- Offer Profile

-

Our products are top range grinding machines and centres "Made in Germany“. We have been one of the leading manufacturers worldwide – for more than 80 years.

Progress is a tradition at KEHREN.

Thanks to decades of experience in grinding machine manufacturing, KEHREN possesses extensive technical knowhow in machine design and application engineering.

The machines are designed, manufactured and assembled in house.

The motivation and the skills of our teams as well as the high precision design guarantee the outstanding quality of KEHREN grinding centres.

From Grinding to complete Machining

-

Over the past years, grinding operations have become more and more complex, a tendency which will further develop in the future. Here, the driving factor is the complete machining of workpieces in one set-up, resulting in highest precision possible and bringing the wanted rationalization effect.

Since 1950, KEHREN GmbH in Hennef/Sieg has built grinding machines. During this time, products have continuously developed to the high-tech machines of today.

With the integration of machining by geometrically defined cutting edges, the range of application of the Ri machine type could be substantially increased. Depending on the machine configuration, the following machining processes can be implemented in only one set-up:

- Surface grinding

- Grinding internal and external diameters

- Grinding taper and radii

- Curve grinding

- Grinding centric and eccentric slots

- Grinding of Hirth and curvic coupling

- Finish drilling of eccentric bore

- Milling and drilling

- Hard turning

- Jig grinding

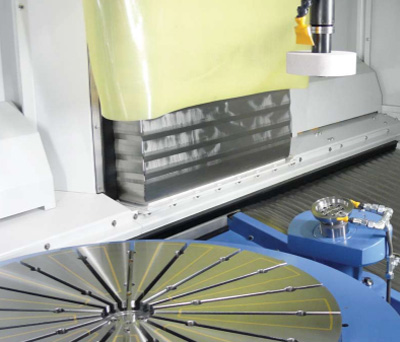

Ri 8-4 interior room, right hand side

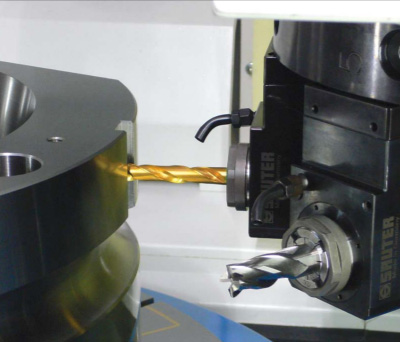

Horizontal drilling

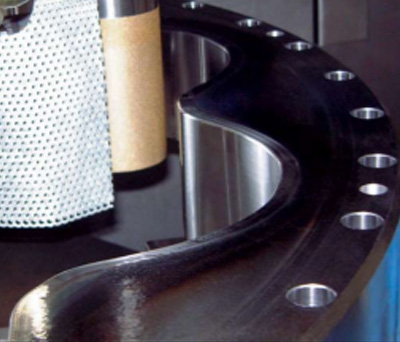

Hard turning for stock removal

Drilling of an off-set bore in horizontal plane

Grinding of an internal contour

Contour dressing

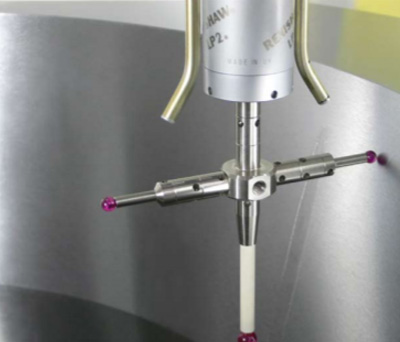

In-process calibration of the probe

In-process measuring

Milling of a horizontal flute

Machine type Ri and Ri

- Vertical grinding centres are available from 500 mm upt to 1,600 mm table diameter. The grindturn design provides additional equipment for hard turning and hard milling applications. The turrets can be equipped with up to 5 tools. Solid gray cast iron design guarantees a stiff machine with excellent damping properties.

X-axis, Bed saddle movement

- For over 45 years, hydrostatic bearings have been used, and in combination with high precison ball screws as adjusting element, smallest movements of 0.001 mm are possible.

C-axis, Movement of the rotary table

- Also the rotary table bearing is hydrostatic and pre-loaded in axial and radial direction. Thus, radial and axial running accuracies of < 0.001mm mm can be achieved, with a table load of 1,500 up to 7,500 kgs, depending on the machine size. All rotary tables are powered by a backlash free direct drive. The direct drive provides a positioning accuracy of +/-1.5 seconds of an arc.

Z-axis, Vertical movement of the grinding turret

- A monorail guidance system is used for the vertical axis. The positioning element is a high-precision ball screw.

B-axis, Turret

-

Within the 280° swivel range, the turret can be positioned in 1° increments, in a very precise and also reproducible way.

The positioning is hydraulically powered, and a Hirth coupling gives repeatability of the highest precision. On request, it is possible to have NC controlled positioning. The turret can be fitted with up to five tool stations, specially equipped for grinding or hard turning and milling application, with the possibility of automatic tool changing.

Y-axis, Machining in horizontal plane

- By means of the optional Y-axis, work pieces can also be machined in the horizontal plane. This flexibility significantly widens the range of application of the Ri machine. Here again, an optional tool changer is available, offering easy tool change.

Machine control system

-

The automatic machining processes are implemented by a Siemens Sinumerik 840 D control. The standard Siemens software is supplemented by the KEHREN-WOP-Software (Workshop Oriented Programming). This features for example reading of CAD data for contour grinding - ready to use without further corrections.

An adaptive speed control allows grinding process times to be reduced: The feed is controlled by the spindle load; thus process times without work piece contact, for example during jig grinding, can be minimized.

Dressing of grinding wheels

-

Dressing cycles can be selected by program or manually at any time. For conventional grinding wheels, single or multiple grain diamonds are normally utilized for dressing. Using a dressing spindle, fitted with diamond wheel, contour dressing is possible for conventional grinding wheels and for CBN wheels. In this process, an axially parallel, orthogonal or angulate position towards the tool axis can be chosen for the driven dressing tool. With all procedures, the required forms and contours can be realized.

By compensating dressing infeed and wheel wear, parts can be machined in series and without measuring, in repeatable tolerances of less than 0.01 mm.

Measurement system

-

However, when implementing the optional Renishaw in process measurement system with probe together with a calibration unit, much closer tolerances can be achieved. The measurement system can be used for gauging all machining surfaces.

The measuring data can be read into the NC control and necessary corrections can be realized.

Vertical grinding centres

Vertical grinding centres - Ri

-

Remarkable features of KEHREN Ri Vertical grinding centres:

- Wide range of applications

- High precision machining

- Rigid casting design

- Hydrostatic guide ways in the X- and C-axis

- Outstanding long-term precision and longevity

- Ergonomic and easy to operate

- Compact and space saving design

- Good damping properties

To increase productivity, all Ri grinding centres can be equipped with two rotary tables.

For all Ri grinding centres a wear-less direct drivein the X-axis is available, providing excellent machining and measuring accuracy.

The product lines Ri 6 to Ri 12 can be equipped with an optional Y-axis as side support for horizontal machining.

All product lines can be delivered in standard or in grindturn design. The grindturn design includes a

turning tool adapter instead of a grinding spindle. The machine can also be equipped with a chip conveyor.Various tool changing systems are available for all product lines.

Today, complete work piece machining has become an important feature.

The following operations can be machined in only one set-up:

- Faces

- Internal and external diameters

- Internal and external tapers

- Radii

- Noncircular and jig grinding

- Serrations (Hirth / Curvic)

- Hard turning (Fine machining)

- Hard milling (Fine machining)

- Boring (Fine machining)

All diameters and faces can be measured automatically by an optionally integrated measuring unit. For noncircular and jig grinding, this measuring unit can also be used for the localisation of a work Piece.

Vertical grinding centres in portal design

-

KEHREN portal type grinding machines extend the Ri product line:

- 5-faces complete machining

- Highest accuracies

- Rigid casting design

- Hydrostatic guide ways in the X-, Y- and C-axis

- Outstanding long-term precision and longevity

- Ergonomic and easy to operate

- Compact and space saving design

- Table diameter 800 to 2.500 mm

- Work piece weight up to 10.000 kgs

- Rotary and long table design

- Excellent damping properties

To increase productivity, all portal type grinding centres can be equipped with two rotary tables, if requested in differing designs.

For all grinding centres in portal design, a wear-less direct drive in the X- and Y-axis is available, providing excellent machining and measuring accuracy.

Various tool changing systems are available for all product lines.

Today, complete work piece machining has become an important feature.

The following operations can be machined in only one set-up:

- All machining applications of the Ri grinding centres

- Horizontal machining

- Grinding of guide ways

- 3-axis jig grinding

- Flat grinding in oscillating movement

- Machining of special materials, for example special types of class or ceramics

With the optionally integrated measuring unit, all diameters and faces can be measured automatically. In noncircular and jig grinding applications, this measuring unit can also be used for work Piece localisation.

In general, all grinding centres in portal design are built according to customer‘s requirements. Other than the new RP 8 model, for which a standard is defined.

Vertical grinding centre RP 8

-

Our new vertical grinding centre RP 8 in portal design is notable for its compact design and the following properties:

- 5-side complete machining

- Outstanding machine and measuring accuracies

- Rigid casting design

- Hydrostatic guideways in the X-, Y-, and C-axis

- Wearless direct drives in the X-, Y- and C-axis

- Outstanding long-term precision and longevity

- Ergonomic and easy to operate

- Compact and space saving design

- Table diameter 800 mm

- Maximum work piece weight 2,000 kgs (steady load)

- Excellent damping porperties

- The machine can be equipped with up to 2 grinding spindles and a sensor in the grinding head.

Various tool changing systems are available for the RP 8 model.

Today, complete work piece machining has become an important feature.

The following operations can be machined in only one set-up:

- All machining applications of the Ri grinding centres

- Horizontal machining

- Grinding of guide ways

- 3-axis jig grinding

- Flat grinding in oscillating movement

- Machining of special materials, for example special types of class or ceramics

All diameters and faces can be measured automatically by an optionally integrated measuring unit. For noncircular and jig grinding, this measuring unit can also be used for the localisation of a work Piece.

Surface grinding machines with rotary table

Surface grinding machines with rotary table and vertical grinding spindle - RS

-

KEHREN RS machines are notable for:

- Maximum stock removal

- Highest accuracies

- Rigid casting design

- Hydrostatic guideways in the X-axis and in the rotary table

- Outstanding long-term precision and longevity

- Ergonomic and easy to operate

- Compact and space saving design

- Best damping properties

- Direct, wearless drive in the rotary table

Whenever good stock removal performances and flatness are required, RS machines are an economic choice, as in most cases it is not necessary to pre-machine the work piece.

Surface grinding machines with two rotary tables and vertical grinding spindle - D

-

KEHREN D machines are notable for:

- Maximum stock removal

- Highest accuracies

- Rigid casting design

- Hydrostatic guideways in the X-axis and the rotary table

- Outstanding long-term precision and longevity

- Ergonomic and easy to operate

- Compact and space saving design

- Best damping properties

- Direct, wearless drive in the rotary table

If good stock removal performances and surface finish are required, RS machines are an economic choice, as in most cases it is not necessary to pre-machine the work piece.

By using surface grinders with two rotary tables, cycle times of batch products can be reduced by up to 50 %, when setting during main time.

Surface grinding machines with rotary table and horizontal grinding spindle - RW

-

KEHREN RW machines are notable for:

- Maximum stock removal

- High accuracies

- Rigid casting design

- Hydrostatic guideways in the X-axis and the rotary table

- Outstanding long-term precision and longevity

- Ergonomic and easy to operate

- compact and space saving design

- Best damping properties

- Direct, wearless drive in the rotary table

RW machines are an economic choice, if good surface finish and close tolerances are required on large annular parts or on small parts which can be mulitply loaded on the rotary table.

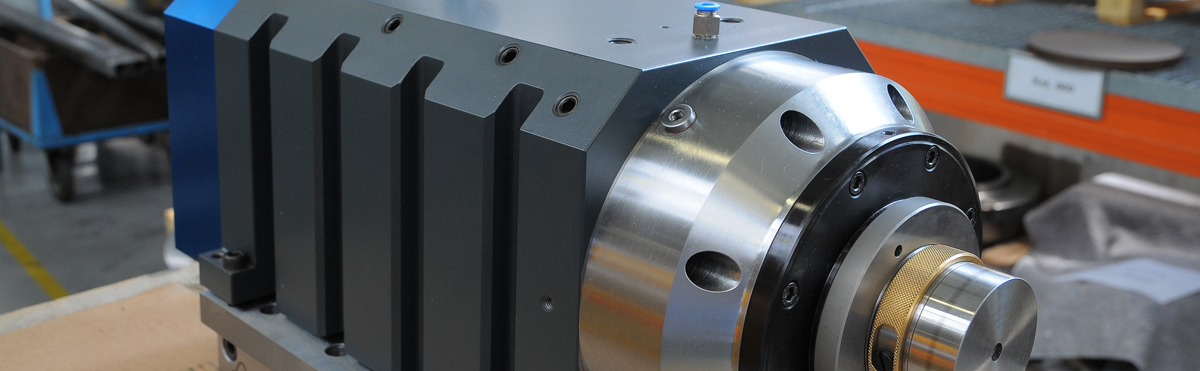

The RW models with table diameter 600 and 800 mm are also available with two rotary tables. Grinding spindles

-

From now on, KEHREN grinding spindles for all machine models are available, with excellent performance data and manufacturing properties.

All spindles are – like our machines – MADE IN GERMANY