- Offer Profile

- For every requirement for accurate fine-finishing of surfaces, we have the most appropriate professional solution for you. The flexible machine concept makes it possible to adapt the machine to changing workpieces or modifications to the surface requirements quickly and easily. Exactly the way your production needs it to be. In this way, you can respond rapidly to the changing needs of your customers and consolidate your own market position.

Functionally perfect surfaces

-

Engineering with High Precision

No matter the tolerance or requirements, let our decades of process know-how and machine tool building experience help you to improve efficiency and profitability.

Proving Precision

Our technology centers provide the ability to run your workpieces on our machines in a practical environment, partnering with you to develop the optimal process for your application. A climate-controlled Metrology Lab with state-of-the-art measuring equipment delivers precise and reliable results.

Weltweit führend in den Technologien der Oberflächenbearbeitung bieten wir Ihnen abgestimmte Maschinen und Lösungen für Ihre Bearbeitungsaufgabe vom kleinen Anbaugerät bis zum kompletten Bearbeitungszentrum mit Automation:

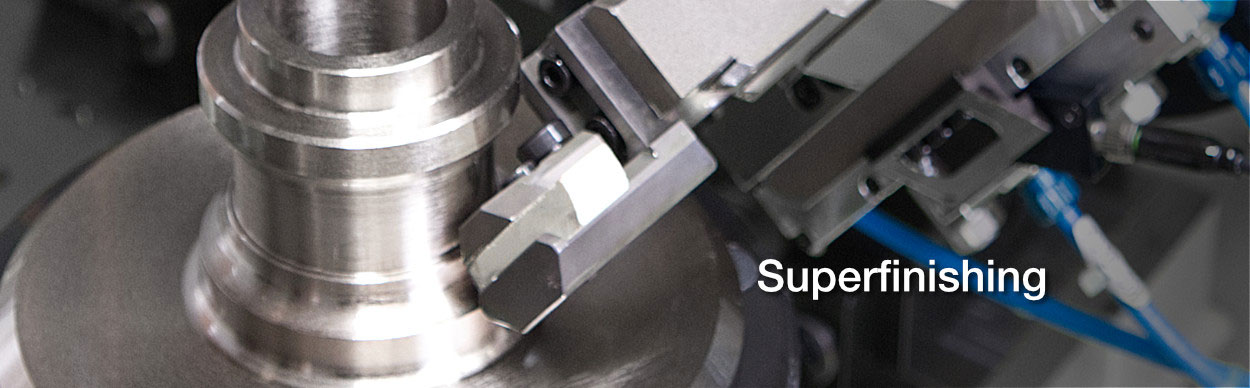

- Superfinishing

- Precision Abrasive Machining

- Attachments and Tools

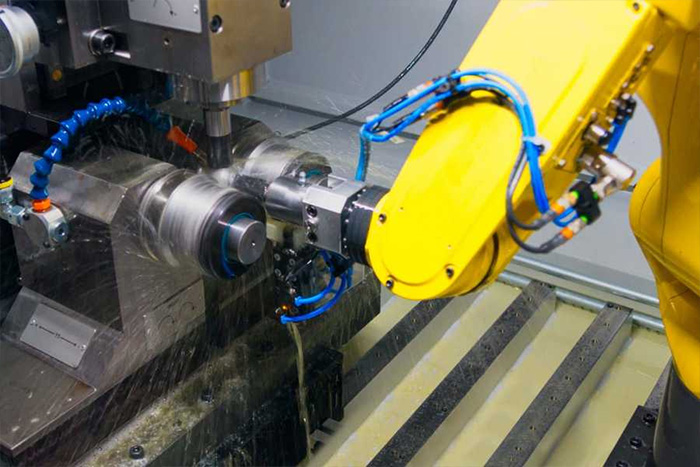

- Precision Robotics Machining

- Services

Linked to success

-

Single machine · Interlinking · Robot cell

Along with precision, every production process naturally focuses on profitability. Supfina has a long history of providing unique solutions that achieve both.

Whether automated loading and unloading by gantry loader; linking of systems in an existing production structure; or using innovative robot cells — all in close consultation with the customer — we develop the best possible solutions for different production conditions.

Supfina is also setting standards in digitization. Thanks to intelligent networking and IoT connectivity, systems can be better coordinated to optimize maintenance and reduce wear.

With Supfina’s deep integration of assets, intelligent automation, and digital connectivity, we can boost your production’s profitability and overall equipment effectiveness (OEE).

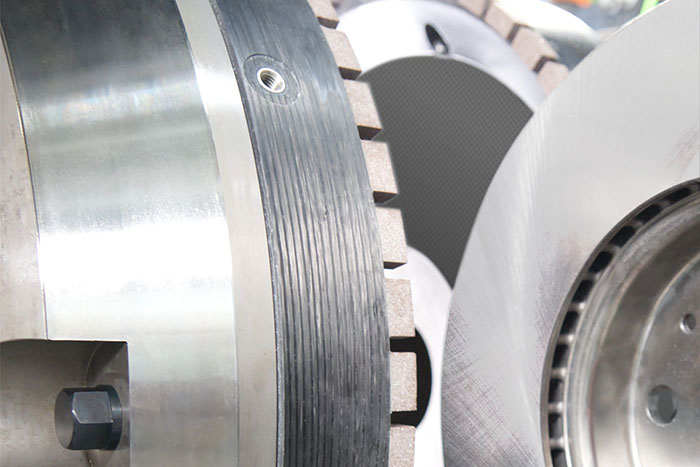

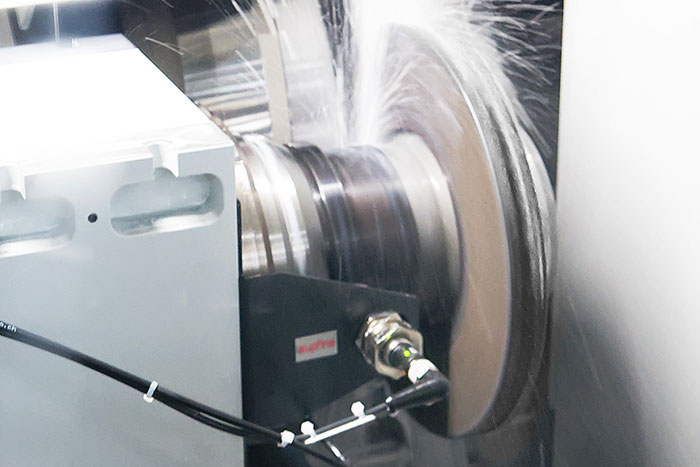

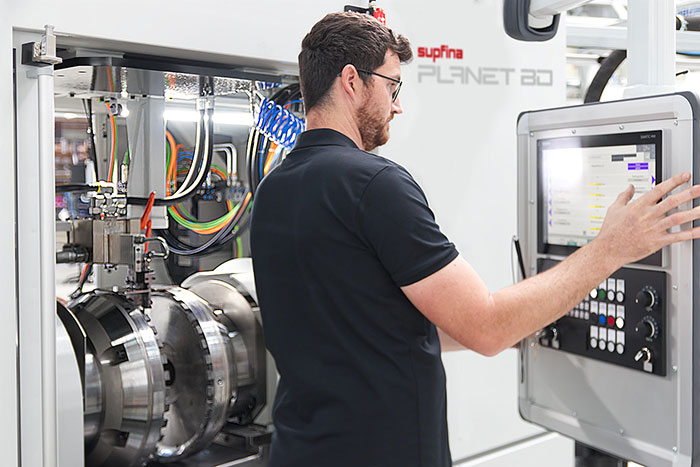

Solutions for grinding coated brake discs

-

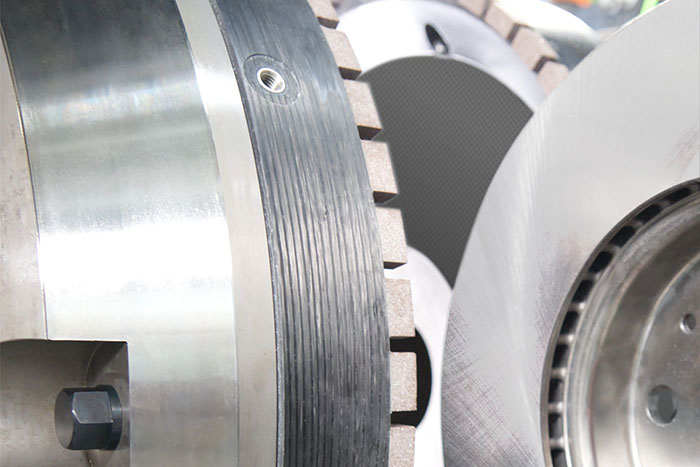

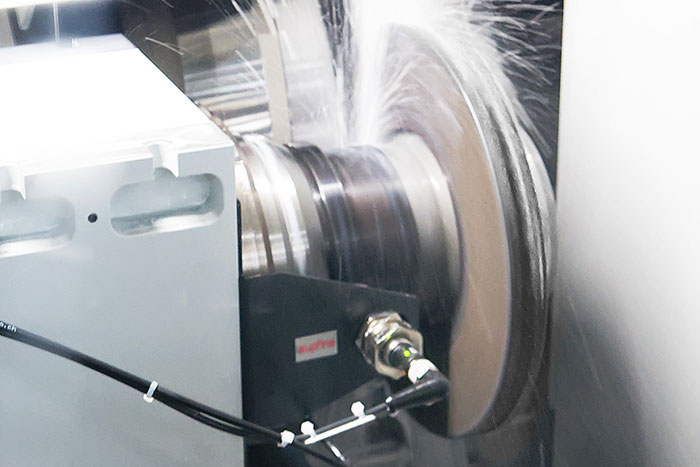

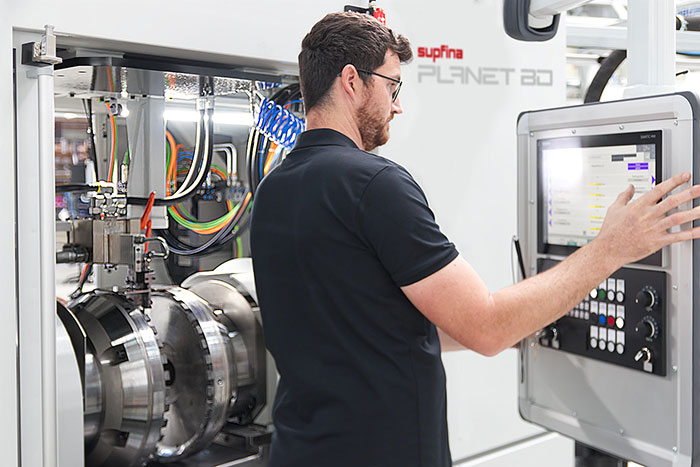

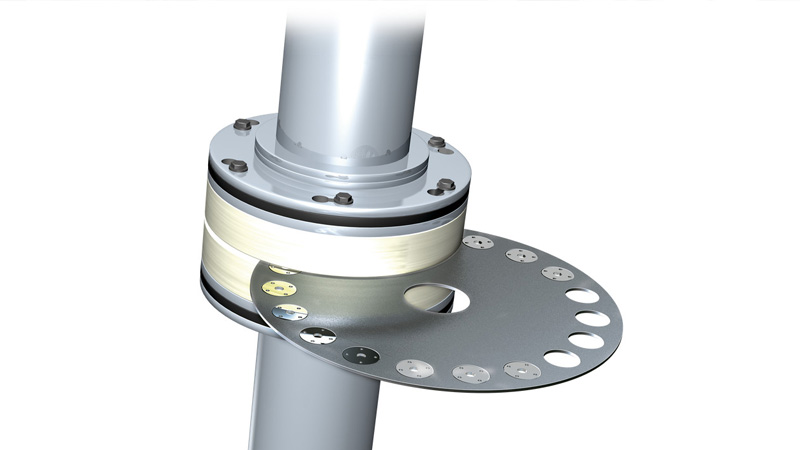

The Supfina solution : Planet BD

Coated brake discs are becoming the benchmark for reducing particulate emissions from the braking system of all motor vehicles and providing the necessary corrosion protection for electric vehicle brakes.

The production of hard- coated brake discs requires an extended production chain. Supfina has developed high -performance processes for the face grinding that is now required again.

Superfinishing machines

-

Superfinishing machines for the perfect surface

Supfina offers the right machine for every superfinishing operation, optionally expanded with extensive automation.

Flexible and universal

Superfinishing is a chip removing machining process. But not one that is comparable to any other. In contrast to the classic lathe turning and grinding methods, there is full surface contact between the tool and the workpiece.

This is precisely the feature that produces the unique characteristics of a perfectly machined surface. This is superfinishing!- Plunge-cutting superfinishing machines

- Stone finishing machines

- Tape finishing machines

- Centerless superfinishing machines

- Superfinishing machines with rotating cup wheel

- Superfinishing attachments

Race finishing

-

Superfinishing of antifriction bearings Inner and outer rings

The world of rolling bearings is almost endless. From the gigantic bearings of offshore wind turbines to the micro bearings of the smallest variable displacement motors in our cars, a wide variety of shapes and sizes are used. Whether small batch production or series production in flexible production lines, we can supply you with the most suitable machine for processing your surface requirements, including complete automation.

Supfina always provides the appropriate solution for the perfect surface.- Deep groove ball bearings

- Angular ball bearings

- Cylindrical roller bearings

- Tapered roller bearings

- Self-aligning roller bearings

Race finishing

-

Superfinishing of antifriction bearings

Inner and outer ringsThe world of rolling bearings is almost endless. From the gigantic bearings of offshore wind turbines to the micro bearings of the smallest variable displacement motors in our cars, a wide variety of shapes and sizes are used.

Whether small batch production or series production in flexible production lines, we can supply you with the most suitable machine for processing your surface requirements, including complete automation.

Supfina always provides the appropriate solution for the perfect surface.- Deep groove ball bearings

- Angular ball bearings

- Cylindrical roller bearings

- Tapered roller bearings

- Self-aligning roller bearings

Race

-

pecialist of the series

The innovative Supfina Race is setting new standards in Superfinishing ball bearing inner and outer rings.

It has been optimized to meet the highest productivity demands, while achieving best quality results, fast set-up times and superior reliability.- Automatic loading and unloading

- Multi-step process with automatic sequence

- Stone and tape machining can be combined

- Minimized loading times

- Set-up times < 15 minutes

- Optimum accessibility

- State-of-the-art controller system with a technology memory

Technical data

- Working stations: 2

- Workpiece diameters: 62 – 160 mm

- Workpiece width: up to 65 mm

- Contact angle: 0 – 55°

RaceNeo

-

Cost-effectiveness through robot handling

Flexibility, reliability, safety and highest machining quality have always been the values of the Supfina machines Race, RacePro and RaceFlex.

The new Supfina RaceNeo combines these values with the demand for highest machining quality and increasing requirements regarding economic efficiency in series production at the same time.- Shortest non-productive times and safe loading due to integrated robot

- Small footprint and compact design

- Easy integration into automated production lines

- Modular adaptation of workpiece holder

- Proven core components

Workpiece data

- Workpiece diameter max Size A: 100 mm

- Workpiece diameter max Size B: 200 mm

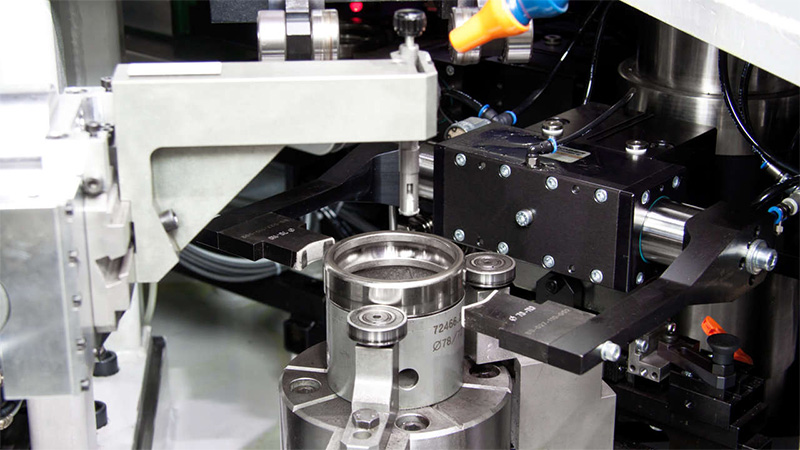

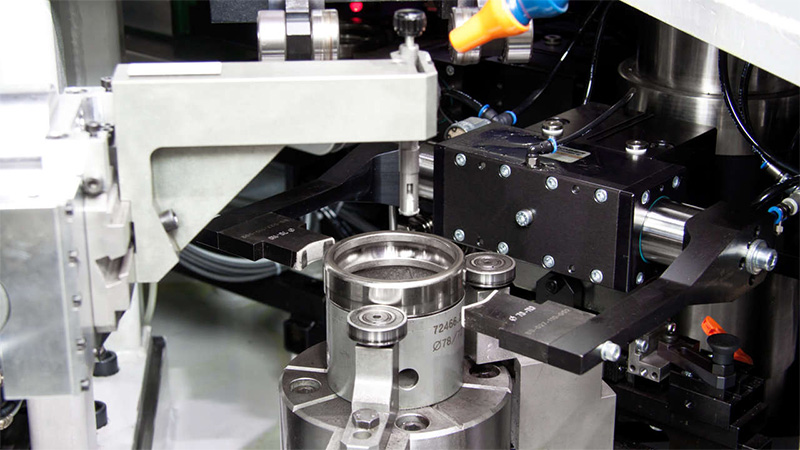

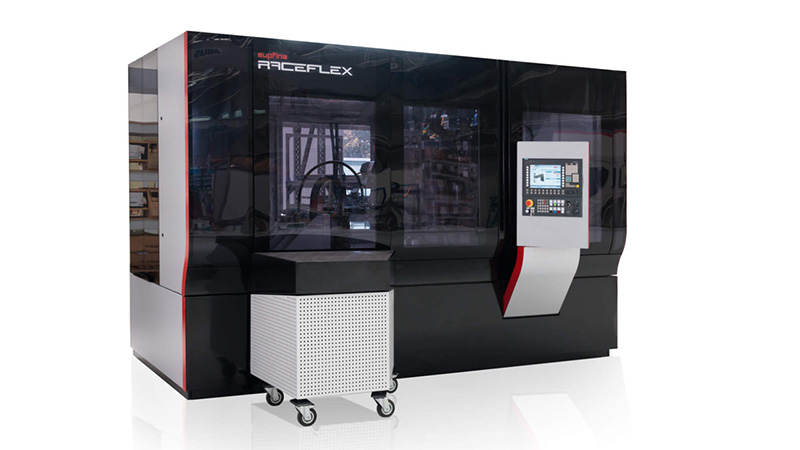

RaceFlex

-

Flexibility for small-scale production

The Supfina RaceFlex can consistently produce rolling bearing races of the highest quality with maximum adaptability, even for prototypes or small-scale production.

A combination of up to four different superfinishing units allows almost limitless flexibility- The greatest possible flexibility when machining any raceway geometries

- The highest quality is easily achieved, even for small batches and single parts

- Creation of a surface with a high load-bearing capacity and good lubricating properties

- Improved tool life

- Ideal for small and medium batches

- Production flexibility makes it a sound investment

Workpiece data Workpiece diameter Workpiece width 30 – 200 mm 5 – 75 mm 50 – 650 mm 8 – 100 mm 100 – 800 mm 20 – 200 mm 600 – 1600 mm 50 – 500 mm

RacePro

-

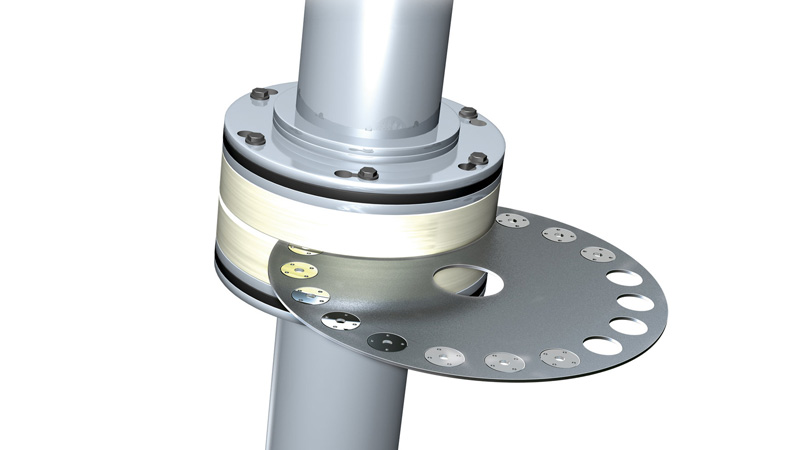

Superfinishing in mega format

Even the largest rolling bearing rings require superfinishing of the raceways to withstand the high stresses. The Supfina RacePro is specially designed for the flexible superfinishing of large rings. The design of the machine allows loading by overhead crane or by roller conveyor from the front and rear.

The inner and outer rings of large rolling bearings are required in a wide variety of applications, such as:- Wind turbines

- Cranes

- Helicopters

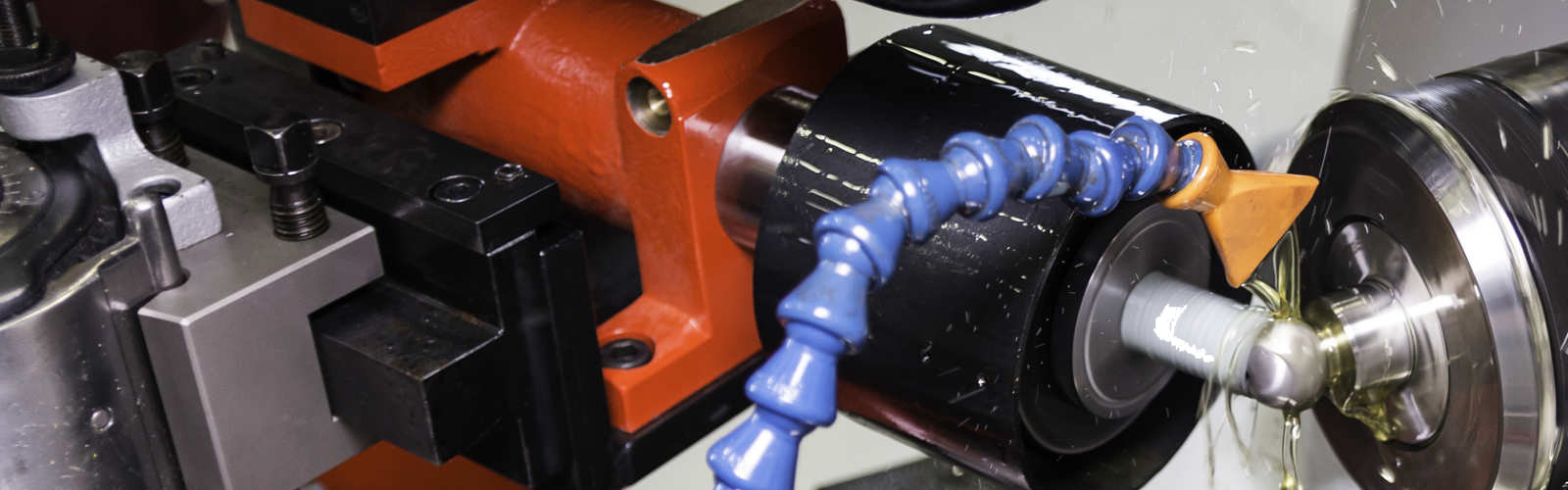

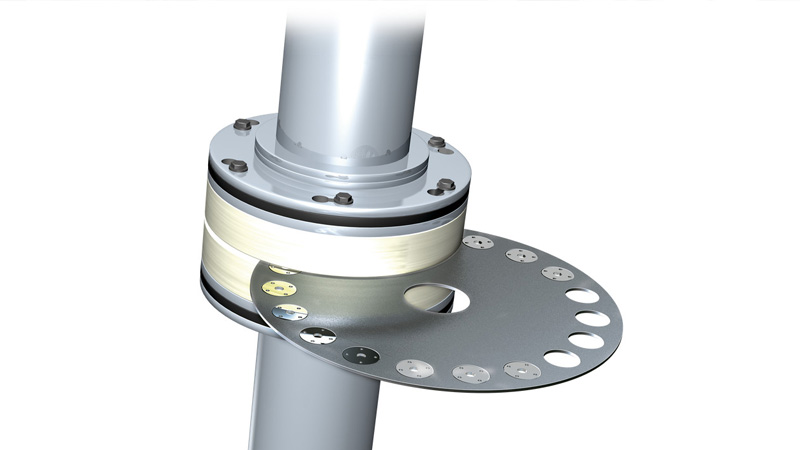

Plunge machining

-

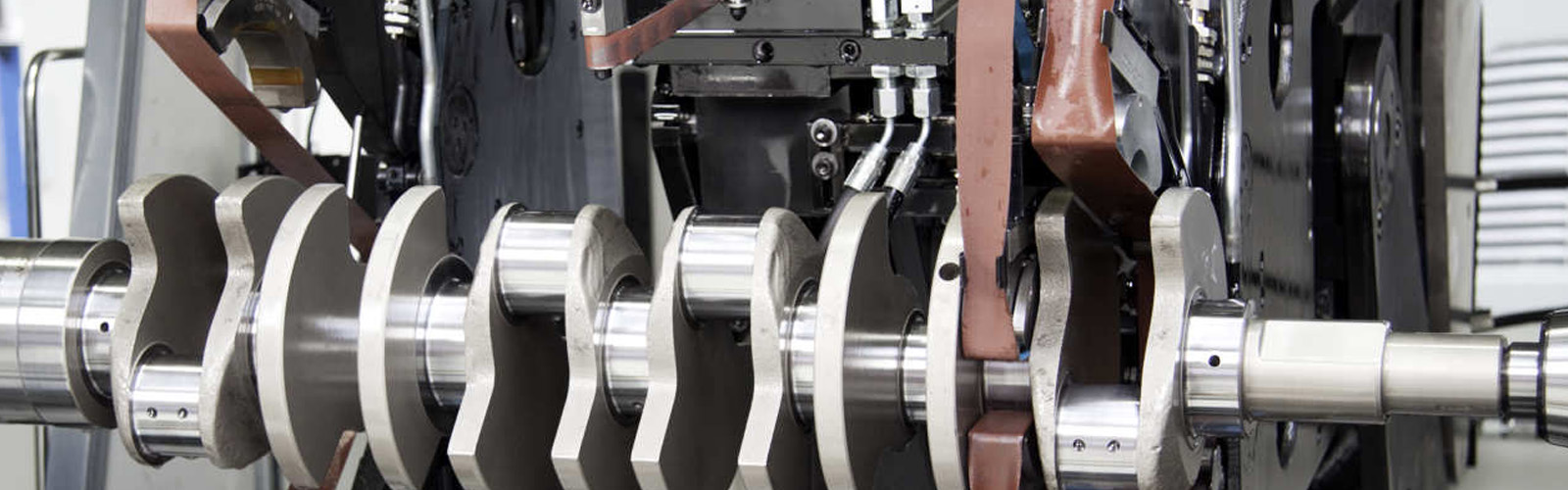

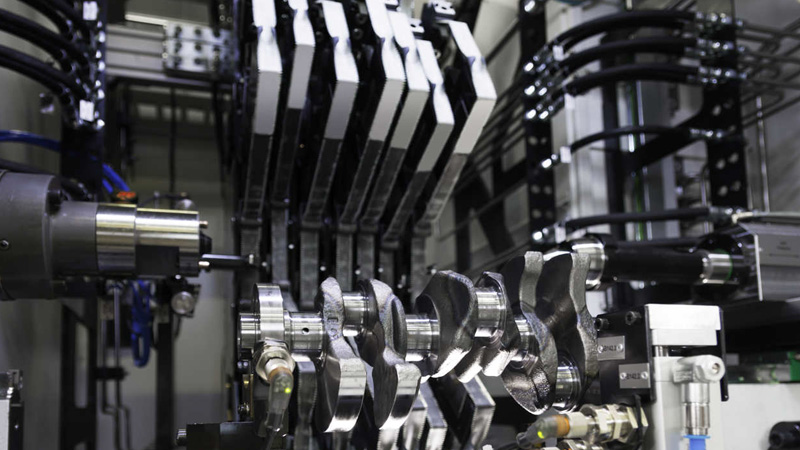

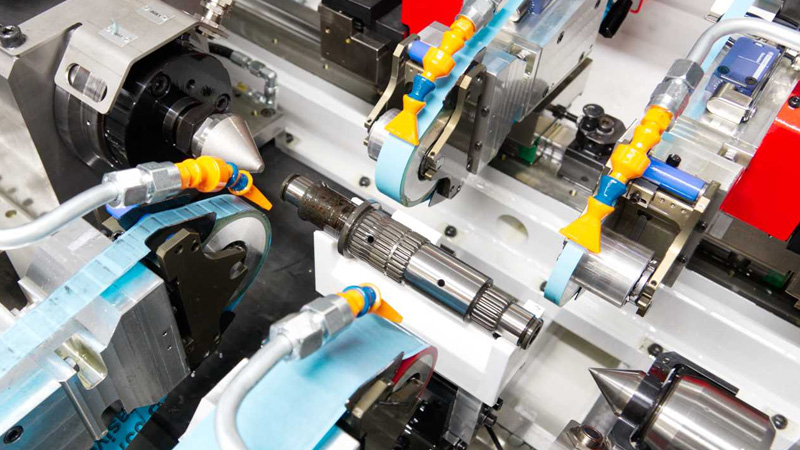

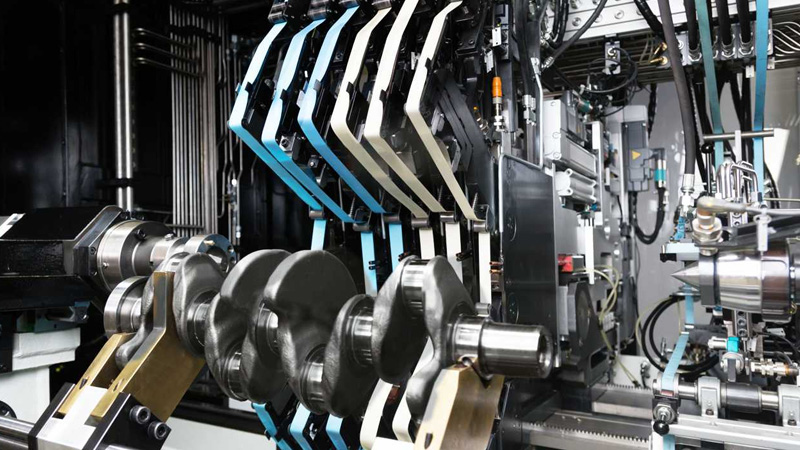

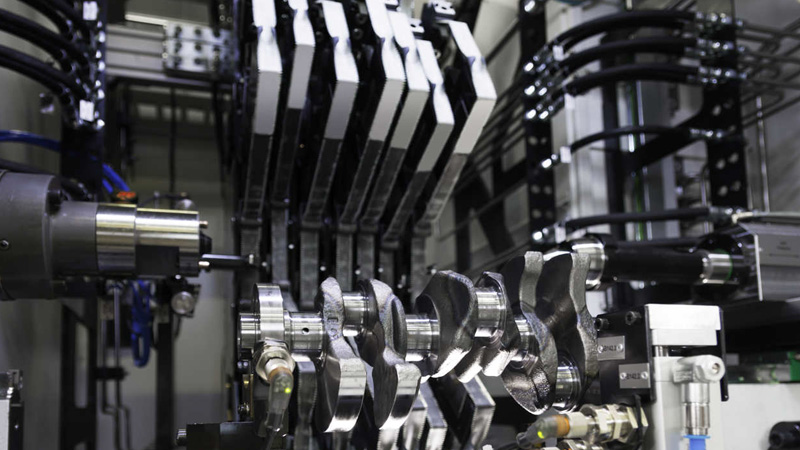

Superfinish for pinion, cam and crankshafts

The Supfina machine series Cenflex, Cenpro, MultiTool and LCM are used for plunge-cutting of shafts between centers.

In combination with a wide range of automated solutions, these machines can finish surfaces on a wide variety of shafts.- Car and truck crankshafts

- Large crankshafts for industrial engines,

- marine diesel engines and locomotives

- Camshafts, eccentric shafts

- Balancer shafts

- Gear shafts

- Pump gears

Plunge machining

-

Superfinish for pinion, cam and crankshafts

In the powertrain of an automobile, some components are exposed to extreme loads. Gears and shafts are among them. Only an absolutely perfect surface guarantees longevity and low wear - and Supfina has the right solutions here.

Our superfinishing machines not only produce components of outstanding quality. They can be used very flexible, and work extremely economically and reliably.

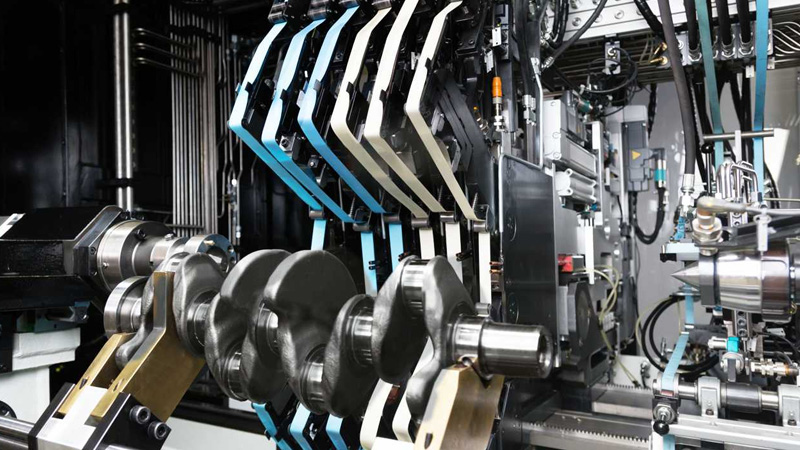

CenFlex 1

-

The Supfina CenFlex 1 covers the entire range of superfinishing tasks in the automotive industry, both in small batch production and series production in flexible production lines.

Depending on the application the set-up is either a one- or multi-step machining process of the workpiece or a step by step process of a camshafts and crankshaft on the same machine.

- Automatic tool adjustment of all installed Superfinishing tape arms to the workpiece

- Up to 15 Superfinishing block or step-by-step (per CNC program)

- Varying types of shafts on the same machine

- Universal loading and unloading: manual gantry loader or swivelling pallet system

Technical data

- Workpiece (shaft) length 400 – 1000 mm

- Stroke (for crankshafts) max. 100 mm

- optional max. 120 mm

- Superfinishing tape arms max. 15

CenPro S

-

By using the Supfina CenPro as our starting point, creating the smaller CenPro S was more consistently achieved.

This modular machine can reduce the footprint by up to 36 percent. A redesigned swivel loader – which moves the workpiece from the handover position of customer’s gantry-loading system into position between centers – eliminates unnecessary machine movements.

This allows fixed piping for the finishing units; far fewer maintenance-intensive hoses and energy guides; and even more reduced installation space.

- Highly stiff frame construction with lighter weight and simplified accessibility

- 300 m tape rolls with a service life of up to 37,500 workpieces

- Proven Supfina systems featuring hard, diamondcoated shoes for high removal rates and optimized microgeometry

- Faster setup times that optimize user-friendliness and machine availability

Technical data

- Workpiece length max. 500 mm

- Workpiece diameter swing max. 200 mm

- Stroke of pin bearing, top dead center to bottom dead center max. 100 mm

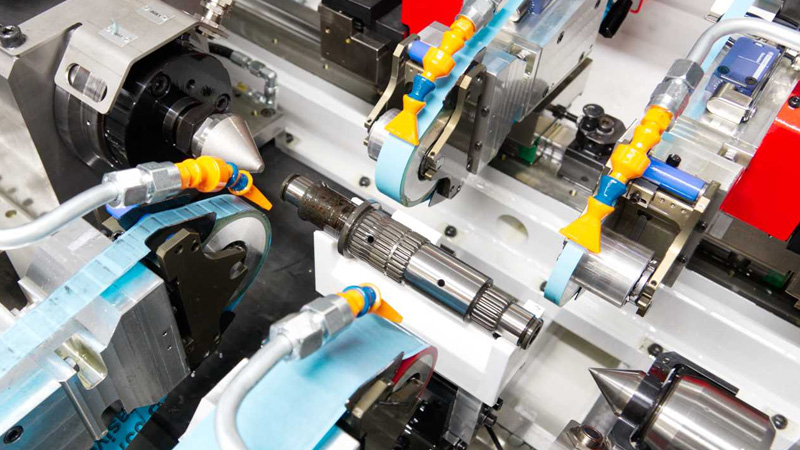

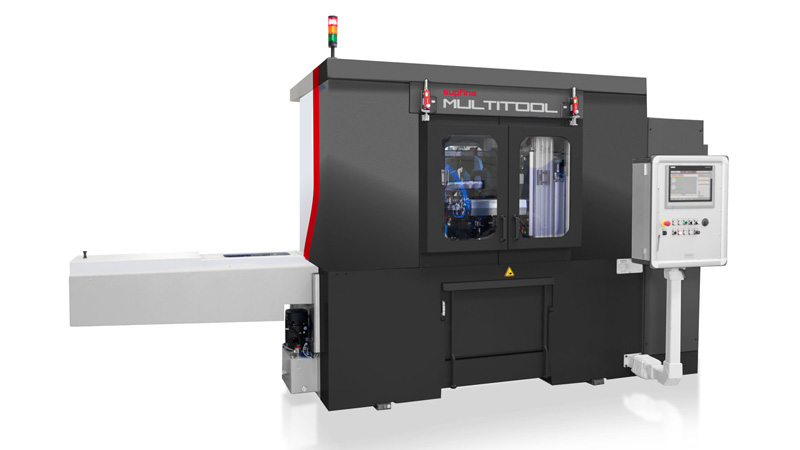

MultiTool

-

The new Supfina MultiTool combines many years of Supfina surface superfinishing Know How with ideas from our numerous well known customers in the automobile industry as well as suppliers to the automobile industry.

Depending on the customer requirements, superfinishing of high volume workpieces can be optimized to the shortest finishing cycle or designed for flexible production of similar workpieces. Tooling can be either tape or stone.

- Simple pneumatic/electric construction for low acquisition and operation costs

- Compact superfinishing units facilitate the simultaneous finishing of adjacent surfaces, or two step processes with varying workpiece specifications with only one clamping

- Possibility to select individual attachments or arms for rework

Technical data

- Center width 50 – 500 mm

- Spindle speed 100 – 375 U/min optional up to 750 U/min

- Oscillation Frequency max. 350 double strokes/min optional max. 800 double strokes/min

- Superfinishing Attachments max. 15

MultiFlex

-

Supfina’s MultiFlex series machines are modular constructions. The simple implementation of various processes using the same base machine, e.g. tape superfinishing, stone finishing, ball spindle finishing and brushing make them universally applicable.

In this way, all processes needed to finish state-of-the-art steering racks can be run using the same machine concept, with short cycle times and a high degree of flexibility.

- Machining of steering racks and toothed racks

- Threaded ball spindle finishing

- Y flats finishing

- Superfinishing of the tooth backs

- Superfinishing piston surfaces

- Brush descaling and deburring

- Journal and cam finishing with tape and / or stones

Technical data

- Workpiece length max. 1000 mm

- Workpiece diameter max. 100 mm

- Ball spindle diameter max. 35 mm

LeanCostMachine LCM

-

With its new LeanCostMachine, Supfina offers versatility of the highest level for superfinishing small and medium-size runs – economically and flexibly.

The Supfina LeanCostMachine® can be equipped with ready-assembled modules designed to match specific machining tasks. Whether fixed in place, manually adjustable or NC controlled, as many as six Supfina attachments for stone and tape finishing can be used at the same time as brushing and polishing attachments.

- New comfort control panel for easier operation and faster workpiece setup

- As many as six Supfina attachments can be fitted to the NC slide or dovetail guide or installed permanently on the machine base.

- We provide exactly the right workpiece clamping system for every machining process. The changeover is quick and cost effective.

- The workpieces to be machined can be manually placed in adjustable workpiece holders or automatically positioned or fed through by an optional infeed system from above, the front or the side straight into the work space.

- Complete automation (for integration into a production line) is easily implemented.

Technical data

- Distance between centers 40 – 800 mm

- Workpiece diameter 250 mm

- Superfinish tools Superfinish tape or stone, cup-wheel, Brushing and polishing disk

- Superfinishing attachments 1– 6

- Compressed air supply 4,5 – 6,0 bar

LCM Crank

-

The Supfina LCM Crank was developed to complement the high-production CenPro and the CenFlex series crankshaft finishing machine and can be quickly changed over to accommodate a variety of workpieces.

It’s also the perfect machine for those who want to superfinish critical crankshaft surfaces (for example, main, connecting rod, thrust bearings, and oil seal) in small to medium volumes.

- A new comfort-control panel allows easier operation and fast tooling setup

- Up to six Supfina attachments can be installed on an NC slide; a linear ball bearing and guideway assembly; or a dovetail guide. They also can be rigidly mounted to the machine bed

- We offer the right workpiece clamping system for every manufacturing process. Changeover is quick and inexpensive

- Workpieces can be placed manually in the adjustable workpiece supports, or they can be placed automatically by using an optional feeding system from above, from the front, or from the side.

- Complete automation (for integration into a production line) is easily implemented.

Technical data

- Workpiece length max. 500 mm

- Workpiece diameter swing max. 160 mm

- Stroke of the connecting rod bearing, upper to lower max. 80 mm

- Minimum groove width min. 14 mm

Centerless machining

-

Superfinishing of roller bearings, piston rods and other cylindrical workpieces

Time is money. That old adage applies to the road as much as it does to production. Yet time is not everything: Quality must be perfect as well.

Supfina’s throughfeed-finishing machines help to achieve high production rates with minimal work effort, thanks to reduced retooling times and long service lives for the tools.

The Supfina machine series RollerFlex and RollerPro, with their various levels of configuration and automation, offer the right solution for the surface finishing of rolls:- Spherical rollers

- Cylindrical rollers

- Tapered rollers

- Piston pins

- Piston rods

- Rollers

RollerPro

-

The Supfina RollerPro is the sprinters among the Superfinishing machines.

Depending on the workpiece dimensions, hundreds of rollers per minute can be machined in the centerless through-feed process. At the same time, the highest demands regarding geometrical and surface quality are met

- Spherical rollers

- Cylindrical rollers

- Tapered rollers

- Piston pins

- Piston rods

- Rollers

RollerFlex

-

In the most recent generation of roller bearings, the improvements in performance and permissible load are based on the consistent reproduction of exactly defined surface parameters.

The highly productive Supfina RollerFlex plays a crucial role and is the industry standard for superfinishing of spherical, cylindrical and tapered rollers.- Spherical rollers

- Cylindrical rollers

- Tapered rollers

Ball machining

-

Superfinishing of spherical components

Whether hydraulic, valve or hip balls, the surface has to resist high stresses and guarantee tightness no matter how different the application.

To achieve this, superfinishing of the surface is necessary. The Supfina machine series LCM TS, Face and the attachment series 291/293 are designed for this purpose.

- Valve balls

- Spherical bearings

- Hip joint balls

- Hydraulic tappets

LCM TS

-

Machining of spherical plain bearings with robotic feeding

Based on our decades of experience in superfinishing and the automation of manufacturing processes, our solutions meet these demands with precision.

In cooperation with our customers, we develop systems that meet any specific requirements.

In this way, maximum accuracy and consistent surface quality are achieved, even for individual components, with low unit costs.

- Increase of OEE through automation

- Fulfillment of the required qualities

- Increase of material carrying capacity

- Improvement of microgeometry

- Optimization of surface structure

- Competitive advantage through high flexibility

Face

-

Spherical superfinishing with highest precision

The rotary transfer machine Supfina Face generation: a flexible rotary transfer solution with a unique machine structure allowing the highest production volumes while also being flexible for maximum cost efficiency.

The development was based on the general standards of: cost efficiency, flexibility, safety and environment.

- Vertical spindle orientation for highest precision

- Fast setup processes through software-supported adjustment of the machining unit

- Bridge construction for maximum stiffness

- Optimal accessibility for retooling and maintenance tasks

- External loading by robots gantry systems possible

- Integrated loading systems available

- Integrated fire extinguishing system for optimal safety

- Maximum energy efficiency by omitting cooling systems

- Supfina IQ-Finish process control for continuously best results and high quality

- Best possible work ergonomics

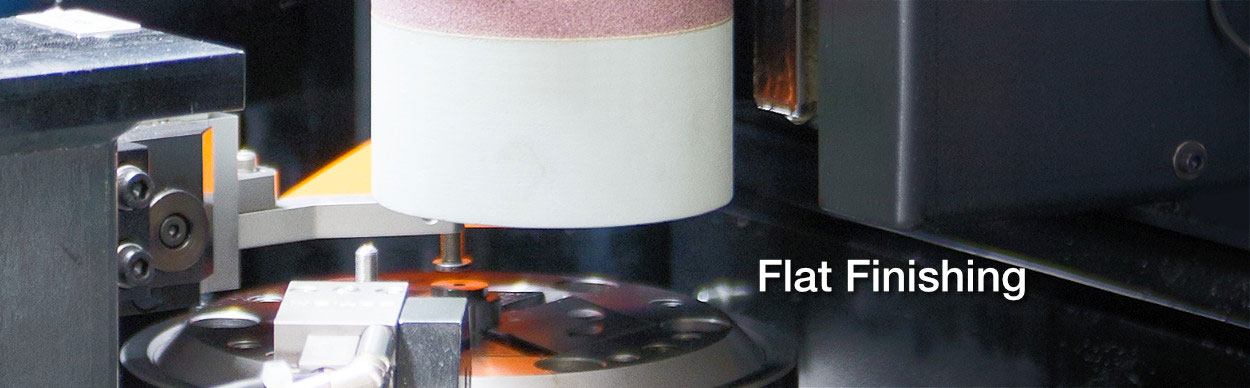

Flat finishing

Nano

-

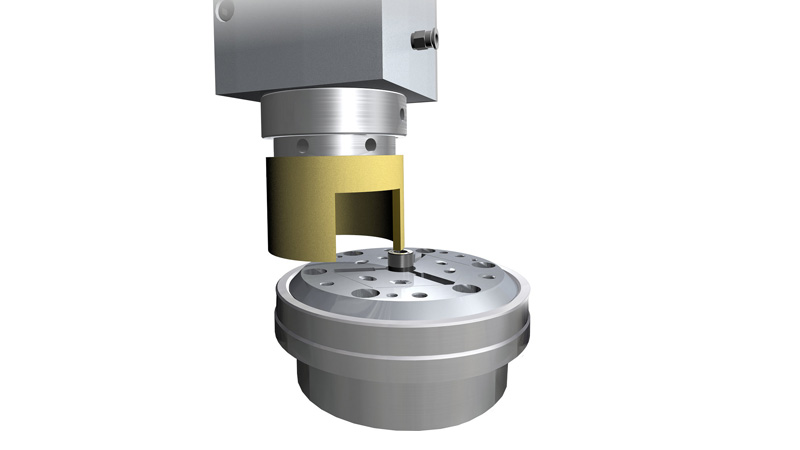

Compact and precise

The Supfina Nano machine series covers a wide range of flat finish processing needs.

Transmission components, engine parts, components from the fields of injection technology, hydraulic or engine parts can be produced with the tightest tolerances in the tenth micrometer range and with highest reliability and efficiency.

- Automatic adjustment of the cup wheel center line

- Simple tool change

- Suitable for use with conventional and super abrasive tools (CBN/diamond)

- Efficient adjustment for new tools

- Universal loading and unloading: manually, with a portal loader or robot systems

- Optimal accessibility

- Moveable and flexible in-process measuring system

- Modern process adjustment for optimal and consistent quality results

- Angle adjustment for spherical processing

Technical data

- Workpiece length 150 mm

- Workpiece diameter 100 mm

- Machining diameter 50 mm

- Superfinishing attachments 1 – 2

- Spindle speed rpm 30000

Face

-

Flat Finishing for changing requirements

Supfina Face – the new rotary transfer machine generation: a flexible rotary transfer solution with a unique machine structure allowing the highest production volumes while also being flexible for maximum cost efficiency.

The development of the Face series was based on the general standards of: cost efficiency, flexibility, safety and environment.

- Vertical spindle orientation for highest precision

- Fast setup processes through software-supported adjustment of the machining unit

- Bridge construction for maximum stiffness

- Optimal accessibility for retooling and maintenance tasks

- External loading by robots and gantry systems possible

- Integrated loading systems available

- Integrated fire extinguishing system for optimal safety

- Maximum energy efficiency by omitting cooling systems

- Supfina IQ-Finish process control for continuously best results and high quality

- Best possible work ergonomics

Technical data

- Workpiece length up to 200 mm

- Workpiece diameter up to 200 mm

- Machining diameter up to 150 mm

- Superfinishing units up to 7

- Chuck up to 8

- Process integration Flat finishing with cup wheels, brush deburrers, size measurement, tape finishing

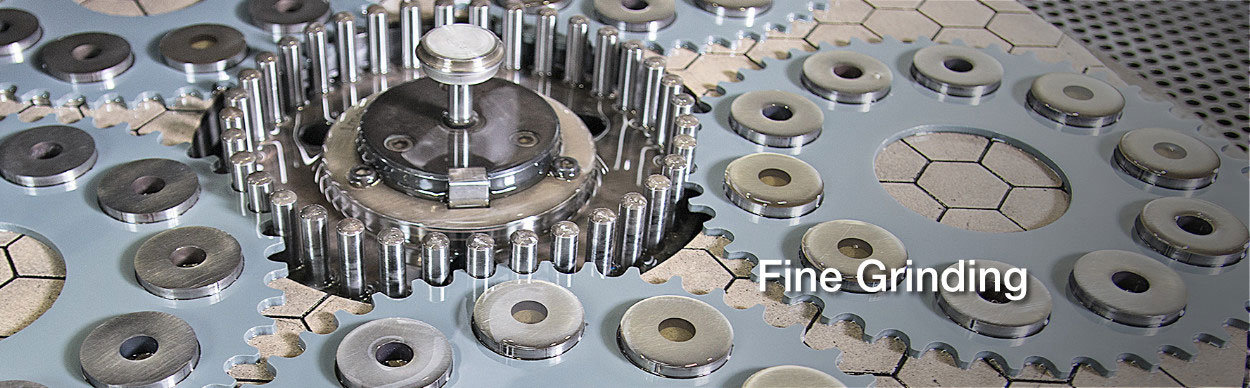

Economical Fine Grinding

-

with proven Supfina precision

No matter your workpiece properties, the Supfina Spiro offers an ideal fine grinding solution for your most stringent tolerance and material requirements.

We work closely with you to determine your wants and needs and fine a solution based on your budget. Precision without compromise, it’s our lifelong promise.

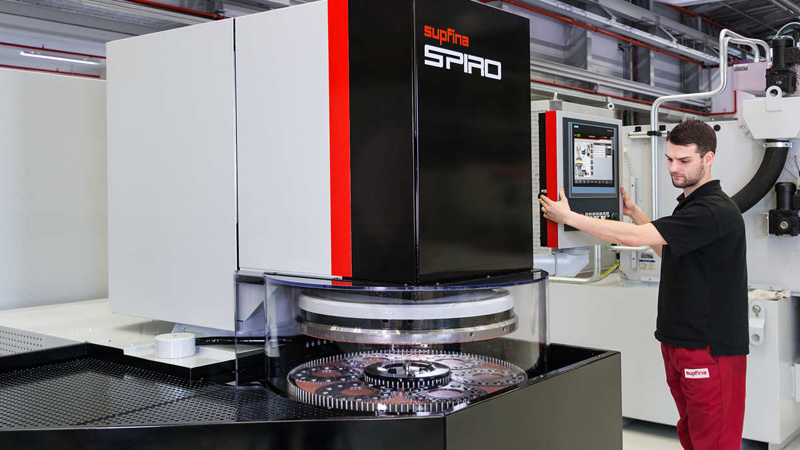

Spiro line

-

- High drive performance

- Maximum flexibility for many applications

- Individually customizable for optimal machining results

- Reduced tool wear thanks to the low-vibration machine stand and guard

- High-precision, noncontact measurement control

- Visual process control for consistently high precision

- User-friendly and intuitive operation

- Great accessibility

Spiro F5

-

Compact design, great performance

The Supfina Spiro F5 was specially developed for fine grinding smaller workpieces that require highly precise plane parallelism. It’s the perfect fit for your needs.

- 100-program storage

- Integrated sharpening programs

- Up to seven process cycles

- Optional loading table

Workpiece specifications

- Wheel diameter 445 / 475 mm

- Ring width 120 / 150 mm

- Maximum pressure 300 daN

- Workpiece diameter 4 – 150 mm

- Workpiece thickness 0,3 – 50 mm

Spiro F7

-

Fine grinding in large-scale production

The flexible Spiro F7 fine-grinding machine is ideal for creating precise flat surfaces on workpieces made from a wide variety of materials.

- Memory for 192 programs

- Rigid machine concept

- User-friendly, thanks to visual-process control

- Workpiece specifications

- Wheel diameter 720 mm

- Ring width 200 mm

- Maximum pressure 1800 daN

- Workpiece diameter 5 – 220 mm

- Workpiece thickness 0,6 – 80 mm

Spiro F12

-

For large workpieces

Our largest Spiro machine is designed to process workpieces with diameters of 6 mm to 420 mm and with special height, parallelism, and flatness requirements, all with high precision and cost-effectiveness.

- Energy-efficient, low-maintenance drive concept

- Very good accessibility

- User-friendly, thanks to visual-process control

- Flexible connection to different loading systems

Advantages of using a torque motor

- Energy efficient with very high initial torque

- No vibration due to geared components

- Direction change without backlash or loss of motion

- New machining sequences possible

- Maintenance-free operation

- No gear oil required

- Smaller footprint

- Maximum rigidity

Workpiece specifications

- Wheel diameter 1160 mm

- Ring width 341 mm

- Maximum pressure 3000 daN

- Workpiece diameter 6 – 420 mm

- Workpiece thickness 1 – 100 mm

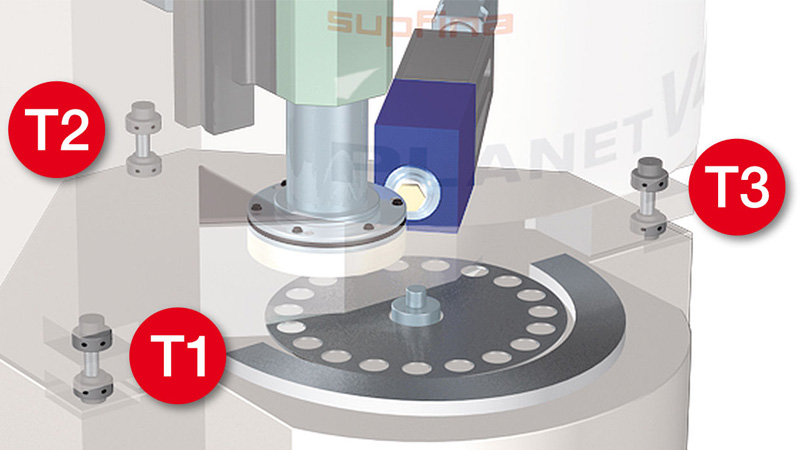

Double-Disk Grinding

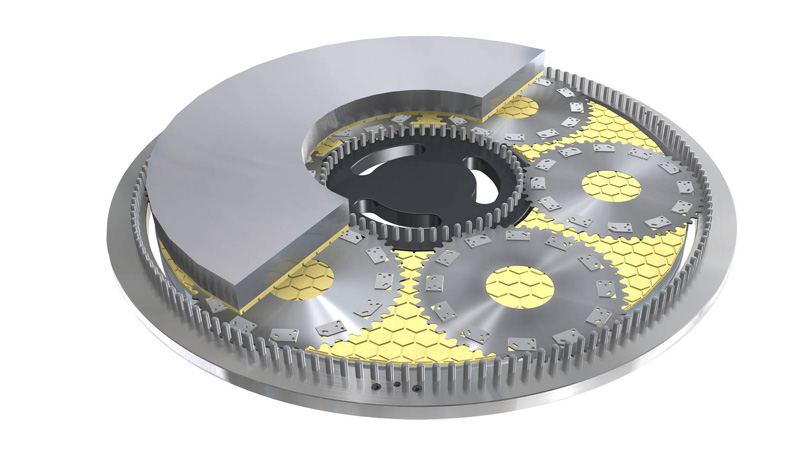

Supfina Solutions: Double-Disk Grinding

-

Considered one of the “classic” grinding processes, double-disk grinding is performed when both sides of a workpiece must be ground so that both surfaces are exactly plane and parallel. The workpiece is not fixed for this process. Instead, it is loosely placed in the “nest” of the workpiece carrier. Then both sides of the workpiece are simultaneously machined between two grinding wheels. The upper grinding wheel is adjusted with the “tilt” navigation setting, which allows the upper wheel to maintain the desired angle with the lower wheel. Thus, the gap between the grinding wheels is greater on the infeed side than on the outfeed, resulting in the required amount of stock removal.

Through regular dressing, the grinding wheels maintain their form and sharpness.

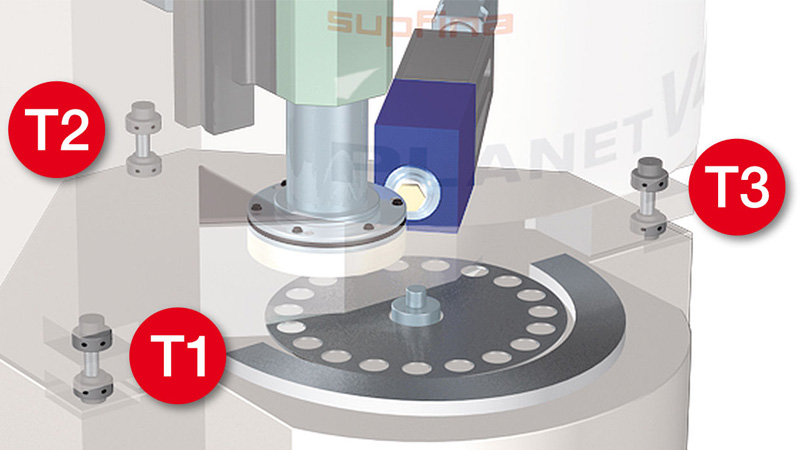

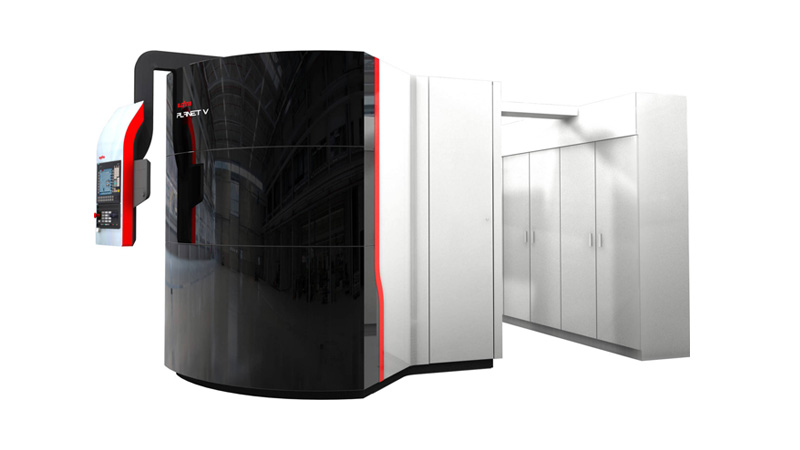

Planet V4

-

The benchmark

With a new generation of Planet V, precision, productivity, and ease of use in Double Disk Grinding have increased once again, with a smaller footprint and reduced costs.

Workpiece data

- Workpiece diameter 6 – 85 mm

- Workpiece thickness 0.6 – 40 mm

Planet V7

-

One size bigger

Supfina offers the Planet V7 for larger requirements in Double Disk Grinding.

It includes all the advantages of the Planet V series. Two 64 kW powerful motors allow stock removal of 3mm and up with cycle times of ~37 seconds.

Workpiece data

- Workpiece diameter 10 –180 mm

- Workpiece thickness 1–100 mm

Solutions for grinding coated brake discs

-

The Supfina solution : Planet BD Double -disk grinding machine of the proven Planet series for grinding coated brake discs.

- Double side grinding (simultaneous machining of both friction ring surfaces) for high throughput / short cycle times

- Optional coating, grinding and automation as a complete solution

- Maximum quality through innovative process control, optionally with in -process gaging

- Optional automation of loading and unloading for various feeding and discharging systems

- Significant cost reduction by optimizing the process chain coating - double surface grinding

- Safety thanks to Supfina experience

Robotics – Process & Automation

-

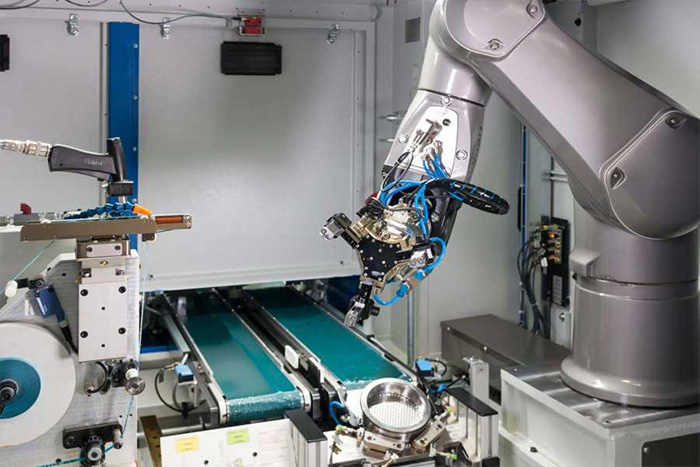

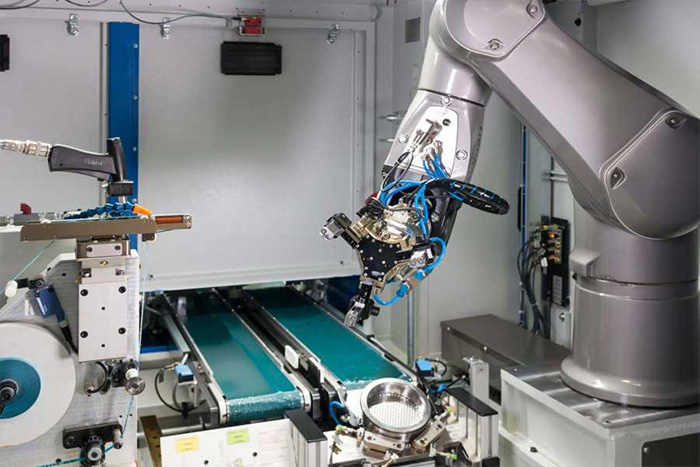

Customized solutions

Are you looking for a flexible, modular, and economical solution for your processes? With the R-Cell, Supfina presents an innovative robotic cell that easily meets all these requirements. In the modular cell, a large number of components can be arranged entirely according to your own needs and, thanks to the flexible design, can also be expanded or adapted at any time.

This ensures increased flexibility and quicker reaction times and offers great potential for savings thanks to efficient production in a compact space.

R-Cell compact

-

Flexibility within a small space

The R-Cell compact machining cell offers you a wide range of machining options for your workpieces for robot-based shaping and surface processes.

Components of small to medium size can flexibly be brought to the desired quality using this solution. Moreover, workpieces of different materials and component features are possible.

- Highest demands on surface and geometry

- Multi-stage machining

- Workpiece or tool guided processes

- Force-controlled and -regulated machining

- Simple changeover

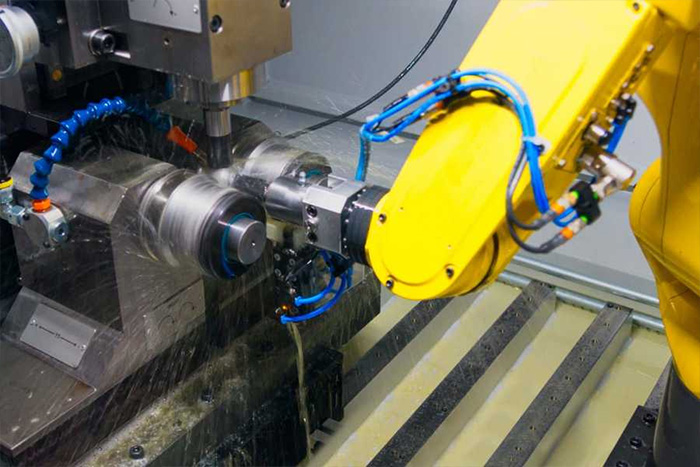

R-Cell

-

Performance and quality

A modular design and high performance in terms of workpiece geometry, process, and precision enable flexible and cost-effective output.

Whether dry machining or processes cooled by cooling lubricant, the R-Cell offers all possibilities for effective and precise robot-assisted machining of your components…

- Power-intensive processes

- Flexibility through modularity

- Traceable process safety

- Maximum work safety (operation and environment)

Technology

-

TECHNOLOGY FOR EVERY SURFACE. WE ARE THE SPECIALISTS

All that shines…is not necessarily smooth – unless it was processed in a special-purpose Supfina machine to produce the ideal surface.

Whether visible or concealed, in the household, the car or on the high seas – it is both amazing and fascinating to discover the many and varied products and applications that use superfinishing and grinding technologies made possible by Supfina.

Supfina, with its state-of-the-art technology founded on its traditional roots has perfected the technology required today for excellent surface finishes. Our continual research efforts contribute to the development of cutting-edge surface finishing technology to enable us to build machines of the highest quality to empower our customers to achieve the high standards of functional surfaces they require.

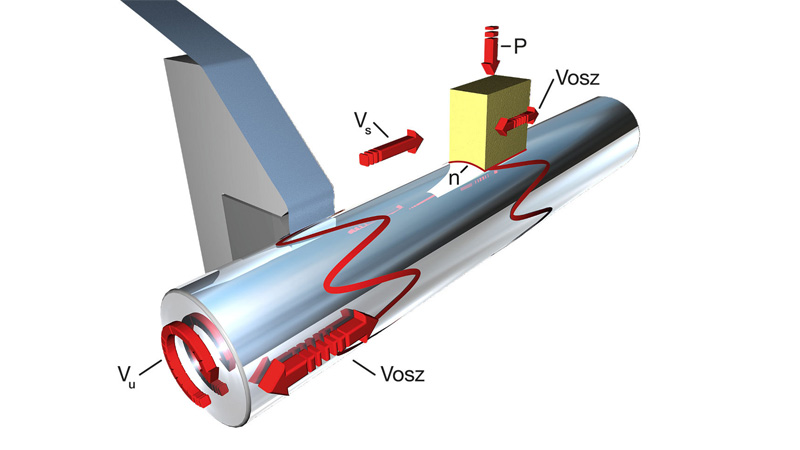

Superfinishing Technology

-

What is superfinishing? The perfect finish.

Tape and stone superfinishing

Superfinishing is a chip removing machining process. But not one that is comparable to any other. In contrast to the classic lathe turning and grinding methods, there is full surface contact between the tool and the workpiece.

This is precisely the feature that produces the unique characteristics of a perfectly machined surface. This is superfinishing!

By overlaying workpiece rotation and tool oscillation, each individual grain travels along a sinusoidal line – a feature typical for this process.

All the grinding grains in contact with the workpiece create a machining pattern by means of overlaying individual sinusoidal lines that cross each other at a particular angle. This generates a specific, defined pattern of grooves and plateaux, which, in turn, results in the particular advantages of the superfinishing process. The grooves act as channels to aid uniform distribution of the lubricant, while the plateaux guarantee a high percentage contact area.

The tools in use here are either bonded grinding compound on a solid substrate, such as ceramic, or on a flexible backing such as a textile tape.

Uniform lubricant distribution, higher bearing ratio, improved microgeometry, optimized peak heights – this is workpiece quality made by superfinishing.

Flat finishing

- Flat finishing is primarily the process of using a cup wheel to machine a workpiece’s face. The workpiece is clamped in a chuck and rotated. The rotating cup wheel is then precisely advanced to the workpiece’s surface.

Precision slides allow the finishing unit to be adjusted in multiple directions — thus giving the workpiece a characteristic “cross-hatch” pattern, in addition to concave or convex adjustments. With these capabilities a flat, concave, convex, or spherical surface can be produced.

One key difference between double-disk grinding and flat finishing is that, for the latter process, the tool is self-dressed during the machining of components and regular wheel dressing is not necessary.

Fine grinding

-

Fine grinding is also used when workpieces require both surfaces to have plane parallelism, but with more precision than can be achieved with double-disk grinding. Workpieces are placed in carriers that have teeth on the outside diameter. An inner pin ring rotates the carriers as they shift on a stationary outer pin ring in an orbiting manner. Machining takes place between two rotating grinding wheels. The optimal machining force is applied by the upper wheel, which is mounted on an oscillating pendulum. Fine grinding’s central feature is that a fixed number of parts can be processed simultaneously, or in batches.

Each of these machining technologies has its particular strengths. For maximum stock removal as well as output of finished workpieces, double-disk grinding is preferred. For example, within large-scale production, single cams can be ground with a cycle time of fewer than 0.5 seconds with a continuous-feed loading system.

However, for maximum precision and size accuracy, fine grinding is preferred. Hydraulic components, for example, can be finished with an accuracy of ± 0.001 mm.

Double-disk grinding

-

Considered one of the “classic” grinding processes, double-disk grinding is performed when both sides of a workpiece must be ground so that both surfaces are exactly plane and parallel. The workpiece is not fixed for this process. Instead, it is loosely placed in the “nest” of the workpiece carrier. Then both sides of the workpiece are simultaneously machined between two grinding wheels. The upper grinding wheel is adjusted with the “tilt” navigation setting, which allows the upper wheel to maintain the desired angle with the lower wheel. Thus, the gap between the grinding wheels is greater on the infeed side than on the outfeed, resulting in the required amount of stock removal.

Through regular dressing, the grinding wheels maintain their form and sharpness.

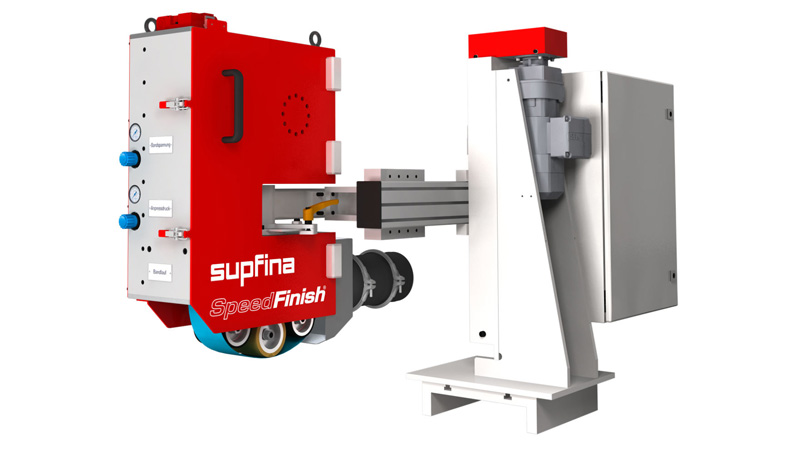

SpeedFinish

- Supfina developed its SpeedFinish technology to combine the advantages of grinding with those of superfinishing; i.e., to achieve high ¬removal volumes in the shortest possible finishing times while achieving homogenous surface roughness free of half-moon markings.

The name says it all: SpeedFinish is faster than comparable processes. Workpieces are machined at high speed, reducing the machining process by as much as 75 percent.

This improves efficiency while — at the same time — improving competitive advantage, thanks to reduced costs.