WALTER

Videos

Loading the player ...

- Offer Profile

- Walter Maschinenbau GmbH produces CNC machines for grinding and/or eroding metal, wood and PCD tools and rotationally-symmetrical production components.

The production range is supplemented by CNC measuring machines for non-contact complete measurement of complex precision tools and rotationally-symmetrical parts with documented accuracy in a single clamping. Our grinding and measuring expertise is incorporated into the development of our own software. We also offer comprehensive "tool machining" services. Together with our sister company Ewag AG and its broad product range for the production of indexable inserts, including an innovative laser machine tool, we see ourselves as a system and solution provider for tool machining. Our customer orientation and our global sales and service network with its own branches and staff have been valued by our customers for decades.

Product Portfolio

Grinding

- Tool grinding machines for production and regrinding at the state of art - from entry level to high-end solutions.

HELITRONIC BASIC

-

The entry level to the world of premium tools

With its 5 CNC axes, the HELITRONIC BASIC sharpens and grinds a wide spectrum of precision tools for metal and wood with the highest precision and quality. Short setup and idle times produce economic results from a batch size of 1 even in multiple shift operation with low staffing levels. For new entrants to the world of premium tools, this is a good recommendation.

Within the HELITRONIC family, the HELITRONIC BASIC system embodies the ideal resharpening machine for rotationally symmetrical tools with a diameter from 3 to 320 mm and a length of up to 350 mm. Items can weigh up to 50 kg.

HELITRONIC POWER

-

This is our most sold unit

With up to six grinding wheels on the belt-driven spindle, the HELITRONIC POWER grinds complex geometries with only one clamping cycle. Working together with the optional grinding wheel changer and a variety of loading systems, it sets standards in productivity and flexibility. Our customers appreciate these functions, which is why it is the best-selling WALTER tool grinding machine worldwide.

Around the world, the HELITRONIC POWER stands for top quality in the production and resharpening of rotationally symmetrical tools. Permissible diameters range from 3 to 320 mm, tool lengths can be up to 350 mm, each item may weigh up to 50 kg.

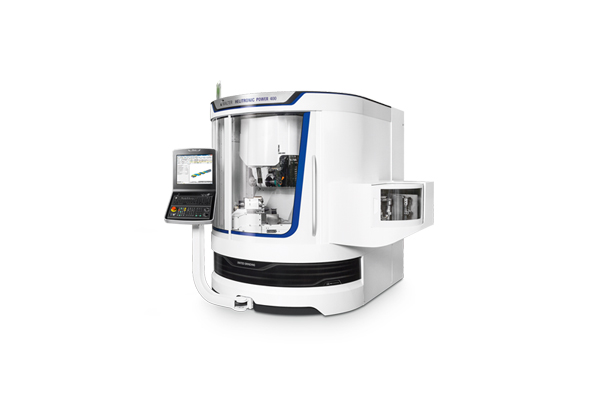

HELITRONIC Power 400

-

The HELITRONIC POWER 400 with wheel changer is the high-performance top version

with maximum flexibility for mid-sized to large series. Around the world, it

stands for top quality in the production and resharpening of rotationally

symmetrical tools. Permissible diameters range from 3 to 315 mm, machining

lengths can be up to 520 mm and weight up to 50 kg.

For the production and resharpening of rotationally symmetrical tools in a single clamping cycle, even with complex geometries. Working together with the grinding wheel changer, a variety of loading systems and the motor spindle, it sets standards in productivity and flexibility.

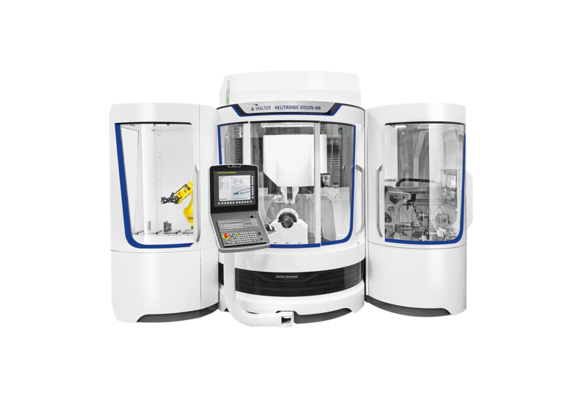

HELITRONIC VISION 400 L

-

The HELITRONIC VISION 400 L is the next generation of the globally established

HELITRONIC VISION. An even more rigid mineral cast machine bed with very good

vibration dampening ensures that the highly dynamic drive acts optimally on the

grinding wheel and its extremely low temperature sensitivity makes the grinding

process particularly stable. The highprecision CNC tool grinding machine can

grind lengths of up to 420 mm on the perimeter and provides optimum conditions

for grinding rotationally symmetrical tools in production and/or resharpening

facilities.

The HELITRONIC VISION 400 L produces rotationally symmetrical tools and production parts with complex geometries in series with a high level of precision. Permissible diameters up to 315 mm, tool lengths up to 420 mm and weight up to 50 kg.

HELITRONIC VISION 700 L

-

High-performance tool-grinding machine for tools up to 700 mm in total length

The HELITRONIC VISION 700 L is particularly suitable for machining long drills and tools clamped between tips, such as long hob cutters. An automated work table and moving support systems ensure millimetre precision and quality for long tools. Thanks to its grinding wheel changer and robot loader the HELITRONIC VISION 700 L is able to guarantee optimum productivity – from single-item to largescale production.

The HELITRONIC VISION 700 L from the HELITRONIC range is the new benchmark for productivity with long, rotationally symmetrical tools. Tool lengths up to 700 mm, tool diameters from 3 to 200 mm.

HELITRONIC MICRO

-

The high precision system for small tools

The HELITRONIC MICRO from the HELITRONIC family produces and sharpens rotationally symmetrical tools and production parts with smaller diameters. From 0.1 mm diameter in production, from 3 mm diameter when resharpening, maximum diameter12.7 mm, tool length up to 120 mm, maximum weight up to 12 kg.

Grinding complex geometries on rotationally symmetrical tools, in the growth market of small to the smallest diameter, is the core capability of the HELITRONIC MICRO. High mechanical process stability and sophisticated kinematics, with five interpolation axes and two positioning axes, ensure excellent grinding results in production or regrinding.

HELITRONIC MINI POWER

-

Flexibly produce and resharpen tools with smaller diameters

The HELITRONIC MINI POWER grinds and sharpens tools in the low to medium range of diameters for the metalworking and woodworking industries with only one clamping cycle. Frequent tool changes and complex geometries are every day matters for the HELITRONIC MINI POWER. A suitable loading system is optionally available for low staffing levels in multishift operation. With its compact design and low weight, it is a real alternative for the best use of your production space.

With the HELITRONIC family, the HELITRONIC MINI POWER is well suited for small to medium tool diameters. It will grind and/or sharpen rotationally symmetrical tools with a diameter in the range from 1 to 100 mm. Tool lengths up to 255 mm, items may weigh up to 30 kg.

HELITRONIC ESSENTIAL

-

Economic tool grinding from 1 – 100 mm Ø and up to a total length of 255 mm

The 5-axis CNC tool grinding machine HELITRONIC ESSENTIAL is the first choice in the HELITRONIC family when it comes to the flexible regrinding and production of rotationally symmetrical tools and production components in the above-mentioned dimension range. Its productivity is unrivalled here.

HELITRONIC MINI AUTOMATION

-

High volume production of tools with diameters from 1 mm up to 16 mm

The 5-axis CNC HELITRONIC MINI AUTOMATION tool grinding machine is the first choice in the HELITRONIC family when it comes to the highest productivity and quality expectations in volume production. For rotationally symmetrical tools and production components with maximum flexibility.

Eroding

- Tool grinding and eroding machines with the "Two-in-One concept" for a risk free entry into the PCD business.

HELITRONIC POWER DIAMOND

-

Two-in-one, high performance rotary eroding and grinding machine

With belt-driven spindle for max. 6 electrodes/grinding wheels. This tailoring to customer requirements shows how productive the HELITRONIC POWER DIAMOND can be. It is at the forefront for surface quality and precision in a wide range of materials.

Grinding of HSS/carbide tools and rotary eroding of CBN/PCD tools, switching as you wish, is the particular strength of the HELITRONIC POWER DIAMOND system within the HELITRONIC family. Tool diameters from 3 to 320 (400) mm, tool lengths up to 350 mm, each item can weigh up to 50 kg.

HELITRONIC POWER DIAMOND 400

-

Two-in-one, high performance rotary eroding and grinding machine with

grinding wheel/electrode changer as standard

witching between rotary eroding of PCD/CBN tools and grinding of HM/HSS tools is the particular strength of the HELITRONIC POWER DIAMOND 400 with a grinding wheel/electrode changer within the HELITRONIC FAMILY. Tool diameter ranges from 3 to 380 mm, machine lengths can be up to 520 mm and each item may weigh up to 50 kg. Two-in-one, high performance rotary eroding and grinding machine with grinding wheel/electrode changer as standard

The new generation of “Two-in-one” all-rounder: with electrode or wheel changer and motor spindle for max. 3 electrodes/grinding wheels. This tailoring to customer requirements shows how productive the HELITRONIC POWER DIAMOND 400 can be. Together with our FINE PULSE TECHNOLOGY, it is at the forefront for surface quality and precision in a wide range of materials.

HELITRONIC DIAMOND EVOLUTION

-

Efficient rotary eroding and grinding machine, Two-in-one

The HELITRONIC DIAMOND EVOLUTION is a high efficient solution within our EDM portfolio for rotary eroding of PCD/CBN tools and grinding of HSS/carbine tools in one single clamping cycle on a minimal footprint. Tool diameters from 1 to 165 mm, tool lengths up to 185 (255) mm,each item can weigh up to 30 kg.

HELITRONIC DIAMOND EVOLUTION

-

Two-in-one, high performance rotary eroding

Two-in-one: Two machines in one for the rotary eroding of CBN/PCD tools and the grinding of HSS/carbide tools, switching as you wish. The HELITRONIC VISION DIAMOND 400 L is the only eroding machine to combine linear and eroding technologies in a single machine. It machines complex geometries fully automatically with three rotating electrodes and three grinding wheels on a belt-driven spindle in one clamping cycle. This is just right for the high requirements of volume production.

Eroding of CBN/PCD tools and the grinding of HSS/carbide tools in volume production is the particular strength of the HELITRONIC VISION DIAMOND 400 L. Tool diameters up to 315 mm, tool lengths up to 420 mm and a weight up to 50 kg.

Measuring

- Optical CNC metrology from WALTER enables accurate measurements and visualizes quality.

HELICHECK PRECISION

-

Optical CNC measuring machines for non-contact tool measurement

HELICHECK PRECISION und HELICHECK ADVANCED can measure complex geometries of rotation-symmetrical tools with a reproducible accuracy of 1.5 μ. Fully automated, contact-free, wear-free and precise. Both machines offer added value with the measurement of production goods like grinding wheels and diamond dressing rolls.

Fully automated measuring machines HELICHECK PRECISION / ADVANCED for rotation- symmetrical tools. For tool diameters from 2 to 320 mm, tool lengths up to 420 mm. Tool weight up to 25 kg.

HELICHECK ADVANCED

-

Optical CNC measuring machines for non-contact tool measurement

HELICHECK PRECISION und HELICHECK ADVANCED can measure complex geometries of rotation-symmetrical tools with a reproducible accuracy of 1.5 μ. Fully automated, contact-free, wear-free and precise. Both machines offer added value with the measurement of production goods like grinding wheels and diamond dressing rolls.

HELICHECK PRO

-

4-axes CNC measuring machine for non-contact complete measurement of precision tools, grinding wheels, rotationally-symmetrical workpieces and flat workpieces

The different geometries are measured reliably, thanks to optimum stability and maximum measuring accuracy. E1=1.4µm±L/300 (as per VDI/VDE 2617) The measuring results are obtained quickly, with high precision, close to production, operator-independently, intuitively and for a diverse application range, with a high degree of flexibility.

HELICHECK PLUS

-

4-axes CNC measuring machine for non-contact complete measurement of precision tools, micro tools, grinding wheels, rotationally-symmetrical workpieces and flat workpieces

In comparison with HELICHECK PRO, HELICHECK PLUS also enables the high-precision measurement of micro tools with diameters from 0.1 mm. Even the smallest details are visible and measurable thanks to the special reflected light unit and the diffusor. All the advantages of HELICHECK PRO are naturally also present in this optical CNC measuring machine. The linear measurement deviation in accordance with VDI/VDE 2617 is E1 = (1.4 + L/300)µm.

HELISET

-

Manual tool measuring device for the measuring of grinding wheels and tools

Comfortable measurement of grinding wheels, reduction of down times. With HELISET you are now able to measure your grinding wheels easily, fast and precisely. While the production of tools is running the next grinding wheel can already be prepared offline. It is your benefit.

HELISET PLUS

-

Manual device for measuring complex tools before eroding

Measure – Erode – Control.

Optimizing the machining time by means of up-front measurement - save valuable time in the erosion machine and for tool preparation by carrying out measurement operations at the same time in parallel on the HELISET PLUS.

HELICHECK 3D

-

You scan a tool. You get a 3D model. You measure. You compare.

Never easier. Never faster. Never better. Now the new HELICHECK 3D features state-ofthe- art Iaser technology for ultra-fast scanning of cutting tools and production parts. As time matters, this technology is perfect for digitizing tools and parts quickly. Whether it is the measurement of the most important parameters or the comparison to the master model: Just do it on HELICHECK 3D!