- Offer Profile

- RIFTEK develops and fabricates optoelectronic instruments for measuring geometrical quantities for industrial automation and research applications. We offer fully-integrated solutions to control and automate factory problems – from individual sensing devices and transducers to multi-functional measurement and control systems. Our sensor and instruments are used by worldwide customers from more than 40 countries in various industrial and research applications.

Sensors

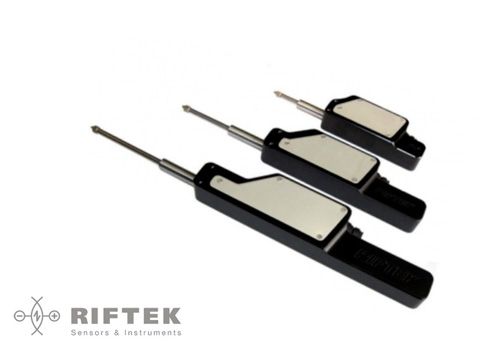

Absolute Linear Encoders

-

Absolute encoders are designed for measuring and checking displacements, dimensions, run-outs, surface profiles and deformations of engineered objects.

Riftek’s absolute encoder series includes two models: The RF251 for hard industrial environments and the RF256 sensors with a built-in display option for laboratory environments.

RF251 Series

-

- wide temperature range

- IP67

- Measuring range, mm: 3 and 25

- Accuracy, µm: ±1

- Resolution, µm: 0,1; 0,5 and 1

RF256 Series

-

- built display option

- batteries powered

- Measuring range, mm: 15, 35 and 55

- Accuracy, µm: ±1

- Resolution, µm: 0,1; 0,5 and 1

Laser Triangulation Sensors

-

These sensors measure and detect object position, dimensions, surface profiles, deformations, vibrations, sorting and sensing presence or absence. Laser triangulation sensors also measure the levels of liquids and bulk materials.

The series includes four lines of models: RF603 - universal sensors with 2 to 1250 mm operating ranges, RF603HS - high speed sensors, RF600 - large-base and long range sensors, RF605 - compact value sensors.

RF603 Series – Multi-purpose Laser Sensors

-

- Available with Red or Blue laser diodes

- Varied diode powers for indoor or outdoor applications

- Binocular sensors for laser scanning

- Measuring ranges, mm: from 2 to 1250

- Linearity, % of F.S: ±0.1

- Measuring rate, kHz: 9.4

RF603HS Series – High Speed Triangulation Sensor

-

- Universal, high-speed laser sensor in compact case

- Available in Red and Blue diode wavelengths

- Ideal for capturing fast events and road profiling

- Measuring ranges, mm: from 2 to 1250

- Linearity, % of F.S: ±0.1

- Measuring rate, kHz: 180

RF600 Series – Long-range Laser Sensors

-

- Up to 2.5 m range in a compact sensor

- Varied offset distances for custom applications

- Available in Blue diode wavelength for measuring hot objects

- Measuring ranges, mm: from 10 to 2500

- Linearity, % of F.S: ±0.1…0.2

- Measuring rate, kHz: 9,4

RF605 Series – Compact Laser Sensors

-

- Ultra-compact design for space-saving installations

- Value model for high-volume applications

- Measuring ranges, mm: from 50 to 500

- Linearity, % of F.S: ±0.1

- Measuring rate, kHz: 2

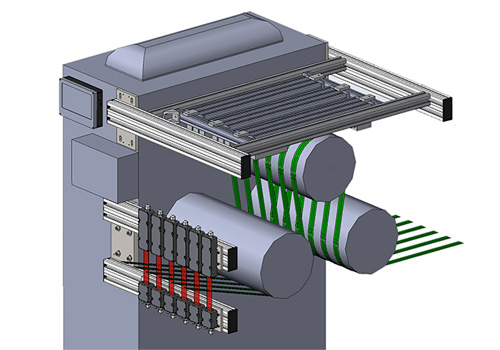

2D Laser Scanners

- The laser scanners are intended for non-contact measuring and checking of surface profile, dimensions, sorting and sensing of technological objects, 3D models construction.

RF625 Series

-

- Universal, high-speed laser scanners

- Available in Red, Blue and IR diode wavelengths

- Measuring ranges, mm: from 5 to 1400

- Linearity, % of F.S: ±0.1

- Measuring rate, profiles/s: 250, 500, 1875

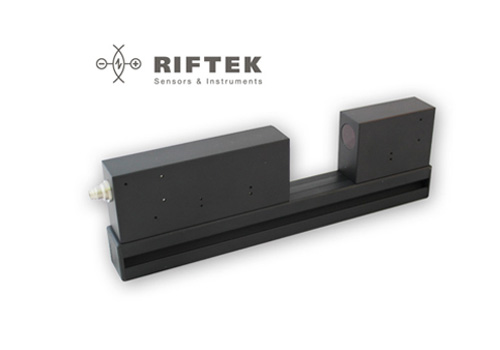

Optical Micrometers

-

Optical micrometers use a “shadow” measurement principle whereby collimated laser light is transmitted towards a receiver. The edges of the shadow cast by an object in the beam’s path are accurately measured by the detector array inside the receiver unit. Optical Micrometers are non-contact devices that ideally measure diameters of wires, rods and other cylinders in addition to gaps, edge positions and dimensional characteristics of geometric objects.

The series includes two lines of models: RF651 - direct through beam micrometers and RF656 – high precision through beam micrometers with telecentric lens

RF 651 Series

-

- direct through beam micrometers

- long distance between transmitter and receiver

- Measuring ranges, mm: 25, 50, 75, 100

- Accuracy, µm: ± 3…20

- Measuring rate, kHz: 2, 10

RF 656 Series

-

- high precision micrometers with telecentric lenses

- Measuring ranges, mm: 5, 10, 25

- Accuracy, µm: ± 0,3…1

- Measuring rate, kHz: 2, 10

Measurement Instruments for Railway Transport

Wheel Diameter Measuring Gauge

-

- high-precision wheel diameter measurement

- large numeric display

- Bluetooth interface for data transfer

Electronic gauge is designed for measuring wheel rolling circle diameter.

Measurements are made directly on rolling stock without wheel set roll-out. The measurement of the diameter is performed according to the "three points" technique, without the complete wheel coverage. The gauge contains numeric display to show the value of the wheel diameter. IDK-BT gauge contains Bluetooth interface for transfer results into wheel-set wear database management system

IDK Series

-

- Measurement range, mm: 400…1400 or on request

- Measurement error, mm: ±0.2

- Bluetooth: no

IDK-BT Series

-

- Measurement range, mm: 400…1400 or on request

- Measurement error, mm: ±0.2

- Bluetooth: yes

Railway Wheel Profile Gauge

-

- PDA based handheld measurement instrument

- laser scanning and analysis of wheel profile

- contactless measurement of wheel flange parameters

- software for wheel wear data base support

The laser profilometer is employed for measuring geometrical parameters of the rail wheel flange (thickness, slope, height), rim/tire thickness and for taking full profile of the wheel roll surface.

The device is supplied with database and software package for wheel sets wear data storage and processing.

IKP-5 Series

-

Measurement ranges, mm:

- Sh 10...45

- Sd 10...40

- qR 0….25

- rim thickness 36…100

- measurement time, s: 3

IKP-5-short Series for tramway wheels

-

Measurement ranges, mm:

- Sh 10...45

- Sd 10...40

- qR 0….25

- rim thickness 22…52

- measurement time, s: 3

Back-to-Back Distance Measuring Gauge

-

- contactless measurement of back-to-back distance between railway wheels

- large numeric display

- Bluetooth interface for data transfer

Electronic gauge is designed for measuring back-to-back distance of railway, metro and tram wheels in the course of checkup, examination, repair and formation of wheel sets. Measurements are made directly on rolling stock without wheel set roll-out.

IMR Series

-

- Measurement range, mm: L±25(L – nominal distance

- Measurement error, mm: ±0.1

- Indication discreteness: 0.1mm, or 0.01 inch

IMR-L Series

-

- Measurement range, mm: 1345..1375 or on request

- Measurement error, mm: ±0.3

- Indication discreteness: 0.1, 0.01 mm, or 0.01 inch

- Bluetooth: yes

Disk Brakes Profile Gauge

-

- PDA based handheld measurement instrument

- laser scanning and analysis of brake disks profile

- contactless measurement of disks wear parameters

- software for disks wear data base support

PDA based handheld instrument is employed for laser scanning and measurement of brake disks wear parameters.

The device is supplied with database and software package for disks wear data storage and processing. IKD Series

-

- Wear measurement range, mm +5…-5

- Scanning range,mm 160

- Accuracy, mm ±0.01

- Measurement time, sec 6

Rail Profile Measurement Gauge

-

- PDA based handheld measurement instrument

- laser scanning and analysis of rail head profile

- contactless measurement of rail wear parameters

- software for rail data base support

Portable laser rail profilometer (PRP) is designed for non contact registration of cross-section of the railhead acting face.

The main functions of PRP are:- obtaining the information on the cross-section profile of the working railhead surface;

- full profile scanning and analyze of the railhead acting face;

- visualization of the combined graphical images of actual and new crosssection;

PRP Series

-

- Railhead vertical wear, mm -5,0 …+14,0

- Lateral railhead wear, mm -5,0…+18,0

- Redused railhead wear, mm Up to 14,0

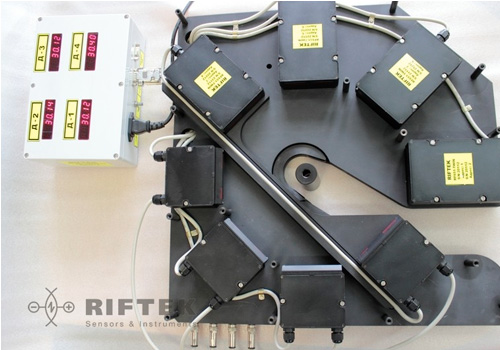

Automated Systems for Wheel Sets Control

-

- contactless laser measurement of all geometric features of wheelsets

The systems are designed for making automatic measurement of geometric parameters of railway wheel sets in the course of incoming and outgoing inspections carried out in railcar/wheel shops, wagon depots.

"Geopar-VKP"system

-

The system is designed for making automatic measurement of 27 geometric parameters of wheel pairs of

wagons in the course of incoming and outgoing inspections carried out in railcar/wheel shops, wagon depots and

wheel pair repair and gathering workshops.

Parameters under control

Wheel parameters: out-of-roundness, deviation of roll surface countour from desired profile, wheel flange parameters, wheel tread width and thickness, defects on rolling surface, and wheel separation distance.

Axle journal parameters: average diameters underneath the first and second bearings, out-of-roundness and taper.

Axle parameters: diameters and ovality of pre-wheel-seat parts, diameters of wheal seats and middle parts of axle

"Geopar-LKP"system

-

The system is intended for use in automated measurement of 17 geometric parameters of locomotive wheelsets in the process of repair.

Parameters under control

Wheel parameters controlled: diameter and out-of-roundness of wheel tire over the rolling circle, wheel tire thickness and width, flange thickness and height, deviation of the rolling surface profile from maximum profile values.

Controlled parameters of a toothed gear wheel: tooth thickness

Controlled parameters of a wheelset: the distance between inner lateral faces of tires, hubs and gear wheels.

Controlled parameters of a wheelset axle: box journal diameters, pre-wheelseat parts, middle axle parts, diameter of journal for motor-axle bearing

"Geopar-KC" System

-

The system is intended for use in automated measurement of 8 geometric parameters of

wheel centers in the process of repair.

Parameters under control

Rim diameter, variability of diameter along lateral and longitudinal sections, rim diameter difference, inter-rim distance, inter-rim distance difference, rim radial runout, rim width.

Laser Systems for Power Rail Position Dynamic Control

-

- сontactless control of power rail vertical position

The system is intended for contactless control of displacement dynamics of power rail.

RF064

-

- Diameter measurement range, mm: 200

- Accuracy, mm: ±0,2

- Sampling rate, meas/s 8000

Real time wheels geometry measurement system

-

- contactless profile and diameter measurement

The system is designed for contactless automatic measurement of geometrical parameters of railway wheels and uses a combination of 2D laser scanners, mounted wayside in the track area.

The system can be easily installed at any type of rail infrastructure. 3DWheel

-

Measured parameters:

- Wheel profiles

- Flange height

- Flange width

- Flange angle

- Rim thickness

- Tread width

- Back to back distance

- Wheel diameter

Equivalent conicity calculation program

-

- contact points position

- rolling radiuses difference depending on displacement of wheel set

- contact angles and their difference depending on displacement of wheel set

- equivalent conicity

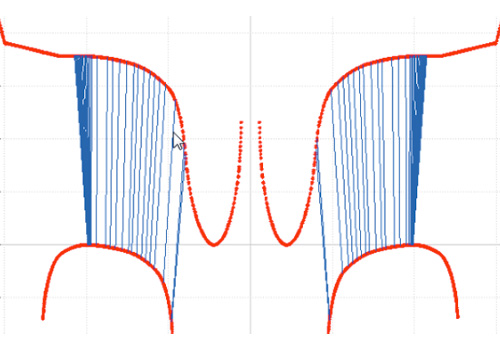

Equivalent conicity calculation program

-

Equivalent Conicity is a parameter that is used when investigating dynamic interaction between railways vehicle and track. The parameter describes behavior of contact between wheels and rails for straight and large radius parts of track.

The program calculates the next parameters:- Contact points position.

- Rolling radiuses difference depending on displacement of wheel set.

- Contact angles and their difference depending on displacement of wheel set.

- Equivalent Conicity.

Special Measurement Instruments

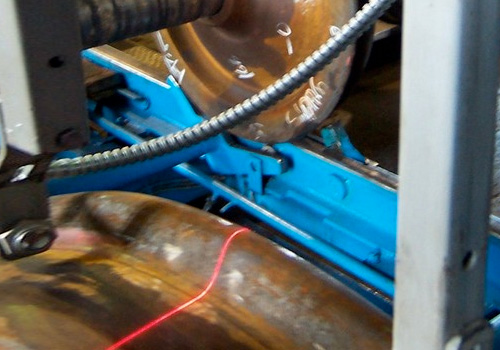

Online Systems for Control and Regulation of Diameter

-

- contactless diameter measurement of wire, cables, rods

- multicoordinate diameter measurement systems

The systems are intended for in-process non-contact measurement, control and regulation of diameter of various objects (wire, hoses, tubes, rods, sausage casings, etc.)

SKD-MSh System

-

- control and regulation of diameter of medical tubes

- Measurement range, mm: 25

- Accuracy, µm: ±10

- Number of axes under control:

2

SKD-KO System

-

- control and regulation of diameter of sausage casings

- Measurement range, mm: 50

- Accuracy, µm: ±50

- Number of axes under control:

1

SKD-KB System

-

- control of diameter of cables

- Measurement range, mm: 20...60

- Accuracy, µm: ±20

- Number of axes under control:

4

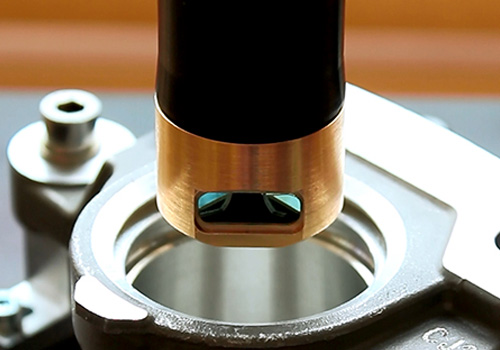

Laser systems for inner diameter measurement

-

- contactless measurement of inner diameter of pipes and gun barrels

Systems are intended for contactless measuring of inner diameter of gun barrels, cylindrical and taper pipes, holes, stators of progressive pums.

RF040 on the base of stationary sensors

-

- Measurement range, mm : from 4,5

- Accuracy, µm: from ±2

- Number of laser sensors 6

RF096 on the base of rotational sensors

-

- Minimum measured diameter, mm: 12

- Accuracy, µm: from ±2

- Number of laser sensors up to 6

Automated system for motor shafts measurement

-

- high-precision measurement of shafts geometric values

Optical Measurement System

- Optical Measurement System Video

Laser Debris Inspection System

-

- non-contact debris detection

- non-contact holes inspection

The system is intended for non-contact detection of the debris inside the circular grooves of different technological items, for example brake calipers and so on. The system can be used also for groove seal profiling (seal deformation inspection).

RF096-Insp

-

- Inspected grooves diameter range, mm 35..53

- Minimal size of detected debris, mm 0,03 (thickness) x 0,1 x 0,1

- Inspection time, s 1,2

Automated system for tapes geometry measurement

-

- high-precision measurement of width and thickness of strapping tapes

The system is designed to control the geometrical parameters (width and thickness) and the temperature of the tapes, in particular, packing straps during the manufacturing process.

The system is applied in the mass production. Production line is the place of installation.

Technical characteristics of the system can be changed for a specific task. RF089

-

- Width measurement accuracy, um: ±10

- Thickness measurement accuracy, um: ±5

Laser Caliper

-

- measuring and control of diameters of standing timber

The calliper is designed for measuring and control of diameters of standing timber of various kinds

Laser Caliper

-

- Diameter measurement range, mm: 60...940

- Measurement error, mm: ±5

- Indication resolution, mm 1

Edge Sensor

-

- non-contact measuring and monitoring the position of the edge

The sensors are intended for non-contact measuring and monitoring the position of the edge (edges) of various objects, such as tapes, plates, substrates, etc.

RF659

-

- Measurement range, mm 7

- Accuracy, um ±20

- Repeatability, um 1

- Distance between transmitter and receiver, mm 30

3D Laser Scanning Systems

3D Laser Scanning Kit "Shtrikh-2"

-

- non-contact scanning for 3D computer model obtaining

- universal laser systems for CNC machines

3D Laser Scanning Kit is designed for mounting on any type of CNC machine and intended for non-contact scanning of products and obtaining 3D computer-simulated models.

Laser 3D scanner Shtrikh-2

-

- Scanning field for XY arbitrary

- Average scanning speed, points/s 4500

3D Laser Sorting Machine

-

- non-contact measurement of sunflower seeds

- sorting functions

The measuring machine is designed for non-contact measurement of geometrical parameters of objects, specifically sunflower seeds, and is a standalone software/hardware system.

Technical characteristics of the machine can be changed for a specific task. 3D Laser Sorting Machine RF1010SS

-

- Scanning Field, mm 300x400

- Accuracy, mm ±0,1

3D Laser Measurement Machine

-

- non-contact measurement of suspension arms

The measuring machine is designed for non-contact measurement of geometrical parameters of objects, specifically suspension arms, and is a standalone software/hardware system.

Technical characteristics of the machine can be changed for a specific task. 3D Laser Measurement Machine RF1010SL

-

- Scanning Field, mm 370x70

- Accuracy, mm ±0,05

3D Laser system for large diameter pipes measurement

-

- automatic laser control of pipes geometrical parameters

The system is designed for non-contact measurement of geometrical parameters (diameter, roundness, curvature) of large diameter pipes.

Technical characteristics of the system can be changed for a specific task. 3D Laser system for large diameter pipes measurement MRT1420-RF1420TB

-

- Pipes nominal diameter, mm 450...1525

- Measurement accuracy, mm ±0,15

- Pipe length, m 9...18,5

- Throughput, pipes/hours 25

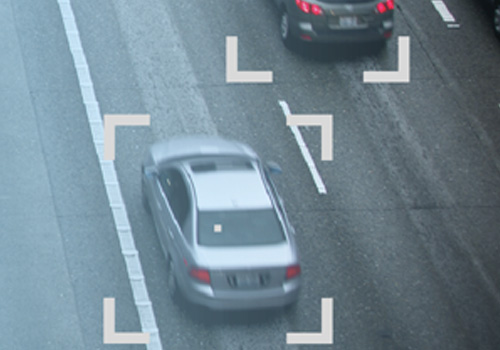

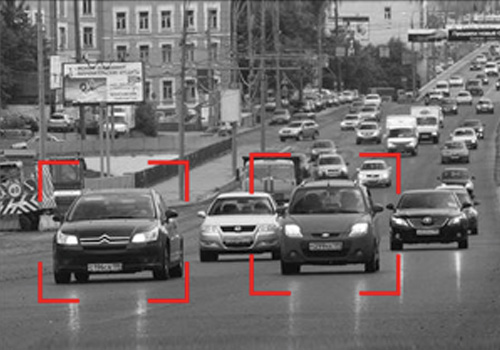

Video Processing IP-cores and hardware

Video processing FPGA IP Cores

-

Software IP cores are designed for analytical processing of video information from one or several sources and serve as modules to be included in the FPGA project.

IP cores meet the challenges of object detection, automatic object tracking, image processing to improve its quality and others and allow the use of high-performance video processing algorithms in custom projects of any configuration.

T-COR-10

-

- tracking of various classes of objects: ground, surface, aerial objects and people

- Video source: anyone with resolution up to 2048x2048 pixels

- Frame rate, Hz: up to 30

- Number of tracking objects: up to 5

T-COR-11

-

- automatic video tracking of any objects types. Easy FPGA project integration

- Minimum object contrast: from 10%

- Frame rate, Hz: up to 30

- Number of tracking objects: up to 5

D-MOT-10

-

- motion detector of various objects: ground, surface, aerial objects and people

- Video source: anyone with resolution up to 5120x5120 pixels

- Frame rate, Hz: up to 30

- Number of tracking objects: up to 128

S-COR-10

-

- 2D video stabilization. Easy FPGA project integration. Small time computing

- Video source: up to 1024x1024 pixels

- Calculation time: no more than 10 ms

- Offset determination accuracy: 2 pixels

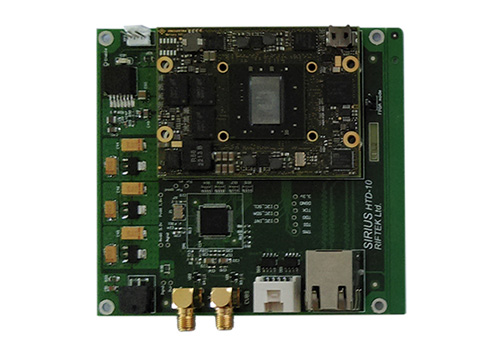

Video Tracker HTD-10

-

Video Tracker HTD-10 is an electronic module intended for automatic tracking of any type of objects selected by an operator in the video. HTD-10 is designed as an automatic tracking device to be used in intelligent security and surveillance systems.

HTD-10 can be connected to 2 video sources of PAL standard through a coaxial cable. HTD-10 allows to track up to 5 objects independently. HTD-10 performs stable tracking of small-sized and low contrast objects. HTD-10 has small size and weight. HTD-10

-

- automatic video tracking of all object types

- Size of tracking strobe: from 16x16 to 128х128 pixels

- Size of tracking object: from 8x8 to 128х128 pixels

- Frame rate, Hz: up to 30

- Number of tracking channels: 5 independent channels

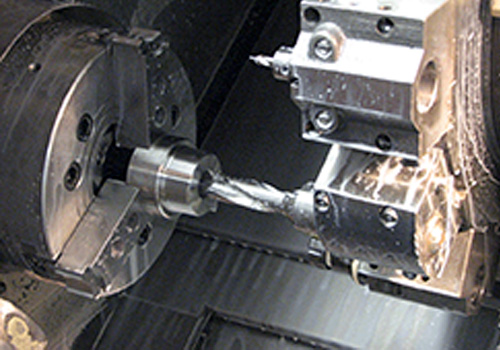

Metalworking

RIFTEK TECHNO. Metalworking Company

-

RIFTEK TECHNO was founded in 2012 and is a subsidiary of RIFTEK LLC. The main direction of enterprise activity is manufacturing of mechanical units and parts of devices and other products on orders of Belarusian, Russian and other foreign manufacturers.

RIFTEK TECHNO provides the following services:- turning on CNC machines,

- milling on CNC machines,

- turning, milling , jig boring , grinding working on universal equipment,

- punching, bending and welding of small sized parts.

Together with metal working the company is able to provide heat treatment services, electroplating and polymer coating.

CNC machines produced by «DMG», «DECKEL-MAHO» and «HAAS» are used in production process together with the universal equipment.

We accept single-piece, small-scale and large-scale orders for manufacturing of products according to customer's samples and drawings.

Turning on CNC machines

-

Main features

- part diameter from 0,8 to 400 mm

- part length up to 1500 mm

- machining accuracy of the axes X/Z 0,005/0,005

- processing of parts with a hardness of up to 55 HRC

- workpiece material: steel and alloys, non-ferrous metals of all brands, polymeric materials

Milling on CNC machines

-

Main features

- part width up to 500 mm

- part height up to 500 mm

- part length up to 800 mm

- machining accuracy of the axes X/Y/Z 0,005/0,005/0,005

- workpiece material: steel and alloys, non-ferrous metals of all brands, polymeric materials

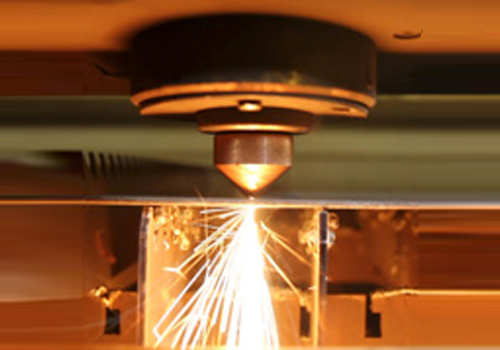

Laser cutting

-

Main features

- maximum sheet size 2000x6000 mm

- thickness of black steel and stainless steel from 0.5 to 12 mm

- clean cut of stainless steel sheet with nitrogen "999" from 0.5 to 4 mm

- aluminum and dural: maximum sheet thickness from 0.5 to 4 mm

Punching, bending and welding

-

Main features

- stamping, forming and bending of workpieces

- bending of sheet metal

- bench-work of parts

- bench-work and assembly, finishing assembly of units and devices

- fitting and welding, welding in argon and carbon dioxide, resistance welding