Global Retool

Videos

Loading the player ...

- Offer Profile

- Global Retool Group - market

leaders in retooling, retrofitting, overhauling and service of machine tools

Innovative technology for the worldwide market –

this is what the Global Retool Group stands for.

We are market leaders in retooling, retrofitting and overhauling of machine tools of any kind and brand.

Our worldwide presence in Germany, Europe, China and North America allows us to act as a turn-key partner in international projects and to offer a consistent partnership to our customers at all their production facilities around the

globe.Everywhere in the world car manufacturers, component suppliers and many other industries place their confidence in the diverse products and technical services of the GLOBAL RETOOL GROUP.

Product Portfolio

Machinery & Plant Engineering

Retooling & Retrofit

-

Within the GLOBAL RETOOL GROUP WEMA VOGTLAND Technology GmbH is the leading supplier of overhauling, relocation, retooling and retrofitting solutions for machine tools – from single machines in job shops to the mechanical engineering industry and up to large production lines in the automotive industry and the automotive

supply industry.

Decades of experience and a comprehensive knowledge of machine tools of virtually any type and make have established WEMA VOGTLAND’s excellent reputation as a manufacturer-independent retooling company.

From the European locations in Plauen, Germany and (AL), Italy as well as from the locations of the GLOBAL RETOOL GROUP in the USA and Asia retooling, overhauling and relocation projects are planned and implemented on site.

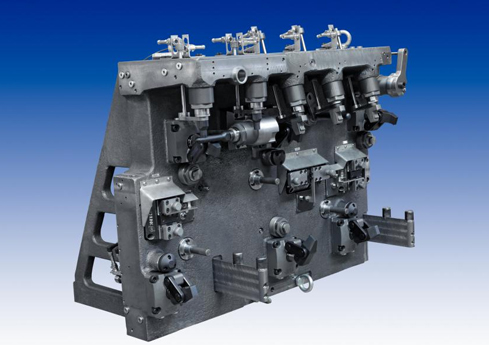

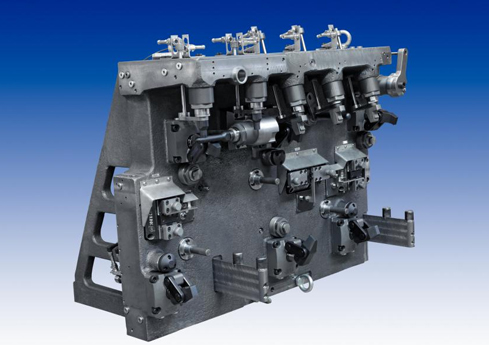

Retooling

As international market leader in retooling WEMA VOGTLAND Technology GmbH can be proud of numerous references from individual machines to complete lines for manufacturing of engine blocks, cylinder heads and transmission housings.Our comprehensive retooling know-how allows us to give our customers professional support in projects of any size and in any phase of a project.

With our large pool of production machinery for in-house machining of replacement parts and the high technical skills of our service personnel we make sure that retools, also in combination with overhauling, will be carried out quickly and professionally.

Retrofitting and overhauling

After several years in operation a machine loses accuracy and productivity which affects the economic efficiency of the production. This is where WEMA VOGTLAND steps in. Experienced specialists and different service offerings make the machine fit for the second half of its operating life, no matter what the task is - from a mere overhauling to a complete retrofitting, i.e. a modernization comprising new components such as new controls, automation or tool handling.

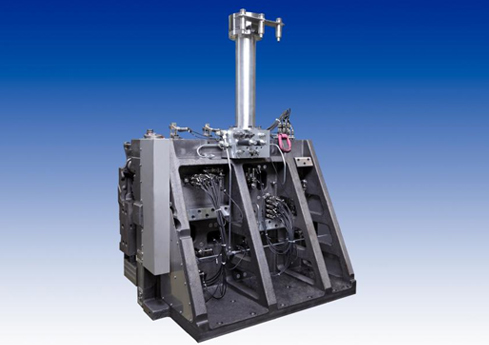

Special Machines

-

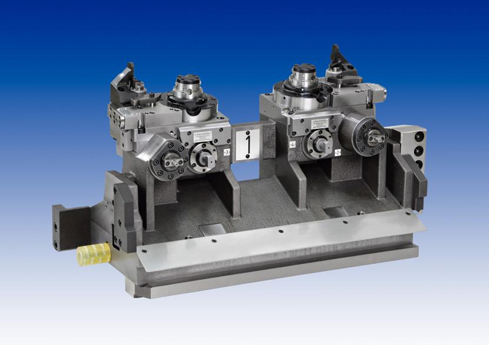

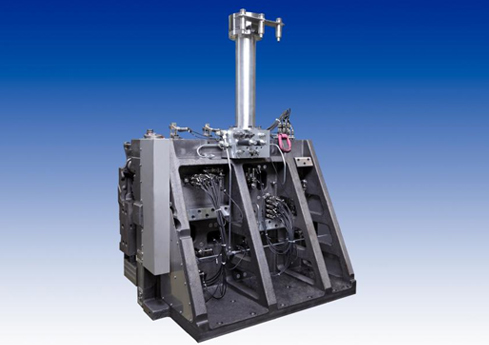

Particularly engineered for your component

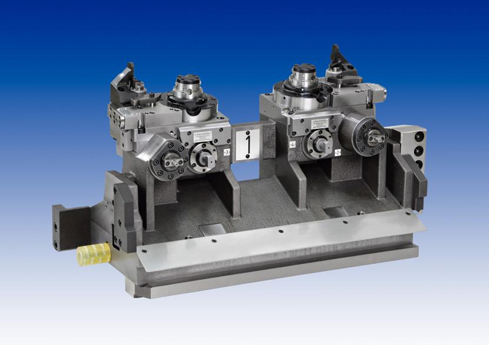

In the framework of re-tool projects but also as new stand-alone solutions we offer customized special purpose machine tools based on a modular concept.

Rotary table machines, rotary transfer machines, transfer lines and custom-designed special-purpose machines – all these machine types are designed and manufactured on demand, always tailored to customer’s individual needs. They are designed for large and mid-scale production and can be used in flexible machining systems.

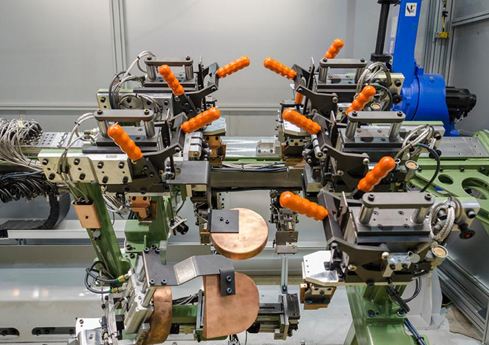

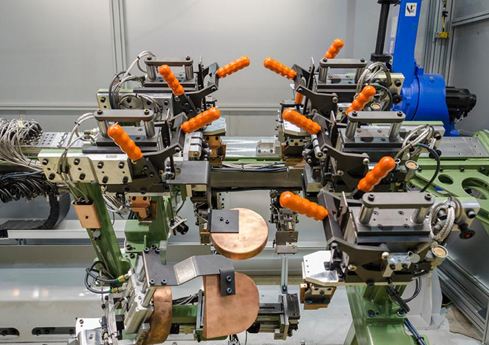

In permanent close co-operation with our customers we do not only work out problem solutions, but invest in new patented technologies which are often a result of joint development.

An excellent example for this approach is the Linetec machine developed by SVQ GmbH. From the beginnings of a lineboring fixture to a complete, fully automatic machine for precise lineboring of cylinder heads in a micron range. A proven solution which has since been sold to customers worldwide.

Relocation

- WEMA VOGTLAND Technology GmbH relocates machines in combination with the necessary overhaul or rebuild activities, no matter whether it is a single machine or a complete manufacturing plant. Based on our broad logistic know-how proven in many successfully completed projects we can offer even relocations of complete manufacturing plants.

Fixtures for metal cutting manufacturing

- Optimum clamping of the workpiece is one of the most important factors of the machining process. SVQ GmbH as a leading fixture company with many years of experience and own engineering, manufacturing and assembly resources in Germany and China offers customized clamping solutions, whether it’s for a new investment or the modernization of existing equipment.

Welding fixtures & welding lines

-

SVQ supplies welding fixtures for both passenger car and truck exhaust systems and stuctural parts.

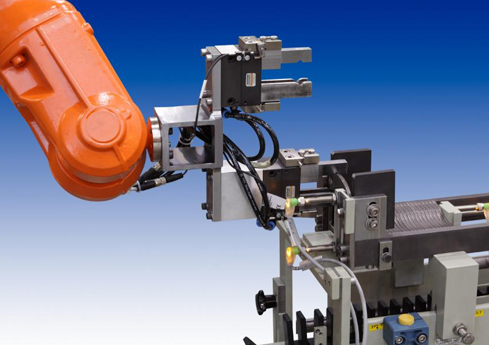

In addition SVQ has made a name for itself as a reliable partner for the design and build of robotized turn-key welding lines welding for the automotive and commercial vehicle industry and other manufacturing industries.

SVQ and SATEG jointly implement welding projects from planning of the welding process, 3D design, accessibility studies with robot simulation, mechanical manufacturing, control cabinet build, and programming up to complete installation and commissioning at the customer’s plant.

State-of-the-art Grinding Technology

-

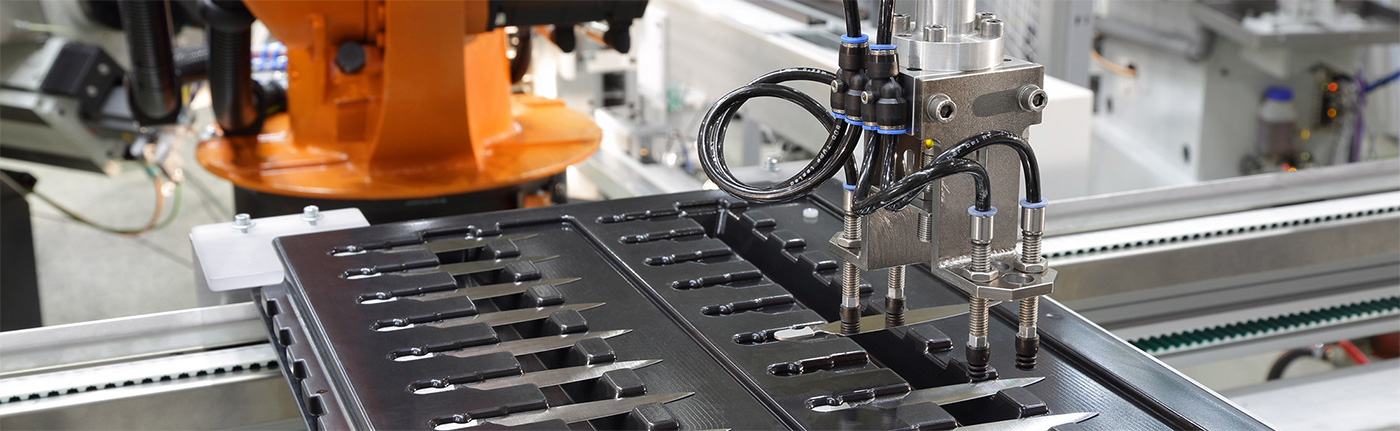

SIEPMANN® Grinding and Polishing Technology for a wide Variety of Applications

SIEPMANN state-of the-art grinding technology and automation concepts provide solutions for a wide range of grinding applications in the knife and cutlery, tools and surgical instruments industries worldwide. Continuous improvement and groundbreaking innovation have been the foundation for the global success of our SIEPMANN products.

To suit the individual needs of our customers SIEPMANN machines can be configured as complete grinding cells or as interlinked systems.

The integration of additional processes such as deburring, polishing and sharpening is increasingly gaining importance for the configuration of grinding cells and lines. Following this trend additional robot machining operations and the integration of further manufacturing steps, such as laser marking, electrolytic etching and injection moulding are more and more often included in SIEPMANN grinding cells and lines.

In addition SIEPMANN supplies robot cells of course as stand alone solutions for both machining and palletizing operations.

Beside the well-known grinding, glazing and polishing machines for knives, scissors, hand tools, machine blades or agricultural knives the large SIEPMANN product portfolio also includes special grinding machines for circular knives.

Automation & Digitalization

Your automation task - our solution

-

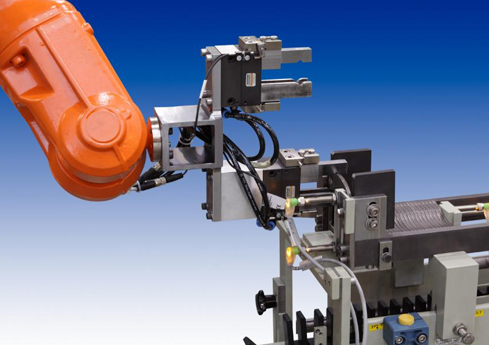

Effiency and high productivity in manufacturing require a corresponding system automation.

The GLOBAL RETOOL GROUP with its SPICHER® brand offers a complete system of modular solutions applicable for the modernization of existing equipment as well as for new machinery. Based on the customer's requirements the SPICHER engineers choose the suitable solutions from this modular system or customize the design if necessary.

For many decades we have been implementing solutions for the interlinking of individual manufacturing

machines and cells by means of conveyors, robots and gantries and even complete automation systems for processing lines and factory halls - from loading of the rough parts to unloading of the finished parts.

We are offering a wide range of conveyor and handling systems from simple gravity conveyors to multi-axis NC gantries.

For the verification of automation concepts, for planning complex processes and for the analysis of clash conditions we are using a simulation tool which allows us to visualize, verify and optimize automation solutions alreday in the planning stage.

Retrofit 4.0

-

In the light of the megatrend Industry 4.0 the GLOBAL RETOOL GROUP jointly with a partner from the software industry developed the concept Retrofit 4.0, a complete package consisting of hardware, a software product and a retrofit service package which is aiming first of all at existing manufacturing plants.

The GLOBAL RETOOL GROUP as a retrofit and automation specialist with the relevant PLC and data base programming skills and the hardware know how for the necessary sensor systems takes over the retrofitting of the required measuring and control equipment.

The software tool allows collection of the data, processing them in a usable manner and visualizing them accordingly. Thus decision-makers are provided at the right moment with relevant information. Plan deviations are recognized at an early stage, optimization potentials are identified and evaluated easily and efficiently.

In addition, the tool can be used for the precise planning of servicing and maintenance activities. The goal is to replace the traditional predictive maintenance by a „maintenance on demand“ where the machine itself gives an alarm as soon as it requires maintenance or inspection.

Mobility Concepts & Automatic Parking

Automatic Parking Systems

-

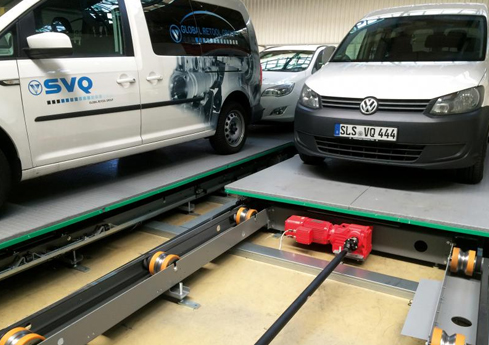

parQing® –

The intelligent solution for maximum parking space

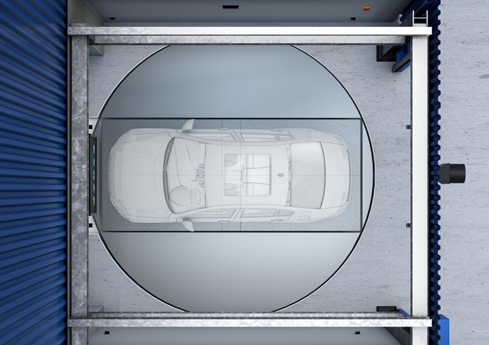

The parQing puzzle parking system optimizes and efficiently increrases the desity of existing parking space. parQing relieves drivers of the search for a free parking space, makes the usually required special parking spaces redundant and guarantees more safety for people and cars in comparison with conventional car parks.

Digital technologies permit communication between the car park and the driver and thus facilitate the identification of free parking spaces, the retrieval of the car at the desired moment and cashless payment.

parQing is based on a patented system. The vehicles are parked on pallets which are arranged and moving on self-centering conveyor modules and are thus efficiently accommodated in the available parking space. The combination of cross, longitudinal and cross-longitudinal conveyor modules allows optimum movement patterns while using one free space in the

system.

An intelligent software determines the shortest possible path thus offering short waiting times for the retrieval of the

cars. The most efficient puzzle parking system convinces with ease of operation and a high level of comfort for the end user.