- Offer Profile

- Based in Kaiserslautern, Germany, we have specialized in the development, manufacturing and sale of precision tools equipped with ultra-hard cutting materials such as PCD (polycrystalline diamond), CVD-D (CVD thick film diamond), UltraDiamond (binderless) and CBN (cubic boron nitride). As a leading manufacturer of tools with lasered cutting edges, we offer machining solutions in the areas of turning, milling, grooving, drilling, reaming and tool holders. In order to be able to process ultra-hard cutting materials such as PCD, CVD-D, UltraDiamond (binderless) and CBN with precision tools economically, we recognized early on that we had to develop further from the old production technology „grinding“ to new technologies such as the „laser ablation process“.

Turning

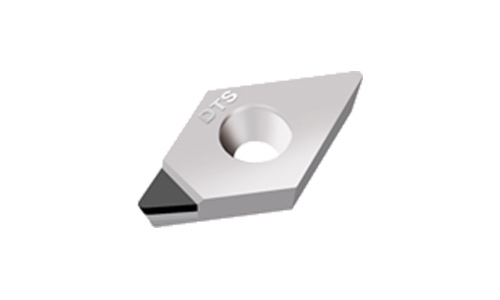

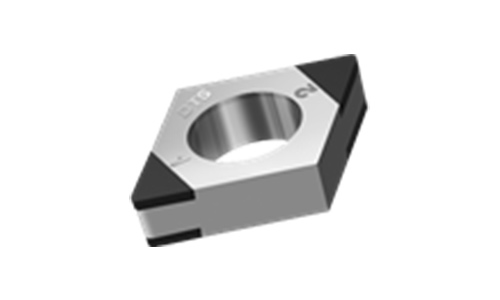

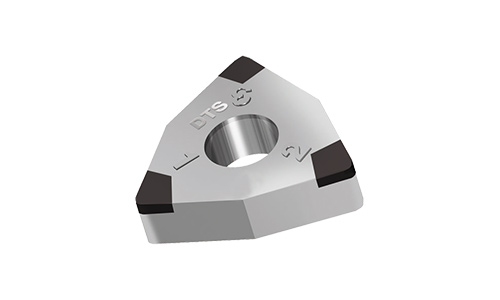

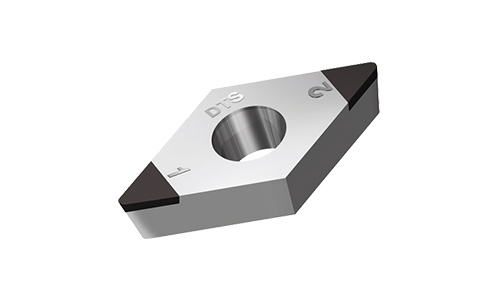

PCD and CVD-D Inserts

-

Take advantage of our selection of diamond inserts

You can choose between three diffrent diamond types from our catalog. For more information about your chosen diamond type, click on one of the type buttons.

PCD-Diamond

-

The areas of application for PCD-Diamond are:

- Aluminium <10%Si

- Copper/ Tungsten copper

- Brass

- Composite materials such as CFRP/ GFRP

- Graphite

- PEEK

CVD-Thickfilm Diamond

-

CVD-Thickfilm Diamond is ideally suited for processing highly abrasive materials such as:

- Aluminium >10%

- Plexiglass

- Copper/ Tungsten copper

- Glass- and Glass ceramic

- Hard metal G-type >12% Co

- Hard metal K-type >15% Co

- Titanum (Finishing operations)

- Any abrasive non-ferrous materials

- Other hard, brittle non-ferrous materials

UltraDiamond

-

UltraDiamond is successfully used for processing:

- Hard metal G-type <12%

- Co Hard metal K-type >7%Co

- Carbide with Ni Binder

- Glass- and Glass ceramic

- Quartz glas

- Other hard, brittle non-ferrous materials

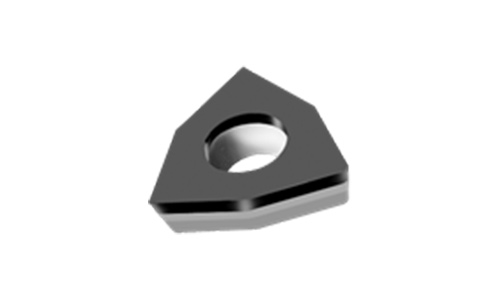

CBN Inserts

-

Inserts from 12 CBN sorts for 5 diffrent material groups

You have 12 diffrent CBN sorts in our CBN catalog for various tasks e.g. available for smooth and interrupted cuts. For more information on the respective CBN sort click on the appropriate button.

CBN grade H

-

The CBN grade H was specifically designed for the machining of:

- Hardened steels up to a hardness of 72HRC

- Hardened sintered steel

- Clear chilled cast iron

CBN grade X

-

The CBN grade X was specifically designed for the machining of:

- Hardened tool steel up to 72 HRC

- Special alloys such as ASP, CPM, HARDOX

- Stellite

- Hard metal >20%Co

CBN grade K

-

The CBN grade K was specifically designed for the highspeed machining of:

- Grey cast iron

- Ductile cast iron

CBN grade P

-

The CBN grade P was specifically designed for the madhining of:

- Sintered steel

CBN grade S

-

The CBN grade S was specifically designed for the machining of:

- Inconel

- Ni-, Co-, Fe- and Cr-alloys

- Titanum alloys

Boring bars

Brazed diamond and CBN boring bars

-

Internal turning steels with brazed cutting edges for bore machining from ø1,00mm. These can be used both for turning in the lathe and for spindling in the milling machine.

To get more information about the respective products, click on one of the buttons.

Boring bars- From ø1,00mm as standart catalog product

- Very stable holder made from carbide

- For internal turning on turning machines

- For spindling on milling machines

Boring bars with mini-inserts from ø 3,50mm

-

Grooving with diamond and CBN grooving systems

For grooving and parting off, you have two grooving systems with different grooving widths and depths available from our stock.

Particularly economical due to the double loading with PCD / CVD-D and CBN. Suitable for smooth and interrupted cuts.

Grooving systems from B1,00 – 6mm

ECO-Line grooving systems

- Grooving with diamond and CBN grooving systems

For grooving and parting off, you have two grooving systems with different grooving widths and depths available from our stock.

Particularly economical due to the double loading with PCD / CVD-D and CBN. Suitable for smooth and interrupted cuts.- Grooving and parting

- Grooving depth up to 25mm

MICRO-Line systems

- For grooving and parting off, you have two grooving systems with different grooving widths and depths available from our stock.

Particularly economical due to the double loading with PCD / CVD-D and CBN. Suitable for smooth and interrupted cuts.

- Grooving and parting

- Grooving depth 3,80mm

Milling

Diamond or CBN end mills ø 0,20-20mm

- Milling tools made from CBN and diamond

For milling demanding brittle-hard materials and series parts, you will find milling cutters made of 4 cutting materials here: PCD, CVD-D, UltraDiamond and CBN.

Milling tools- End mills made of diamond ø0,9 – 20mm

- CBN milling tools ø0,2 – 12mm

- Diamond end mill multiple fluted with internal cooling and up to 14 teeth

Our milling tools are available in following materials for the displayed application areas:

PKD Application range:- Aluminium

- Brass

- Zinc

- Plastics

- Graphite

CVD-D Application range:- Carbide G-type>8% Co

- Carbide K-type>15% Co

- Ceramic / Glass ceramic

- Aluminium >7%Si

- Titanum (Finishing operations)

- Copper/ Tungsten copper

- Composite materials CFRP / GFRP

- Glass / Plexiglass

- Other brittle non-ferrous materials

Ultra Diamant Application range:- Carbide G-type

- Carbide K-type >7%Co

- Carbide with Ni Binder

- Ceramic / Glass ceramic Quartzglass / Glass

- Other brittle non-ferrous materials

CBN-H Application range- Hardened steels up to a hardness of 72HRC

- Hardened sintered steel

- Chilled cast iron

- Hardened tool steel up to a hardness of 72 HRC

- Special alloys like ASP, CPM, HARDOX

- Stelite

- Carbide >20%Co

Weldon end mill for multiply tipped inserts

-

More ecomonical trough their 2-edge equippment and with internal cooling.

You can choose between 5 diffrent cutting materials for our multiple edge tipped inserts with the following application ranges:

PKD/PCD

Application range:

- Aluminium <10%Si

- Brass

- Zinc

- Plastics

- Graphite

- Carbide G-type>8% Co

- Carbide K-type >15% Co

- Ceramic / Glass ceramic

- Aluminium >7%Si

- Titanum (Finishing operations)

- Copper/ Tungsten copper

- Composite materials CFRP / GFRP

- Glass / Plexiglass

- Other brittle non-ferrous materials

CBN-H

- Hardened steels up to a hardness of 72HRC

- Hardened sintered steel

- Clear chilled cast iron

CBN-X

Application range:

- Hardened tool steel up to 72 HRC

- Special alloys like ASP, CPM, HARDOX

- Stellite

- Carbide >20%Co

CBN-K

- Chilled cast iron

- Ductile cast iron

Milling cutter system ø 32 – 400mm

- Milling systems for multiple edge tipped diamond and CBN inserts

Slip-on cutter:- Steel body

- Internal cooling

- For DIN ISO inserts

Cassette milling cutter with interchangeable cassettes, base body optionally made of aluminium or steel:- Height adjustable

- With internal cooling

- 5 different cassettes to choose from for 5 different ISO inserts

All multiple edge tipped inserts can be bought in following cutting materials for the listed application ranges:

PKD-PCD Application range:- Aluminium

- Brass

- Zinc

- Plastics

- Graphite

CVD-D Application range:- Carbide G-type>8% Co

- Carbide K-type>15% Co

- Cermic / Glassceramic

- Aluminium >7%Si

- Titanum (Finishing operations)

- Copper / Tungsten copper

- Composite materials CFRP / GFRP

- Glass / Plexiglass

- Other brittle non-ferrous materials

CBN-H Application range:- Hardened steel up to a hardness of 72HRC

- Hardened sintered steel

- Chilled cast iron

CBN-X Application range:- Hardened steel up to a hardness of 72 HRC

- Special alloys ASP, CPM, HARDOX

- Stelite

- Carbide >20%Co

CBN-K Application range:- Cast iron

- Spheroidal graphite iron

Drills / Reamer

CBNCoat Drill starting from ø 2 – 12mm

- CBNCoat drill

Our CBNCoat drill was designed for drilling into roughly machinable and very hard materials.

Our CBNCoat drills are available from ø2,0 – 12,0mm. Designed to drill:- Hardened steels up to a hardness of 68HRC

- Hardened tool steel up to a hardness of 68HRC

- Tool steel in the soft state

- Inconel

CBN Reamer starting from ø 1,50 – 6mm

- CBN Reamers

CBN Reamers for reaming hardened materials

Our CBN Reamers are available from ø1,5 – 6,03mm. For reaming of H5, H6 and H7 tolerances.

Application range:- Hardened steel up to a hardness of 68HRC

- Tool steel up to a hardness of 68HRC

- Carbide >20%Co

- Inconel

Chip breaker, Special tools , Adapters and Resharpening

Chip breaker, Special tools , Adapters and Resharpening

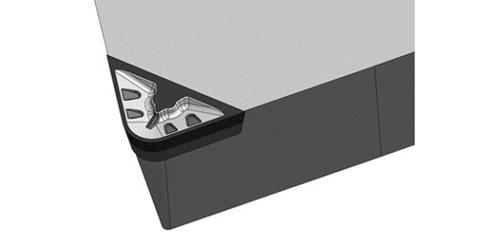

- 3D-Chip breaker

In case of chip problems you can use our 3D lasered chip breakers.

You can find them in our PCD/CVD-D catalog.

On request we also laser 3D chip breakers in CBN inserts.

For chip breaking you can choose between two standard chip breakers:- Finishing chip breaker Rough chip breaker

The standard chip breakers can be used in:- Aluminium

- Brass Lead-free

- Thin-walled workpieces

- Copper

You have problems with chip breaking and need a special solution?

We can offer you:- Chip breakers on grooving tools

- Chip breakers on CBN inserts for hard turning

- Chip breakers on CBN inserts for hard-/soft turning

- Chip breakers on bell tools

- Chip breakers on monoblock tools

- Chip breakers on boring tools

Special tools on request

- Special tools

We manufacture any standing and rotating tool, adapted to your component and process.

The production concerns PCD, CVD-D, UltraDiamond and CBN tools.

Tool holders

- Clamp holders

Clamp holders for external machining

Specially adapted for machining with diamond or CBN inserts.

Available in various versions.

Clamp holders for internal machining

Specially adapted for machining with diamond or CBN inserts.

Available with carbide or steel shank.

Clamp holders for grooving

Specially adapted DTS grooving inserts for cutting with diamond or CBN grooving inserts. Available in different holder cross-sections and grooving depths.

Resharpening of PCD, CVD-D and CBN

- Resharpening

On request.

Have your used tools made of ultra-hard cutting materials such as PCD, CVD-D, UltraDiamond and CBN resharpened up to 5 times.

Service on request via our request form or by phone.

Cutting materials

PCD Diamond

- Polycrystalline diamond (PCD), the well-known standard diamond

PCD is a synthetically produced, extremely tough, intergrown mass of diamond particles with random orientation in a metal matrix. It is produced by sintering selected diamond particles at high pressure and high temperatures.

Graphite serves as a catalyst so that the PCD crystals grow together. PCD has high thermal conductivity and good heat dissipation out of the cutting area. In addition, PCD has the highest flexural strength of all cutting materials.

PCD is very suitable for machining aluminium with a Si content of up to 12% and/or other abrasive fillers. The hot hardness is approx. 750°C, the areas of application are similar to those of CVD thick film diamond, however, the high economic efficiency of CVD thick film comes into play with hard-brittle materials or aluminium with a Si content of 12% or more.

With PCD you can machine materials like:- Aluminium

- Zinc

- Brass

- Plastics

- GFRP (*First choice CVD-D)

- CFRP (*First choice CVD-D)

- Copper

- Graphite coarse-grained

- Ceramic green compact

- Carbide green compact

CVD-D Diamond

- CVD thick film diamond (CVD-D), the star among diamond cutting materials

For machining hard-brittle materials such as ceramics, glass and glass-ceramics, hard metal, MMC and fibre composites such as CFRP and GFRP. Due to the lack of a bonding matrix, the diamond content is much higher than with PCD. In the group of ultra-hard cutting materials, binderless CVD-D is one of the hardest, artificially produced diamond cutting materials.

CVD-D is characterised by a high hardness as well as a high wear resistance. These properties make CVD-D the perfect cutting material for machining abrasive materials. Compared to PCD, which is damaged by the abrasive particles due to its soft metallic binder phase, the CVD-D cutting edge remains stable due to its binderless anchoring in the diamond matrix.

If CVD-D is used correctly, the tool life can be increased by up to 10 times (and even more) compared to PCD!

With CVD you can machine materials like:- Aluminium >10%Si

- GFRP

- CFRP

- MMC

- Carbide >8% Co

- Tungsten copper

- Tungsten

- Graphite fine-grained

- Magnesium

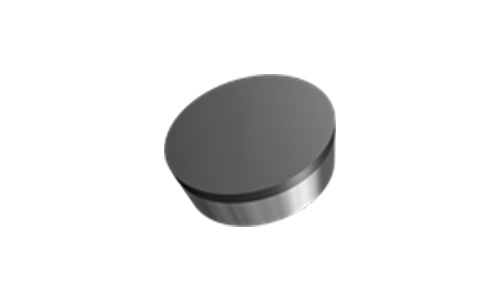

UltraDiamond

- Binderless diamond (UltraDiamond), the hardest single crystal

Single-crystal elements for our tool cutting corners are lasered out of diamond blanks in a defined orientation using laser segmentation technology. This new technology makes it possible to solder a monocrystal (UltraDiamond) onto any tool carrier under high vacuum, in addition to the highly hard polycrystalline cutting materials like PCD and CVD-D. Compared to PCD, the tool life can be increased by approx. 15-25 times and to CVD-D by approx. 2-5 times.

The areas of application are similar to PCD and CVD-D, but this monocrystalline cutting material offers a further significant increase in tool life for all applications where PCD and CVD-D reach the limits of economic viability.

Economical machining of very hard, highly brittle materials such as: Ceramics, glass, glass-ceramics and hard metals with low cobalt or nickel binder (

With UltraDiamond you can machine:- Carbide

- Ceramic Glass ceramic

- Highly abrasive and brittle, non-ferrous materials

CBN for hard turning

- Polycrystalline cubic boron nitride (CBN), chemically resistant and stable at high temperatures up to 1.400°C

Boron nitride powder is the starting point for the production of CBN, which has been available since the end of the 1960s. It is produced under high pressure as well as at temperatures of over 1,500°C and specially adapted to the final application through many different substrates.

Today, CBN is considered the second hardest material after diamond cutting materials!

The applications of CBN are in the automotive industry, aerospace, tool and mould making and mechanical engineering. The wide spectrum as a cutting and abrasive material includes hardened steels, cast iron, chilled cast iron, sintered materials, stellites, nickel and cobalt-based superalloys. In many applications, cubic boron nitride is preferred to diamond cutting materials because it is absolutely stable in air at temperatures up to 1,400°C. Diamond, on the other hand. Diamond, on the other hand, begins to decompose at a temperature of approx. 750°C.

Compared to PCD, CBN is also characterized by its chemical resistance to ferrous materials.

Our CBN grades for machining hardened steels up to 72 HRC:- H25 designed for the smooth cut

- H35 is new in our programme and is developed for the smooth to slightly interrupted cut

- H45 and the H65 are the all-rounders for the smooth to heavily interrupted cut

- H85 was specially developed for the heavily interrupted cut

CBN for tool steel

- Polycrystalline cubic boron nitride (CBN), chemically resistant and stable at high temperatures up to 1.400°C

Boron nitride powder is the starting point for the production of CBN, which has been available since the end of the 1960s. It is produced under high pressure as well as at temperatures of over 1,500°C and specially adapted to the final application through many different substrates.

Today, CBN is considered the second hardest material after diamond cutting materials!

The applications of CBN are in the automotive industry, aerospace, tool and mould making and mechanical engineering. The wide spectrum as a cutting and abrasive material includes hardened steels, cast iron, chilled cast iron, sintered materials, stellites, nickel and cobalt-based superalloys. In many applications, cubic boron nitride is preferred to diamond cutting materials because it is absolutely stable in air at temperatures up to 1,400°C. Diamond, on the other hand, begins to decompose at a temperature of approx. 750°C.

Compared to PCD, CBN is also characterised by its chemical resistance to ferrous materials.

The CBN grade-X has been specially developed for hard turning and hard milling of tool steels up to a hardness of 72HRC. Among other things, you can machine these materials with this CBN grade:- HSS

- ASP and other PM steels

- Cold work steels

- Hot work steels

- VHM >20%Co

- Solid carbide steel joints

CBN for cast iron

- Polycrystalline cubic boron nitride (CBN), chemically resistant and stable at high temperatures up to 1.400°C

Boron nitride powder is the starting point for the production of CBN, which has been available since the end of the 1960s. It is produced under high pressure as well as at temperatures of over 1,500°C and specially adapted to the final application through many different substrates.

Today, CBN is considered the second hardest material after diamond cutting materials!

The applications of CBN are in the automotive industry, aerospace, tool and mould making and mechanical engineering. The wide spectrum as a cutting and abrasive material includes hardened steels, cast iron, chilled cast iron, sintered materials, stellites, nickel and cobalt-based superalloys. In many applications, cubic boron nitride is preferred to diamond cutting materials because it is absolutely stable in air at temperatures up to 1,400°C. Diamond, on the other hand, begins to decompose at a temperature of approx. 750°C.

Compared to PCD, CBN is also characterized by its chemical resistance to ferrous materials.

The CBN grade K has been specially developed for high-speed turning and milling of cast materials. Among other things, you can machine these materials with this CBN grade:- Cast iron

- Spheroidal graphite cast iron

- Lamella ball cast connection

CBN for sintered steel

- Polycrystalline cubic boron nitride (CBN), chemically resistant and stable at high temperatures of up to 1.400°C

Boron nitride powder is the starting point for the production of CBN, which has been available since the end of the 1960s. It is produced under high pressure as well as at temperatures of over 1,500°C and specially adapted to the final application through many different substrates.

Today, CBN is considered the second hardest material after diamond cutting materials!

The applications of CBN are in the automotive industry, aerospace, tool and mould making and mechanical engineering. The wide spectrum as a cutting and abrasive material includes hardened steels, cast iron, chilled cast iron, sintered materials, stellites, nickel and cobalt-based superalloys. In many applications, cubic boron nitride is preferred to diamond cutting materials because it is absolutely stable in air at temperatures up to 1,400°C. Diamond, on the other hand, begins to decompose at a temperature of approx. 750°C.

Compared to PCD, CBN is also characterized by its chemical resistance to ferrous materials.

The CBN grade P has been specially developed for turning sintered materials. Among other things, you can machine these materials with this CBN grade:

Sintered steel- You can machine hardened sintered steel with our CBN-H grade

CBN for Inconel

- Polycrystalline cubic boron nitride (CBN), chemically resistant and stable at high temperatures up to 1.400°C

Boron nitride powder is the starting point for the production of CBN, which has been available since the end of the 1960s. It is produced under high pressure as well as at temperatures of over 1,500°C and specially adapted to the final application through many different substrates.

Today, CBN is considered the second hardest material after diamond cutting materials!

The applications of CBN are in the automotive industry, aerospace, tool and mould making and mechanical engineering. The wide spectrum as a cutting and abrasive material includes hardened steels, cast iron, chilled cast iron, sintered materials, stellites, nickel and cobalt-based superalloys. In many applications, cubic boron nitride is preferred to diamond cutting materials because it is absolutely stable in air at temperatures up to 1,400°C. Diamond, on the other hand, begins to decompose at a temperature of approx. 750°C.

Compared to PCD, CBN is also characterized by its chemical resistance to ferrous materials.

The CBN grade S has been specially developed for turning and milling difficult-to-machine aerospace materials. Among other things, you can machine these materials with this CBN grade:- Ni, Co, Fe & Cr alloys

- Inconel 718

Application engineering

Tool design

- You’re planning a new product and you need tools for its creation?

No matter if standard or special tools, give us a call and we will support you with your project! Process optimization

- You have a new project?

We help you to design the entire process in cooperation with the right machine manufacturer.

Process reliability and economic efficiency are always in the foreground. Initial equipment

- You are planning to buy a new machine or you have bought a new machine?

We can equip your machine with quality fixtures and tools. For the equipment of your machine are many articles in stock such as:- Milling fixtures

- Clamp holders

- Milling tools in CBN and diamond

- CBN and diamond turning tools

- Drilling tools

- Reaming tools

Technology change

- You have an existing process and are considering whether it can be improved or even completely changed?

Talk to us, we have a lot of experience with process changes.

Trainings

- We would be happy to train you and your colleagues in the use of ultra-hard cutting materials. The training courses can be held at your premises or at ours.

We have a variety of practical training courses such as:- What are ultra-hard CBN and diamond cutting materials and where do I use them?

- Aluminium and zinc machining with diamond tools

- Non-ferrous machining with diamond tools

- Hard metal cutting with CBN tools

- High-speed machining of cast iron with CBN tools

- Machining of plastics, GRP and CFRP with diamond tools

- Machining of tool steel with CBN tools

- Machining of carbide

- Applications and possibilities in toolmaking

- Machining of aircraft materials such as titanium and Inconel

- Chip breaking on aluminium and lead-free brass

- Chip breaking during hard turning, hard-soft turning

- Reducing cutting pressure during machining

Profitability

- You want to change your way of processing or to test our tools with your process and you dont know if its economically worth it?

We can carry out a profitability calculation that shows you by how many percent and € you will be more economical. This calculation will be recalculated after the test. Cooperation with machine manufacturers

- You are planning to buy a new machine, but don’t really know which one suits your component, or you already have the right machine and are still looking for the right tools for the specific process? Then talk to us. We will help you.

You are a machine manufacturer, have a project and need suitable tools or advice on tools? Contact us and we will accompany your project to the end.

We work together with various well-known machine manufacturers and help with the design of various processes.