- Offer Profile

- KAAST was founded when

several senior executives left the biggest German machine tool importer.

With the start of KAAST we wanted to realize our own idea of a modern trading company for machine tools. We have branches in Germany, USA, Russia and Taiwan. Our vision became reality!

We have grown more quickly than expected as a result of reliable partners and satisfied customers.

Cutting systems

Waterjet cutting

Watersonic

-

Technical Specifications:

- X-axis 1002 mm - 6002 mm

- Y-axis 2002 mm

- Z-axis 200 mm

- Max. table load 600 kg/m2

- Positioning accuracy +/- 0.1 mm

- Repeatability +/- 0.5 mm

Watersonic- modern waterjet cutting systems for flexiblesingle-part and series production

A wide range of materials can beprocessed

This separation process is an extremely efficient alternativeto milling and EDM processing. The method enables material and time-saving nesting of several operations with better cutting performance. Very complex shapes can be manufactured with high precision and clean cut edges without material or surfaces being deformed. Whether single or series production, this cold cutting process guarantees a low cost production with maximum precision and minimum tolerances. Cold cutting is especially important for the increasing need for production of miniaturized components. Using precision, micro waterjet technology intricate work pieces can be cut in many materials with a positioning accuracy of 0.0025 mm and within the tolerance range of + / - 0.01 mm.- Steel / stainless steel, alloyed and non alloyed, heat resistant alloys, titanium, aluminum, copper, bronze

- All kinds of stone: granite, marble, ceramic, concrete

- Glass, acrylic, bullet proof glass, security glass and plexiglass

- Art and foams

- Carbon, carbon fiber and glass fiber

- Gaskets, rubber, fabric, leather

- Wood, cardboard, etc.

Advantages of the abrasive water jet Cutting Technology:- Environmentally friendly technology, no toxic cutting gases

- “Cold Cut” - no work hardening and microstructural changes

- No mechanical loading / torsion on the workpiece

- Cutting complex contours possible

- High-precision machining for excellent cutting results

- Quick setup of the workpiece

- Low noise levels

- Optimal use of the material

- Flexible and economical production of individual parts and series

Watersonic ECO

-

Technical Specifications Watersonic ECO:

- X-axis 1002 mm - 3002 mm

- Y-axis (bridge) 1002 - 1502 mm

- Z-axis 200 mm

- Max. table load 600 kg/m2

- Positioning accuracy ± 0.2 mm

- Repeatability mm ± 0.15

Watersonic is state-of-the-art waterjet cutting.- Our Waterjet is ideal for short-run production, just-in-time manufacturing, tooling, and prototype part development. It requires no tool changes or complex fixturing, so you can reduce setup times by at least 50%

- The high edge quality often eliminates the need for secondary machining but when required, the lack of heat affected zone speeds processing. As a result, waterjet cutting system can dramatically increase your profitability

- A solid and rust-free construction of aluminium and stainless-steel, coupled with first-class components, ensures long-lasting low maintenance production

- Virtually any material can be cut with this high pressure 4000 bar (58,000 psi) waterjet technology

Advantages of waterjet cutting- Eco-friendly cutting, no toxic gases or vapours

- "Cold" cut - no heat affected zone

- No mechanical stresses or distortions

- High cutting quality and precision

- Ideal for complicated contours

- Rapid set-up, no tool changes are required

- No burrs

- Efficient use of material

- Flexible and economic production of components and prototypes

Watersonic Micro

-

Technical Specifications Micro 0705:

- X-axis 700 mm

- Y-axis 500 mm

- Z-axis 150 mm

- Max.Rapid feed 10 m/min

- Repeatability ± 0.01 mm

A compact water jet cutting system, which is suitable for micro-jet cutting and thus for the production of very small components. Ideal for limited floor space and the need for maximum precision with minimal noise and pollution.

Ball screw spindles ensure high precision and perfect cutting results, which speak for themselves.

Plasma cutting

Plasmasonic

-

Technical Specifications:

- Table length 3000 mm - 12000 mm

- Table width 2000 mm - 3000 mm

- Cutting speed 7500 mm/min 9800 mm/min

- Positioning speed 15000 mm/min

- Repeatability ± 0.05 mm

Cut, write, mark and perforate - all with one machine

Plasmasonic series meets the highest standards of productivity, reliability and automation.

Through advanced CNC control, with automatic tool addressing the parameter database, various technologies, such as Plasma or flame cutting / gas cutting in conjunction with pipe cutting and weld preparation are combined.- The design of the system ensures its smooth operation, even under tough conditions

- Magnetic holder of the cutting head allows rapid change and in the case of collision avoids damage to the cutting head.

- Multiple head-operation of plasma cutting units and oxy-acetylene cutting heads optional. The controller allows the use of up to 4 cutting head-carriers (plasma and oxy-acetylene cutting heads with independent height adjustment), in any combination

- Dual AC servo motors precisely drive the bridge double-sided, which means no lag error

- User-friendly control panel allows not only the engine but also its source of power, suction and filtration system to be monitored centrally

- Plasma cutting machines, which are equipped with our precision fine beam plasma generators are able to combine the highest cutting quality with low wearing parts. The fine-beam generators PP (Precision Plasma) ensure a very fast piercing and high cutting speeds, in an unusually clean and almost rectangular cutting edge

- Our plasma cutting machines are equipped with an automatic CNC-controlled gas mixing console (PP 130 and PP 260), marking (PP 130 and PP 260), cutting table equipped with sectional suction, suction unit and particulate filter system

- Furthermore, the flat bed machines are combined with a pipe cutting device

- Optional bevel cutting unit for 5th axis operation to produce quick and accurate welding grooves

Laser cutting

Lasersonic B

-

Technical Specification

- Cutting range (X-axis, Y-axis) 3000 x 1500 mm, 4000 x 2000 mm, 6000 x 2500 mm,

4000 x 2500 mm - Positioning accuracy of the X/Y-axis ±0.03 mm/m

- X/Y-axis worktable with repeated positioning accuracy ±0.02 mm/m

- Max. traversing speed 140 m/min

- Weight 8.8-16.5 t

Features- Rexroth/Aventics brand, best quality and stability

- Honeycomb structure machine tool

- Intelligent dust exhaust system

- Raytools cutting head

- Servo motor system with excellent performance, easy operation and long life span

- Gear and rack

- Fluid chiller

- Automatic lubrication system

- Cutting range (X-axis, Y-axis) 3000 x 1500 mm, 4000 x 2000 mm, 6000 x 2500 mm,

Lasersonic Pro

-

Technical Specifications

- Cutting range (X-axis, Y-axis) 3000 x 1500 mm, 4000 x 2000 mm, 6000 x 2500 mm,

6000 x 2500 mm - Positioning accuracy of the X/Y-axis ±0.03 mm/m

- X/Y-axis worktable with repeated positioning accuracy ±0.02 mm/m

- Max. traversing speed 169 m/min

- Weight 8.8-16.5 t

Features

- Rexroth/Aventics brand, best quality and stability

- Machine tool with honeycomb structure

- Intelligent dust extraction

- Raytools cutting head

- Servomotor system with excellent performance, easy operation and long service life

- Gear wheel and rack

- Liquid cooler

- Automatic lubrication system

- Cutting range (X-axis, Y-axis) 3000 x 1500 mm, 4000 x 2000 mm, 6000 x 2500 mm,

Speedmaster

-

Technical Specifications Speedmaster 2512 3015 3020 4020

- X 1250 mm - 2000 mm

- Y 2500 mm - 4000 mm

- Z 80 mm - 80 mm

- A endless - (optional axis of rotation 360°)

- Max. work feed 40 m/min

- Max. positioning speed 150 m/min

- Max. speeding up 15 m/sec2

- Positioning accuracy ± 0.005 mm

- Repeatability ± 0.025 mm

Traversing speed 150 m/min! high cutting accuracy and smooth contours combined with modern linear motors- Modular construction with small, highly functional footprint

- Cutting of various metallic materials such as steel alloys, carbon steels, titanium and bronze

- Integrated laser power control

- CO ² slab laser technology combines reduced gas consumptation with low maintenance

- Beam guidance via two mirrors provides stable cutting operation over the entire operating range

- High traveling speed -150 m / min

- Оptional: RTX - pipe cutting device. This can be placed lateral to the workstation. This allows cutting tubes and profiles in the diameter range from 20 to 250 mm. Machining length: Ø20-105 mm - 6 m, Ø105 -250 mm - 3 m

- High-performance Siemens 840D CNC control

- Non-contact cutting head Precitec HP 1.5 "

- Easy accessibility to the work area of the system for maintenance

- Progressive lens cooling system

Tubemaster

-

Technical Specifications Tubemaster 110 DC015:

- X 7000 mm (optional: 13000 mm)

- Y 350 mm

- Z 120 mm

- A1 360°

- A2 360°

- Max. positioning speed: X 120 m/min - Z 60 m/min

- A1, A2 0-120 rpm

- Working height ±1000 mm

- Max. load capacity 30 kg/m

- Workpiece length 3500-7000 mm (optional: 13000 mm)

- Positioning accuracy in X, Z axes ± 0.01 mm

- Positioning accuracy in Y-axis ± 0.05 mm

- Repeatability ± 0.025 mm

Tubemaster

- Machine frame is a compact, stress-relieved weldment

- The system is designed specifically for 3 or 4 axis laser tube processing. The system allows pipes up to 110mm, square profiles to 80x80mm, with a max length of 7000 mm (optional up to 13000 mm). Automatic loading, positioning and cutting

- Machining of tube profiles of different cross-sections (round, square, rectangular, oval, etc.)

- Processing of tubes with a wall thickness of 1 to 5 mm and a diameter range of 20 to 110 mm

- Max tube diameter - 600 mm

- The machine axes are driven by Siemens servo motors and preloaded ball screws. The drive of the tube linear transport is a rack and pinion with helical teeth

- 5 lifting areas with lifting belt

- Pneumatic tube lifter

- Tube loading magazine

150-fold your savings of CO2 slab laser with the conventional laser technology!- CO2 Slab laser makes conventional gas circulation systems, such as Roots pumps and turbines, superfluous. The built-in laser head premix gas bottle is enough for about 12-18 months of continuous use. Consumption only 0.2l / h instead of the previous 30 l / h

- Energy savings due to no blowers

Milling

CNC vertical machining center

Alpha Center V11L

-

- Siemens 828D incl. 10.4" TFT monitor

- High-quality HIWIN linear guides in all axes

- Meehanite cast iron tempared for stress relief to ensure structural stability without deformation

- C3 class ballscrews ensure the highest accuracy an durability

- Powerful main spindle, (ROYAL / Cells), 10.000 min-1 ISO or BT 40

Technical Specification

- CNC control Siemens 828D Basic inkl. Shopmill

- Table size mm 1200 x 600

- T-slot ( width x number x distance) mm 18 x 5 x 100

- Max. table load kg 800

- X/Y/Z Travel mm 1100 / 600 / 600

Alpha Center V13L

-

- Siemens 828D incl. 10.4“ TFT monitor

- High-quality Rexroth linear guides in all axes

- Meehanite cast iron tempered for stress relief to ensure structural stability without defornation

- C3 class ballscrews ensure the highest accuracy and durability

- NSK or FAG main spindle bearings

- Powerful main spindle, (ROYAL / Cells), 10.000 min-1 ISO or BT 40

Technical Specification

- CNC control Siemens 828D Basic

- Table size mm 1400 x 600

- T-slot (width x number x distance) mm 18 x 5 x 100

- Max. table load kg 1000

- X/Y/Z Travel mm 1300 / 760 / 670

Alpha Center V15L

-

- Siemens 828D incl. 10.4“ TFT monitor

- High-quality Rexroth linear guides in all axes

- Meehanite cast iron tempered for stress relief to ensure structural stability without defornation

- C3 class ballscrews ensure the highest accuracy and durability

- NSK or FAG main spindle bearings

- Powerful main spindle, (ROYAL / Cells), 10.000 min-1 ISO or BT 40

Technical Specification

- CNC control Siemens 828D

- Table size mm 1700 x 600

- T-slot (width x number x distance) mm 18 x 5 x 100

- Max. table load kg 1200

- X/Y/Z Travel mm 1500 / 760 / 670

Alpha Center V7L

- Technical Specification

- Table size mm 900 x 420

- T-slots (width x number x distance) mm 14 x 3 x 125

- Max. table load kg 350

- Travel X/Y/Z mm 762 / 450 / 520

Alpha Center V9L

-

- Siemens 828D incl. 10.4" TFT monitor

- High-quality HIWIN linear guides in all axes

- Meehanite cast iron tempared for stress relief to ensure structural stability without deformation

- C3 class ballscrews ensure the highest accuracy an durability

- Powerful main spindle, (ROYAL / Cells), 10.000 min-1 ISO or BT 40

Technical Specification

- CNC control Siemens 828D Basic inkl. Shopmill

- Table size mm 1060 x 600

- T-slot (width x number x distance) mm 18 x 5 x 100

- Max. table load kg 650

- X/Y/Z Travel mm 900 / 600 / 600

Delta Center V10L

-

Technical Specification

- CNC Siemens 828D Basic

- Table size mm 1100 x 500

- T-slot (width x number x distance) mm 18 x 5 x 100

- Max. table load kg 600

- X/Y/Z travel mm 1020 / 520 / 550

Delta Center V6L

-

- Siemens 828D incl. 10.4“ TFT monitor

- High-quality Rexroth linear guides in all axes

- Meehanite cast iron tempered for stress relief to ensure structural stability without defornation

- C3 class ballscrews ensure the highest accuracy and durability

- Strong main spindle, (ROYAL / Cells), 10.000 min-1 ISO oder BT 40

Technical Specification

- Table size mm 750 x 400

- T-slots (width x number x distance) mm 14 x 3 x 125

- Max. table load kg 350

- Travel X/Y/Z mm 600 / 400 / 450

MINI Center

-

Technical Specification

- Table size mm 650 x 300

- T-slots (width x number x distance) mm 14 x 3 x 100

- Max. table load kg 200

- Travel X/Y/Z mm 500 / 300 / 400

Port-Mill 550 · 700 · 1000 · 1500 · 1800 · 2200

-

Milling centers with extremely heavy gantry design for high quality milling, even when processing difficult materials

Innovative closed bridge construction

High stability, even under heavy milling loads

The closed bridge construction combined with extra strong linear guides, ensures high stability throughout the entire milling process. This results in high accuracy of the machined work pieces.

Targeted for extra heavy cutting roller linear guides from SCHNEEBERGER on the X-, Y- and Z-axis offer capacity 3.5-6 times higher than conventional guideways

Spiral chip conveyor on both sides of the machine

Two spiral chip conveyors located on both sides of the machine bed, transport the chips to the front of the machine to a chain chip conveyor

Technical Specification

- X-axis travel mm 550 700 1000 1500 1800 2200

- Y1-axis travel mm 600 800 1300

- Z-axis travel mm 500 600

Power Center V11

-

- Siemens 828D inkl. 10.4" TFT Bildschirm

- High-quality flat track guides in all axes

- Meehanite cast iron tempered for stress relief to ensure structural stability without deformation

- C3 class ballscrews ensure the highest accuracy and durability

- Powerful main spindle (ROYAL / Cells), 8.000 min-1 SK40 / BT 40

Technical Specification

- Table size mm 1200 x 600

- T-slot (width x number x distance) mm 18 x 5 x 110

- Max. table load kg 850

- X/Y/Z Travel mm 1100 / 600 / 560

Power Center V15 • V18

-

- Siemens 828D inkl. 10.4" TFT Bildschirm

- High-quality flat track guides in all axes

- Meehanite cast iron tempered for stress relief to ensure structural stability without deformation

- C3 class ballscrews ensure the highest accuracy and durability

- Powerful main spindle (ROYAL / Cells), 8.000 min-1 SK40 / BT 40

Technical Specification

- Table size mm 1700 x 800 1900 x 900

- T-slot (width x numberl x distance) mm 22 x 5 x 135 18 x 7 x 120

- Max. table load kg 2000

- X/Y/Z Travel mm 1500 / 800 / 700 1800 / 900 / 700

PVT-Mill 2500 • 3500 CNC

-

- Machine with highly rigid bed made of Meehanite GA 350 cast iron and bed-type fixed-position table. Heat-treated and stabilized crystal structure of the castiron.

- Fixed-position table length of 2500 mm and heavy-duty supporting structure. The max. load capacity of the table is1800 kg. Machine's working envelope length is 2200 mm.

- Movable column with high-precision linear guideways in 3 axes ensuring rapid traverse speeds up to 32 m/min.

- It can also be equipped with optical linear scales for better positioning accuracy and contouring, up to 0.005 mm.

- The machine is equipped with an automatic tool changer installed on the column side. The tool magazine is located in the X-axis, thus lying outside of the table working envelope. Such an arrangement prevents the tool system from colliding with large-workpieces.

- The machine can be fitted with through-spindle coolant (20 bar) for machining deep holes, improved surface machining and better accuracy.

- The standard machine configuration includes a 32-pos. tool magazine. Additionally, it can be equipped with a 40-pos. tool magazine (optional).

- High-precision spindle with 8000 rpm.

- It is also possible to equip the machine with a spindle running on P4 Class high-precision ceramic bearings with 10.000 or 12.000 rpm. This makes the machine ideally suited for 3D machining of molding and press tools.

- The coolant filtration system with filter mesh size of 0.02 mm. It serves to prevent the high-pressure pump from dirt ingress and clogging.

- Around-spindle coolant supply system: 6 adjustable supply nozzles around the main spindle.

- The machine is equipped with a coolant gun and an air pistol for rinsing and air-purging of the working area.

- Automatic lubrication system with level warning and failure alarm.

Twin-Mill T 500 • 700 • 1000

-

Machining centers, in massive gantry design, with two separate desks for simultaneous loading during machining

Machine frame made from high-grade Meehanite cast iron for many years of superior processing, accuracy and reliability.

High speeds additional accessories for further automated, will increase your productivity.Technical Specification

- X-axis travel mm 500 700 1000

- Y1-axis travel mm 600

- Y2-axis travel mm 600

- Z-axis travel mm 500

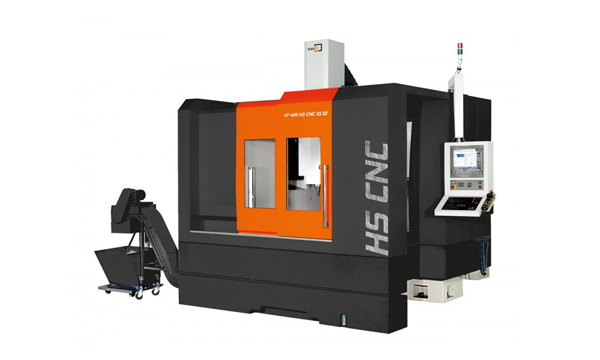

VF-Mill HS CNC

-

Milling and engraving in the high-end segment with up to 60,000 rpm

- Every single VF Mill HS CNC milling machine is subjected to an exacting quality control process. Our goal is to ensure optimal machine performance

- The machine design guarantees a maximum of accuracy, speed and cutting ability

- The spindle oil cooling provides efficient heat removal and ensures long-lasting durability and precision of the spindle unit

- The use of automatic workpiece measurement system guarantees extremely high accuracy of work piece referencing and thereby shorter setup times

- The use of the optional laser tool inspection system ensures high machining and repetition accuracy. The automatic tool measurement further automates your manufacturing

- Optionally, the spindle with coolant function, improves tool life and allows high-speed machining

- Central lubrication

- Schneeberger Linear guidance systems

- Machines with dynamic gantry construction (from 6.6 models)

VF760 • VF900 • VF1100 • VF1300

-

- Siemens 828D inkl. 10.4" TFT monitor

- High-quality HIWIN linear guides in all axes (roller design)

- Heavy Meehanite cast body for optimum vibration damping

- Ball screw of accuracy class 3

- Powerful main spindle, 12,000 min-1 ISO or BT 40, Ø=160 mm, Ø=140 mm (VF760)

Technical Specification

- Table size mm 900 x 420

- 1060 x 600 1300 x 600 1500 x 650

- T-slot (width x number x distance) mm 14 x 3 x 125 18 x 5 x 100

- Max. table load kg 350 650 800 1000

- X/Y/Z Travel mm 762 / 450 / 520 900 / 600 / 600 1100 / 650 / 600 1300 / 650 / 600

CNC 5-axis machining center

CRONUM 630.5X

-

Technical speci fications

- Size mm Ø 630

- Max. loading capacity Kg 500 (Opt. 850)

- Height mm 880

- Max. workpiece dimension(diameter x height) mm Ø 800x500

- A/C axis min. indexingincrement °0.001

- Taper SK 40

- Speed rpm Fanuc: Built-in type 14.000 (opt.20.000) Heidenhain: Built-in type 14.000 (opt.20.000)

- X-/Y-/Z-axis mm 760/820/560

3D Interference Protection System- Supports the operator with setup of tools, workpieces, and clamping device as a clear 3D model. Uses 3D simulation to check spindle, tool, workpiece, and clamping device in interaction for possible collisions

- In operating mode, the activated system stops the feed before collision

- With online milling function simulation

Automatic workpiece position detection- Mutual correction of the axis center

- Tool length measuring

- Tool breakage detection

Intelligent spindle design- Spindle bearing temperature monitoring and compensation

- Spindle vibration monitoring

Multi Mill 600.5 X

-

5-axis simultaneous high performance milling

Technical specifications

- X-axis travel 600 mm

- Y-axis travel 700 mm

- Z-axis travel 600 mm

- Diameter 630 mm

- Max. load 700 kg

- Weight 12.000 kg

V-Mill 1000.5X CNC

-

- Massive machine bed made of high quality cast iron for better vibration damping

- Rigid gantry frame construction consisting of base, double racks and stable crossbeam ensuring high rigidity and cutting performance

- Powerful spindle: 16000 rpm, 15/22.5 kW (48/72 Nm), BT 40 spindle taper

- 40 station tool magazine

- High-strength, precision ground guides and high-quality ball screws ensure high-precision machining

- Large work table 1000x800 mm, max. table load 1500 kg

Technical specifications

- Axis travel: X 1000 mm/ Y 800 mm/Z 700 mm

- Table dimensions 1000x800 mm

- Max. table load capacity 1500 kg

- Working feed rate 10 m/min

- Max. spindle speed 15000 rpm

- Spindle taper BT 40

- Max. tool weight 7 kg

- Weight 15000 kg

CNC horizontal machining center

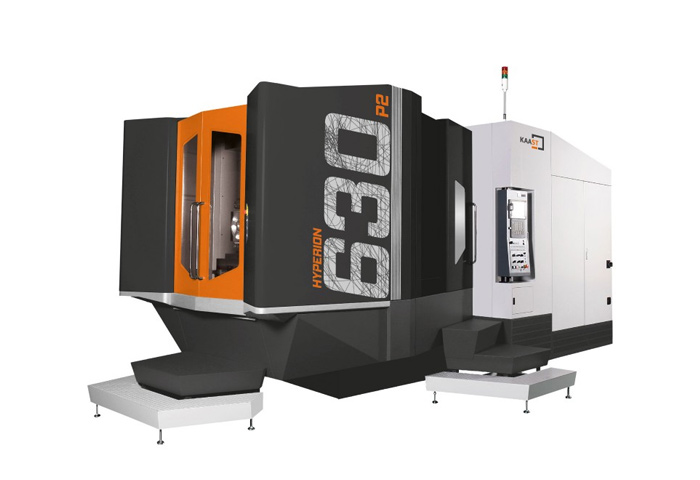

HYPERION 630 P2 · 800 P2

-

The development of this machine focused on flexibility of application and reduction of the tooling and downtimes. This ensures that max. output is always guaranteed in the fast-paced cutting industry of today.

The machine frame optimized by FEA has outstanding dynamics, paired with high rapid traverse speeds and simultaneous effective vibration absorption with any milling application.Technical speci fications

- X-axis mm 1050 - 1200

- Y-axis mm 850 - 1000

- Z-axis mm 970 - 1000

- Spindle nose to table center mm 100 - 1200

- Spindle center to tablesurface mm 100 - 1100

- Max. load kg 1200x2 - 1800x2

- Steps 2 Stufen, elektr.

- Taper BT 40 / ISO 40

STRATOM 400 P2 · 500 P2

-

Space-saving machine concept

- Designed for low space requirement

- Powerful main spindle, S2 = 25 kW (35 Hp) with double speed reduction for a high torque up to max. 235 Nm

- Ideal for flexible cutting of numerous different material classes because of the speed band width up to max. 12000rpm.

- Tool measuring system for easy and safe work

- Chip flushing system for cleaning of the machining area

- Clamping of the B-axis is done by hydraulic conical dowels generating a clampingforce of 17 tons. This ensures exact positioning and clamping even with heavy cutting.

- The standard double table change device even permits loading of max. 400/500 kg and this offers sufficient provision for workpiece and clamping device.

- Because of their innovative design, the machines in this series have an extremely heavy machine bed in 3-point design with constant high dynamic in the main spindle and the feed axes of up to 0.9 G acceleration

- All axes are equipped with high-quality roller linear guides

Technical specifications

- X-axis mm 610 - 710

- Y-axis mm 580 - 680

- Z-axis mm 580 - 680

- Speed rpm 12000

- Feed m/min. 60

- Cutting feedrate mm/min. 1-20.000

- Tool shank BT 40

- Number of positions pc. 60

- Max. tool lenght mm 410 410

- Max. tool weight Kg 12

CNC gantry-type milling center

PFC-Mill CNC

-

- Extremely robust and solid base frame provides great rigidity, stability and vibration-free work even with heavy duty cutting

- Rigid frame structure consisting of a solid machine bed with a large gantry

- Work piece movement in the x-axis is carried out by table movement on triple V and flat guideways

Technical specifications

- Column to column distance mm 1850 - 3650

- Max. load capacity of table kg 12000 - 26000

- X-axis mm 2200 - 6000

- Y-axis mm 1800 - 3600

- Z-axis mm 800

- Spindle taper BT 50

- Cutting feed rate mm/min 5-8000

- Positioning accuracy mm ±0.005/300

- Repeatability mm ±0.003/300

PSD-Mill CNC

-

- Extremely robust and solid base frame provides great rigidity, stability and vibration-free work even with heavy duty cutting

- Rigid frame structure consisting of a massive machine bed, two movable uprights and a strong crossbeam, ensures excellent positioning stability and high cutting efficiency

Technical specifications

- Distance between columns mm 2450 - 5450

- X-axis mm from 6m to 36m in 1m increments

- Y-axis mm 2400 - 5400

- Z-axis mm 1100 (optional 1400)

- W-axis (optional) mm 1000 (optional 1500 to 2500)

- Spindle taper BT 50

- Spindle speed rpm 6000

- Work feed mm/min 5–8000

- Positioning accuracy mm ±0.005 / 300

- Repeatability mm ±0.003 / 300

Port-Max 1300 • 1600

-

- The Port-Max series are particularly suitable for large and heavy workpieces. The portals realize feed in all axes, thus avoiding movement of the components by the machine. The rigid machine table supports loads up to 2000 kg/² andthus offers sufficient provision for very large workpieces.

- The guidance concept uses high-load roller linear guides that avoid the slip-stick effect and ensure permanent precision over many years, even with the most heavy duty demands in hard every day production. The accuracy of the machine is thus truly remarkable in regard to the feed length in interaction with the high resolution digital drives and accordingly always delivers parts with accurate dimensions to your customers.

- Standard tool changer with 24 positions, ZF Duoplan transmission for main spindle withmax. 660 Nm (487 ftlb) torque, automatic lubrication, and double chip conveyor provide for a effective basic model in this series, ideal for numerous milling applications.

- Flexibility in the choice of CNC controls, Mitsubishi, Siemens,Fanuc, or Heidenhain, together with options like IKZ, various milling heads, glass scales, etc., enable optimum conformance with customer requirements.

Technical specifications

- X-axis travel 2000 - 30000 mm

- Y-axis travel 1300 mm 1600 mm

- Z-axis travel 800 mm (opt. 1100 mm)

- Distance between columns 1300 mm - 1600 mm

- Table length 2000 ~ 30000 mm

- Table width 1100 - 1400

- Spindlenose - table 320 ~ 1120 mm

- Spindle taper BT50

V65HS

-

Technical specifications

- Table size mm 600 x 500

- T-slot (width x number x distance) mm 18 x 5 x 100

- Max. table load kg 300

- X/Y/Z Travel mm 600 / 500 / 250

V1613HS

-

Technical specifications

- Table size mm 1700 x 1200

- Table-slot (width x number x distance) mm 18 x 7 x 150

- Max. table load kg 3000

- X/Y/Z travel mm 1600 / 1300 / 600

V2013 • V2317 • V3317 • V3025 • V4025

-

Techncal Specifikations

- Tiable size mm 2100 x 1200, 2300 x 1500, 3300 x 1500, 3000 x 2100, 4000 x 2100

- T-slots (width x number x distance) mm 18 x 7 x 150, 22 x 8 x 170, 28 x 9 x 220,

- Max. table load kg 4.000, 8.000, 10.000, 8.000, 10.000

- X/Y/Z travel mm 2000/1300/800, 2300/1600/800, 3300/1600/800, 3000/2500/1000, 4000/92500/1000

CNC milling & tapping center

Delta Center T6 • T7

-

Technical specifications

- Table size mm 700 × 420, 900 x 420

- T-slots (width x number x distance) mm 14 x 3 x 125

- Max. table load kg 350

- Travel X/Y/Z mm 600 / 400 / 300 760 / 450 / 420

CNC & conventional universal milling machines

H-Mill 1500 U • P • T / H-Mill 1330

-

Technical specifications

- T-slots (distance) mm 60 - 70

- Swivel range table l/r deg. 45

- X-axis travel mm 1150 - 950

- Y-axis travel mm 400 - 380

- Z-axis travel mm 500 - 450

- Max. table load kg 700 - 500

Infinitely variable feed speed in all axes

TW-Mill 2 • 5

-

Technical specifications

- Table dimensions mm 320x750 - 500x900

- Vertical table dimensions mm 250x880 - 250x1200

- X-axis (Manual/Auto) mm 400/385 - 600/585

- Y-axis (Manual/Auto) mm 200/185 - 480/465

- Spindle nose ISO 40

- Weight kg 1180 - 1450

- Slideways are hardened and precision ground on the column and vertical table surface

- Quill stroke is 100 mm, to work the handle located on right side of head stock

- TW-Mill 5: The X and Y-axes are dovetail way, Z-axis is square way

- TW-Mill 2: The X-, Y- and Z-axes are dovetail way

- The X- and Y-axes are transmitted by precision ball screw (Z-axis ball screw type as option)

- The operating control panel is equipped with a swivel arm type, wich will be more convenient and comfort for operator to work the machine at right side

- Outer arbor support for horizontal milling

- Can be installed with air power drawbar system, DRO system and automatic lubrication system as option

- Automatically feeding travel on X-, Y- and Z-axes by inverter driven

WF 500 CNC

-

Technical specifications

- Table size mm 400 x 800

- Vertical table size mm 250 x 1.200

- T-slots, work table mm 14 x 63 / 6 no.

- T-slots, vertical table mm 14 x 63 / 3 no.

- Table load capacity kg 380

- X / Y / Z travel mm 500 / 350 / 400

bed-type milling machine

V-Mill 1400

-

Technical specifications V-Mill 1400:

- Table dimensions 1400x400 mm

- T-slots (number x width x spacing) 3x18x100 mm

- X-axis travel 800 mm

- Y-axis travel 400 mm

- Z-axis travel 500 mm

- Weight 3860 kg

Machine for machining large and heavy parts- Large sturdy box construction and ribbed frame to reduce vibration

- Large flat guides, hardened and ground, guarantee stability, even under heavy milling loads

- Manual quill stroke, service is effected via a handwheel

- Infinitely adjustable speed range (20-1800 rpm) with high torque and spindle brake

- High table load capacity due to massive Meehanite cast iron construction

V-Mill C 2100

-

Technical specifications V-Mill C 2100:

- X-axis travel 1500 mm

- Y-axis travel 670 mm

- Z-axis travel 0-670 mm

- Table dimensions 2100x500 mm

- Max. table load capacity 2000 kg

- Weight 7300 kg

Solid cast iron frame, powerful drive and massive guideways - perfect for heavy-duty machining- Generous flat guides, hardened and ground to ensure stability and precision even with extremely high table loads

- Spindle speed of 40 - 1600 rmin

- Universal milling head, can be swiveled to any angle, as well as horizontally to ensure flexible milling

- Infinitely variable length and crosswise feed

- Heavy construction for optimum vibration damping permits heavy-duty high-quality perfect milling

V-Mill C 2500

-

Technical specifications V-Mill C 2500:

- X-axis travel 1800 mm

- Y-axis travel 600 mm

- Z-axis travel 700 mm

- Table dimensions 2500x575 mm

- Max. table load capacity 3000 kg

- Weight 10000 kg

10.000 kg machine weight for heavy-duty cutting- The universal milling head can be adjusted to any 360° angle including horizontal

- The sturdy cast iron construction with a weight of 10.000 kg allows a maximum table load capacity of up to 3.000 kg

- Servo drives on all axes, the automatic feed rates are infinitely variable in the X- and Y-axis

- Simultaneous movement of several axes

- Rapid traverse in all axes

- Automatic central lubrication

- Hanging panel for optimum operating comfort

- Powerful hydraulic clamping in X-, Y-and Z-axis

- Good accessibility to the machine table and the cutter head facilitate the loading and unloading as well as work on the milling head

- A wide array of uses are possible with this machine through optional special accessories (eg. dividing head, rotary table, tailstock)

Lathes

CNC Ultra High Precision

UHP-Turn 450

-

Technical specifications UHP-Turn 450:

- Max. Turning diameter over bed mm 450

- Max. Turning diameter over slide mm 280

- Max. workpiece diameter mm 280

- Max. workpiece length mm 330

- Chuck size mm 150/175

- Spindle bore mm 45

- Spindle speed rpm 6000

- Power (peak) kW 11

- Spindle nose A2-5

- Travel X-axis mm 150+10

- Travel Z-axis mm 350

High precision spindle rotation of = <0.8 µm

Special characteristics of the linear guideway series RG

The new RG series from Hiwin features a roller as the rolling element instead of steel balls. The roller series offers super high rigidity and very high load capacities. The RG series is designed with a 45-degree contact angle. Elastic deformation of the linear contact surface, during load, is greatly reduced thereby offering greater rigidity and higher load capacities in all 4 load directions. The RG series linear guideway offers high performance for high-precision manufacturing and achieving longer service life.

CNC slant bed lathes

Alpha-Turn

-

Technical specifications

- Max. workpiece diameter mm Ø250 - Ø550

- Max. workpiece length mm 200 - 950

- Spindle bore mm Ø42 - Ø103

- Spindle speed rpm 6000 - 2500

- Power (peak) kW 7.4 - 30

- X-axis mm 420 150+10 150+10 195+15 220+20 235+20 285+25

- Z-axis mm 220 220 350 435 610/1010 630/1025 975/1525

- Positioning accuracy mm ±0,004

- Repeatability mm ±0,002

- Tank capacity l 100 - 300

Improved machine utilization - increased profits!

Serial production with our automation solutions. The “gantry loader“ - individual, tireless and efficient We will be happy to work with you on your individual offer. KAAST. Your Production Partner.

The high quality MEEHANITE cast iron

ensuring long-lasting accuracy and stability. Each Alphaturn cast iron frame has been tested in the production of authorized Meehanite foundries.

Level bed with two guide planes

The alpha-turn cast iron bed has a 2-step guidance system in order to guarantee constant stability, especially in heavy-duty machining. The occurring forces, during machining will be better distributed on dual rails. For the user this means larger infeed, faster in two levels working feeds and a perfect image rotation in conjunction with the powerful main spindle.

Alpha-Turn MC

-

Technical specifications

- Max. turning diameter over bed mm Ø530 - Ø650

- Main spindle chuck size mm Ø200 - Ø300 opt.

- Spindle bore mm Ø52 - Ø78

- Spindle speed rpm 5000 - 3500

- Power (peak) kW 15 - 30

- Travel X-axis mm 195+10 220+20 235+20

- Travel Z-axis mm 355 550/950 550/950

- Positioning accuracy mm ±0.004

- Repeatability mm ±0.002

- Tank capacity l 200 - 250

- Weight kg 4100 5400 - 5800

Driven attachment with C-axis

The C-axis has an extremely high resolution and thus enables production of extremely precise true to size work pieces. The tool turret from Sauter is standard with VDI tool holders. The high torque of the rotary tool allows powerful metal cutting in the alpha-turn lathes.

THK – NR Type

Linear guides for heavy processing · High axial load capacity and rapid feed. The minimal coefficient of friction and backlash-free preloaded linear guideways allow for fast processing, high repeatability and high positioning accuracy. In order to achieve a fast rapid feed and a high load capacity, large guideways from THK have been used.

Alpha-Turn T • MCY • TMC • TMCY

-

Technical specifications

- Spindle speed rpm 3500 - 3500

- Spindle speed rpm 6000 - 4500

- Power (peak) kW 15 - 18.5

- Travel X-axis mm 225+25 250+25 225+25 250+25 225+25 250+25 225+25 250+25

- Travel Y-axis mm 100 - 120

- Travel Z-axis mm 600 std./1000 opt. 600 std./1000 opt.

- Travel B-axis mm 600 std./1000 opt. 600 std./1000 opt.

- Positioning accuracy mm ±0,004

- Repeatability mm ±0,002

Multi-axis machining options

The Y-axis (MCY / TMCY models), combined with C-axis spindle orientation and driven tools, allows complex turning and milling operations of the work pieces.

F-Turn 330 • 485 CNC

-

- F-turn 330 CNC machines are equipped with heavy-dutyspindle and 2‑step ZF-gearbox

- F-turn 485 CNC machines are equipped with 3‑stepgearbox

- F-turn 485 CNC machines are fitted with heavy-dutyhydraulic-driven 12‑pos. tool turret ensuringhigh positioning accuracy

- F-turn 330 CNC machines are fitted with heavy-dutyhydraulic-driven 10‑pos. tool turret ensuring highpositioning accuracy

- 12‑pos. hydraulic tool turret with live tools available onF-turn 330 CNC

- Hydraulic pump to control 3-jaw chuck and tool turretoperation

- F-turn 330 CNC machines can be equipped with steadyrest for machining of long parts

- Spindle oil cooling - for efficient heat removal and spindleand gearbox temperature control (F-turn 485 CNC)

- Programmable hydraulic tailstock motion driven byservodrive. The system is controlled by CNC М-codes(F-turn 485 CNC)

Technical specifications

- Swing over bed mm Ø660 Ø970

- Swing over carriage mm Ø480 - Ø720

- Max. workpiece diameter mm Ø500 - Ø850

- Center-to-center distance mm 820 - 3200

- Work feeds mm/min 0,001-500

F-Turn 390 TMCY CNC

-

Slant (45°) bed machine. Rigid bed of Meehanite cast iron ensuring high load capability- «T»-versions are equipped with 2 C-axes

- 45° inclined slant-type bed with significant reinforcement ribs made of Meehanite cast iron

- Roller-bearing linear guideways X, Z, Y-axis

- 12-pos. tool turret DUPLOMATIC SMBR with servodrives for live tools from Fanuc. Quick tool changing and superior positioning accuracy 0.001 mm

- Synchronized high-precision spindle and sub-spindle (P4 accuracy grade)

- Hydraulic tool turret and turning chuck

- Optional automatic tool setting system

Technical specifications

- Swing over bed mm Ø780

- Max. workpiece diameter mm Ø300 - Ø230

- Max. turning length mm 260 - 470

- X-axis mm 185 185 150

- Z-axis mm 310 560 540

- Y-axis mm ±40 ±40 ±50

- E-axis (Spindle/ Counterspindle rechuck) mm 260 - 470

- Hydraulic motor kW 1.5

- Volume hydraulic tank l 60

IMTA 320 T2 · 320 T3

-

Interaction Milling Turning Application

- The consistent 75° steep bed design allows the near rectangulararrangement of X-, Y-, and Z-axes to each other,which has a positive effect on stability and accuracy.

- Good accessibility, particularly for loading of the machine,and the ideal chip flow are other highlights of this design.

3D Interference Protection

Multi-axes machining places considerable demands on the user. To prevent expensive downtime, the IMTA 320 has 3D interference protection simulation software as standard. This avoids collisions when new programs are inserted and thus ensures max. availability of your investment.Technical specifications

- Max. turning dia. over bed mm Ø 720

- Max. turning dia. over slide mm BMT-65 (opt. VDI-40)310 Ø 310

- Max turning diameter mm Ø 320

- Max. turning length mm 600

- Spindle speed rpm 4500 (opt. 6000)

- Tool shankBMT-65 (opt. VDI-40)

OPUS 410 · 530

-

- Solid, polished, and hardened flat guides in combinationwith a powerful drive system of the main spindle and onthe feed axes provide for always sufficient reserve withdifficult cutting. The rigid spindles are provided withgenerous bearings and always provide sufficient torque tothe optional transmission

- Optional C-axis and tool changer with driven tools (max.5.5 kW (7.4 Hp) at 4500 rpm) for milling and boring work

- Programmable tailstock

- Optional hydraulic steady rest for support of longerworkpieces

Technical specifications

- Max. turning diameter over bed mm Ø 620 (opt. Ø 1000/ Ø 1200)

- Bar capacity mm Ø 75 - Ø 90

- X/Z- axis travel

- mm 245/1000 - 245/2000

- Tank capacity l 200 (opt.240/280)

- Weight kg 6500 7000 - 8200

Tailstock

The programmable tailstock is fed together withthe tool changer. The hydraulic clamping providesfor maximum positional accuracy even with heavyworkpieces

R-Turn 315/1890 CNC

-

- Linear guides for increased speeds

- Massive cast iron bed ensures high machine stability, absorption of vibrations and long-lasting machine accuracy

- 2-step gear transmission with automatic engagement

- Optional live tooling and C-axis provides various tool capacities and fast tool positioning

- Optional steady rest maintains high precision for long work pieces

- Siemens controller is available

Technical specifications

- X-axis travel mm 290

- Z-axis travel mm 1590

- C-axis travel degr 360º (0.001º)

- Overall dimensions (LxWxH) mm 5325х1950х2200

- Weight kg 9770

TITAN 620

-

- 45° mono-block, Meehanite cast machine bed is extremely heavy for max. absorption of vibrations and taking up ofcutting forces.

- Amply dimensioned, induction-hardened, and precision-ground square guides provides precise turning results over many years even with the heavy use in hard daily production.

- The main spindle is provided as standard with 30/37 kW (40/50 Hp) and max. 1479 Nm (1090 ftlb) torque. If required, it can be upgraded with a Ø 180 mm (7”) spindle bearing, dual transmission, and a 37/45 kW (50/60Hp) drive. A max. torque of more than 2,200 Nm is then available.

- Baruffaldi BMT-75 tool changer with driven 11/15 kW (15/20 Hp) milling tools

- Hydraulically clamped and programmable tailstock

Technical specifications

- Bar capacity mm Ø 90 (opt. Ø 116)

- X/Z-axis travel mm 365/1200 - 365/3000

- Tank capacity mm 990/150 - 2790/150

- Hydraulik Tank Kapazität l 40

- Tankvolumen l 240 - 400

- LxWxH mm 4350x2100x2280- 6500x2150x2280

- Weight kg 8500 - 17000

VERTUS 220 · 220 MC

-

In compact design for manufacturing of short standard parts

The optional loading robot completes theloading/unloading process in just 4.8 seconds.This clearly reduces down times and makeseffective unmanned operation possible.- Compact design, even with driven tools and optional automationof loading and unloading

- C-axis and driven tools for expanded applications (Vertus 220 MC)

- Dynamic spindle acceleration/deceleration for reduction ofdowntimes

- Turned parts up to 220 mm (8.6”) diameter and 200 mm (7.9”)length can be machined extremely precisely and quickly

- Integrated chip conveyor

- The robust cast bed provides for high stability of the machine

- Large ball screws and flat guide

Technical specifications

- Bar capacity mm Ø 26 (opt. Ø 44/ Ø 51)

- Travels X/Y axis mm 155/220

- Hydrl. tank capacity l 30

- LxWxH mm 1410x1450x1730

- Weight kg 2350

S-Turn 200 CNC • 200M

-

- A2-6, 4200 rpm

- Max. turning diameter Ø370 mm

- Max. turning length 500 mm

- Max bar capacity Ø52 mm

- 30 degree saddle design

- High precision roller guideway and C3 ball screw

- Sauter 12 tools servo turret

- High performance power turret enables milling and drilling

- Robot solution available

CNC heavy duty lathes

AXIOM 330 • 430 • 500 • 600 • 700 • 800 • 1000 • 1200 • 1300

-

Technical specifications AXIOM 330 - 1300:

- Width of bed mm 558 - 1400

- X-axis travel mm 330 - 1300

- Z-axis travel as peak width is reduced by 350 mm - 650 mm

- Tailstock travel mm 300 - 600

- For extremely heavy workpieces and machining lengths up to 30

- Large ballscrews ensure long-lasting precision

- The standard telescopic enclosure can be moved for loadingand unloading of the machine, to provide good accessibilityto the most important areas

- For the machines of the AXIOM Series, only componentsfrom leading manufacturers were used so as to ensuremaximum machine availability

- The impressively high workpiece weights for this class ofmachines can be significantly increased by steady-restsfrom SMW-Autoblok

- Powerful spindle motors with high torque for efficientprocessing even in difficult to cut materials

- The machine bed impresses with extremely high stiffness,due to the heavily ribbed casting

- Large bed widths from 585 to 1400 mm

CNC cycle lathes

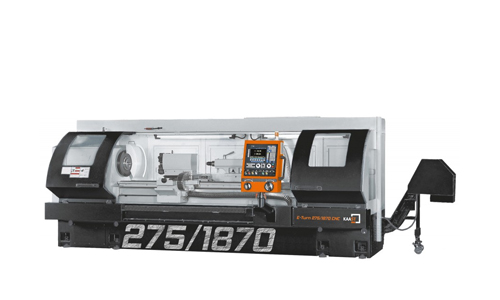

E-Turn 275 CNC

-

Technical specifications E-Turn CNC 275/87 - 275/2870:

- Turning capacity mm Ø550

- X-axis travel mm 300

- Z-axis travel mm 780 - 2780

- X-axis rapid traverse m/min 7.5

- Z-axis rapid traverse m/min 10

- Coolant tank Liter 60 - 240

- Overall dimensions (LxWxH) mm 3200х2300х2230 - 5200х2300х2230

- Weight kg 4050 - 5300

- 2-step transmission ensuring high rotation torque

- Manual handwheel controlled operation

- Programmable turning cycles

- Auto-switch pneumatically changes the gear speeds

E-Turn G 205 • G 230 CNC

-

Technical speci fications E-Turn G CNC 205/890 - 230/1400:

- Turning capacity mm Ø410 - Ø460

- Travel X-axis mm 205 - 230

- Travel Z-axis mm 815 - 1350

- X-axis rapid traverse m/min 7.5 7.5

- Z-axis rapid traverse m/min 10 10

- Overall dimensions (LxWxH) mm 2470х2030х2200 - 3360х2115х2340

- Weight kg 2150 - 2600

- 2-step transmission ensuring high rotation torque

- Manual handwheel controlled operation

- Programmable turning cycles

- Auto-switch pneumatically changes the gear speeds

TLG 220/1000 • 220/1500 • 220/2000

-

Technical specifications TLG 220/1000 - 220/2000:

- Max. workpiece length 1000 mm - 2000 mm

- Width of bed 2000 mm - 3020 mm

- Travel X-axis 280 mm

- Travel Z-axis 920 mm - 1940 mm

- Feed X-/Z-axis 6 m/min / 8 m/min

- Weight 1800 kg - 2300 kg

- Interactive, graphically supported programming cycles forvolume and single part production

- High productivity due the 4-way automatic tool changer

- Solid and heavy construction

- Triple support precision bearings for main spindle

- Optimal results with stepless speed adjustment

- 2 electronic handwheels enable manual operation

- High precision recirculating ball screws

- Programming of complex work pieces, even without DINprogrammingknowledge

- Implemented cycles for facing and plain turning, cone,radius, thread, plunge-cut and complete contouring

- Wide, hardened and ground prism guides ensure excellentstability of the lathe’s bed, even with large centre distances(>HB 400)

- Automatic central lubrication

- Automatic gearbox ensures a high torque

TLG 255/1000 • 255/1500 • 255/2000

-

Technical specifications TLG 255/1000 - 255/2000:

- Max. workpiece length 1000 mm - 2000 mm

- Width of bed 2000 mm - 3020 mm

- Travel X-axis 280 mm

- Travel Z-axis 920 mm - 1940 mm

- Feed X-/Z-axis 6 m/min / 8 m/min

- Weight 2100 kg - 2600 kg

- Interactive, graphically supported programming cycles forvolume and single part production

- High productivity due the 4-way automatic tool changer

- Solid and heavy construction

- Triple support precision bearings for main spindle

- Optimal results with stepless speed adjustment

- 2 electronic handwheels enable manual operation

- High precision recirculating ball screws

- Programming of complex work pieces, even without DINprogrammingknowledge

- Implemented cycles for facing and plain turning, cone,radius, thread, plunge-cut and complete contouring

- Wide, hardened and ground prism guides ensure excellentstability of the lathe’s bed, even with large centre distances(>HB 400)

- Automatic central lubrication

- Automatic gearbox ensures a high torque

CNC vertical lathes

iVL 20 • 25 • 30

-

- X- and Y-axis have a linear drive guaranteeing feed rates of60/40 m/min (2360/1575”/min) and the highest precision

- Constant temperature by spindle cooling system

- The ideal chip drop guarantees trouble-free work and longtool life

- The machine has good accessibility, and the servicingpoints are easily accessible

Technical specifications

- Feed X/Z-axis m/min 36/36 - 30/30

- Travel X/Z-axis mm 180+560/260 - 300+1660/600

- Capacity l 30 - 40

- Volume system l 120 - 220

- Overall dimensions (LxWxH) mm 1680x1830x2405 - 3640x2850x3330

- Weight kg 3600 - 9700

Spindle pick-up principle

The rotating spindle moves in the vertical as well as in thehorizontal plane and thus is able to pick up workpieces autonomously from the workpiece pool and to deposit the magain after machining. This simple automation concept provides for extremely high availability and productivity withmodest investment costs.

V-Turn A 560 • 800 • 1000 • 1320 CNC

-

Technical specifications

- X/Z-axis rapid traverse mm/min 20/20

- X-axis travel mm 275 - 625

- Z-axis travel mm 460 - 1000

- Overall dimensions mm 1700х3100х2855 - 2700х4000х4050

- Weight kg 6500 - 21000

For high-speed turning of large capacity work pieces

- Turning of work pieces up to Ø1100 mm (43”)

- 12-position tool turret standard

- High machine rigidity ensures long-lasting process accuracy

- Functional and easy-to-operate Fanuc CNC 0i-TD as standard

- High machine reliability due to use of high-quality components manufactured by renowned manufacturers

V-Turn B CNC

-

Technical specifications

- Max. workpiece diameter mm 1250 - 10000

- Table diameter mm 1000 - 7200

- Max. workpiece heigth mm 1000 - 5000

- Max. workpiece weight kg 3500 - 40000

- Weight kg 9000 -310000

Flexible, optional driven tools and tool changer- High machine rigidity as a result of quality casting HT300

- Heavy ribbed pillar with wide flat guides ensuresmaximum stability with very good damping properties

- Precision ballscrew for x and y-axis

- Hydraulic compensation cylinder instead of acounterweight for the tool

- Asymmetrical work pieces can be easily clampedusing the 4-jaw faceplate chuck

- Good accessibility of the working area makes tooling,set up and unloading easier

- Machine suitable for internal and external turning, optionally for boring and millingapplications

- Hydraulic clamping of the cross member

- All guideways are supplied with lubricant by centralized lubrication

- Quadruple tool revolver as basic equipment

- Main spindle drive up to max. 90 kW (120 Hp)

- Gearing for sufficient torque at any time

- Machine for machining of large and heavy workpieces

- All castings are annealed to minimize stress, guideways are counter laminatedwith Turcite B

- The entire machine frame has beendesigned, calculated, and optimizedwith FEM technology

- Digital drive package of Siemensor Fanuc

- Ball screw drive from THK / Japan

V-Turn Pro CNC • V-Turn Proplus CNC

-

Technical specifications

- Table diameter mm 1250 - 2500

- Max. Turning diameter mm 1600 - 3000

- Max. workpiece diameter mm 1500 - 3000

- Max. working height mm 1250 - 1600

- Max. weight of workpiece kg 6000 - 15000

- Machine dimensions mm 5900x3800x5360 - 7900x6100x6300

- Weight kg 20500 - 51000

For high-speed turning of large work pieces

With turning diameters of up to 3,000 mm and more, with a maximum work piece weight of up to 21,000 kg. The V-Turn Pro Series impresses by excellent processing results. The optional driven milling tools with integrated C-axis and automatic tool changer, offer the possibility of complex complete machining in one setup.

Patented octagon tool bar design

The unique structure guarantees the highest precision and controlled thermal expansion. The special octagonal structure provides superior mechanical properties and thus exhibits a higher stiffness than conventional, square tool carriers.

V-Turn B 1350 HS

-

Technical specifications

- Max. swing diamete mm 1350

- Max. cutting diameter mm 1350

- Worktable diameter mm 1000

- Max. workpiece height mm 1200

- Max. worktable load kg 5000

- Max. output torque of worktable Nm 25.000

heavy duty lathes

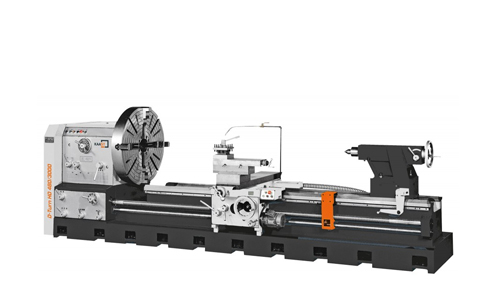

D-Turn F 700/5000

-

Technical specifications

- Swing Ø over bed Ø1600 mm

- Swing Ø over toolholder Ø1250 mm

- Max. weight of workpieces 12 t

- Max. length of workpieces 5000 mm

- Width of machine bed 970 mm

- Tool shank dimensions 45x45 mm

- Spindle Ø Ø 200 mm

- Taper hole of spindle 1:20

- Spindle bore Ø Ø 100 mm

- Stroke of top toolholder 300 mm

- Stroke of tailstock sleeve 250 mm

The Heavy-Duty-Allrounder

The D-Turn F heavy duty lathe belongs to the Multi-function lathes, with an impressvie maximum workpiece machining of 12 tons.

With their high precision, high reliability, high rigidity, precise production, elegant appearance and the comfortable maintenance is the D-Turn F for almost all tasks, like rough-or finish cutting of metal-and non-metal workpieces suitable.

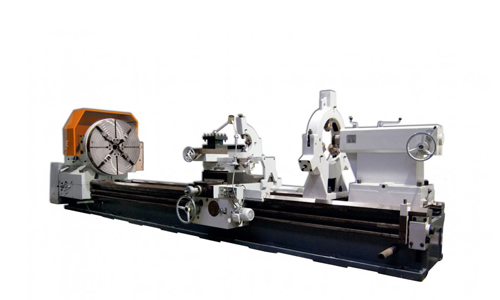

D-Turn Giant

-

Technical specifications D-Turn Giant 1600 - 1800:

- Center height mm 800- 900

- Max. turning diameter over bed mm Ø1600 Ø1800

- Max. turning diameter over slide mm Ø1230 Ø1430

- Max. turning diameter over gap mm Ø1900x750 Ø2100x750

- Width of bed mm 888

Technical specifications D-Turn Giant 2000 - 2300:

- Center height mm 1000 - 1150

- Max. turning diameter over bed mm Ø2000 Ø2300

- Max. turning diameter over slide mm Ø1630 Ø1700

- Max. turning diameter ober gap mm Ø2300x750

- Width of bed mm 888 - 1400

For workpieces with extremely high weight and very long length. A very robust lathe!- Heavy FC-30-cast machine bed with strong ribbing helps to minimize vibrations

- Case hardened and ground machine bed guideways

- Transmission gears and shafts made of hardened and ground high alloy steel running in oil bath

- Robust multi-plate clutch for driving main spindle

- X and Z-axis coated with Turcite B

D-Turn HD

-

Technical speci fications D-Turn HD 480:

- Center-to-center distance 2000 mm - 8000 mm

- Turning capacity Ø960 mm

- X-Axis600 mm

- Z-Axis 2000 mm - 8000 mm

- Z-Axis 370 mm

- Weight 8800 kg - 15400

Technical speci fications D-Turn HD 560:

- Center-to-center distance 2000 mm - 8000 mm

- Turning capacity Ø1120 mm

- X 600 mm

- Z 2000 mm - 8000 mm

- Z 370 mm

- Weight 8300 kg - 14300

For machining large diameter and long work pieces. They feature extremely rigid structure and superior precision in rough and finish machining- Heavy FC-30 cast machine bed with strong ribbing helps to minimize vibrations

- Transmission gears and shafts made of hardened and ground high alloy steel running in oil bath

- Robust multi-plate clutch for driving main spindle

- Case hardened and ground machine bed guideways to ensure precision for years

- X and Z-axis coated with Turcite B

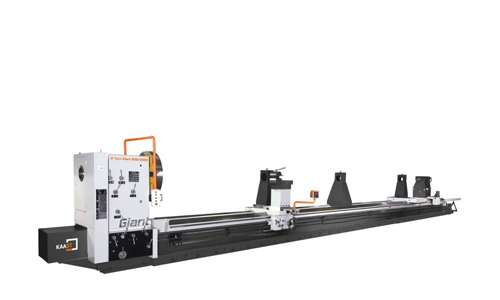

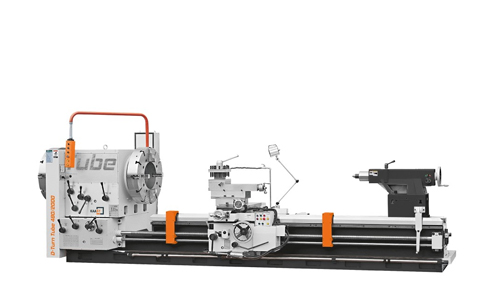

D-Turn Tube 480

-

Technical specifications D-Turn Tube 480:

- Center height 480 mm

- Swing over bed Ø960 mm

- Center-to-center distance 1500 mm - 9000 mm

- X-Axis (feeds) (48) 0.065–0.96 mm/rev

- Z-Axis (feeds) (48) 0.13–1.92 mm/rev

- X-Axis 540 mm

- Z1– overslide 300 mm

Suitable for use in oil, gas and heavy-duty industries- Very large spindle bore

- Main spindle bearings ensure high machining accuracy, even when machining long work pieces

- Two turning chucks for safe and reliable clamping of pipes (option)

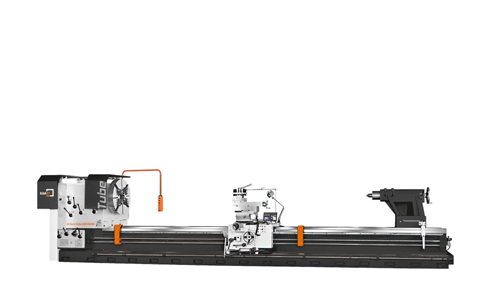

D-Turn Tube 600 • 800

-

Technical specifications D-Turn Tube 600 D-Turn Tube 800:

- Center height mm 600 - 800

- Swing over bed mm Ø1200 - Ø1600

- Swing over carriage mm Ø830 - Ø1230

- Swing over gap mm Ø1750 Ø2150

- Gap Width mm 600

- Machine bed width mm 800

Suitable for use in oil, gas and heavy industrie- Very large spindle bore - max. Ø535 mm

- Main spindle bearings ensure high machining accuracy even when machining long work pieces

- Two turning chucks for safe and reliable clamping of pipes (option)

- Various options available to increase flexibility

universal lathes

C-Turn 230 • 270

-

Technical specifications C-Turn 230 C-Turn 270:

- Center height 230 mm 270 mm

- Swing over bed Ø460 mm Ø540 mm

- X-axis travel 280 mm - 330 mm

- Toolholder travel Z1 130 mm 150 mm

- Weight net 2000 kg - 3200 kg

- Guideways are hardened and precision-ground

- Exceptionally low noise

- Universal type gearbox allowing for cutting metric, Whitworth, module and diametral threads with no need to change gears

- The feed handwheel can be ordered (left or right) in accordance to the needs of the operator

C-Turn 315 · 385 · 420

-

Technical specifications C-Turn 315:

- Center height 315 mm- 420 mm

- X-axis travel 330 mm - 450 mm

- Toolholder travel Z1 120 mm - 250 mm

- Weight 2550 - 3550 kg/3350 kg - 5700 kg/3650 kg - 5800 kg

Optional with extra large spindle hole

Max. Spindle diameter: 155 mm, 230 mm, 255 mm, 305 mm, 355 mm

Lathes from KAAST meet the highest quality standards

It is our aim to offer the best possible lathes to our customers. In order to fulfill this promise, we ourselves have set the very highest demands and apply strict quality control during the entire manufacturing process. Before delivery, each machine is subjected to intensive inspections and tests with regard to accuracy, performance and reliability

Characteristics of the V-models- 3 transmissions with variable spindle speeds

- Electronic control for automatic speed control

- The spindle speed is shown in the LED display

- Stepless speed setting by frequency converter

- Constant cutting speed by automatic speed regulation with different workpiece diameters

vertical lathes

V-Turn Con • V-Turn Con D

-

Technical specifications V-Turn Con 1250- 4000 D:

- Max. workpiece diameter mm 1250 - 4000

- Table diameter mm 1000 - 2830

- Max. workpiece height mm 1000 - 2000

- Max. workpiece weight kg 3200 - 10000

- Weight kg 8000 - 50000

For turning of extremely large work pieces- Turning of work pieces with diameters up to Ø 4000 mm (157”)

- Manual tool turret as standard

- P5 Precision table bearing

- High quality HT300 cast iron

- Rigid machine design ensures long-lasting accuracy

Eroding

Electric Discharge

S-EDM CNC / Z-EDM CNC

-

Technical Specifications

- Axis travel X/Y S-EDM mm 280 x 230 - 480 x 380

- Axis travel X/Y Z-EDM mm 300 x 250 - 500 x 400

- Dimensions mm 600 x 300 - 850 x 450

- Working tank volume l 190 - 350

- Weight kg 1700 - 450

CNC sinker EDM

- Technical parameters can be accessed and edited during the erosion process

- Programming parallel to operation

- Compact design

- 3D-simulation

- Automatic calculation of the cutting parameters

- PC based control

Z-EDM BL

-

Technical Specifications

- Table size mm 550 x 300 - 1200 x 650

- Axis travel X / Y / Z: mm 320 x 220 x 250 - 700 x 500 x Z-350+W-350

- Max. table load capacity kg 400 - 2000

- Dimensions mm 1200 x 1200 x 2100 - 4000 x 1800 x 2300

- Dielectrical tank volume l 450 - 800

- Weight kg 1500 - 3000

Mechanical features

- Cast iron machine body of highest stability

- Z-axis adapts to the lienar guide travel and the Sanyo servo motor

- Pedrollo oil pump

- Central lubrication system

- Precision linear guides

- Precision ball screws

Wire Discharge

W-EDM CNC

-

Technical specifications

- Max. workpiece dimensions mm 800x550x200 - 1600x1000x350

- Max. table load capacity kg 350 - 1500

- X / Y mm 350/250 - 1200/700

- U / V mm 50/50 - 150/150

- Z mm 200 - 350

- Dimensions mm 3100x2400x2400 - 3100x4500x2300

- Weight kg 1800 - 6500

- Tank capacity l 420 - 580

Highly effective with coaxial wire EDM flushing

High-performance wire EDM machine for the production of high-precision molds and electrodes- Very good surface quality with modern cutting technology

- Copy, turn, flip, scale, rotate

- Automatic dielectric monitoring in the W-S EDM machines

- Automatic adjustment of the dielectric filling level corresponding to the height of the work piece

- High-precision direct drive ball screws (class C1) and linear guideways in all axes

- Travel dependent automatic lubrication of the X and Y-axis guides

- Work table and dielectric tank made of stainless steel

- Fast underwater cutting of work pieces with a thickness of up to 450 mm (W-EDM S series)

- Substantial saving of working time through the use of automatic wire control system (AWT) (Option)

- High-quality, automatic wire threading (copper wire Ø 0.15 - 0.3 mm) with a water jet of 1 mm diameter

- Key components imported from Japan and Switzerland

W-EDM S CNC

-

Technical specifications

- Max. workpiece dimensions mm 700x450x180 - 1600x1000x310

- Max. table load capacity kg 350 - 1500

- X / Y mm 350/250 - 1200/700

- U / V mm 50/50 - 150/150

- Z mm 200 - 350

- Dimensions mm 2800x2800x2400 - 5300x5000x2800

- Weight kg 2000 - 7000

- Tank capacity l 630 - 4800

Highly effective wire with water bath

High-performance wire EDM machine for the production of high-precision molds parts and electrodes- Very good surface quality with modern cutting technology

- Copy, rotate, flip, scale, rotate

- Automatic dielectric monitoring at the W-S EDM machines

- Automatic adjustment of the dielectric filling level corresponding to the height of the work piece

- High-precision direct drive ball screws (class C1) and linear guidesway in all axes

- Travel dependent automatic lubrication of the X-and Y-axis guides

- Work table and dielectric tank made of stainless steel

- Fast underwater cutting of work pieces with a thickness of up to 450 mm (W-EDM S series)

- Substantial saving of working time through the use of automatic wire control system (AWT) (Option)

- High-quality, automatic wire threading (copper wire Ø 0,15 - 0.3 mm) with a water jet of 1 mm diameter

- Key components imported from Japan and Switzerland

W-EDM TCM

-

Technical specifications

- Table size mm 570x350 - 950x600

- Dimensions mm 1300x1800x2100 - 1600x2300x2500

- Max. table load kg 500 - 1500

- Trave X / Y Axes mm 320x250 - 700x500

- Cutting accuracy mm ≦ 0.008

- Weight kg 1500 - 3000

- THK ( Japan ) High-precision linear guides

- Double nut with play compensaion function

- AC servo drives for X and Y-axis

- Bi-directional wire tension device

- Frequency converter for wire roller, stepless adjustable

- Noise and maintenance arm

- Industrial PC with CNC software based on Windows XP

- Programming and parameter changes possible during processing

- In-house CAD / CAM application directly on the machine

- Import of DXF/DWG files possible

- Constant wire tension mechanism

- Workpiece surface roughness between 0,8 ~ 1,0 Ra possible, with a stable cutting efficiency of 40-60 mm²/min

- Maximum cutting speed of up to180 mm²/min at an angle of maximum 15° and a height of 60 mm möglich

- Cutting accuracy 0,008 mm

- Enclosed enclosure of the work area prevets splash water leakage and guarantees safety

- Integrated central lubrication

- Tension-free annealed gray cast iron frame in T-construction (extra stable, with low center of gravity)

- Handheld terminal

- Molybdenum wire with high tensile and abrasion resistance, guarantees a long service life

Drilling

CNC Drills

HBW

-

Technical specifications

- Table size mm 1600x1400x0.001° 2000x1800x0.001°

- X-axis mm 2000 - 4200

- Y-axis mm 2000 (2500) - (2000) 2500 (3000)

- Z-axis mm 1700 - 2000

- W-axis mm 550 - 700 (900)

- Coolant tank volume L 400

Z-axis as mobile column construction, worktable as B-axis- Moving column design

- Main spindle with powerful ZF transmission

- Resolution of 0.001° in the rotary table

- Glass scales in X-, Y-, Z-axis

- 40-piece tool changer/chain magazine

- FANUC Oi-MD CNC control

HBW 110 CNC

-

Technical specifications

- Max. table load capacity 5000 kg

- Transverse axis 1200 mm

- Positioning accuracy

- X 0.04; Y 0.32; Z 0.04 mm

- Repeatability in X-, Y-, Z-axes 0.015 mm

- Dimensions (LxWxH) 5347x3098x2889 mm

- Weight 12000 kg

Heavy boring machine with Siemens 802D CNC for machining of large and heavy work pieces- Optimum cutting performance through variable speed control of main spindle and facing slide

- 3-axis control by means of proven Siemens or Fanuc controls

- Robust and highly accurate, even for high work piece loads and dimensions, thanks to a wide machine bed with 4 stable hardened and precision-ground square guides

- Cylindrical roller bearings for centering table offer exceptional accuracy

- Precise operation of drill spindle with up to 1100 rev / min

- Effective protection of the bed rails by telescopic steel covers

HBW 110 • 130

-

Technical specifications

- Table dimensions 1100x960 mm 1800x1600 mm

- Max. table load 5000 kg 10000 kg

- x-axis 900 mm 2000 mm

- z-axis 1400 mm 2000 mm

- Dimensions (LxWxH)

- 4910x2454x2750 mm 7030x4665x3800 mm

- Weight 11500 kg 29300 kg

- Solid construction with hardened and ground guideways for long-lasting precision results

- Mechanical interlocking of functions for safety

- Slip clutches protect the headstock, and the feed gear from damage caused by overload

- Standard tapping unit ensures quick and convenient work

- Individual selection of spindle speed and facing head allows always suitable speeds even for difficult applications

- High flexibility due to full table rotation through 360°

- Effective protection of the bed guidways through telescopic steel covers

HBW 110R CNC • 135TR CNC

-

Technical specifications

- X-axis (table travel) mm 1500 - 4000

- Y-axis (spindle vertical travel) mm 1500 - 2800

- Z-axis (head vertical travel) mm 1100 - 1700

- Table dimensions mm 1400x 1250 - 1800x2000

- Dimensions mm 4650x 6200x 3800 - 7780x7550x5320

- Weight kg 22800 - 43700

- Horizontal boring mill with large travels and high intrinsic weight for the machining of heavy and large workpieces

- The Spindle cooling ensures a constant temperature for long-lasting accurate results

- Both the hardened HRC62-68 spindle and the housing are made of high quality steel alloys which combined with the two-stage automatic gearbox allows high cutting rates

- The hardened HRC 43-47, rectangular guides, on a huge rigid machine bed, are coated with Turcite B and precision ground, so smooth operation is achieved even for small movements at low speed

- The TR and TR2 also have two external guides which allow high workpiece weight and ensure the accuracy of the Z axis

- Pendant control panel - for best user performance

- The HBW 135 CNC machines can be equipped with a vertical or universal milling head

HBW-F

-

Technical specifications

- Table size mm 630x630 - 800x800

- X-axis mm 1500 (1600) - 2000

- Y-axis mm 1200 - 1400 (1700)

- Z-axis mm 1000 (1100) - 1400 (1600)

- Dimensions mm 6100x4400x3500 - 6200x4700x3900

- Weight kg 11.000 - 14.500

Fixed spindle quill with indexing table- Fixed column construction

- Fixed spindle

- 5°/72 indexing rotary table is standard of HBW-F 630

- 1°/360 indexing rotary table is standard of HBW-F 800

- Spindle is driven by a gearbox

- Linear scales on X, Y, Z-axis

- 40 tools chain type magazine

- FANUC OiMD CNC control

Heavy duty construction helps to boost stability- Linear guide way on X, Z-axis

- Four linear ways on the base provide stable support for heavy Ioad

- Box ways on Y-axis allow for heavy cutting with great stability

- X, Y, Z-axes are equipped with linear scales to assure the highest positioningaccuracy

HBW-FC

-

Technical specifications

- Table size mm 1250x1250x0.001°

- X-axis mm 2000

- Y-axis mm 1700

- Z-axis mm 1400

- W-axis mm 400 (500)

- Max. load kg 5000

- Weight kg 26000

- Fixed column construction

- Main spindle with powerful ZF transmission

- Resolution of 0.001° in the rotary table

- Glass scales on X, Y, Z-axis

- 40 piece tool changer / chain magazin

- FANUC OiMD CNC control

Max. stability through robust design

- Solid floor design offers solid support for very heavy workpieces

- The solid column optimally supports the spindle head and provides for max. stability with heavy duty cutting

- Machine design of strongly ribbed high-quality Mehanitee cast iron

- X-, Y-, Z-axes by default equipped with glass scales to ensure maximum precision

- X- and Z-axis as square guides

- Quadruple linear guides in heavy-duty design in the Z-axis

Grinding

Cylindrical Grinder

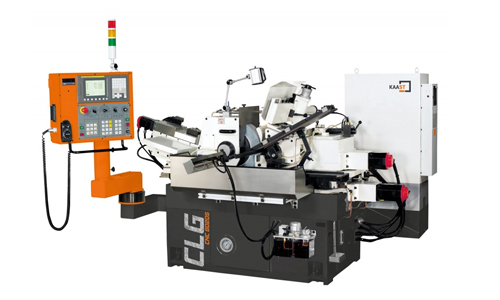

CLG

-

Technical specifications

- Grinding capacity mm Ø1-40 - Ø1-100

- Grinding wheel dimensions mm Ø305x150xØ120 - Ø610x305xØ356

- Regulating wheel dimensions mm Ø205x150xØ90 - Ø330x305xØ127

- Dimensions mm 1750x1050x1400 - 2810x2100x1650

- Weight kg 1650 - 6000

- A heavy Meehanite cast frame, heat treated and relaxed, provides a solid foundation for the CLG centerless cylindrical grinder

- All guideways are hardened and precision ground to ensure consistent accuracy and wear resistance

- The grinding and regulating spindle is made of high quality steel and SNCM-220 after deep hardening (HRC62) and grinding process particularly suited for years of tough production conditions

- The spindles are made of SNCM-4 material and provides specially designed spindle feed rate accuracies of the highest quality

- A wide range of options are available for your special application needs upon request

CLG CNC

-

Technical specifications

- Max. Grinding capacity mm Ø1-40 mm - Ø 1-100

- Capacity increases with special arrangement mm Ø 30-60 - Ø 40-150

- Grinding wheel Dimensions mm Ø 305 x 150 xØ 120 - Ø 610 x 305 xØ 355.6

- Regular wheel Dimensions mm Ø 205 x 150 xØ 90 - Ø 330 x 205 xØ 127

- Weight kg 1700 - 5000

with Fanuc controller- Equipped with a modern Fanuc Oi-MateTD controller

- Digital drive package from Fanuc (drives,axis servos)

- Drive concept with up to 6 CNC axes (X-,Y-, Z-, A-, B-, C-axis)

- Easy size adjustment. Easy to learn and understand

- PLC/controlled oil temperaturemonitoring

- Feed accurately programmable by servo drives

- Variable speed for the regulating wheel

CLG NC

-

Technical specifications

- Max. Grinding capacity mm Ø1-40 mm - Ø 1-80

- Capacity increases with special arrangement mm Ø 30-60 - Ø 40-150

- Grinding wheel Dimensions mm Ø 305 x 150 x Ø 120 - Ø455 x 305 x Ø 228.6

- Regular wheel Dimensions mm

- Ø 205 x 150 x Ø 90 Ø - Ø 255 x 305 x Ø 111.2

- General Dimensions 1750x1050x1400 - 2350x1950x1530

- Weight kg 1700 - 3500

- Equipped with SIEMENS-S7 controller for grooving and feed movement

- The guideways are hardened and ground

- Grinding and control spindle are hardened and have friction bearings

- Frequency-controlled regulating wheel drive by OS motor

- Hydraulically driven dressing devices for grinding and regulating wheel

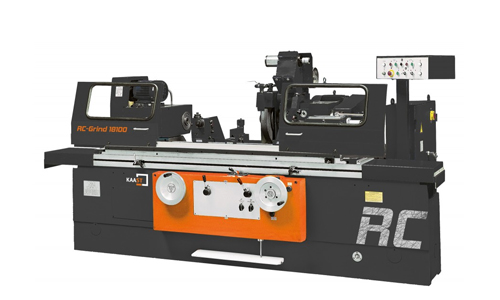

CR-Grind

-

Technical specifications

- Grinding capacity over bed mm Ø550 - Ø800

- Center height mm 275 - 350

- Grinding wheel dimensions mm 710x 19(38)x 203 - 915x 22(38)x 305

- Weight kg 5200 - 11000

- The heavy-duty model with massive stiffened machine bed, allows accurate results with excellent grinding, even with heavy components

- The aerostatic spindle and tailstock storage ensures minimal operating vibration even for long workpieces

- The automatic lubrication system

- Infinitely adjustable feed rate with hydraulic drive

- The automatic "soft stop" significantly reduces the stresses in all components and allows for long term operation

CRG CNC

-

Technical specifications

- Grinding capacity mm 180 - 400

- Max. workpiece weight kg 60 - 150

- Grinding wheel dimensions mm Ø305x38x127 mm - Ø405x50x152 mm

- Weight kg 2250 - 5500

For grinding in the sub-micron range- Advanced machine concept, innovative design andcutting-edge components from reputable manufacturersare key elements which characterize these CNC cylindricalgrinding machines

- Exceptional accuracy

- Standard grinding cycles include dressing of the wheel, aswell as grinding cycles of concave and convex surfaces

- Specially designed fine feeds allow grinding results withmirrored surfaces, to an accuracy of 0.1 micron

- A heavy Meehanite cast frame, heat treated and stressrelieved,provides a solid foundation for the CRG CNCcylindrical grinding machines

- All guideways are hardened and precision ground toensure permanent accuracy and wear resistance. Anotherhighlight of this series is the special table design, whichuses a hydrostatic system for extremely smooth motionand precision

- The grinding spindle is made of high quality steel

- The grinding spindle uses a high-precision hydrostaticspindle bearing that excludes metal-to-metal contact andthus guarantees a true running accuracy of 0.5 microns

- A wide range of options for your special applications areavailable on request

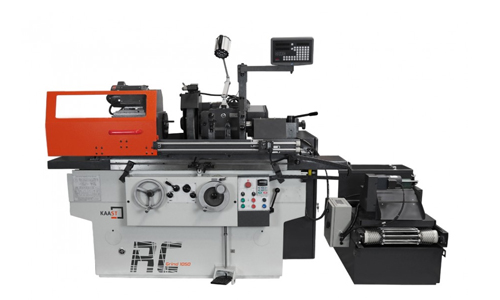

M-Grind 2050

-

Technical specifications

- Max. workpiece diameter Ø200 mm

- Max. workpiece length 500 mm

- Max. workpiece weight 10 kg

- Grinding wheel dimensions 200x20x75 mm

- Machine dimensions 11520x1130x1117 mm

- Weight 1300 kg

The M-Grind universal grinder is highly functional allowing external, internal, and tapered grinding. The M-Grind also allows easy tool grinding (sharpening knives, reamers and turning tools) and is suitable for light surface grinding

Three point bearing

The custom-made three-point mounting of the grinding spindle ensures minimum temperature influence and high quality grinding results

Feed drives

Hydraulic table feed (in the longitudinal direction) with automatic direction change

Grinding spindle

The special design of the grinding spindle head allows the simultaneous use of two different grinding wheels. The grinding spindle can be adjusted in the transverse direction, as well as in height. Further, a pivoting around the vertical-axis is possible

Speeds

The headstock has three different speeds (110, 200, 300 rpm), which are selectable by an easy to use gear unit

R-Grind

-

Technical specifications