equipment for removing all types of chip from the working area. This high-performance machining centre can be transported without being dismantled and set up without a foundation.

Energy efficiency in manufacturing and operationHERMLE manufactures many components using lightweight construction and mineral casting technology. The high degree of own production, local suppliers and components with high efficiency factors also promote energy efficiency. Energy recuperation, high-quality servo drives and the legendary long service lives are all proof of the same high standards during actual operation.

Machining centre C 32 GEN2

-

The C 32 GEN2 machining centre is able to workpieces weighing up to 1000 kg and cutting is undertaken in five axes simultaneously.

The machining centre mills even difficult-to-machine materials in record time and with perfect precision – even fully automated and always with unbeatable operating comfort! The range of applications for the C 32 GEN2 is extensive. The C 32 GEN2 machining centre has two axes in the workpiece and three axes in the tool. Dynamic positioning, short non-productive periods and secure holding in the desired machining position all go without saying. As does the very large working area in relation to the installation space. During this change process, the mechanics, which is fundamental to the precision and long-term accuracy of HERMLE products, was not altered. The key values of the machine remain exceptionally high, thereby clearly reaffirming its dominance in the field of 5-axis technology.

Numerous software and hardware components now feature cutting-edge technology. The entire electrical architecture has been revamped to incorporate ProfiNet as the communication bus, while a significant number of the sensors have been converted to IO Link (international standard). Furthermore, the entire drive network of Heidenhain machines has been revised and equipped with the latest generation of converters. These are all components that make the machines even more efficient. The entire platform introduces new technologies and functions, including cutting-edge interface technology and evaluation/diagnostic capabilities for enhanced service analysis in case of errors.

Machining centre C 42 GEN2

-

The C 42 GEN2 is the ongoing transition towards a new machine generation of the future.

The C 42 GEN2 machining centre from the High-Performance Line is an effective gateway into MT technology – thereby evolving seamlessly into a high-performance milling and turning centre. As a milling and turning centre, the C 42 / C 42 MT GEN2 responds to demands for the highest precision and very small tolerances through its traverse paths optimised to the workpiece dimension and well thought-through 5-axis usage. During this change process, the mechanics, which is fundamental to the precision and long-term accuracy of HERMLE products, was not altered. The key values of the machine remain exceptionally high, thereby clearly reaffirming its dominance in the field of 5-axis technology.

Numerous software and hardware components now feature cutting-edge technology. The entire electrical architecture has been revamped to incorporate ProfiNet as the communication bus, while a significant number of the sensors have been converted to IO Link (international standard). Furthermore, the entire drive network of Heidenhain machines has been revised and equipped with the latest generation of converters. These are all components that make the machines even more efficient. The entire platform introduces new technologies and functions, including cutting-edge interface technology and evaluation/diagnostic capabilities for enhanced service analysis in case of errors.

PERFORMANCE-LINE

Machining centre C 250 GEN2

-

Within the model range, the C 250 GEN2 is the entry-level model into the world of 5-axis milling – and into the HERMLE Performance Line.

Thanks to the wide-reaching swivelling range of the workpieces in the working area, the exploitation of the full traverse range and the large collision circle between the table sections, the C 250 GEN2 has the largest working area in relation to the installation area. And it is constructed for everyday use: The application video shows the HERMLE C 250 GEN2 in the 5-axis version machining a Rockerbox in Toolox33 for vehicle technology. Maximum precision thanks to the HERMLE swivelling rotary table concept. The machining table has a generously dimensioned worm drive. With the A axis, the gearwheel on the table housing is accessed directly.

Comprehensive fluid technology, optimised chip management, variety of cooling lubricant units: Even as an entry-level model, the C 250 GNE2 has a number of highlights to offer, e.g. the right chip disposal equipment for removing all types of chips from the working area. The machining centre with 5-axis milling capability can be transported without being dismantled and set up without a foundation.

Energy efficiency in manufacturing and operationHERMLE manufactures many components using lightweight construction and mineral casting technology. The high degree of own production, local suppliers and components with high efficiency factors also promote energy efficiency. Energy recuperation, high-quality servo drives and the legendary long service lives are all proof of the same high standards during actual operation.

Machining centre C 400 GEN2

-

The C 400 GEN2 is a dynamic and economical machining centre designed for 5-axis / 5-sided machining.

This is where HERMLE’s well-known core competence in 5-axis technology comes into its own. The mineral cast low-vibration machine bed ensures that the C 400 GEN2 has the required static stability. A host of features enables economical 5-axis / 5-sided machining. The C 400 GEN2 machining centre offers a high cutting volume with enormous precision and an optimum surface finish. The C 400 GEN2 has the largest working area in relation to its footprint and can be ergonomically adapted to the respective machine operator – thereby ensuring optimum ease of use.

From the comprehensive fluid technology to the optimised chip management system and a range of cooling lubricant units to the hinged belt conveyor: The C 400 GEN2 Performance Line model has a number of highlights to offer, e.g. the right chip disposal equipment for removing all types of chips from the working area. This machining centre for 5-axis / 5-sided machining can be transported without being dismantled and set up without a foundation.

Energy efficiency in manufacturing and operationHERMLE manufactures many components using lightweight construction and mineral casting technology. The high degree of own production, local suppliers and components with high efficiency factors also promote energy efficiency. Energy recuperation, high-quality servo drives and the legendary long service lives are all proof of the same high standards during actual operation.

Machining centre C 650 GEN2

-

As the youngest member of the HERMLE Performance Line, the C 650 GEN2 sets new standards in terms of the traverse path and load.

In addition, the machining centre integrates the complete range of features which have already proven themselves in the smaller sister models C 250 and C 400. The top speed of the linear rapid traverses is 35 m/min. From machine construction to precision mechanics, from medical engineering to energy production, from the aerospace and automotive industry to tool and mould construction and the general subcontractor industry: The C 650 GEN2 is ideal for a wide range of milling operations.

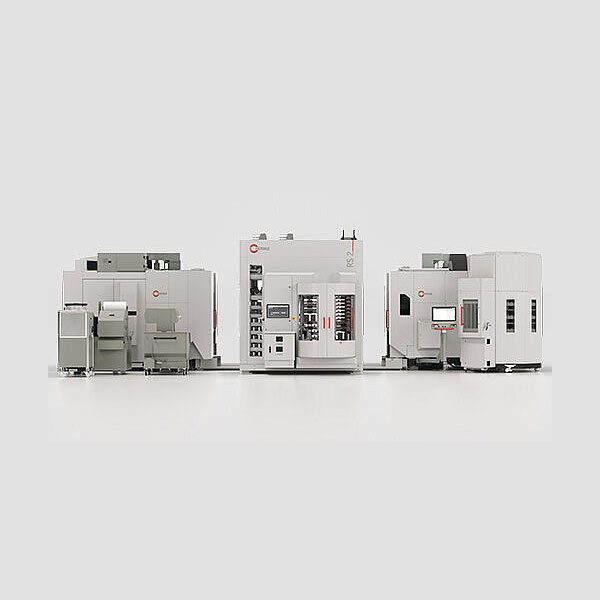

HERMLE automation – everything from a single supplier!

-

We develop solutions to meet your requirements!

The automation of HERMLE machining centres and milling machines has a long tradition at HERMLE. What began with the simplest automation and handling solutions was already transferred to a separate subsidiary HLS HERMLE Systemtechnik GmbH in the mid-nineties, whose focus is on robotics and turnkey projects. Whether pallet changers, pallet storage, additional magazines, handling systems, robot systems or complex turnkey projects, HERMLE offers you the optimal solution for the automation of HERMLE products – and all this from a single source, even in the event of service.

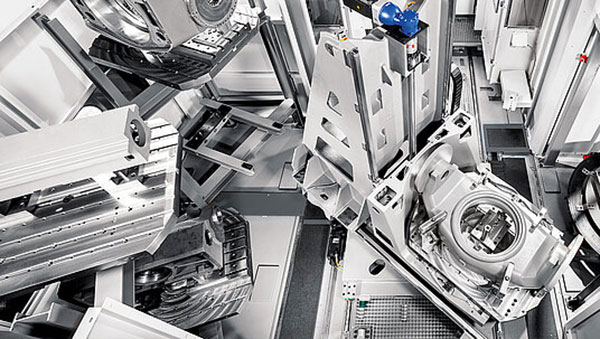

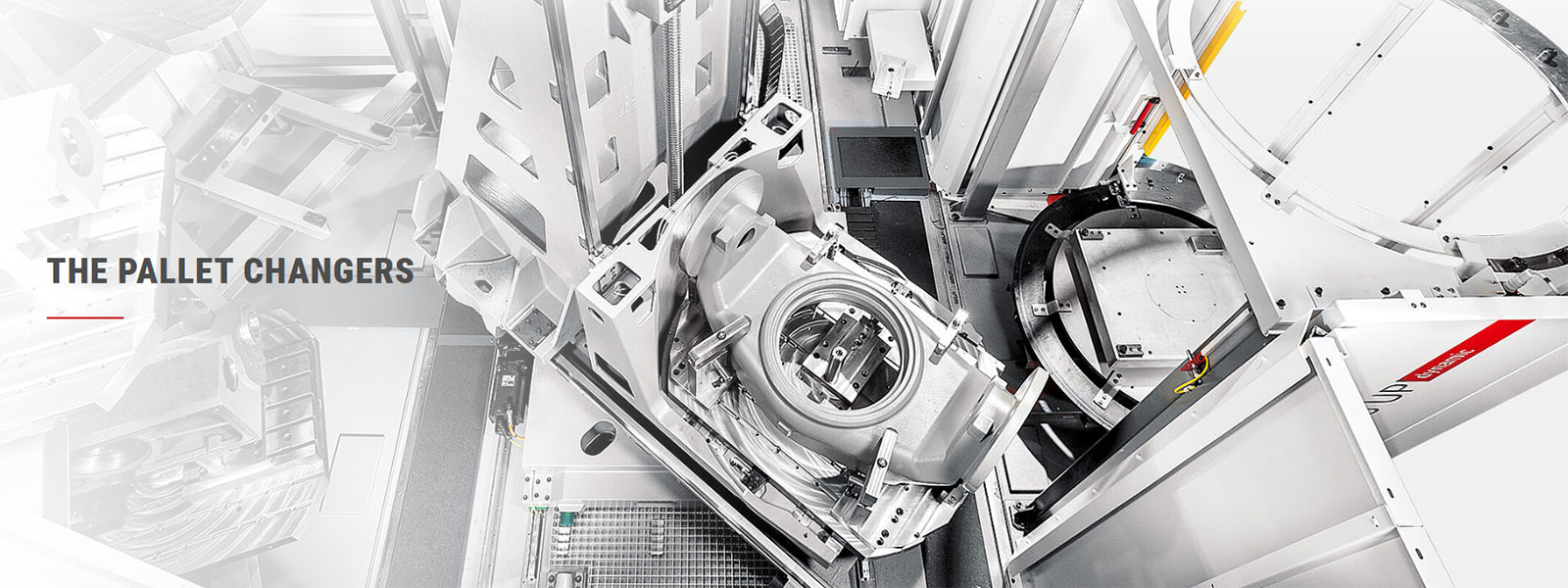

Pallet changer

- Assembly and production of automation systems, robot systems, turn-key projects.

Handling systems

-

Why automation? Mankind has alway been very inventive when it comes to making work easier, avoiding hard and monotonous work and improving productivity. Now the main aims are to increase production times and decrease idle times and downtimes.

The better this can be achieved, the lower the machine-hour rate and the lower the personnel costs, meaning altogether lower capital commitment. Especially in times of staff shortages in the high-qualification areas, automation provides an alternative to manned triple-shift operations.

Robot systems

- For economical production from the very first batch. Improve the productivity of your Hermle machining centre.

Pallet Changer

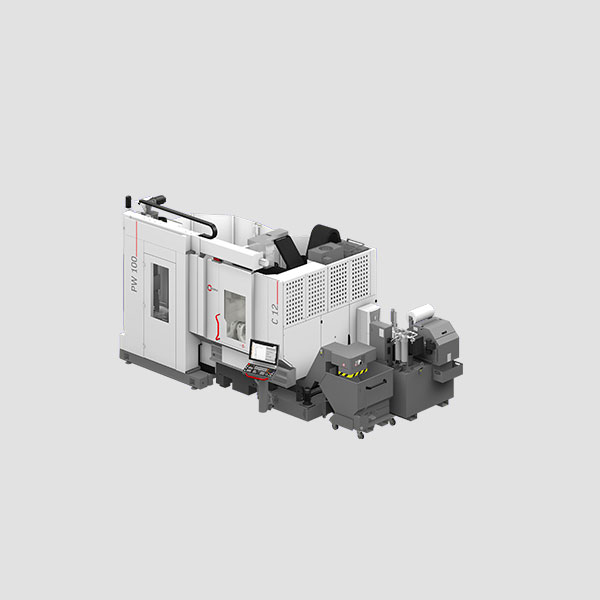

Pallet changer PW 100

-

- Compact pallet changer with large rack storage

- Available for the HERMLE machining centre C 12 GEN2

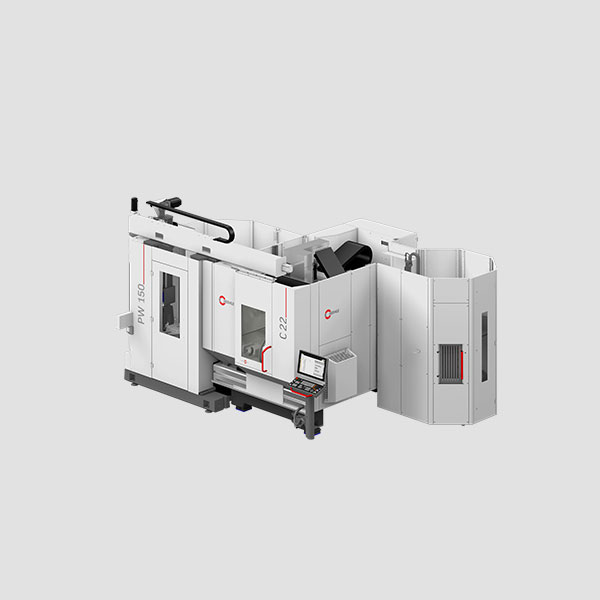

Pallet changer PW 150

-

- Compact pallet changer with large rack storage

- Available for the HERMLE machining centre C 22 GEN2

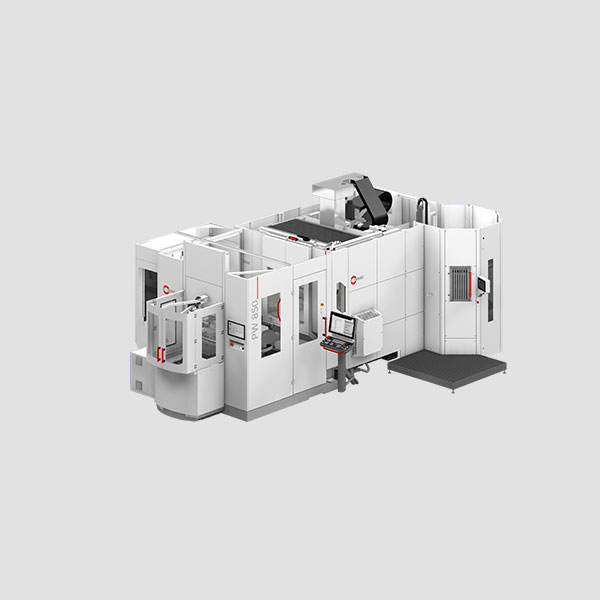

Pallet changer PW 850

-

- Compact pallet changer for large and heavy pallets

- Available for the HERMLE machining centre C 42 U (MT) GEN2

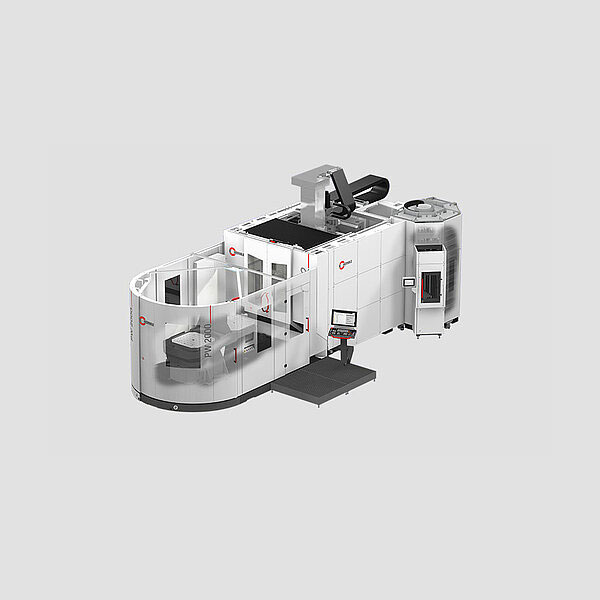

Pallet changer PW 2000

-

- Compact pallet changer for large and heavy pallets

- Available for the HERMLE machining centre C 52 U (MT)

Pallet changer PW 3000

-

- Compact pallet changer for large and heavy pallets

- Available for the HERMLE machining centres C 52 (MT) and C 62 U (MT)

Handling systems

-

Workpieces of various shapes, sizes and weights can be handled automatically by handling systems to save costs and time.

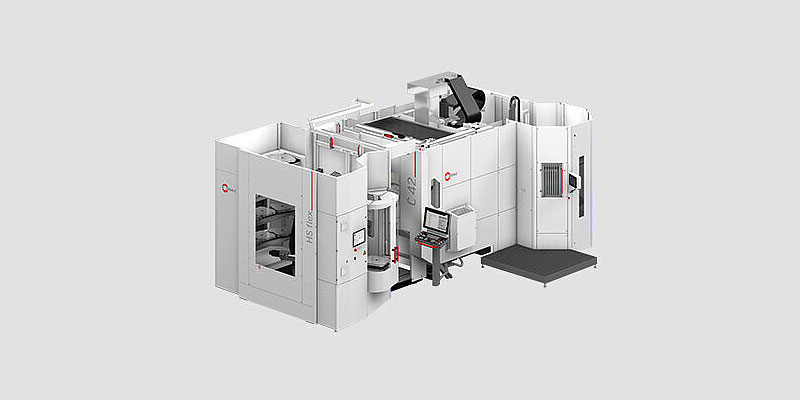

Handling system HS flex

-

- Flexible and compact

- Available for the HERMLE machining centre C 12, C 22, C 32, C 42, C 250 and C 400

- Transport weight: up to 450 kg

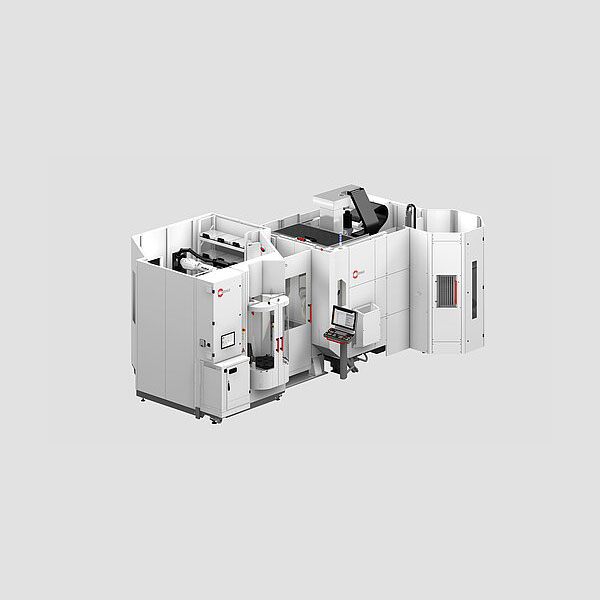

HS flex heavy handling system

-

- Flexible and compact

- Available for the HERMLE machining centre C 32, C 42, C 400 and C 650

- Transport weight: up to 1200 kg

Handling system HS flex hybrid

-

- Flexible and configurable

- Available for the HERMLE machining centre C 12, C 22, C 32, C 42, C 250 and C 400

- Transport weight: up to 450 kg

IH systems

- Available for the HERMLE machining centres C 12, C 22, C 32 and C 42

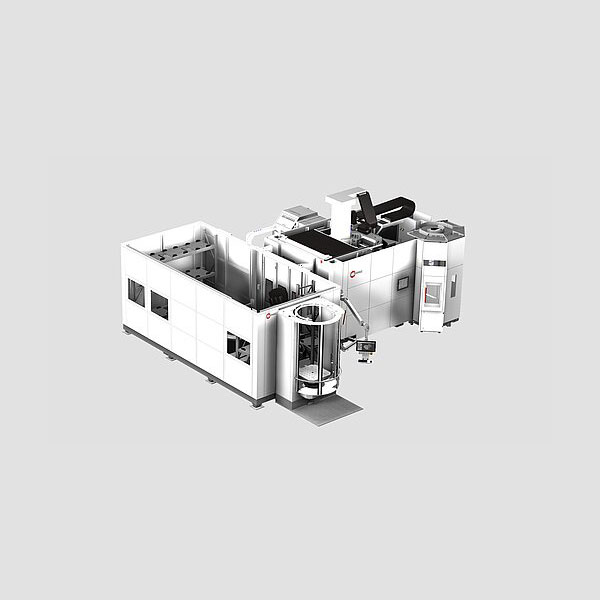

Robot systems

-

- Individually configurable and highly flexible, whether for pallet handling, changing workpieces from dies and/or directly.

- Gripper change from single to double gripper for even more flexibility.

- Wide range of magazine configurations to suit individual customer requirements.

- The robot systems can be adapted to all HERMLE machining centres and they are also available in different versions.

- From the RS 05-2 robot system for small pallets and components to the RS 3 system with a transport weight of up to 420 kg, also including highly productive systems with linear linking.

RS 05-2 robot system

-

- Designed for individual requirements and extremely flexible.

- Available for the HERMLE machining centres C 12, C 22, C 32 and C 250

- Transport weight: up to 10 kg

RS 1 robot system

-

- One system. Endless possibilities

- Available for the HERMLE machining centres C 12, C 22, C 32, C 42, C 250 and C 400

- Transport weight: up to 60 kg

RS 2 GEN2 robot system

-

- Compact, highly modular robot system

- Available for the HERMLE machining centres C 22, C 32, C 42, C 52, C 250, C 400 and C 650

- Six-axis robot with a load capacity of 210 kg

RS 3 robot system

-

- Versatile and individual

- Available for the HERMLE machining centres C 42, C 52, C 400 and C 650

- Transport weight: up to 420 kg

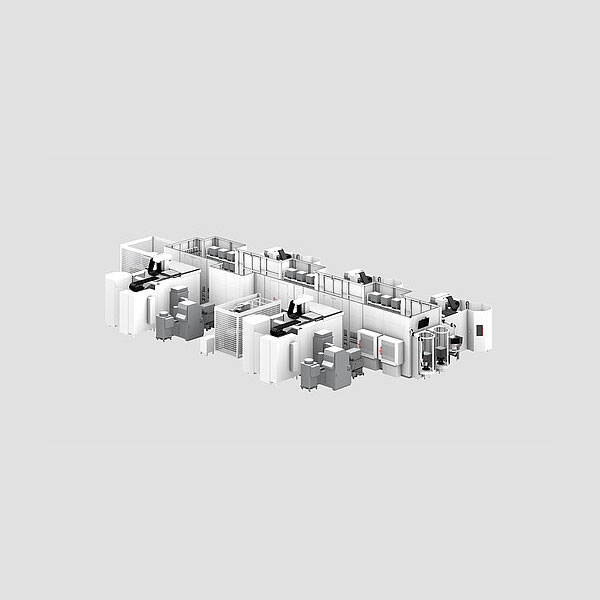

RS L robot system

-

- Variable for maximum productivity

- Available for the HERMLE machining centres C 22, C 32, C 42, C 52, C 250, C 400 and C 650

- Transport weight: up to 420 kg

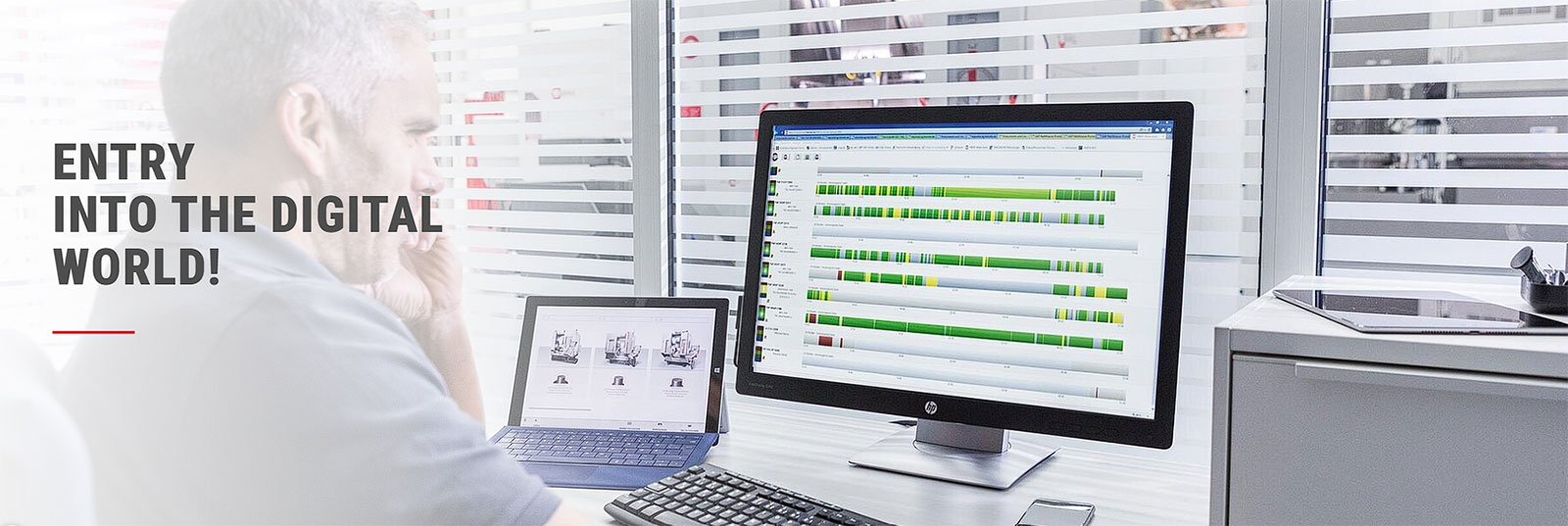

Digital modules - Industry 4.0 and the Smart Factory

- The digital transformation is now becoming the focus of many different production operations. HERMLE is there to provide support while you chart your individual course towards Industry 4.0 and the smart factory. We offer a wide range of software solutions for improving your efficiency, precision and productivity. Our digital modules thus represent links in the chain of smarter production. We can work together in order to find out what your operation needs. With Digital Production, Digital Operation and Digital Service modules, we can put together a comprehensive package that will put your HERMLE machining centres on a firm footing for future tasks: Intelligent order management and transparent machining processes, smart machine tuning, paperless manufacturing and sophisticated technology cycles, as well as options for remote or preventive maintenance. Our digital modules improve productivity, ease of operation and efficiency.

HERMLE Digital Production

-

- HACS – intelligent order management

- HIMS – the central monitoring tool

- HTMC – convenient tool management

- HOTS – convenient tool management

- HOME - customisable views

HERMLE Digital Operation

-

- ACC - Active Chatter Control

- AFC - Adaptive Feed Control

- AVD - Active Vibration Damping

- CTC - Cross Talk Compensation

- HDM – Heavy-Duty Machining

- HERMLE Remote Desktop

- HP - High Production

- LAC - Load Adaptive Control

- 3D-CT - 3D contour tolerance max. (SOFT)

- 3D-CT - 3D contour tolerance max.

- 3D-CT - 3D contour tolerance min.

- 3D-PS - 3D contour smoothing

HERMLE Digital Service

-

- HIMS – the central monitoring tool

- Remote maintenance

- WDS – maintenance diagnostic system