- Offer Profile

KARNASCH PROFESSIONAL TOOLS – ONE COMPANY WORLDWIDE

For more than 55 years, Karnasch Professional Tools stands for an innovative and diverse product range and professional customer-oriented service in more than 50 countries. The amount of know-how contained in our products is demonstrated in daily use. Equipped with excellent performance values, our tools and machines convince customers from all industrial branches worldwide. We are always on hand with help and advice for you - with new innovations and a richness of ideas. You can count on excellent performance, also in the future.

Visit our online-shop

Products

-

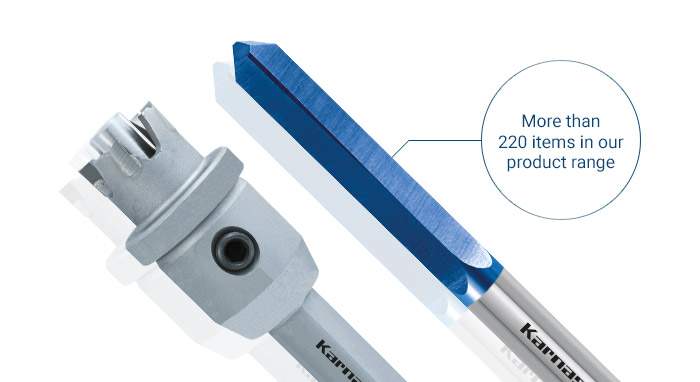

The Karnasch Professional Tools range of premium tools at a glance

The optimal cutting tool for your application

With one of the most comprehensive tool ranges worldwide and more than 20,000 tools and machines in premium quality, the high performance tools by Karnasch offer excellent performances and consistently high qualities throughout its entire range. The purposes of application range from milling, drilling, reaming, countersinking, grinding and sawing of almost all materials.

The quality standards of Karnasch Professional Tools lead continuously to more and more well-engineered products with the narrowest production tolerances. This provides our customers with a constant increase in efficiency and process reliability.

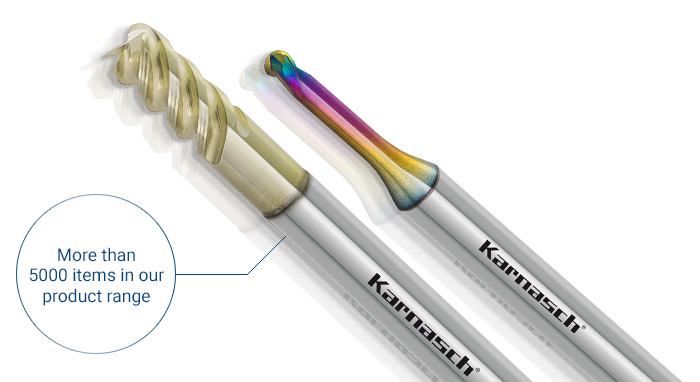

Solid carbide end mills from Ø 0.05 mm

- The high speed cutting CNC milling tools in premium quality for machining of

metal, aluminum, copper, steel, titanium, stainless steel, graphite, GRP/CRP

and plastics.

Karnasch's product range of CNC milling tools represents one of the world's largest range of milling tools.

Karnasch solid carbide end mills fulfill the narrowest production tolerances (e.g. diameter tolerances from 0/-0.010 mm, radius tolerances from +/-0.002 mm and concentricity tolerances from 0.002 mm) for a consistently high quality, top results and process reliability at diameters from 0.05 mm.

The range of Karnasch end mills includes solid carbide end mills, solid carbide finishing cutters, solid carbide circumference milling cutters, solid carbide slot cutters, solid carbide deburrers and solid carbide rough cutters for machining of all materials. They are available in numerous diameters, drill depths and designs (end mills cylindrical, end mills ball nose, end mills corner radius, one-tooth end mills, multiple-tooth end mills, micro end mills and quadrant profile end mills), available in stock.

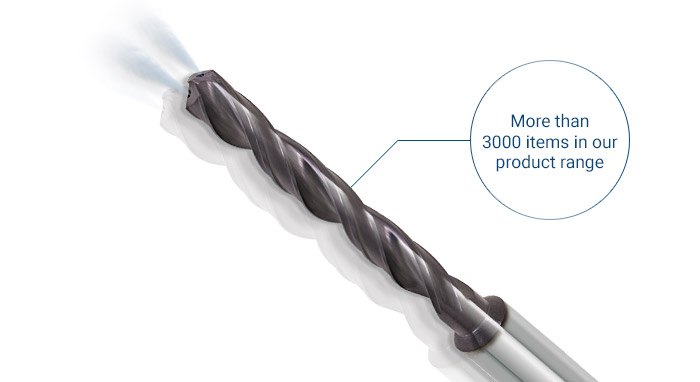

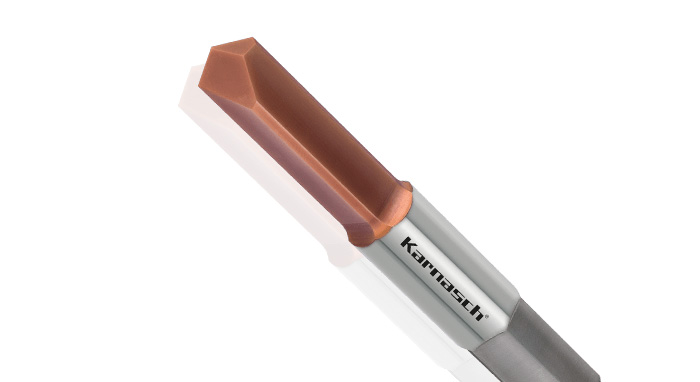

Solid carbide drills from Ø 0.1 mm

- High speed cutting tools in premium quality for drilling into aluminum,

copper, steel, stainless steel, titanium, cast iron, gray cast iron, GRP/CRP

as well as for deep hole drilling and the machining of

hardened material.

The range of high-precision solid carbide drills makes Karnasch one of the world's leading tool manufacturers.

Karnasch high performance drills are available with or without internal cooling. They are delivered with modern coatings (including diamond coatings) which are adjusted to each material, which results in vast tool lives.

By means of their optimization for various purposes, the solid carbide drills build a product range which enables economic drilling for a broad spectrum of applications.

Solid carbide drills by Karnasch are designed especially for deep hole drilling and metalworking of steel, stainless steel, hardened steel < 70 HRC, titanium, inconel, aluminum and GRP/CRP. All solid carbide drills with diameters up to 3 mm and drill depths from 8 x D are provided with a polished flute as well.

The micro drills highlight the range of soli carbide drills by Karnasch Professional Tools. They are available from 0.1 mm (from 0.8 mm including internal cooling).- Micro drills from 0.1 mm

- Micro drills from 0.8 mm with internal cooling

- Micro drills from 2.0 mm up to 30 x D

- Micro drills from 3.0 mm up to 40 x D

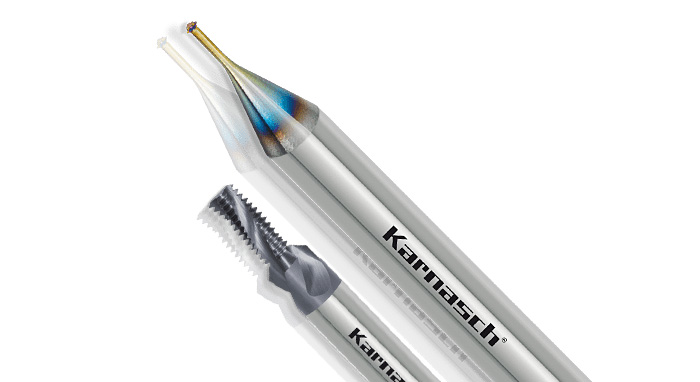

Taps, thread mills, whirling thread cutters from M 0.6

-

Premium HSS-Co / solid carbide taps and solid carbide thread mills/whirling thread cutters for the machining of the most different materials

The range of taps includes HSS-Co Cobalt + TiN coated taps, solid carbide machine taps, solid carbide Whitworth pipe taps as well as solid carbide machine taps fine thread. Available in diameters from M 3 to M 30, the various taps can be used in aluminum/copper/brass, steel, hardened steel up to 63 HRC, cast iron materials and graphite. When machining with taps, use only a cutting paste with high-pressure additives.

The Karnasch tool series of whirling thread cutters is designed for the demanding requirements for thread milling. It offers precise results without burr formation when cutting thread tapping drill holes into materials that are difficult to machine. The whirling thread cutters are suitable for the metalworking of aluminum, copper, steel as well as GRP/CRP, graphite and plastics.

Due to the logarithmic relief grinding, the solid carbide whirling thread cutters achieve considerable improvements of tool lives. In addition, the rake angle and relief ground remain stable, which increases process reliability. With adjusted coatings, you achieve a consequent increase in productivity in metalcutting.

The high speed solid carbide whirling thread cutters by Karnasch in premium quality - small in detail, great in performance.

The Karnasch solid carbide thread mills enable the production of threads in abrasive materials. In sizes from M 3 to M 12, with diamond coating, a 30° spiral and an additional countersinking step, the thread mills can be used in graphite and composites.

The Karnasch taps, thread mills and whirling thread cutters are our solutions for the steadily growing challenges of our customers and for the high expectations of our tools' quality and machining results.

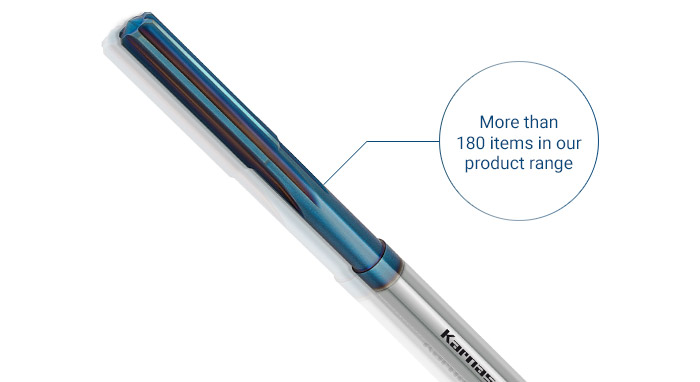

Solid carbide reamers from Ø 0.2 mm

- The high speed cutting solid carbide reamers in premium quality,

particularly suitable for blind hole drilling and through hole drilling

Increase your efficiency and process reliability in metalworking and cut your costs per drilling with reamers by Karnasch. Our range of tools enable maximum cutting performances, even in materials that are difficult to cut. Karnasch solid carbide reamers have polished cutting edges or especially adjusted coatings.

Karnasch reamers, in combination with the specially developed geometries, are excellently equipped for machining of steel, stainless steel, titanium, non-ferrous metal and hardened materials < 67 HRC. The usage of solid carbide reamers increases surface finish and accuracy of form and dimension.

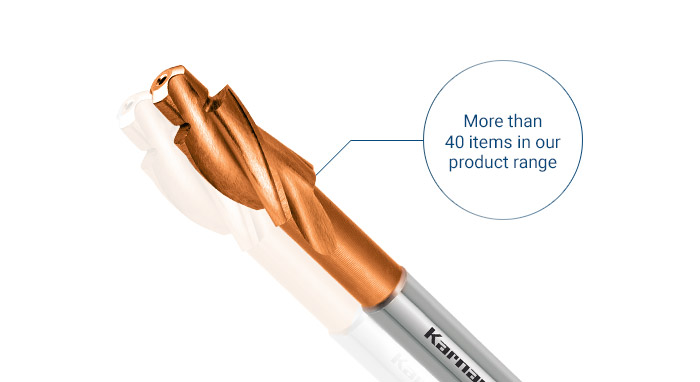

Spade drills from Ø 9.5 mm

- The premium quality spade drills with quick-change function for quick

exchanging of the cutting heads. Particularly suitable for CNC machines such

as pillar drilling machines or radial drilling machines.

Reduce your costs per drilling with Karnasch spade drills and increase the efficiency of your production. Karnasch's range of spade drills is the efficient solution for drilling with exchangeable cutting heads. Karnasch spade drills are highly efficient drilling tools with outstanding performance parameters in terms of tool life and production tolerance. Spade drills replace the outdated drilling technology of drilling tools consisting entirely of HSS / HSS-Co cobalt / powder steel and represent an excellent addition to the range of solid carbide drills.

Microtools from Ø 0.05 mm

- High speed cutting microtools for micro machining in worldwide unique

microtool quality for metalworking of steel, graphite, stainless steel,

copper, titanium, cast iron, gray cast iron, non-ferrous metals, aluminum,

gold as well as composites and plastics.

Karnasch Professional Tools is one of the world's largest microtool manufacturers for micro machining with a comprehensive range of microtools for all the needs of machining all steel materials, non-ferrous metals, stainless steels, laminates, plastics, cast iron and exotic materials.

Intensive developments and many years of expertise in microtool technology have resulted in technically sophisticated product series which are characterized by excellent performance features and high-precision engineering tolerances. This outstanding microtool quality is available in stock and, regarding its entire product range, worldwide unique in this form.

Karnasch microtools (above all micro cutters and micro drills) are used in serial production in CNC centers and industries such as automobile industry, aerospace and aerocraft industry, die and mold construction, fine mechanics, electronics production, jewelry and watchmaking industry, dental industry, medical engineering and prototype construction.

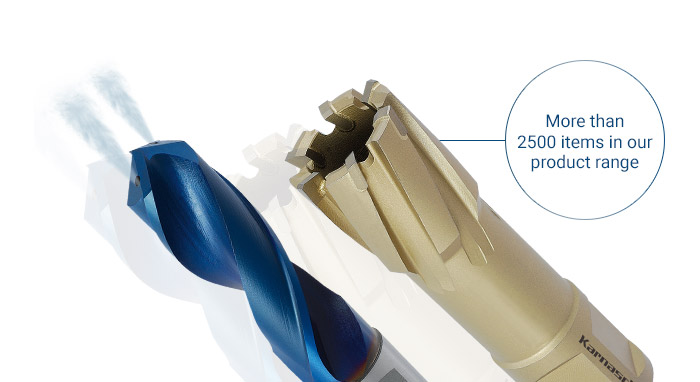

Annular cutters, rail cutters, twist drills

- Karnasch drills offer the optimum price-performance ratio for the

machining of almost all materials

Karnasch Professional Tools presents a wide range of high performance drills for your individual purposes. Choose from a range of annular cutters, rail cutters and twist drills, each carbide-tipped, made of HSS-XE or powder steel, with Weldon shank or with fine-quick-in shank.

Karnasch Premium drills guarantee smooth and easy machining of almost all types of steel, including extremely machinable materials and rail steels. For optimal machining, maximum tool life and best heat protection, you can rely on Karnasch drills.

Our annular cutters are available with diameters from 8 mm. Our rail cutters are available with diameters from 6 mm. Twist drills for general steel machining are available with diameters from 2.5 mm.

Hole saws from Ø 6 mm

- Whether on the hand drill, the pillar drilling machine, the radial

drilling machine, the lathe or on a hole cutting machine, Karnasch's wide

range of tools always provides you with the ideal hole saw for your

application.

Karnasch hole saws offer the highest possible degree of flexibility. The "Easy-Change" quick-change system of the "POWER-MAX" hole saw series stands for a nearly limitless variety of applications. The single body can be used with the respective shank of the "Easy-Change" shank system on all common machines and is thus extremely versatile.

The "POWER-MAX" hole saw program enables the machining of almost all types of steel (from mild steels to stainless steels). They are also ideal for drilling in gray cast iron, aluminum, copper, brass, tin, GRP/CRP, sandwich material, HPL, fiber cement boards, wood, ceramics, tiles, porcelain, masonry and glass as well as for the machining of plastic, composite and mineral materials.

Karnasch premium hole saws are available in diameters from 6 mm to 305 mm and with cutting depths from 6 mm to 60 mm.

Carbide-tipped burrs from Ø 1.0 mm

- Karnasch Professional Tools offers more than 1,800 different rotary burrs in

stock.

15 different cutting edge shapes and 9 different cutting edge geometries, as well as special end mills for locksmiths and mini cutters cover every possible area of application. They are available in the coating variants BLUE-TEC und BLACK-TEC.

Karnasch carbide burrs have optimized front sides for an improved cutting efficiency and extremely smoothly grinded milling surfaces (mirror grinding) for higher material removal. Only the best micro-grain carbide types are used for Karnasch burrs and every single burr is 100% tested for robustness and safety.

Karnasch carbide burrs / rotary cutters enable the machining of steel, stainless steel, aluminum, non-ferrous metal, soft metal, plastic, GRP/CRP, nickel, cobalt and titanium alloys as well as locksmiths and Abloy-Protec cylinder locks.

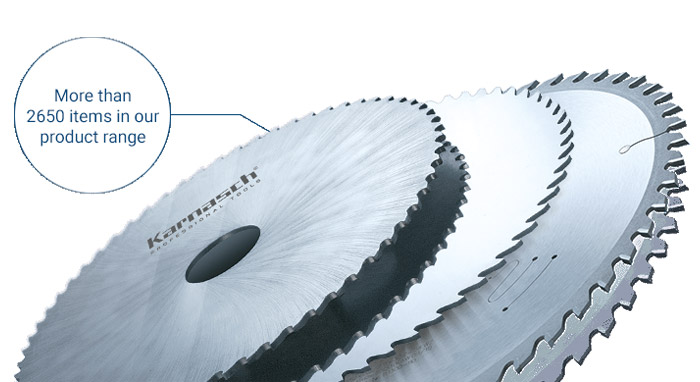

Circular saw blades

- With more than 3,000 different circular saw blades, our range is one of the

most comprehensive in the world.

At Karnasch you will find the right saw blades for your individual plans. Choose between more than 2,000 HSS, HSS-E, DIN and solid carbide circular saw blades or between over 1,000 different carbide-tipped circular saw blades.

Karnasch circular saw blades guarantee first-class results for sawing nearly all materials. All circular saw blades are subject to strict quality controls, are extremely noise- and vibration-damped and available in stock.

The range of circular saw blades by Karnasch Professional Tools includes carbide-tipped circular saw blades, HSS-DMo5 metal circular saw blades, HSS-Co5 cobalt 5% metal circular saw blades, DIN circular saw blades and orbital pipe cutting circular saw blades as well as holders for circular saw blades. Our circular saw blades are available in diameters from 15 mm to 1560 mm.

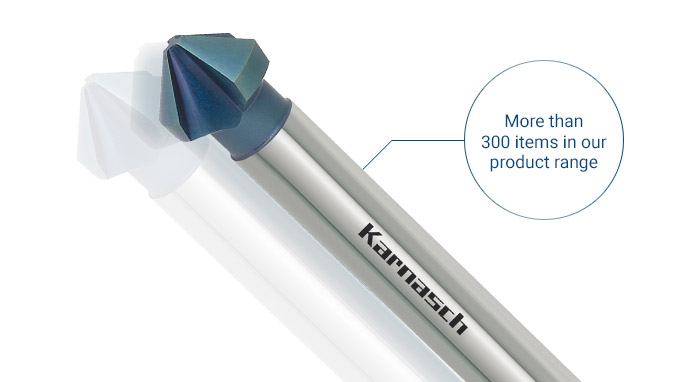

Countersinks from Ø 4.3 mm

- Karnasch countersinks for machining of steel, cast iron, non-ferrous and

light metals, stainless and acid-resistant steels and titanium alloys on CNC

machines

Countersinks belong to the standard products in the tool industry. Almost no drilling takes place without sinking. Countersinks are used for secondary machining of the materials and provide them with the final surface finish. That is why Karnasch relies on the highest quality and the latest tool technologies. Karnasch countersinks are available in different designs for every application. The patented BLUE-TEC coating makes the countersinks by Karnasch additionally unique.

Counterbores from Ø M2

- Karnasch premium high performance counterbores for

sinking of hexagon socket screws

Karnasch HSS-XE and HSS-XE TITAN-TEC counterbores 180° DIN 373 with cylindrical shank and firm guide pin in premium quality for machining of steel, stainless steel, cast iron, aluminum and plastics. Quality grade fine and medium for through hole and for thread core-hole.

Counterbores belong to the standard products in the tool industry and are often in continuous use. That is why Karnasch relies on the highest quality and the latest tool technologies. Karnasch counterbores are available in different designs for any application. The TITAN-TEC coating makes the Karnasch counterbores unique and considerably increases tool life.

Subland step drills from Ø M3

-

Karnasch HSS-XE and HSS-XE TITAN-TEC 90° subland step drills / short stepped drill bits for countersunk screws, 180° screw head sinking as well as thread core hole and countersinking in one working process, in premium quality for the machining of steel, stainless steel, cast iron, aluminum and plastics. Quality grade fine and medium for through hole and for thread core-hole.

Subland step drills / short stepped drill bits belong to the standard products in the tool industry and are often in continuous use. That is why Karnasch relies on the highest quality and the latest tool technologies. Karnasch subland step drills / short stepped drill bits are available in different designs for any application. The TITAN-TEC tool coating makes the Karnasch subland step drills / short stepped drill bits unique and considerably increases tool life.

HSS-XE step drills / tube and sheet drills from Ø 4 mm

- Karnasch premium step drills & tube and sheet drills

One of the most comprehensive stock ranges of step drills and tube and sheet drills

Karnasch step drills are designed to produce perfect circular and simultaneously deburred holes in sheets up to 4 mm. The transition from one step to the other is used for chamfering or deburring the drill hole.

The Karnasch tube and sheet drills are designed for drilling thin sheets up to 4 mm. They are ideal for enlarging existing holes, drilling oblique holes and creating interlocking holes. The peeling cut produces almost burr-free holes on both sides.

Locksmith tools

- Professional drilling and milling in record time

Karnasch Professional Tools develops carbide-tipped tools especially for locksmiths and Abloy Protec cylinder locks.

Our high quality rotary cutters and drilling cutters open cylinder locks in record time. Especially for emergency door openings by fire departments, fast openings are essential, or rather, lifesaving. With five different gearings and specially adjusted coatings, Karnasch rotary burrs and drilling cutters guarantee best results. Karnasch locksmith tools are available in diameters from 3 mm to 6 mm.

For high-security Abloy Protec cylinder locks, Karnasch hole saws are the best choice. With a sprung pin guide for centering in the locking channel, a depth stop and four carbide teeth with a diameter of 15.2 mm, the Karnasch hole saws easily cut through the high-security cylinders.

Tap drill bits

-

Counterboring with Karnasch tap drill bits to remove jammed taps saves time and money!

Your tap has broken off and is stuck in the drill hole? In this case, use our solid carbide tap drill bits to remove jammed taps.

Karnasch tap drill bits are made for steel <65 HRC and threads from M3 to M12. They are available in drill depths from 10 mm to 35 mm.

Approximately 1 to 5 threads can be drilled out with one drill. Due to the cylindrical hexagon shank, the tap drill bits can not only be used on NC machines, but it can also be clamped in normal three- or four-jaw chucks. When used correctly, all materials, including copper, aluminum and hardened materials, will not damage the core hole.

Dental tools

- The high speed cutting dental tools by Karnasch in

premium quality for milling and CNC drilling in chrome cobalt, zirconium,

e.max, titanium, PMMA and wax

The development in dental technology is one of the most dynamic of all and is progressing dynamically. Karnasch Professional Tools has set and achieved a definite goal with the new program of dental tools and the goal "dental tools of tomorrow already today". The result is a wide range of premium high performance dental tools (dental mills and dental drills) with excellent tool lives, suitable for any type of application in dental technology.

Composite tools

- Composite tools by Karnasch are the future in

machining of fiber composite materials

Karnasch's high speed cutting composite tool range includes solid carbide end mills, CVD end mills, PCD end mills, MKD end mills as well as solid carbide drills, PCD drills, spade drills and PCD saw blades. Our composite tools are suitable for 3D copy milling, contour milling, face and step milling, tapping, drilling, circumference milling, deburring, slotmilling, countersinking and sawing.

The Karnasch composite tool range offers versatile solutions for composite materials that are difficult to machine. Karnasch solid carbide composite tools have been specially developed for machining of materials such as aluminum, GRP/CRP, graphite, acrylic, titanium, honey comp and FR4.

One of the latest developments are CVD (chemical vapour deposition) end mills, which have revolutionized the machining of materials in the aerospace and automobile industries. These composite tools are extremely sharp due to their laser-cut cutting edges and ensure a smooth cut with a high-precision cutting tolerance of up to 1µ.

This increases tool lives by up to 300%, prevents delamination and produces very smooth surfaces. Due to special geometries, drilling without cut-outs in GRP/CRP is no problem for Karnasch composite tools.

Magnetic hole cutting machines

- The newest generation of Karnasch professional magnetic hole cutting

machines for universal use in two excellent product series.

With the new magnetic hole cutting machine series BLUE-MAG und SILVER-MAG, Karnasch offers the complete range of high performance machines in the professional segment for a wide variety of applications in craft (workshop) and industry (assembling), for example in steel construction for core drilling, twist drilling, countersinking, reaming and tapping.

When developing and selecting the components for the new Karnasch machine generation, the guiding principle "ONLY THE BEST" was applied in order to guarantee durability, accurate machining, high quality processing, low maintenance requirements and thus economical operations.

Straight grinders

- Premium pneumatic straight grinders by Karnasch

Professional machines for hard and continuous works

Karnasch Professional Tools offers a complete range of straight grinders in the professional segment for a wide variety of milling and grinding works. When developing and selecting the components for the straight grinders, the guiding principle "only the best" was applied in order to guarantee long tool life, high quality processing and thus low maintenance costs. All straight grinders are designed for hard and continuous operations.

The Karnasch range of straight grinders guarantees first class results and process reliability for rotary burrs with diameters from 1 mm to 25 mm.

Lubricants & cutting oils

- High performance cutting fluids / cuttings oils for very long tool lives

and improved surface finishes

Karnasch offers environmentally friendly universal cutting fluids / cuttings oils for a more efficient chip removal. The use of such lubricants not only achieves the best cutting results but also minimizes sustainably the production costs. In addition, lubricants and cutting oils lead to very long tool lives and improved surface finish - for sawing, milling, drilling, turning, reaming and tapping.

Karnasch cutting fluids and cutting oils are propellant-free, of highest quality and guarantee premium precossing. They have been specially designed for machining applications and are also suitable for minimum lubrication.

Application

-

Karnasch tool solutions for metalworking

Precision and highest performance for milling, drilling, reaming, countersinking, grinding and sawing

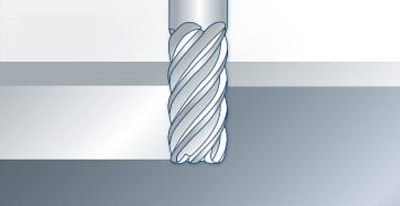

MILLING

Maximum precision for finest milling results

High speed cutting solid carbide end mills in premium quality by one of the world's leading suppliers in the field of precision tools: for finest milling results from from Ø 0.05 mm.

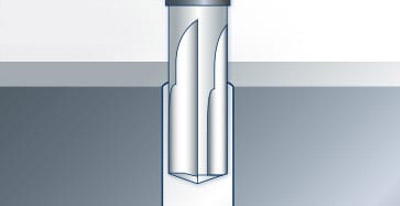

DRILLING

High performance drills for highest demands

High speed cutting drills in premium quality for drilling in aluminum, copper, steel, stainless steel, titanium, cast iron, gray cast iron, GRP/CRP as well as for machining of hard materials: for precise alignment from Ø 0.1 mm, or 0.8 mm with internal cooling.

REAMING

The new standard for micro reamers

High speed cutting solid carbide reamers in premium quality with specially adjusted high performance coatings: for optimal surface finish and shape and dimensional accuracy from Ø 0.2 mm.

COUNTERSINKING

Smooth running due to chatter-free countersinking Countersinks

with BLUE-TEC coating in premium quality with excellent chip removal, groove-free surface, best centering properties and chatter-free countersinking at 60°, 82°, 90° and 120°: for increased surface hardness from Ø 6.3 mm.

GRINDING

Rotary burrs in the world's most extensive variation in stock

Carbide-tipped rotary burrs in premium quality with 15 different cutting edge shapes and 9 different cutting geometries with longest tool lives due to BLUE-TEC and BLACK-TEC tool coatings: for excellent grinding results from Ø 1.0 mm.

SAWING

The world's largest product range of saw blades in stock

HSS, HSS-E, DIN-HSS circular saw blades, DIN, solid carbide circular saw blades and carbide-, cermet- and diamond-tipped circular saw blades as well as orbital circular saw blades in premium quality for sawing of nearly all materials with different cutting widths, number of teeth and side holes: in diameter ranges from 15 mm to 1560 mm.

MACHINES FOR METALWORKING

Quality and endurance for any requirement

Machines in premium quality: magnetic hole cutting machine series BLUE-MAG und SILVER-MAG in the professional segment for core drilling, twist drilling, countersinking, reaming and tapping as well as premium straight grinders for a wide variety of applications in craft and industry.

COOLANTS FOR METALWORKING

Lubricants and cutting oils for highest demands in machining

Water-miscible lubricants and cutting oils for best cutting results when sawing, milling, drilling, twisting, reaming and tapping: for a significant increase in tool life and an improved surface finish.