- Offer Profile

-

Steel processing stands for manufacturing new long lasting structures. While producing such durable materials and products, you will need the most powerful and reliable machines. From locksmith’s shop to steel construction, from bridge building to automotive industry.

Our enthusiastic team of professionals knows your business and the challenges you have to face every day. Many years of experience and high innovation rates enable us to set the standard in the industry, especially in the areas of sustainability and cost effective processing.

Special attention is given to a safe, healthy and pleasant working environment.

PREMIUM QUALITY SOLUTIONS

-

As a trend setter and technology leader, we are able to supply premium quality solutions, combined with an attractive and functional machine design. Robust and durable.

Our product ranges bring total solutions and special machines for sawing, drilling, plate processing, as well as shot blasting and painting, including logistic and control systems.

Powerful, highly versatile systems, whereby quick return on investment is made possible by means of a high level of performance and productivity.

Our software, machinery and skilled service and spare parts department makes it possible to install and run your machine with the highest uptime.

Band Sawing

-

Highly innovative steel band saws which deliver outstanding cutting performance. With our powerful and reliable KALTENBACH system you will be assured of the best possible saw for your business. Fast, precise and comfortable sawing of steel profiles – as single beams as well as in layers or in bundles.

KBB 601

-

Mitering band saw for light- and medium-duty steel fabrication and service centers

Workspace [mm]: 620 x 410BENEFITS AT A GLANCE:

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- High cutting performance

- Powerful clamping system for low vibrations

- Rapid/working feed concept for shorter idle times

- Swarf brush to improve cutting performance

- Cutting pressure and slippage control for perfect quality

- Laser-assisted cutting edge visualisation for manual cuts

KBB 1001

-

Mitering band saw for light- and medium-duty steel fabrication and service centers

Workspace [mm]: 1020 x 410BENEFITS AT A GLANCE:

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- High cutting performance

- Powerful clamping system for low vibrations

- Rapid/working feed concept for shorter idle times

- Swarf brush to improve cutting performance

- Cutting pressure and slippage control for perfect quality

- Laser-assisted cutting edge visualisation for manual cuts

KBS 400

-

Mitering band saw for light- and medium-duty steel fabrication and service centers

Workspace 90° [mm]: 400 x 350BENEFITS AT A GLANCE:

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- High cutting performance

- Powerful clamping system for low vibrations

- Rapid/working feed concept for shorter idle times

- Swarf brush to improve cutting performance

- Cutting pressure and slippage control for perfect quality

- Laser-assisted cutting edge visualisation for manual cuts

KBS 400 DG NA

-

Band Saw with Mitre Unit for light to medium Steel Construction and Trading with an attached Automatic Feed

Capacity Range 90° [mm]: 400 x 350BENEFITS AT A GLANCE:

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- High cutting performance

- Powerful clamping system for low vibrations

- Rapid/working feed concept for shorter idle times

- Swarf brush to improve cutting performance

- Cutting pressure and slippage control for perfect quality

- Laser-assisted cutting edge visualisation for manual cuts

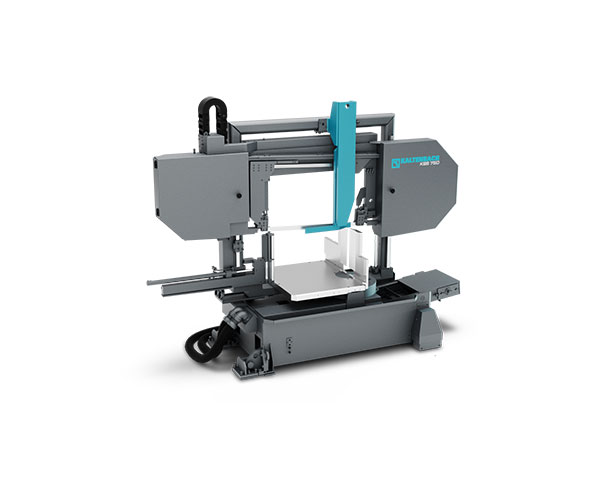

KBS 750

-

Mitering band saw for light- and medium-duty steel fabrication and service centers

Workspace 90° [mm]: 750 x 500BENEFITS AT A GLANCE:

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- High cutting performance

- Powerful clamping system for low vibrations

- Rapid/working feed concept for shorter idle times

- Swarf brush to improve cutting performance

- Cutting pressure and slippage control for perfect quality

- Laser-assisted cutting edge visualisation for manual cuts

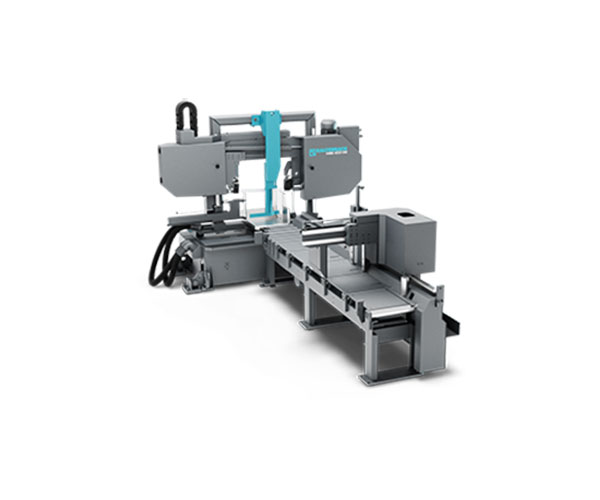

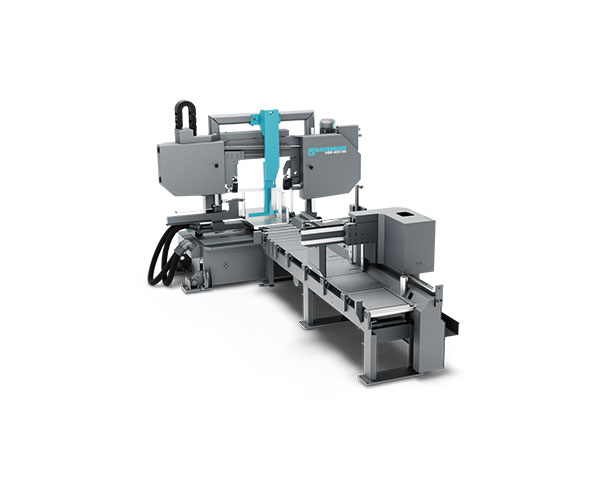

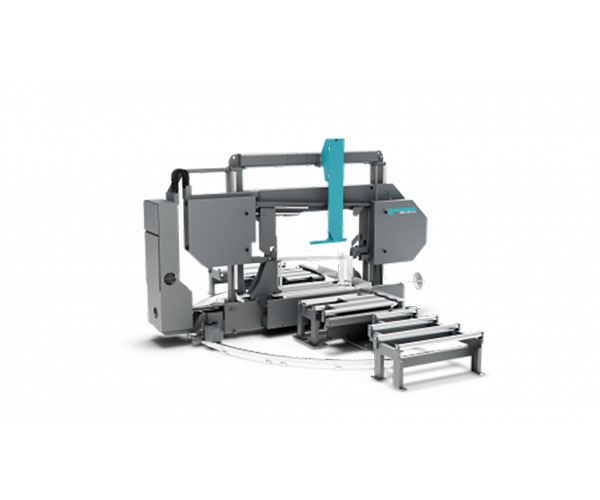

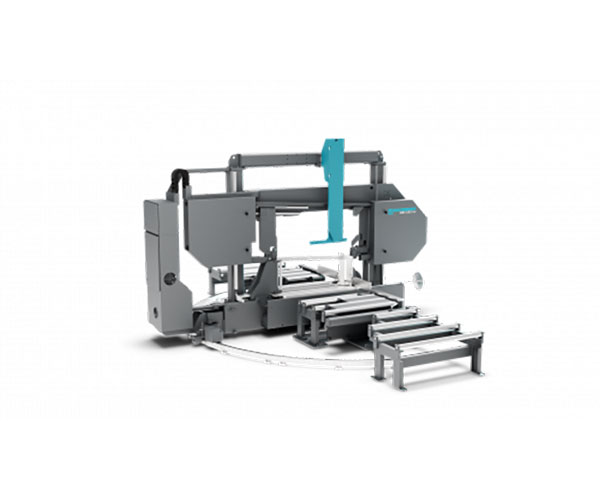

KBS 750 DG NA

-

Band Saw with Mitre Unit for light to medium Steel Construction and Trading with an attached Automatic Feed

Capacity Range 90° [mm]: 750 x 500BENEFITS AT A GLANCE:

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- High cutting performance

- Powerful clamping system for low vibrations

- Rapid/working feed concept for shorter idle times

- Swarf brush to improve cutting performance

- Cutting pressure and slippage control for perfect quality

- Laser-assisted cutting edge visualisation for manual cuts

KBS 1010

-

Mitering band saw for light- and medium-duty steel fabrication and service centers

Workspace 90° [mm]: 1,010 x 500BENEFITS AT A GLANCE:

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- High cutting performance

- Powerful clamping system for low vibrations

- Rapid/working feed concept for shorter idle times

- Swarf brush to improve cutting performance

- Cutting pressure and slippage control for perfect quality

- Laser-assisted cutting edge visualisation for manual cuts

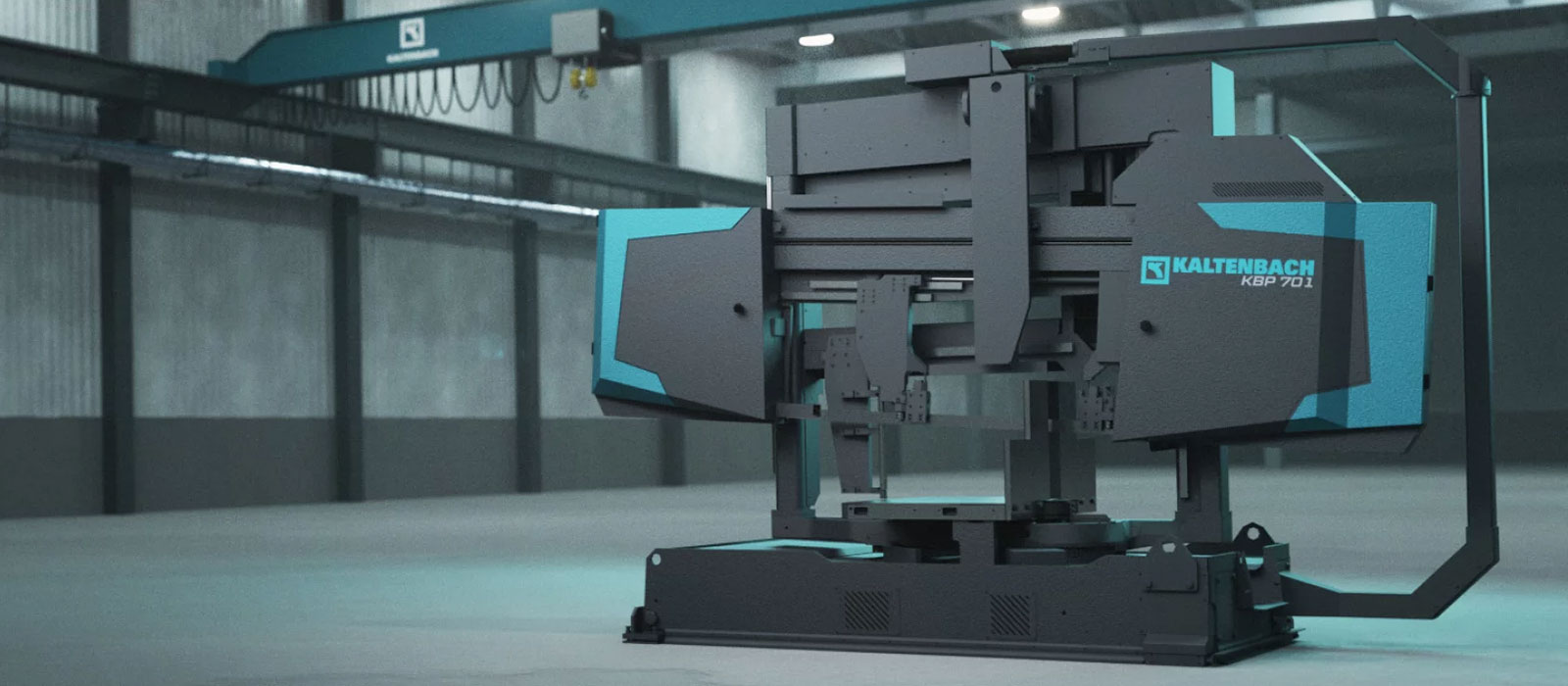

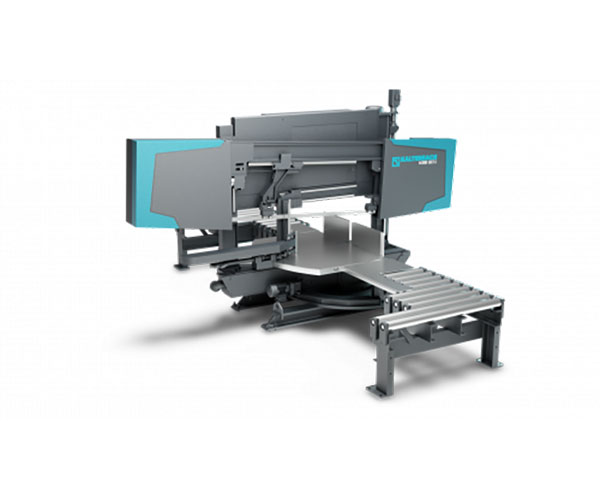

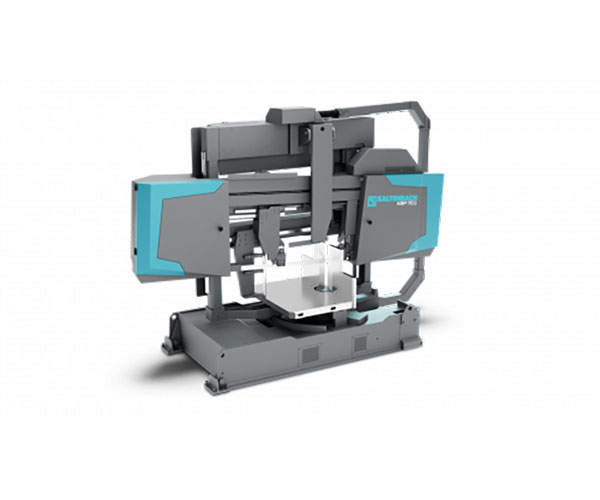

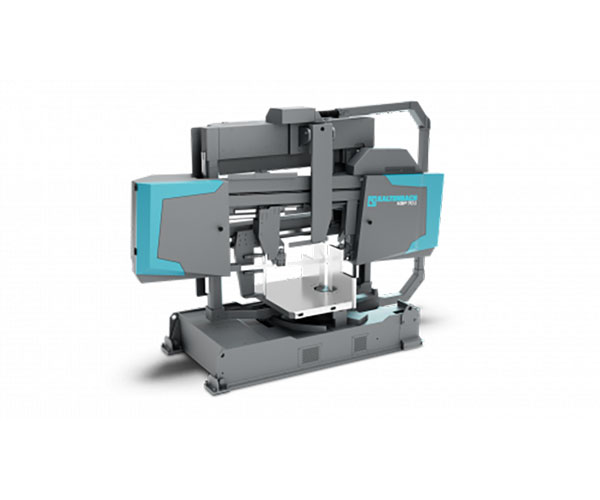

KBP 701 (KBS 761)

-

Mitering band saw for light- and heavy-duty steel fabrication and service centers

Workspace 90° [mm]: 750 x 500BENEFITS AT A GLANCE:

- Highest cutting performance due to carbide saw bands

- AFC automatically reduces cutting time significantly

- Highest automation opportunities for short piece handling

- Fast change of the saw band for low idle times

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- Swarf brush to improve cutting performance

- Powerful clamping system for low vibrations

- Cutting pressure and slippage control for perfect quality

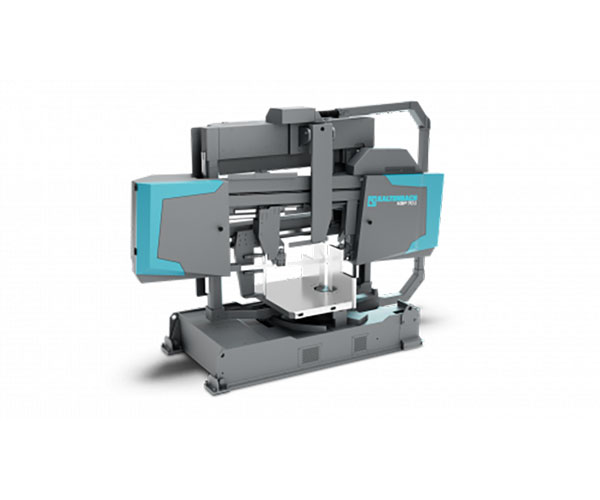

KBP 1001 (KBS 1051)

-

Mitering band saw for light- and heavy-duty steel fabrication and service centers

Workspace 90° [mm]: 1,030 x 500BENEFITS AT A GLANCE:

- Highest cutting performance due to carbide saw bands

- AFC automatically reduces cutting time significantly

- Highest automation opportunities for short piece handling

- Fast change of the saw band for low idle times

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- Swarf brush to improve cutting performance

- Powerful clamping system for low vibrations

- Cutting pressure and slippage control for perfect quality

KBP 1301 (KBS 1351)

-

Mitering band saw for light- and heavy-duty steel fabrication and service centers

Workspace 90° [mm]: 1,330 x 600BENEFITS AT A GLANCE:

- Highest cutting performance due to carbide saw bands

- AFC automatically reduces cutting time significantly

- Highest automation opportunities for short piece handling

- Fast change of the saw band for low idle times

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- Swarf brush to improve cutting performance

- Powerful clamping system for low vibrations

- Cutting pressure and slippage control for perfect quality

KBS 1301

-

Mitering band saw for medium- and heavy-duty steel fabrication and service centers

Workspace 90° [mm]: 1,300 x 700BENEFITS AT A GLANCE:

- Designed for profiles with large material cross-sections

- Highest cutting performance due to carbide saw bands

- AFC automatically reduces cutting time significantly

- Highest automation opportunities for short piece handling

- Fast change of the saw band for low idle times

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- Powerful clamping system for low vibrations

- Cutting pressure and slippage control for perfect quality

KBS 2101

-

Mitering band saw for medium- and heavy-duty steel fabrication and service centers

Workspace 90° [mm]: 2,100 x 800BENEFITS AT A GLANCE:

- Designed for profiles with large material cross-sections

- Highest cutting performance due to carbide saw bands

- AFC automatically reduces cutting time significantly

- Highest automation opportunities for short piece handling

- Fast change of the saw band for low idle times

- Robust construction for perfect cutting results

- Precise setting of cutting angle

- Long blade life and the best cutting quality

- Powerful clamping system for low vibrations

- Cutting pressure and slippage control for perfect quality

Circular Sawing

- Reducing cutting times in steel or aluminium processing while ensuring an unrivalled quality. You can do it with our KALTENBACH circular saw machines. Thanks to perfect material clamp, infinitely variable feed rates and heavy machine construction you will achieve a perfect cutting surface. Automatic cycle control for clamping/sawing/opening the vice significantly reduces non-productive times. High-performance, thin-section sawing systems, specifically designed for your business.

SKL 450 E

-

Semi-automatic mitre saw for non-ferrous metals

Workspace [mm]: 160BENEFITS AT A GLANCE:

- Clamping, sawing, reverse motion, opening – touch of a button

- Suitable for single cuts and processing of small batches

- User-friendly electronic control unit mounted directly on the machine

- Good accessibility for saw blades changes and maintenance work

- Workpiece clamping device on both sides of the saw blade

- Infinitely variable saw blade feed

- KALTENBACH ‘cut from below’ principle ensures good chip flow

- Ergonomically arranged controls for ease-of-use

- Adjustable cutting stroke limit and rapid return of saw blade

SKL 450 NA

-

Fully-automatic saw for non-ferrous metals

Workspace [mm]: 160BENEFITS AT A GLANCE:

- Infeed gripper for material lengths up to 9999 mm

- Special infeed gripper minimises end-piece lengths

- Electro-mechanical material infeed gripper

- Optional chip extraction device

- Efficient minimum quantity lubrication for extended blade life

- Can be combined with fully automatic flat magazine

- Two cutting speeds for different material dimensions

KKS 400 U

-

Semi-automatic mitre saw

Workspace [mm]: 130BENEFITS AT A GLANCE:

- Clamping, sawing, reverse motion, opening – touch of a button

- Push-button adjustment of the cutting height

- User-friendly electronic control directly on the machine

- Space saving installation

- No manual presetting of the vertical clamp

- Two cutting speeds for virtually all applications

KKS 450 U

-

Semi-automatic mitre saw

Workspace [mm]: 150BENEFITS AT A GLANCE

- Clamping, sawing, reverse motion, opening – touch of a button

- Push-button adjustment of the cutting height

- User-friendly electronic control directly on the machine

- Space saving installation

- No manual presetting of the vertical clamp

- Two cutting speeds for virtually all applications

KKS 400 T

-

Semi-automatic mitring circular saw in special design for jig work

Workspace [mm]: 130BENEFITS AT A GLANCE:

- Saw table with tapped holes to enter specific clamping devices

- Electronic cut stroke limitation for a reduction in cycle times

- Reinforced drive motor for high cutting performances

- Optional, dynamic feed control via proportional valve

- Clamping arm with hydraulic long stroke clamping cylinder

- Minimal lubrication for nearly dry saw cuts

KKS 450 T

-

Semi-automatic mitring circular saw in special design for jig work

Workspace [mm]: 150BENEFITS AT A GLANCE:

- Saw table with tapped holes to enter specific clamping devices

- Electronic cut stroke limitation for a reduction in cycle times

- Reinforced drive motor for high cutting performances

- Optional, dynamic feed control via proportional valve

- Clamping arm with hydraulic long stroke clamping cylinder

- Minimal lubrication for nearly dry saw cuts

KKS 450 R

-

Semi-automatic mitring circular saw for straight cuts of bent pipes

Workspace [mm]: 140BENEFITS AT A GLANCE:

- Saw table with tapped holes to enter specific clamping devices

- Electronic cut stroke limitation

- Optional, dynamic feed control via proportional valve

- Clamping arm with hydraulic long stroke clamping cylinder

- Forklift pockets to enable fast transportation between location

- Minimal lubrication for nearly dry saw cuts

KKS 450 H

-

Semi-automatic mitre saw suitable for almost all steel qualities

Workspace [mm]: 150BENEFITS AT A GLANCE:

- Suitable for almost all steel qualities

- Turntable for mitre cuts

- Minimal set-up effort when changing materials

- Modern operation via control panel with plain-text display

- Clamping, sawing, reverse motion, opening – touch of a button

- Ideal for single cuts and processing small batches

- Good accessibility for saw-blade changes and maintenance work

- Space saving installation

KKS 461 NA

-

Fully-automatic mitre saw for profiles and solid materials

Workspace [mm]: 155BENEFITS AT A GLANCE:

- Automatic processing of various materials and profiles

- Automatic material supply via the supply gripper

- CNC-controlled rotary table for mitre cuts

- Graphical operating surface (touchscreen) and PROFICUT Software

- Automatic calculation of cutting speed and saw feed rate

- Removal roll rail to push the cut parts

- Flexible material feed from the left (optionally right) side

- Optional automatic cut sorting

- Continuous one-part machine case in welded execution

KKS 400 DH

-

Double circular saw suitable for almost all steel qualities

Workspace [mm]: 130BENEFITS AT A GLANCE:

- consists of two KKS 400 machines

- with travelling frame and central control system

- one machine can be positioneD

- operation of both machines is controlled via foot switch

- both of the machines can also operated separately

- additionally a length measuring device can be fitted

KKS 463 NA

-

Fully-automatic universal circular saw for profiles, solid materials and tubes

Workspace [mm]: 153BENEFITS AT A GLANCE:

- Automatic processing of flat, angle and solid materials

- Multiple front and back cuts

- Automatic calculation of the cutting speed and saw feed rate

- Electronic cutting-height adjustment

- Rapid reverse motion of the saw blade

- Minimal end-piece lengths

- Automatic cut-off sorting

- Simple operation and programming via touch screen

MSK 471 NA

-

Fully automatic universal saw for straight cutting

Workspace [mm]: 152BENEFITS AT A GLANCE:

- Fully-automatic processing and sorting of finished pieces

- Low vibration due to extreme stiffness of the components

- Minimal end-piece lenghts

- High productivity with good sawblade life

- Material feed gripper

- Sawblade feed with static ballscrew spindle

- Combined drive for HSS and carbide equipped tools

HDM 1432

-

High performance for heavy steel construction and steel service centers

Workspace [mm]: 1,200 x 450BENEFITS AT A GLANCE:

- Vertical saw on robust pivot bearing

- Powerful drive for high-performance cutting

- Single cuts in addition to layer and bundle cuts possible

- NC-controlled cutting-angle setting

- A drill can be incorporated to create a saw-drill combination

- Feed via ball screw for perfect cutting results

Coping

-

Enhance your manufacturing level with the intelligent coping robots of KALTENBACH. Sophisticated systems for applying a wide variety of chamfers, internal contours, longitudinal cuts, slots, holes, mitre and straight cuts. Innovative, mechanized systems for both plasma and oxyfuel cutting. Secure your capital with machinery of excellence!

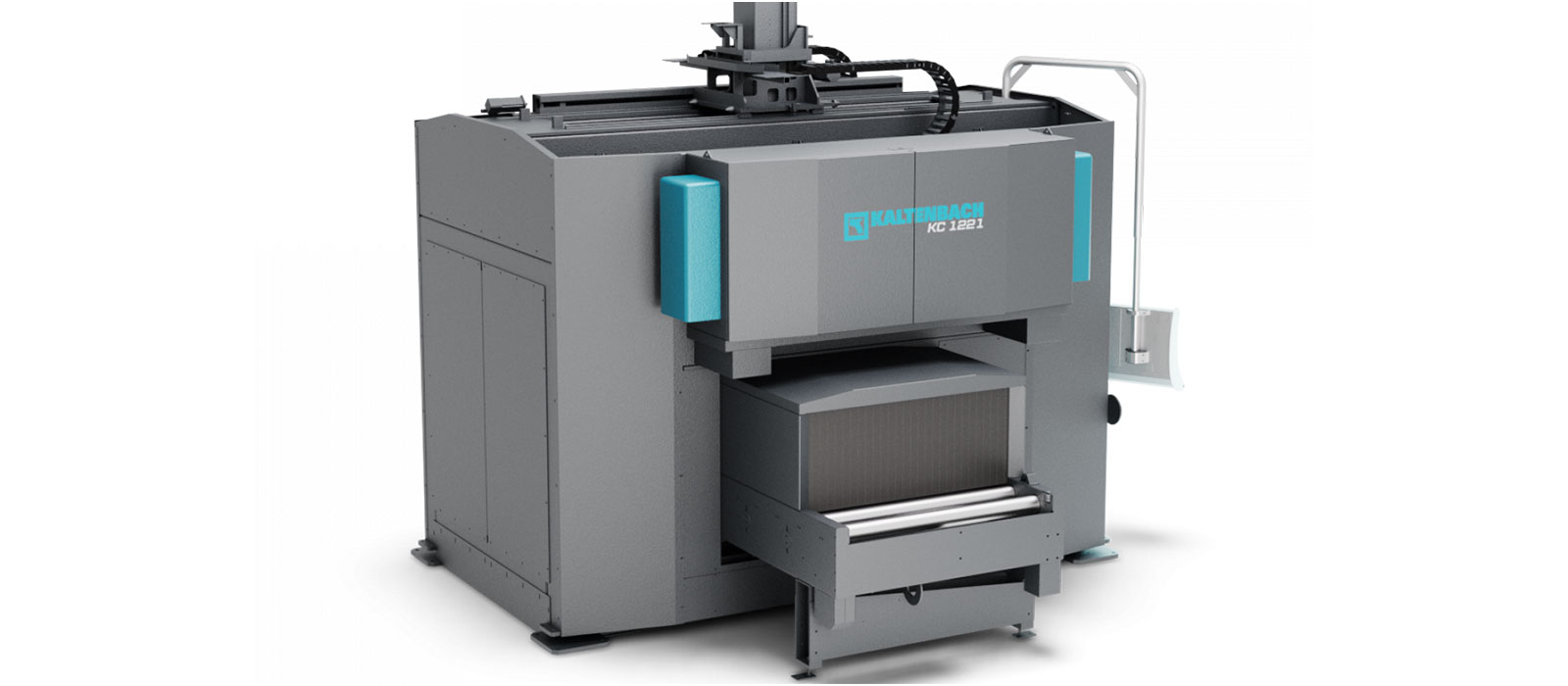

KC 1221

High-performance coping robot which offers you total processing freedom

Workspace [mm]: 1,220 x 475BENEFITS AT A GLANCE

- Marks and cuts structural steel on 4 sides

- Robust, precise, low-maintenance 6-axis Stäubli coping robot

- 3D scanner system accurately detects material geometries

- PerfectHole technology and arc shape compensation

- Minimises manual finishing required for welding

- Silent Cut technology

- Enormous freedom in terms of part design

- Allows machining of welded and drilled connections

- Compatible with modern CAD applications

Plate Processing

-

Achieve the highest productivity and efficiency with our oxy-fuel cutting, plasma cutting and plate drilling systems. Various operations such as drilling, milling, thread-cutting, counter-sinking, centre-marking, contour-marking, hard stamping and thermal cutting can be carried on one single machine. Contact one of our experts to upgrade your production process.

KF 2114/28

-

Plate processing centre for complete steel processing from one single source

Workspace [mm]: 2,100 x 6,000 (optional 12,000)BENEFITS AT A GLANCE:

- Diverse manufacturing technologies

- Milling as standard function of the machine

- Powerful drives

- Higher spindle speed

- Optional downholder roll for optimum plate contact pressure

- Increased stability

- 14/28-place tool changer

- Less space needed for measuring carriage

- Measuring carriage to optimise plate fixation

- Increased traversing speed of axes

KF 2614/28

-

Plate processing centre for complete steel processing from one single source

Workspace [mm]: 2,600 x 6,000 (optional 12,000)BENEFITS AT A GLANCE:

- Diverse manufacturing technologies

- Milling as standard function of the machine

- Powerful drives

- Higher spindle speed

- Optional downholder roll for optimum plate contact pressure

- Increased stability

- 14/28-place tool changer

- Less space needed for measuring carriage

- Measuring carriage to optimise plate fixation

- Increased traversing speed of axes

KF 3114/28

-

Plate processing centre for complete steel processing from one single source

Workspace [mm]: 3,100 x 6,000 (optional 12.000)BENEFITS AT A GLANCE:

- Diverse manufacturing technologies

- Milling as standard function of the machine

- Powerful drives

- Higher spindle speed

- Optional downholder roll for optimum plate contact pressure

- Increased stability

- 14/28-place tool changer

- Less space needed for measuring carriage

- Measuring carriage to optimise plate fixation

- Increased traversing speed of axes

Drillig

-

Our valuable expertise in the field of drilling enables us to produce highly effective machines. Most environmentally friendly solutions with maximum uptime. You will be assured of the most modern, powerful, automated steel processing systems. Easy to operate drills, provided with all modern processing technologies like milling, carbide drilling, tapping, counter-sinking and marking.

KDU 250

-

Drilling machine for smaller profiles

Workspace [mm]: 250 x 250BENEFITS AT A GLANCE:

- Robust, low-vibration design prolongs machine and tool life

- Machine portal in robust welded construction

- Drilling/centre-marking/counter-sinking/thread-cutting

- Powerful clamping system

- Rapid/working feed concept for shorter idle times

- Servomotor and ball screw

- can be incorporated to create a saw-drill combination

- Manual quick-change chuck

- Tool-centric processing minimises tool changes

- Use of HSS drills

- Up to four drill axes each with one drilling tool

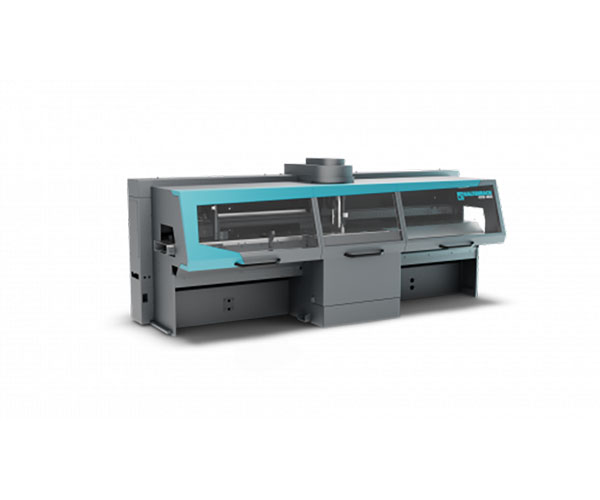

KDB615

-

Drill line for light- and medium-duty steel fabrication and service centers

Workspace [mm]: 620 x 410BENEFITS AT A GLANCE:

- Robust design for a longer machine lifetime

- Efficient drilling, milling, marking, tapping and countersinking

- Powerful clamping system for a longer tool lifetime

- Intelligent material measurement for great process reliability

- Servomotors and ball screw for high-precision

- Tool changer for 5 tools per axis for less setup times

- Compact design for high processing performance

KDB 1015

-

Drill line for light- and medium-duty steel fabrication and service centers

Workspace [mm]: 1,020 x 410BENEFITS AT A GLANCE:

- Robust design for a longer machine lifetime

- Efficient drilling, milling, marking, tapping and countersinking

- Powerful clamping system for a longer tool lifetime

- Intelligent material measurement for great process reliability

- Servomotors and ball screw for high-precision

- Tool changer for 5 tools per axis for less setup times

- Compact design for high processing performance

KDM 615

-

Drill line for light-, medium- and heavy-duty steel fabrication and service centers

Workspace [mm]: 600 x 500 and number of tools: 15BENEFITS AT A GLANCE:

- Robust design for a longer machine lifetime

- Efficient drilling, milling, marking, tapping and countersinking

- Powerful drive for highest processing performance

- Powerful clamping system for a longer tool usage

- Intelligent material measurement for greater process reliability

- Servomotors and ball screw for high-precision

- Tool changer for 5 tools per axis for less setup times

KDM 1015

-

Drill line for light-, medium- and heavy-duty steel fabrication and service center

Workspace [mm]: 1,000 x 500 and number of tools: 15BENEFITS AT A GLANCE:

- Robust design for a longer machine lifetime

- Efficient drilling, milling, marking, tapping and countersinking

- Powerful drive for highest processing performance

- Powerful clamping system for a longer tool usage

- Intelligent material measurement for greater process reliability

- Servomotors and ball screw for high-precision

- Tool changer for 5 tools per axis for less setup times

KDL 2118

-

Drill line for medium- and heavy-duty steel fabrication and service centers

Workspace [mm]: 2,100 x 700 and number of tools: 18BENEFITS AT A GLANCE:

- Robust design for a longer machine lifetime

- Efficient drilling, milling, marking, tapping and countersinking

- Powerful drive for highest processing performance

- Powerful clamping system for a longer tool usage

- Intelligent material measurement for greater process reliability

- Servomotors and ball screw for high-precision

- Tool changer for 6 tools per axis for less setup times

KDP 736

-

Drill line for medium- and heavy-duty steel fabrication and service centers

Workspace [mm]: 750 x 600 and number of tools: 36BENEFITS AT A GLANCE:

- Robust design for a longer machine lifetime

- Efficient drilling, milling, marking, tapping and countersinking

- Powerful drive for highest processing performance

- Powerful clamping system for a longer tool usage

- Intelligent material measurement for great process reliability

- Servomotors and ball screw for high-precision

- Lager tool changer for 12 tools per axis for less setup times

- Additional sub-axis of 500mm for parallel processing

- Machining while sawing for highest parallization

KDP 1036

-

Drill line for medium- and heavy-duty steel fabrication and service centers

Workspace [mm]: 1,030 x 600 and number of tools: 36BENEFITS AT A GLANCE:

- Robust design for a longer machine lifetime

- Efficient drilling, milling, marking, tapping and countersinking

- Powerful drive for highest processing performance

- Powerful clamping system for a longer tool usage

- Intelligent material measurement for great process reliability

- Servomotors and ball screw for high-precision

- Lager tool changer for 12 tools per axis for less setup times

- Additional sub-axis of 500mm for parallel processing

- Machining while sawing for highest parallization

KDP 1336

-

Drill line for medium- and heavy-duty steel fabrication and service centers

Workspace [mm]: 1,330 x 600 and number of tools: 36BENEFITS AT A GLANCE:

- Robust design for a longer machine lifetime

- Efficient drilling, milling, marking, tapping and countersinking

- Powerful drive for highest processing performance

- Powerful clamping system for a longer tool usage

- Intelligent material measurement for great process reliability

- Servomotors and ball screw for high-precision

- Lager tool changer for 12 tools per axis for less setup times

- Additional sub-axis of 500mm for parallel processing

- Machining while sawing for highest parallization

Punching and Shearing

-

Maximum power and an optimal working range. Get to know our excellent series of shearing and punching systems for angled steel. We offer you a precise, high performance cut for large dimensions, with an elimination of residues. Automatic die clearance settings take care of optimum shearing results. Supreme uptime is effected by a quick-change tooling system.

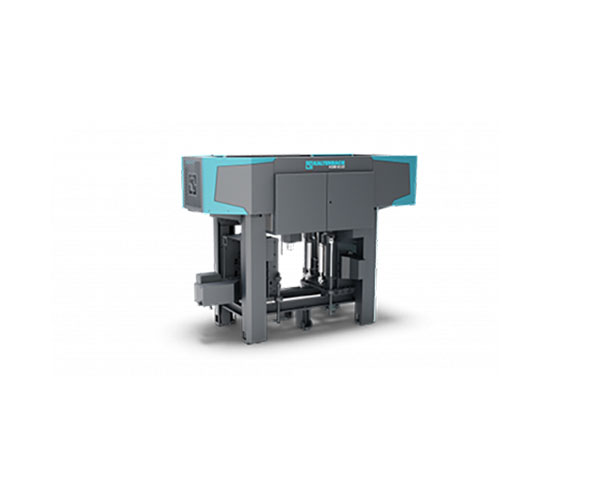

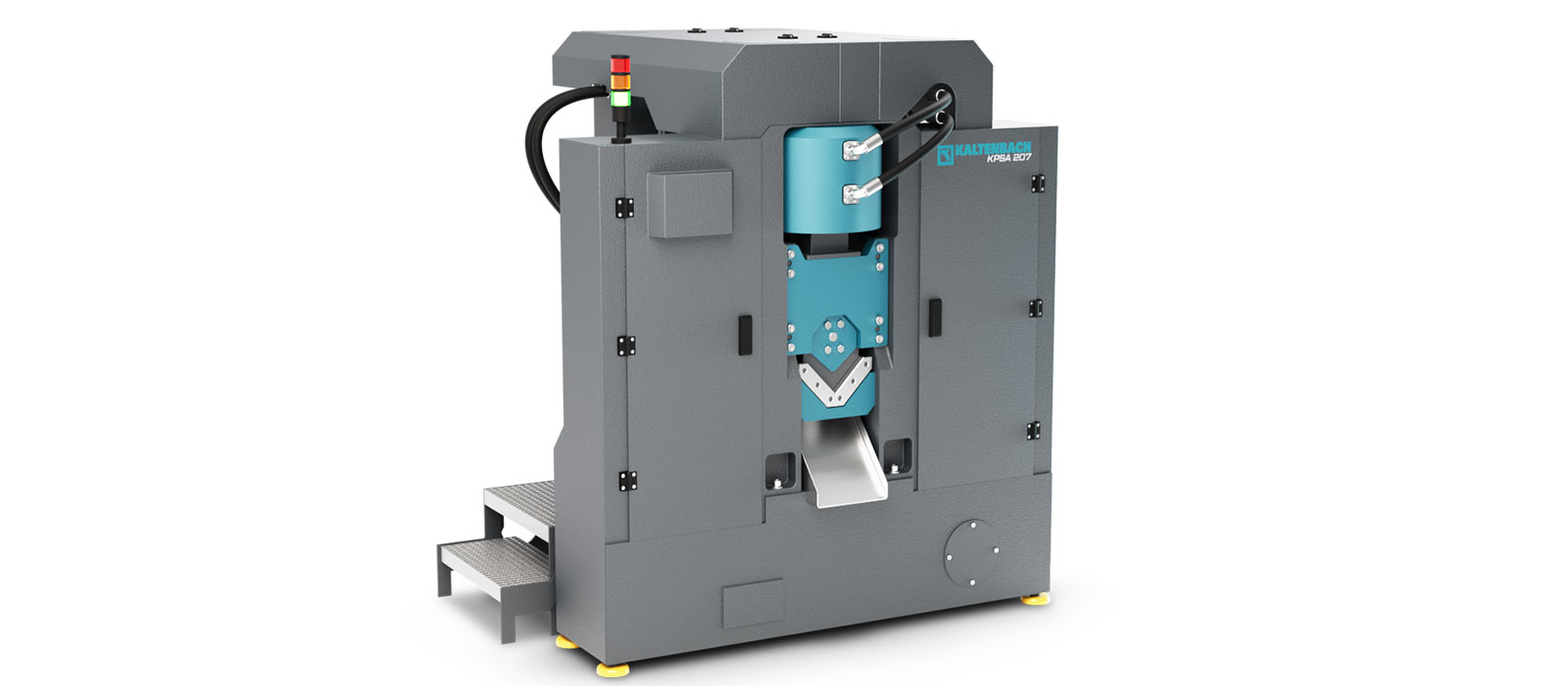

KPSA 207

Powerful punching and shearing system for angle steel

Workspace [mm]: 200 x 200 x 25BENEFITS AT A GLANCE

- High punching and shearing force

- Design is influenced by years of punching/shearing experience

- Sturdy construction for low vibration

- Compact machine design for space-saving installation

- User-friendly MULTILINE Software

- Low maintenance design with optimal access

- Quick tool change system minimal idle time

- Automatic die clearance setting for the highest quality shear

Shot Blasting

- Rust. Mill scale. Impurities. Before steel is fit to be processed it has to be cleaned. With over a century of experience, KALTENBACH | GIETART is the leading, innovative expert for steel surface treatment, with most reliable, high-quality shot blasting and conservation equipment.

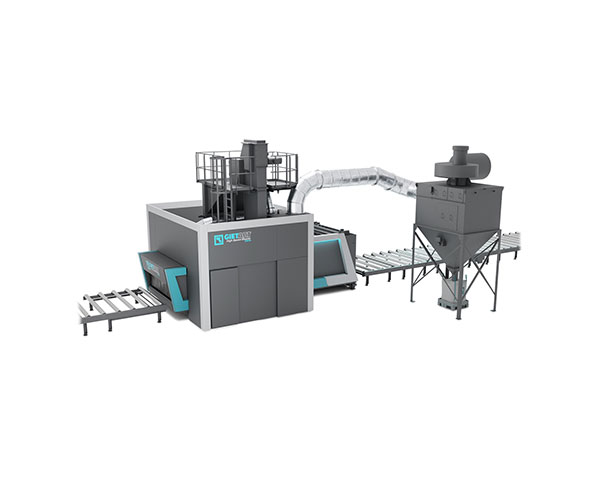

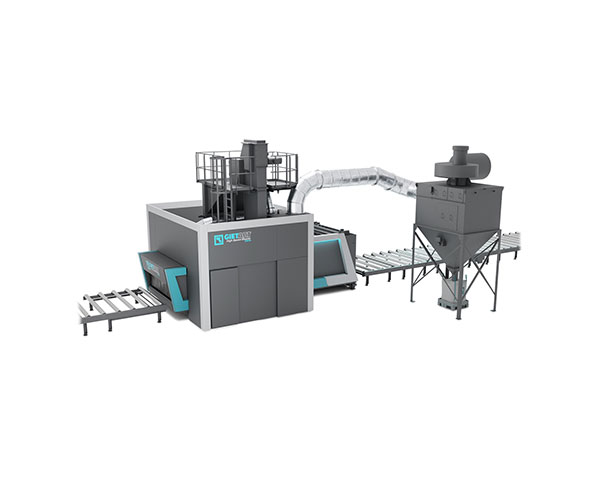

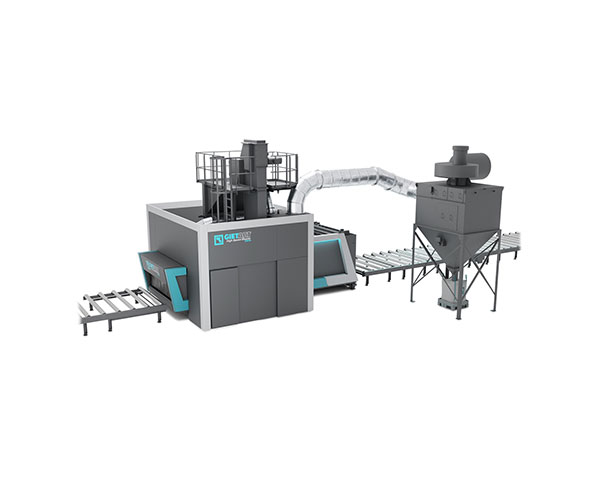

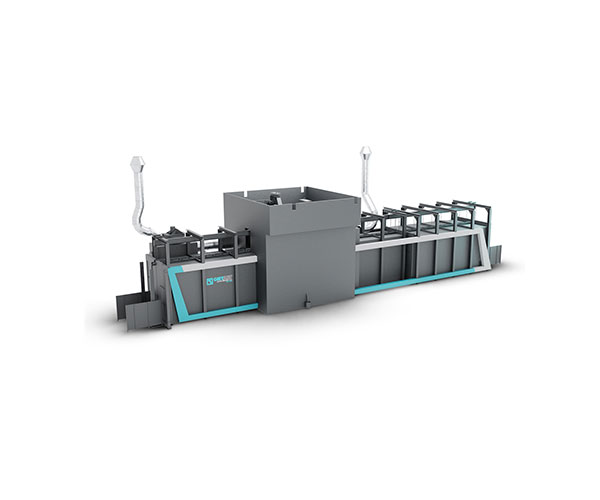

GIETART Compact Blaster 604

-

Compact shot blasting system for cleaning profiles and tubes

Workspace [mm]: 600 x 300 and Number of Turbines: 4

Suitable for a throughput up to 7,500 tons a yearBENEFITS AT A GLANCE:

- Suitable for single beams up to 600 mm width and multiple smaller products

- Placement on the floor - standard

- Small and slim footprint, compact system

- Reliable and durable, high-quality blasted products

- Superior performance at lowest cost of ownership

- User-friendly system, easy to maintain

- Equipped with 6, 9 or 12 m transport system

GIETART ECO Blaster 1504

-

Cost effective shot blasting system for cleaning plates, profiles and tubes

Workspace [mm]: 1,500 x 600 and Number of Turbines: 4

Suitable for a throughput up to 20,000 tons a year

- Substitute for SPRINTBENEFITS AT A GLANCE:

- Highest uptime

- Reliable and durable, high-quality blasted products

- Extendable with various transport systems

- Superior performance at the lowest cost of ownership

- User friendly system. Easy to maintain

- Available with many options

- Highly efficient, cost effective and competitive system

- Best blasting and cleaning results

GIETART ECO Blaster 1506

-

Cost effective shot blasting system for cleaning plates, profiles and tubes

Workspace [mm]: 1,500 x 600 and Number of Turbines: 6

Suitable for a throughput up to 20,000 tons a year

- Substitute for SPRINTBENEFITS AT A GLANCE:

- Highest uptime

- Reliable and durable, high-quality blasted products

- Extendable with various transport systems

- Superior performance at the lowest cost of ownership

- User friendly system. Easy to maintain

- Available with many options

- Highly efficient, cost effective and competitive system

- Best blasting and cleaning results

GIETART ECO Blaster 2506

-

Cost effective shot blasting system for cleaning plates, profiles and tubes

Workspace [mm]: 2,500 x 600 and Number of Turbines: 6

Suitable for a throughput up to 20,000 tons a year

- Substitute for SPRINTBENEFITS AT A GLANCE:

- Suitable for a throughput up to 20,000 tons a year

- Highest uptime

- Reliable and durable, high-quality blasted products

- Extendable with various transport systems

- Superior performance at the lowest cost of ownership

- User friendly system. Easy to maintain

- Available with many options

- Highly efficient, cost effective and competitive system

- Best blasting and cleaning results

GIETART ECO Blaster 3008

-

Cost effective shot blasting system for cleaning plates, profiles and tubes

Workspace [mm]: 3,200 x 600 and Number of Turbines: 8

Suitable for a throughput up to 20,000 tons a year

- Substitute for SPRINTBENEFITS AT A GLANCE:

- Highest uptime

- Reliable and durable, high-quality blasted products

- Extendable with various transport systems

- Superior performance at the lowest cost of ownership

- User friendly system. Easy to maintain

- Available with many options

- Highly efficient, cost effective and competitive system

- Best blasting and cleaning results

GIETART High Speed Blaster 1506

-

Ideal for higher speeds and large quantities

Workspace [mm]: 1,500 x 600 and Number of Turbines: 6

Suitable for a throughput up to 50,000 tons a year, and more

- Substitute for MARATHONBENEFITS AT A GLANCE:

- High loading and blasting capacity

- Suitable for multiple shift operations

- Reliable in realizing the maximum speed

- Unique energy saving concept

- Low emission values

- Flexible logistic solutions

GIETART High Speed Blaster 2506

-

Ideal for higher speeds and large quantities

Workspace [mm]: 2,500 x 600 and Number of Turbines: 6

Suitable for a throughput up to 50,000 tons a year, and more

- Substitute for MARATHONBENEFITS AT A GLANCE:

- High loading and blasting capacity

- Suitable for multiple shift operations

- Reliable in realizing the maximum speed

- Unique energy saving concept

- Low emission values

- Flexible logistic solutions

GIETART High Speed Blaster 3008

-

Ideal for higher speeds and large quantities

Workspace [mm]: 3,200 x 600 and Number of Turbines: 8

Suitable for a throughput up to 50,000 tons a year, and more

- Substitute for MARATHONBENEFITS AT A GLANCE:

- High loading and blasting capacity

- Suitable for multiple shift operations

- Reliable in realizing the maximum speed

- Unique energy saving concept

- Low emission values

- Flexible logistic solutions

GIETART 3D Blaster 1508

-

Perfect for blasting welded steel constructions

Workspace [mm]: 1,500 x 800 and Number of Turbines: 8

Capacity depending on the shape and weight of the parts

- Substitute for TRIATHLONBENEFITS AT A GLANCE:

- Especially developed for welded steel constructions

- Perfectly cleaned end products

- Optimum recirculation of used abrasive

- Easy inspection and maintenance

- Option HD version: heavier turbines, higher impact, double speed

- Also available with significant energy saving option

GIETART 3D Blaster 3010

-

Perfect for blasting welded steel constructions

Workspace [mm]: 3,000 x 1,600 and Number of Turbines: 10

Capacity depending on the shape and weight of the parts

- Substitute for TRIATHLONBENEFITS AT A GLANCE:

- Especially developed for welded steel constructions

- Perfectly cleaned end products

- Optimum recirculation of used abrasive

- Easy inspection and maintenance

- Option HD version: heavier turbines, higher impact, double speed

- Also available with significant energy saving option

GIETART Aerial Blaster

-

High flexibility with customized monorail blasters.

Especially designed for flexible construction parts.

Capacity depending on shape and weight of parts.

- Unique MONORAIL systemBENEFITS AT A GLANCE:

- Unique turbine configurations for welded steel constructions

- Optimal blasting and cleaning results

- Ideal interface combination with existing monorail systems

- In line with monorail painting system

- Extendable with various transport systems

- Meeting the latest requirements in the field of safety

Robotic Handling System ECO 1504 - RHS

-

Automate your handling for the shot blasting process.

Innovative robot with magnetic gripper and visions system for loading and unloading steel parts.BENEFITS AT A GLANCE:

- Suitable for loading and unloading products on racks

- Hybrid solution – during shot blasting of beams, racks can be filled automatically

- Optimal shot blaster filling

- Increased uptime of shot blaster

- Enables unmanned production

- Enhanced ergonomics

- Improves the economics of your production

- User-friendly system, easy to maintain

- Option for refit in existing solutions

- Reduction of open slots in shot blasting process

Painting

-

The leading systems in the market for automated continuous coating systems for steel parts. Our cutting-edge technology enables you to work with highly cost-effective, environmentally friendly solutions in combination with a precise coating technique.

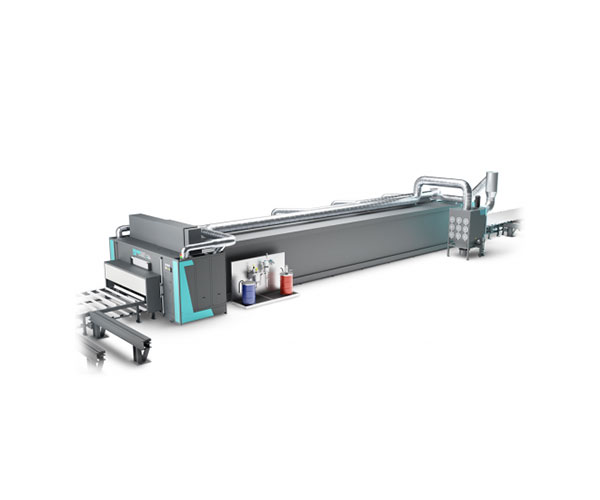

GIETART ECO Primer 1504/2504/3004

-

Complete painting in a single pass

Workspace [mm]: 1,500-3,000 x 600 and number of spray guns: 4

Perfect combination with your GIETART ECO Blaster

- Substitute for KPCBENEFITS AT A GLANCE:

- Optimal pre-heating, painting and drying results

- Suitable for water and/or solvent based paints

- Highly efficient, cost effective and competitive system

- Sensor driven system for painting various types of steel products

- Optimal interface between shot blasting and painting system

- Extendable with VOC air treatment systems

GIETART Top Coating 1512/2512/3012

-

Final painting system for customized steel profiles and constructions

Workspace [mm]: 1,500-3,000 x 800 and number of spray guns: 12

Available with unique 3D scanning system

- Substitute for KTCBENEFITS AT A GLANCE:

- Thickness of paint layer easy adjustable

- Suitable for water and/or solvent based paints

- Various spray gun configurations

- Minimized cleaning times

- Completely integrated control systems

- Possibility for various transport systems

Used Machines

GIETART Shotblasting Line

-

Year of construction 2005

GIETART Shotblasting Line

DETAILS

- Entrance dimensions: 2100 x 600 mm

- Plates max. width: 2000 mm

- Plates min. thickness: 5 mm

- Profiles max.: 1000 x 300 mm

- Flat min.: 60 x 8 mm

- Turbine power: 11 kW

KKS 401 NA

-

Year of construction 1991

2022 refitted completely

DETAILS

- Fully automatic miter cutting machine

- Cutting range round up to 140 mm, square up to 130 mm

- CNC-controlled turntable for miter angles + 30°

- Automatic infeed gripper with a stroke length of 1,000 mm in Single stroke and up to 9,999 mm in multiple stroke

- Graphical user interface with touch screen

- Used, refurbished to mint condition incl. NEW Siemens Touch Screen Control Panel