Neuhaeuser

Videos

Loading the player ...

- Offer Profile

- In our modern and extremely

flexible production center in Prüm, Germany, we develop, optimize and

manufacture special precision tools in a range from single pieces up to mass

production. Focused investments for the expansion and modernization of our

facilities guarantee the high quality of our products and services in the

future.

Besides the machines of well-known brands, such as the 5-axis grinding centers of the "Walter Maschinenbau" Company or the cylindrical grinding machines of the Studer Company, we developed and built our own machines. These are custom machines, built to our specific requirements, for the manufacture of high precision specialty tools.

Product Portfolio

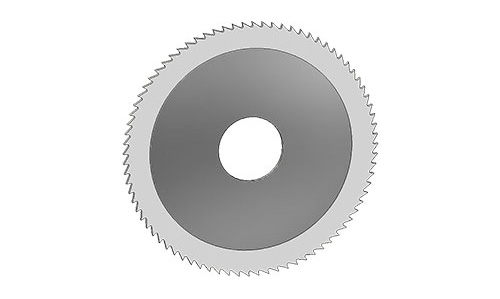

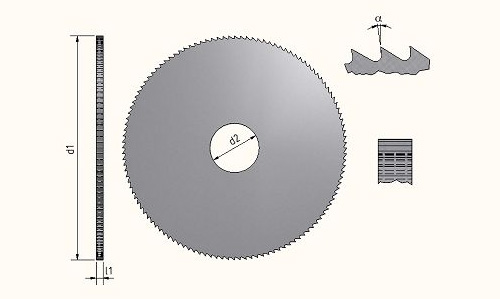

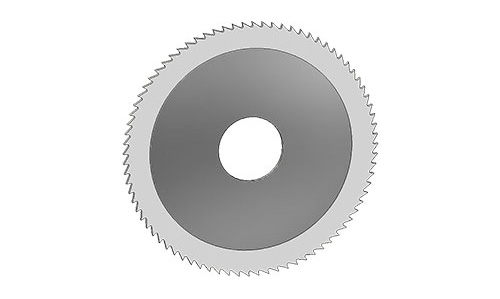

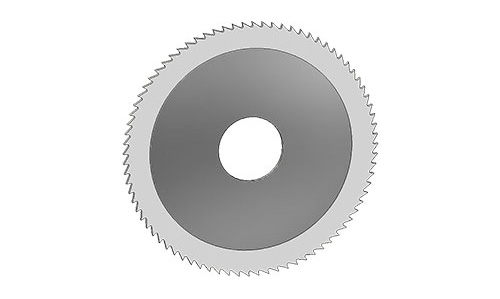

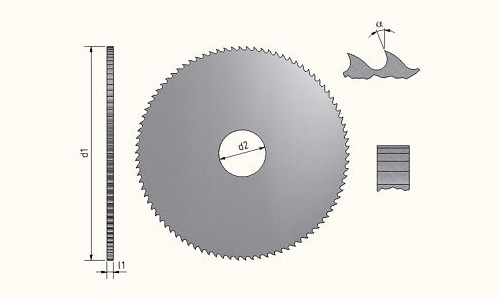

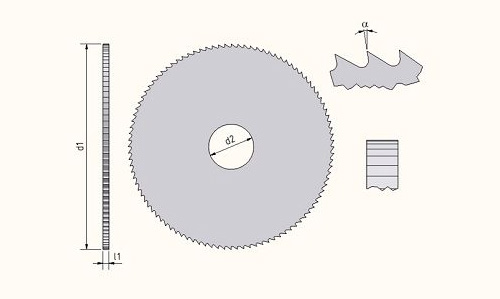

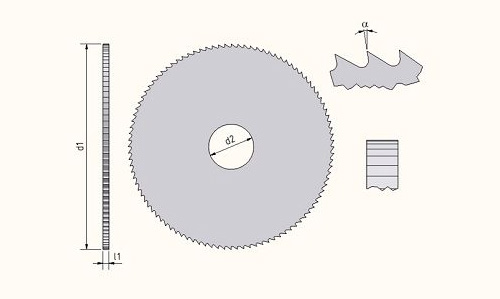

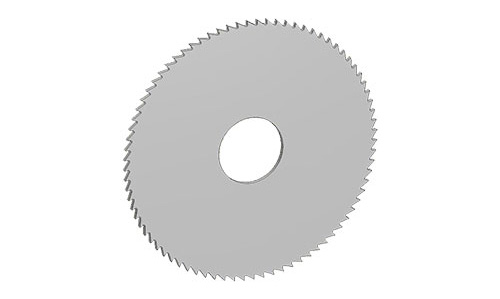

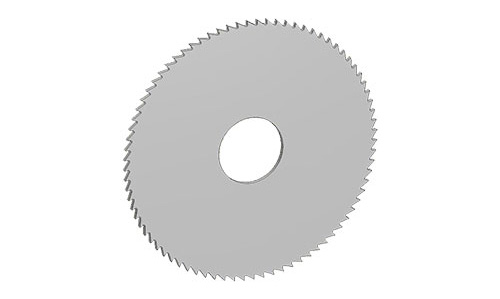

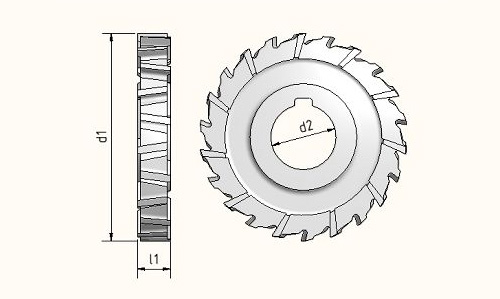

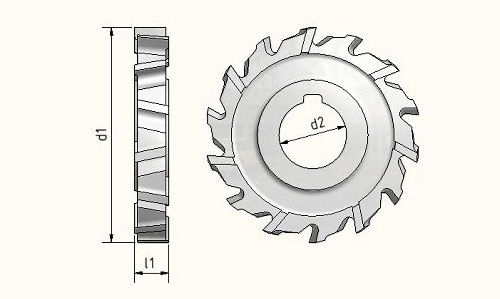

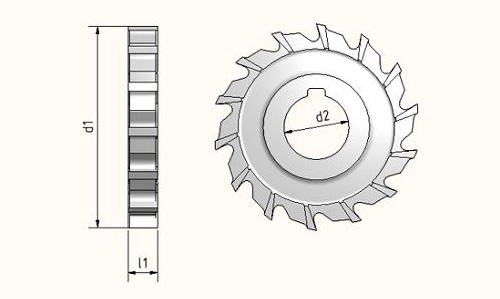

Metal slitting saws

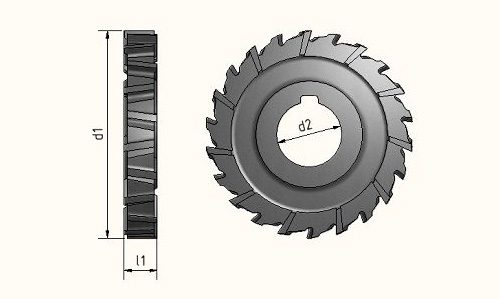

Metal slitting saws - solid carbide

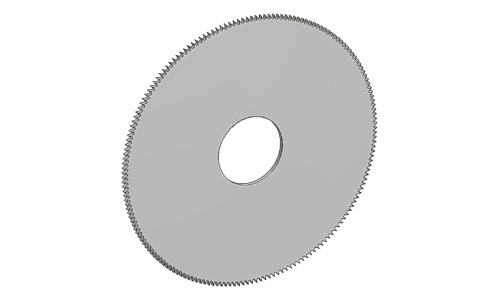

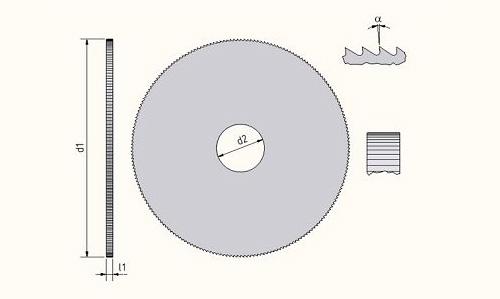

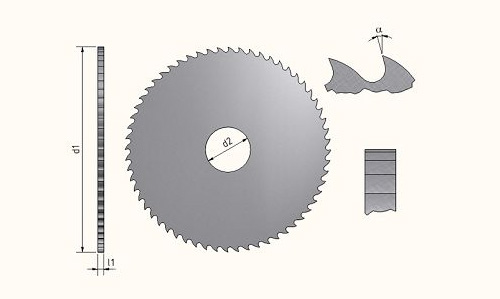

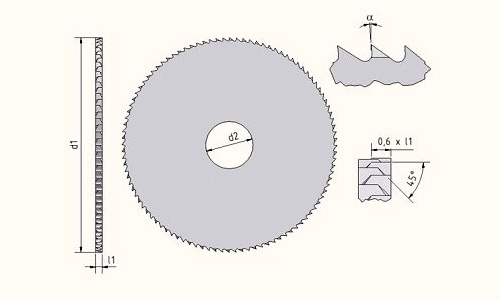

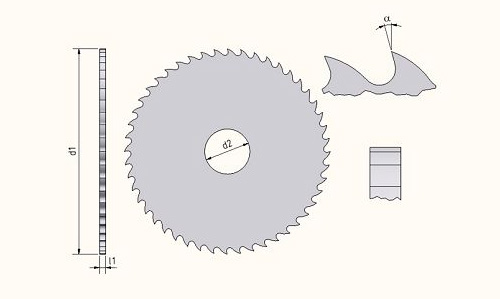

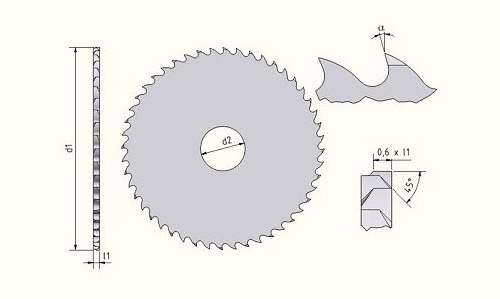

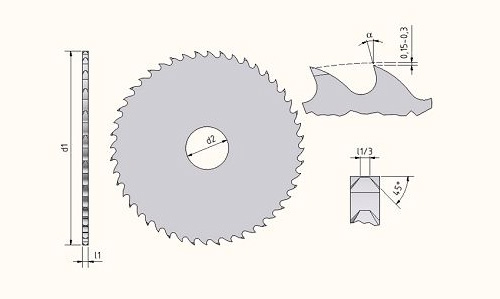

Tooth form A (similar to DIN 1837)

-

For cutting shallow slots or cutting off fine profiles and pipes made out of abrasive or hard materials.

- Outside Dia. 20 - 160

- Rake angle 5°

- Helix angle 0°

- Quality K10

- Cat.-No. 5110

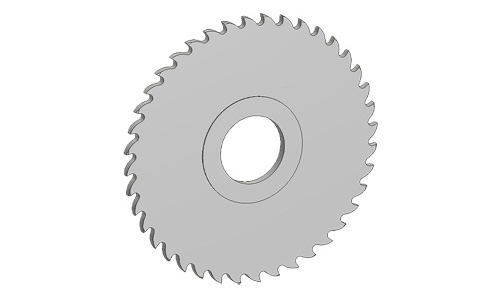

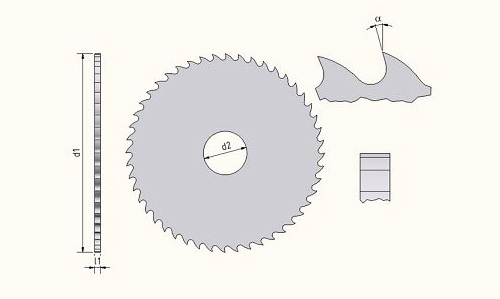

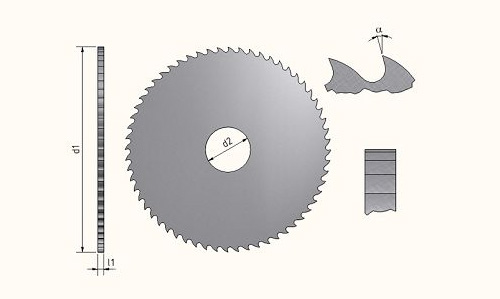

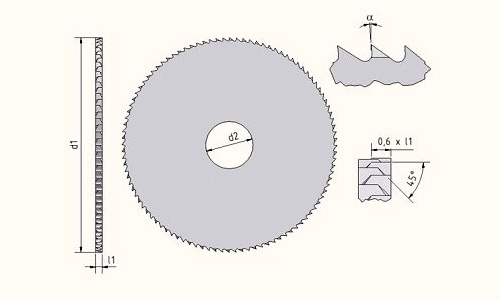

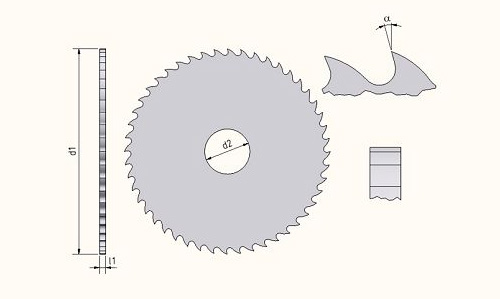

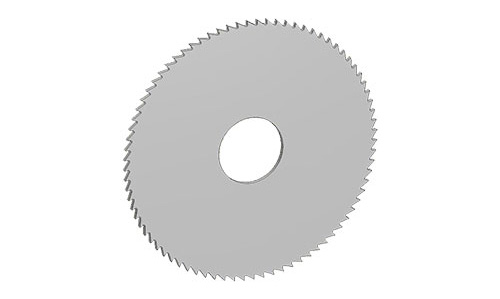

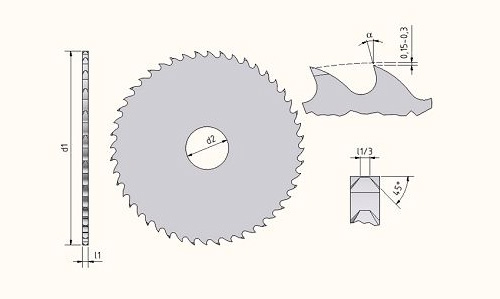

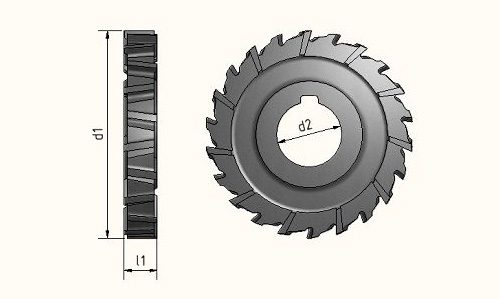

Tooth form B (similar to DIN 1838)

-

For cutting deep slots or cutting off thick pipes and profiles made out of abrasive or hard materials.

- Outside Dia. 20 - 160

- Rake angle 15°

- Helix angle 0

- Quality K10

- Cat.-No. 5120

For Rohbi- and Pressta-Eisele-maschines (brand standard)

-

Designed specifically for usage with machines from Rohbi- and Presta-Eisele in abrasive or hard materials.

Type and number of teeth depends on the customer's application.

- Outside dia. 80 - 200

- Rake angle on demand

- Helix angle 0°

- Material K10

- Cat.-No. 5130

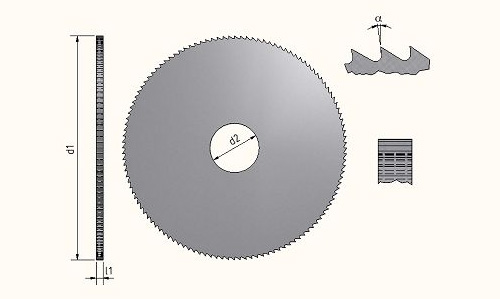

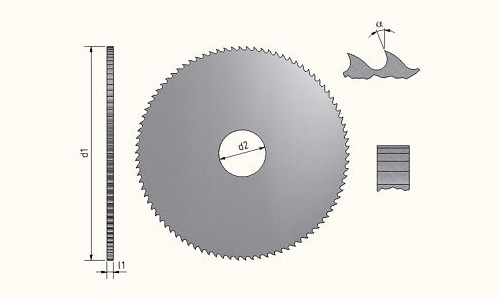

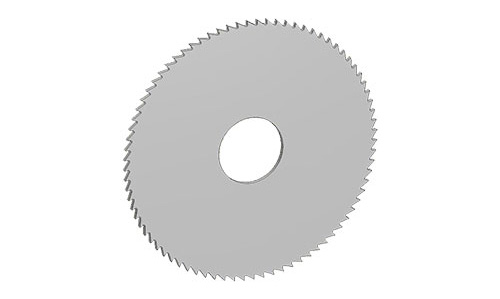

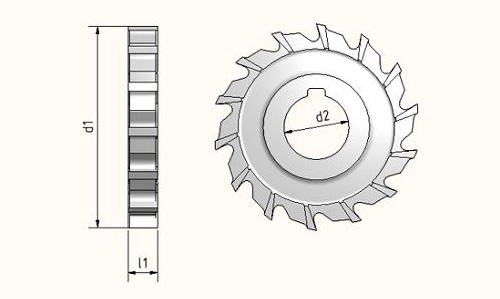

Metal slitting saws - HSS

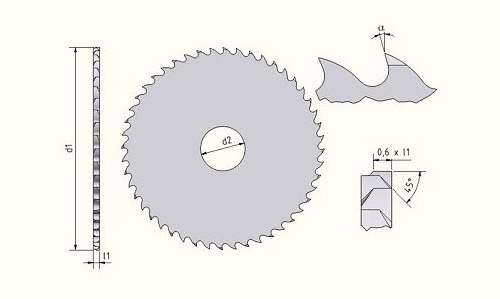

Tooth form A (DIN 1837)

-

For cutting shallow slots or cutting off fine profiles and pipes with high cutting precision.

- Outside dia. 20 - 250

- Rake angle 5°

- Helix angle 0°

- Material HSS

- Cat.-No. 1100

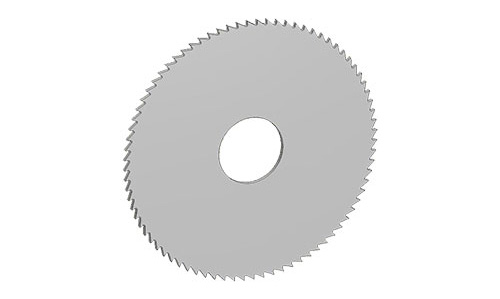

Tooth form Aw (DIN 1837)

-

For cutting shallow slots or cutting off fine profiles and pipes with high cutting precision.

- Outside dia. 50 - 250

- Rake angle 5°

- Helix angle 0°

- Material HSS

- Cat.-No. 1110

Tooth form B (DIN 1838)

-

For cutting deep slots or cutting off thick pipes and profiles.

- Outside dia. 50 - 250

- Rake angle 12 - 15°

- Helix angle 0°

- Material HSS

- Cat.-No. 1200

Tooth form Bw (DIN 1838)

-

For cutting deep slots or cutting off thick pipes and profiles.

- Outside Dia. 20 - 160

- Rake angle 15°

- Helix angle 0°

- Quality K10

- Cat.-No. 5120

Tooth form C (DIN 1838)

-

For cutting off thick solid material.

- Outside dia. 50 - 250

- Rake angle 15°

- Helix angle 0°

- Material HSS

- Cat.-No. 1300

Metal slitting saws for the jewelry industry

Tooth form A (brand standard)

-

For slotting and cutting of gold and silver materials.

- Outside dia. 40 - 63

- Rake angle 5°

- Helix angle 0°

- Material HSS

- Cat.-No. 1620

Metal slitting saws HSS and HSSCo for Pipe-cutting-machines (brand standard)

Tooth form A (brand standard)

-

Designed specifically for usage with machines for cutting pipes (e.g. GF machines).

Type and number of teeth depends on the customer's application.

- Outside dia. 63 - 75

- Rake angle on demand

- Helix angle 0°

- Material HSS / HSSE

- Cat.-No. 1480

Metal slitting saws for special applications

Special tools

-

As an expert in the design of special tools, we develop new tools for the individual demands of our customers almost daily. We also support our customers in optimizing their production processes. This is why all our metal slitting saws with an outer diameter between 10 and 250 mm (0.4” to 10.0”) can quickly be provided as special tools with different

- diameters

- widths

- tolerances

- arbor holes

- material quality grades

- pin holes or keyways

- surface finishing

- geometries

Our customized special metal slitting saws are used in various applications: cutting, slotting or milling in the electronics, metal machining, wood or plastic industries.

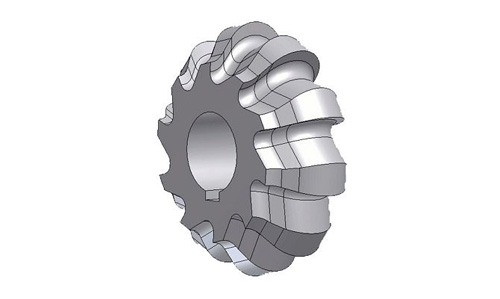

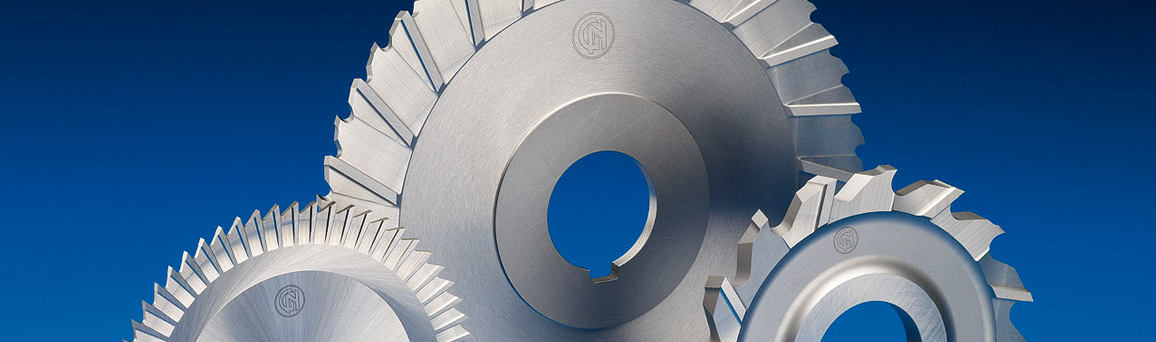

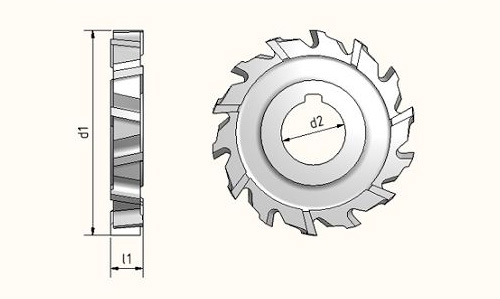

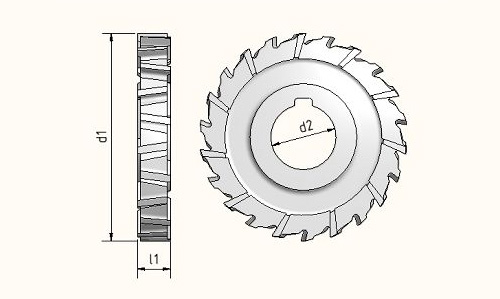

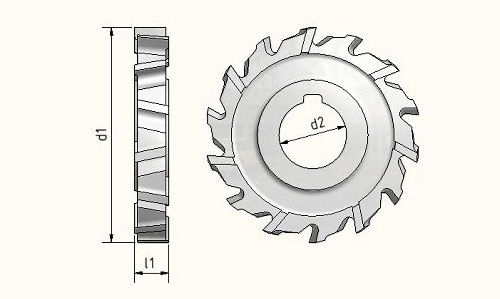

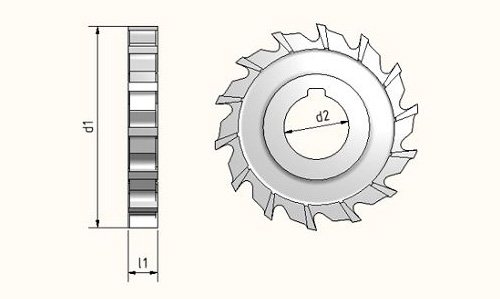

Side milling cutters

Side milling cutters - solid carbide

Tooth form A staggered teeth (similar to DIN 1834)

-

For deep slots in very hard and abrasive materials. With keyway according to DIN 138.

- Outside Dia. 63 - 125

- Rake angle12 - 15°

- Helix angle ca. 10°

- Quality K10

- Cat.-No. 5410

Tooth form IV rough staggered coarse teeth (similar to DIN 1834)

-

For deep slots in plastics, stainless steel and non-ferrous metals like the high-silica aluminum or titanium. With keyway according to DIN 138.

- Outside Dia. 63 - 125

- Rake angle 20 - 25°

- Helix angle ca. 10°

- Quality K10

- Cat.-No. 5440

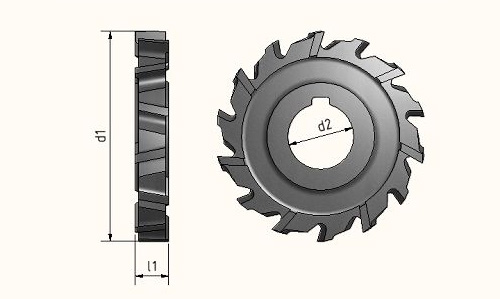

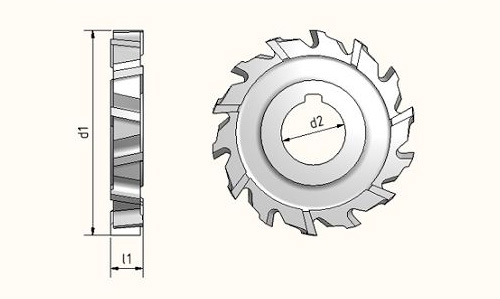

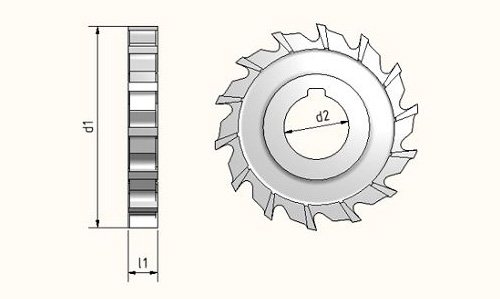

Side milling cutters HSSCo

Tooth form A staggered teeth (DIN 1834)

-

Arbor hole according to DIN 1834 (thin side milling cutters).

For deep cuts in construction or tool steel as well as cast iron. With keyway according to DIN 138.

- Outside Dia. 50 - 200

- Rake angle12 - 15°

- Helix angle ca. 10°

- Quality HSSCo

- Cat.-No. 2410

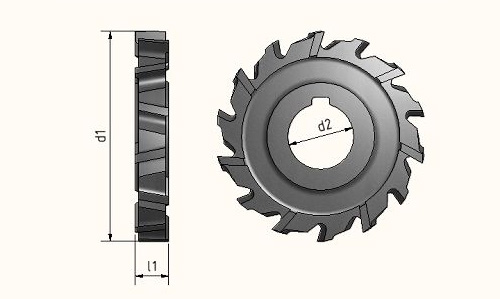

Tooth form A staggered teeth (DIN 1834)

-

Arbor hole according to DIN 1837/38 (slitting saws).

For deep cuts in construction or tool steel as well as cast iron. With keyway according to DIN 138.

- Outside Dia. 50 - 200

- Rake angle 12 - 15°

- Helix angle ca. 10°

- Quality HSSCo

- Cat.-No. 2411

Tooth form IV coarse staggered teeth (DIN 1834)

-

For deep cuts in stainless steel and non-ferrous metals like the high-silica aluminum or titanium. With keyway according to DIN 138.

- Outside Dia. 63 - 160

- Rake angle 20- 25°

- Helix angle ca. 10°

- Quality HSSCo

- Cat.-No. 2440

Tooth form B straight teeth (DIN 1834)

-

Arbor hole according to DIN 1834 (thin side milling cutters).

For deep cuts in tool steel as well as cast iron with high precision and good surface finish. With keyway according to DIN 138.

- Outside Dia. 63 - 160

- Rake angle 10 - 12°

- Helix angle 0°

- Quality HSSCo

- Cat.-No. 2420

Tooth form B straight teeth (DIN 1834)

-

Arbor hole according to DIN 1837/38 (metal slitting saws).

For deep cuts in tool steel as well as cast iron with high precision and good surface finish. With keyway according to DIN 138.

- Outside Dia. 63 - 160

- Rake angle 10 - 12°

- Helix angle 0°

- Quality HSSCo

- Cat.-No. 2421

Side milling cutters for special applications

Special tools

-

Besides our standard product portfolio we also design and manufacture any kind of special side milling cutters to match your specific demands. This includes angular and prismatic cutters, concave/convex radius milling cutters, as well as relieved form milling cutters can be offered. Our standard side milling cutters can be modified as well. This would include such characteristics as:

- dimensions

- number of teeth

- tolerances

- geometries

- surface treatment

- and material

Our high quality special milling cutters are used in various applications such as the production of machines, helicoils, piston rings, filtration and electronic components and many more.

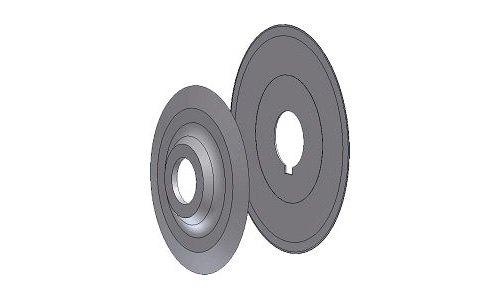

Circular knives

Circular knives

-

Circular knives are used in many different applications, such as in the paper and plastic industry to cut, slice or perforate. For the food industry we use special steel grades for our circular knives.

To match the challenging demands, we manufacture circular knives out of tool steel, high speed steel, powdered metal or solid carbide. Dependant on your requirements the tools vary in many ways such as:

- with or without pin holes or keyways

- with different bevels (symmetric, single-sided etc.)

- with or without keyway

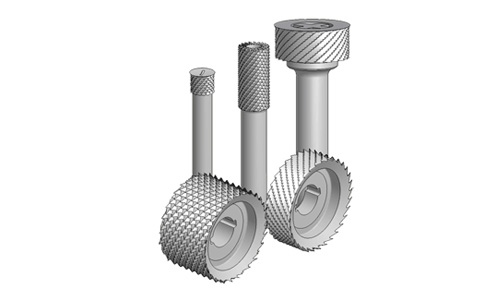

Composite tools

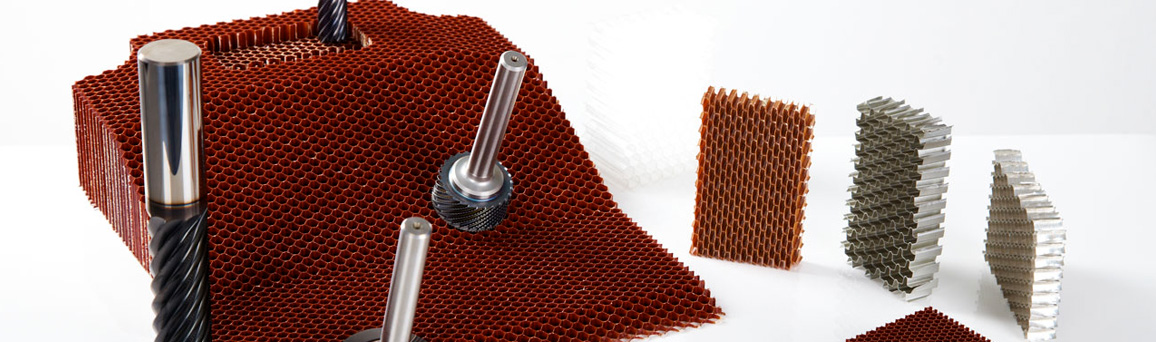

Honeycomb

Corecut

-

Comprehensive and flexible tooling system, mainly for the machining of honeycomb material with 5-axis CNC-machines.

Different types of front-end tools and shredders can be combined to suit the demands of your specific application.

Valve Type

-

Tool combination of circular knife or saw blade and a valve-shaped shank.

Ideal for cut-off operations and chamfering in any kind of honeycomb material.

Pocket Cut

-

Shank tools with axial and radial teeth. Ideal for the machining of pockets and slots in honeycomb materials.

Available with three different tooth geometries to suit your applications.

Profile Cut

-

Shank tools designed for profiling complicated honeycomb parts and structures.

The tools are available in centre cutting and ball nose end teeth. Plunge cuts into the honeycomb material are possible.

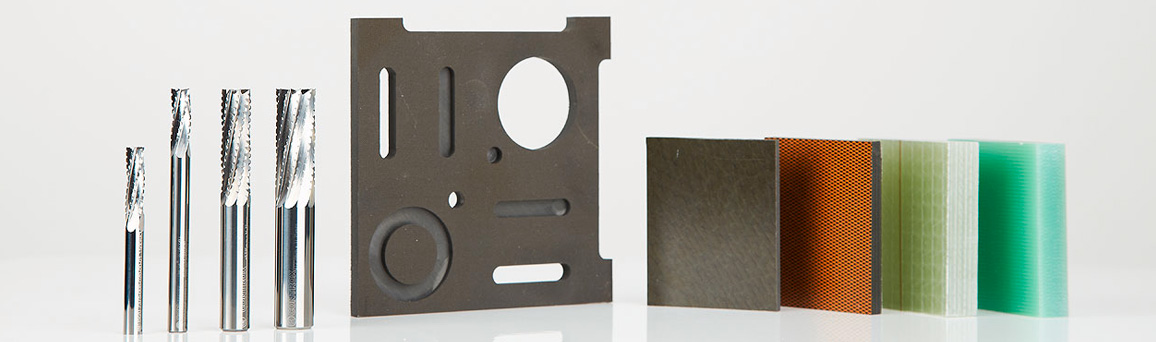

Panel

Panel Cut

-

Shank tools with end teeth designed for profiling and drilling operations in sandwich panels.

Enables extremely high feed rates due to the special tooth configurations.

Decoring Cut

- Shank tools to undercut composite sandwich panels. Especially designed to drill perfectly clean holes and to undercut the panel skins in one step.

Foam

Foam Cut

-

End Mills especially designed for the machining of technical foams. These cutters have axial and radial teeth.

To create smooth radiuses as well as sharp edges on the parts the FOAM CUT tools are in both ball nose and square end available.

CFRP/GFRP

- Solid Carbide routers for the machining of uni- and multi-directional layers as well as woven fabrics made out of CFRP (carbon-fiber-reinforced plastic) or GFRP (glass-fiber-reinforced plastic).

Fiber Cut

- Solid Carbide routers for the machining of uni- and multi-directional layers as well as woven fabrics made out of CFRP (carbon-fiber-reinforced plastic) or GFRP (glass-fiber-reinforced plastic).

Specials

Composite tools for special applications

- The use of a high precision honeycomb core is growing not only in the aeronautical and space industries, but also in the nautical and automotive industries.

Special tools

Special tools

-

We manufacture your individual special tools in our production site in Prüm, Germany, on modern, extremely flexible machines in small, medium and large volumes.

Hereby, our focus is to provide you with the optimal tool and the best cost-performance ratio. At Neuhäuser we define cost-effectiveness by costs per part, not only by the price of the tool. To achieve optimal results in feed rate and tool life, our sales representatives and application engineers are ready to assist you.

In close co-operation, they will design and apply the optimal tool with you and for you. We understand that your machines, tools and products are as diverse and individual as the applications you face every day. We are ready to accept these challenges together with you.

Contract work

Heat treating

- Besides our own products, we also offer our heat treating capabilities to other companies to harden or temper their products in our modern heat treat facilities, installed in 2007.

Circular grinding

- We offer cylindrical grinding of tools up to an outer diameter of 200 mm (8") and a length up to 600 mm (24") as well as grinding of circular profiles on CNC-controlled grinding machines.

Flat grinding

- Grinding of tools and other parts with a diameter up to 250 mm (10") on special CNC controlled grinding machines.

Indenting

- Indenting of tools with an outer diameter up to 250 mm (10") on CNC controlled grinding machines.

Fine grinding - Flat honing

- On our fine grinding machines, we can fine grind tools with diameters between 10 mm and 160 mm (0.4" and 6.5") and a width down to 0,5 mm (0.02").

Industrial Solutions

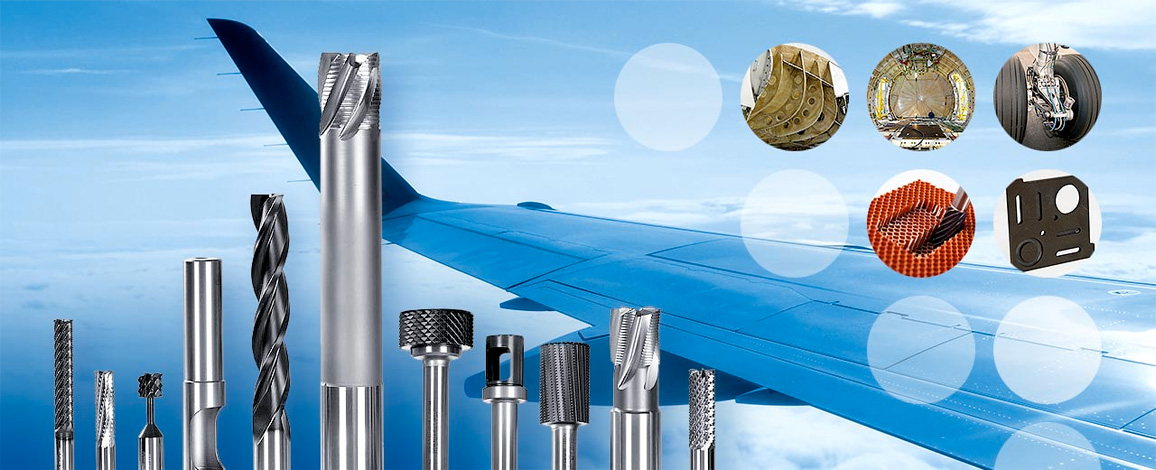

Aerospace

Aerospace

-

Nowadays an airplane, a helicopter or a satellite is always built out of modern composite materials or lightweight metals. The special structure of these materials presents many machining challenges and requires the use of optimally designed cutting tools. Especially for these applications, Controx-Neuhäuser offers a standard program of tools for the machining of composite materials and customer-specific solutions for a variety of applications.

In the aerospace industry, Controx-Neuhäuser offers for example:

- panel routers

- titanium tools

- ultrasonic knives

- valve-type knives

- hollow core drills

- honeycomb tools (Nomex, Kevlar, aluminum, titanium, …)

- CFRP- and GFRP routers

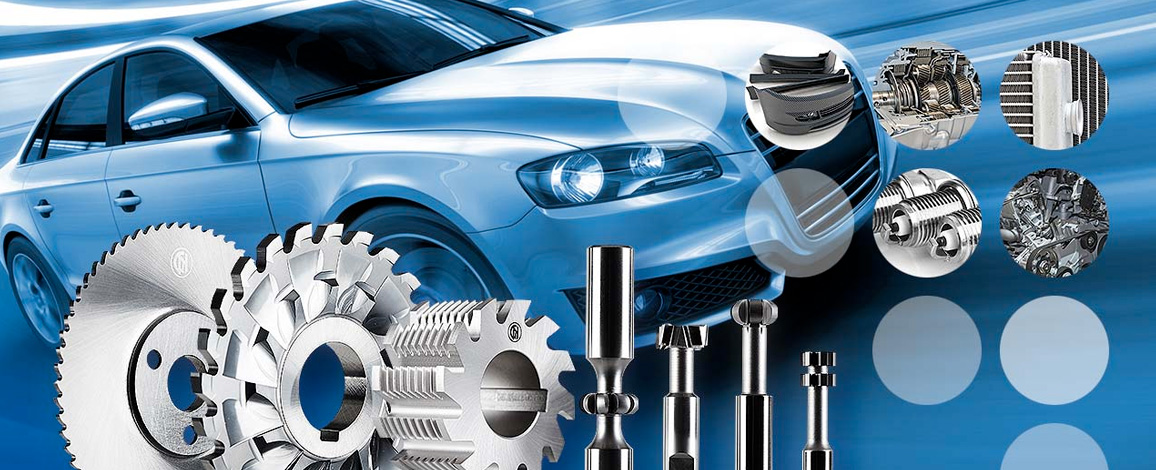

Automotive + Mechanical Engineering

Automotive + Mechanical Engineering

-

Regardless of whether a Constant Velovity Joint (CVJ) has to be slotted for keyways, a V-belt has to be separated in its sizes or general splitting operations have to be done – using disc-shaped precision tools is indispensable in the automotive- and mechanical engineering industry. Controx-Neuhäuser produces special tools adapted to the specific customer application. Based on the know-how and experience along with a variety of cutting materials and coatings Controx-Neuhäuser is able to produce the optimal monolithic precision cutting tool.

In addition to the catalog program of standard side milling cutters and standard saw blades, Controx-Neuhäuser produces e.g. the following special solutions for the automotive and mechanical engineering industry:

- Cut-off- and dicing saws

- Circular knives and cutting wheels

- Form milling cutters

- Oil groove cutters, splitting saw blades, gap saw blades

- Prism cutters, half-round cutters

- Roll forming tools, pins

- Perforating knives

- Keyseat cutters, t-slot milling cutters

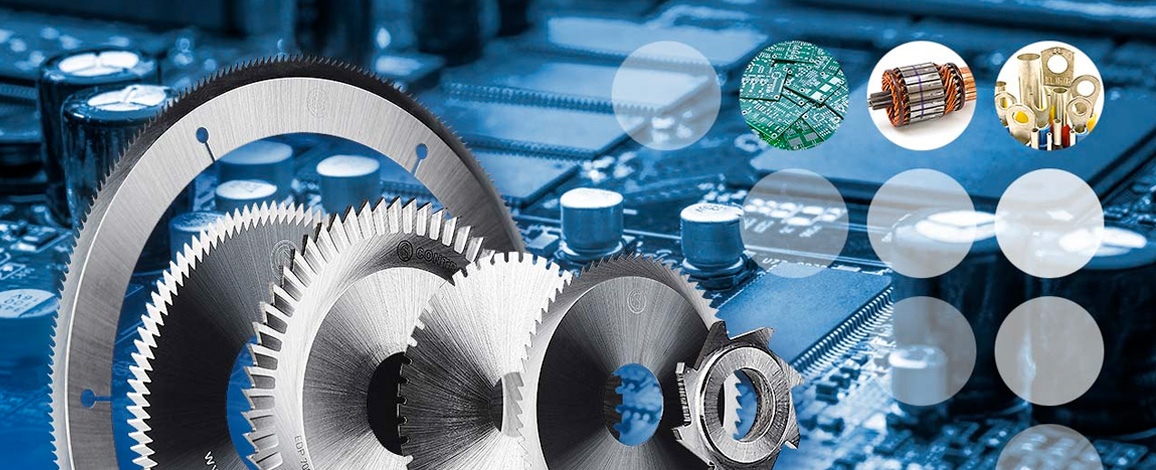

Electronics

Electronics

-

In the electrical and electronic industry there are multiple applications where monolithic cutting tools made of solid carbide or high-speed steel are used. If balancing armatures for electric motors, scoring or splitting PCBs (printed circuit boards) or the production of electrical connectors - Controx-Neuhäuser offers a wide range of special solutions for these specific applications.

Customized to the specific machining tasks Controx-Neuhäuser e.g. offers the following special tools:

- Insulation groove cutters

- Collector cutters, commutator cutters

- Balancing cutters

- V-scoring blades, V-groove cutters

- Cutting saws for depanelling, depanelling knives

- Scoring Saws

- Circular knives, crush cut knives

- Profile-, form-, contour milling cutters

- Circular saw blades

- Blanks for CBN- and diamond cutting wheels

Fashion

Fashion

-

“Fashion” summarizes different industries in the field of clothing, accessories and personal hygiene. Examples are the textile and cosmetics industry or the industries producing jewelry, carpets or glasses. Here several applications require small and very precise cutting tools. These tools are getting used for example for slitting spectacle hinges, cutting rings made of gold or silver or formatting of textiles. Suitable metal slitting saws, circular knives or sets of form cutters are products offered by Controx-Neuhäuser customized according to the specific application.

A selection of special solutions for the field Fashion are for example:

- Circular jeweler saw blades, jewelry slotting saw blades

- Shearing rollers

- Thin metal slitting saw blades

- KZA cutter

Medical

Medical

-

The production of medical products like prostheses, implants or surgical instruments requires commonly the use of saw blades, form milling cutters and form end mills to realize profiles, slots, and cut-offs.

Depending on the specific demands of the customer, Controx-Neuhäuser produces those cutting tools made of HSS, HSS-Co or solid carbide.

In addition to cutting tools that are used for the production of medical products, Controx-Neuhäuser offers tools that are directly in use on medical devices. These include oscillating cast saw blades, bone drills or fingerring saws.

Tubes & Pipes

Tubes & Pipes

-

If as plastic pipes in the wastewater technology, perforated pipes in the oil industry or stainless steel pipes in the food industry – tubes and pipes are being machined in different ways to fulfill their tasks. Drainage pipes, screen tubes and perforated pipes have to be slotted, other pipes have to be trimmed and chamfered, protective tubes have to be opened in axial direction. All these work processes require disc-shaped cutting tools made of high-speed steel or solid carbide.

Controx-Neuhäuser produces especially for this industry e.g. the below mentioned cutting tools:

- Sickle knives

- Orbital saw blades, splitting saws

- Chamfer cutters, double angle milling cutters, V-groove cutters

- Saw blades for Georg Fischer and Axxair pipe cutting machines

- Circular saw blades

- Metal slitting saw blades